Composite rock wool reinforcement plate and preparation method for composite rock wool reinforcement plate

A technology for compounding rock wool and reinforcing boards, which is applied in chemical instruments and methods, building components, thermal insulation, etc., can solve the problems of difficult forming of rock wool thermal insulation boards, low strength and difficult quality assurance of rock wool thermal insulation boards, and achieve fireproof and moisture-proof. Superior performance, good thermal insulation effect and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

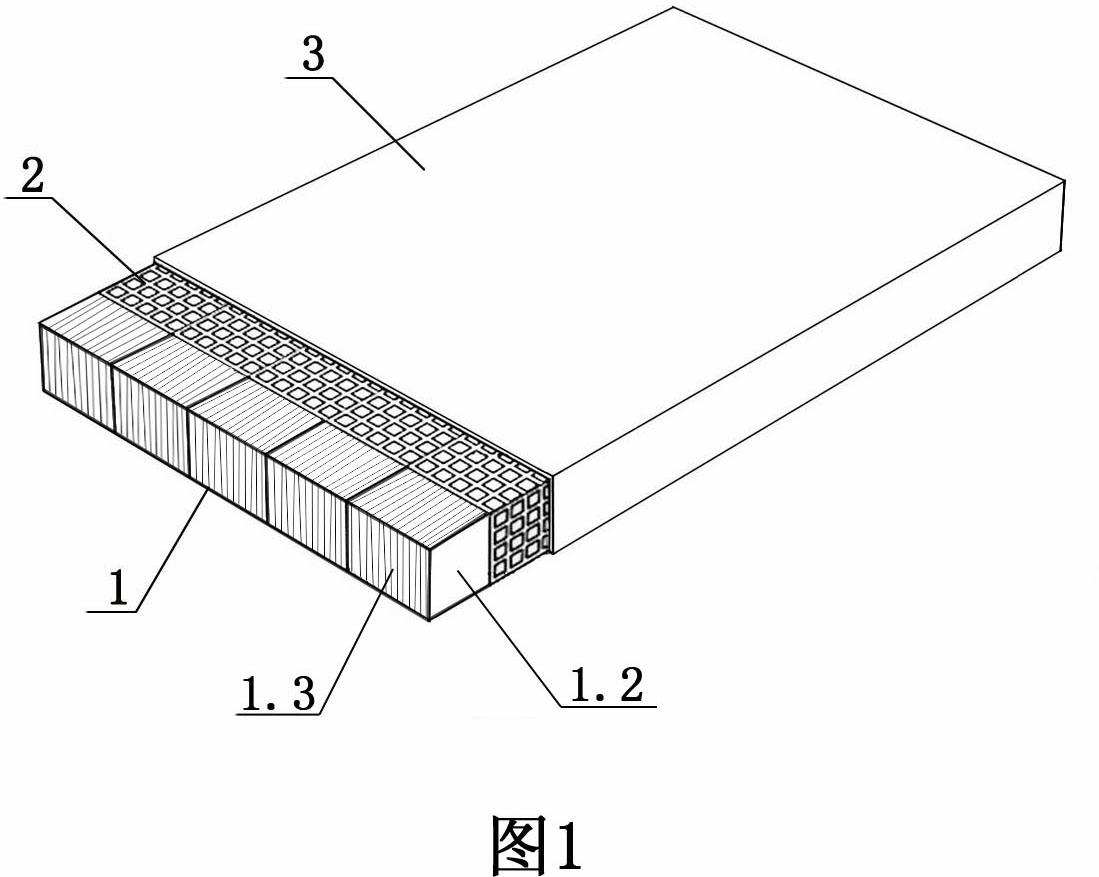

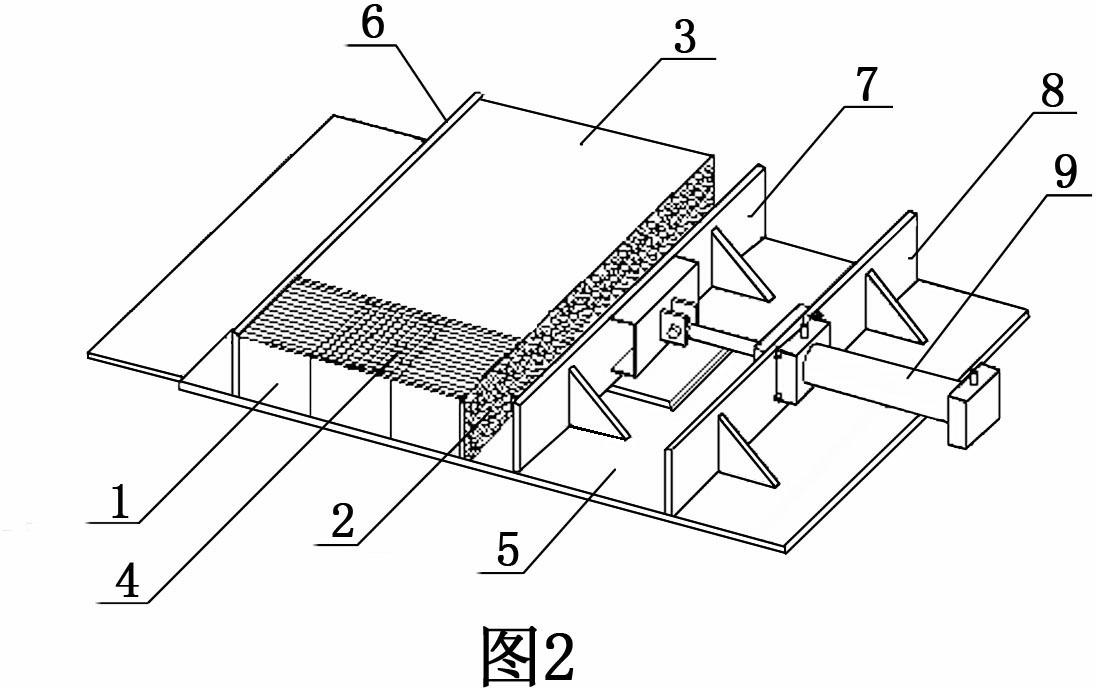

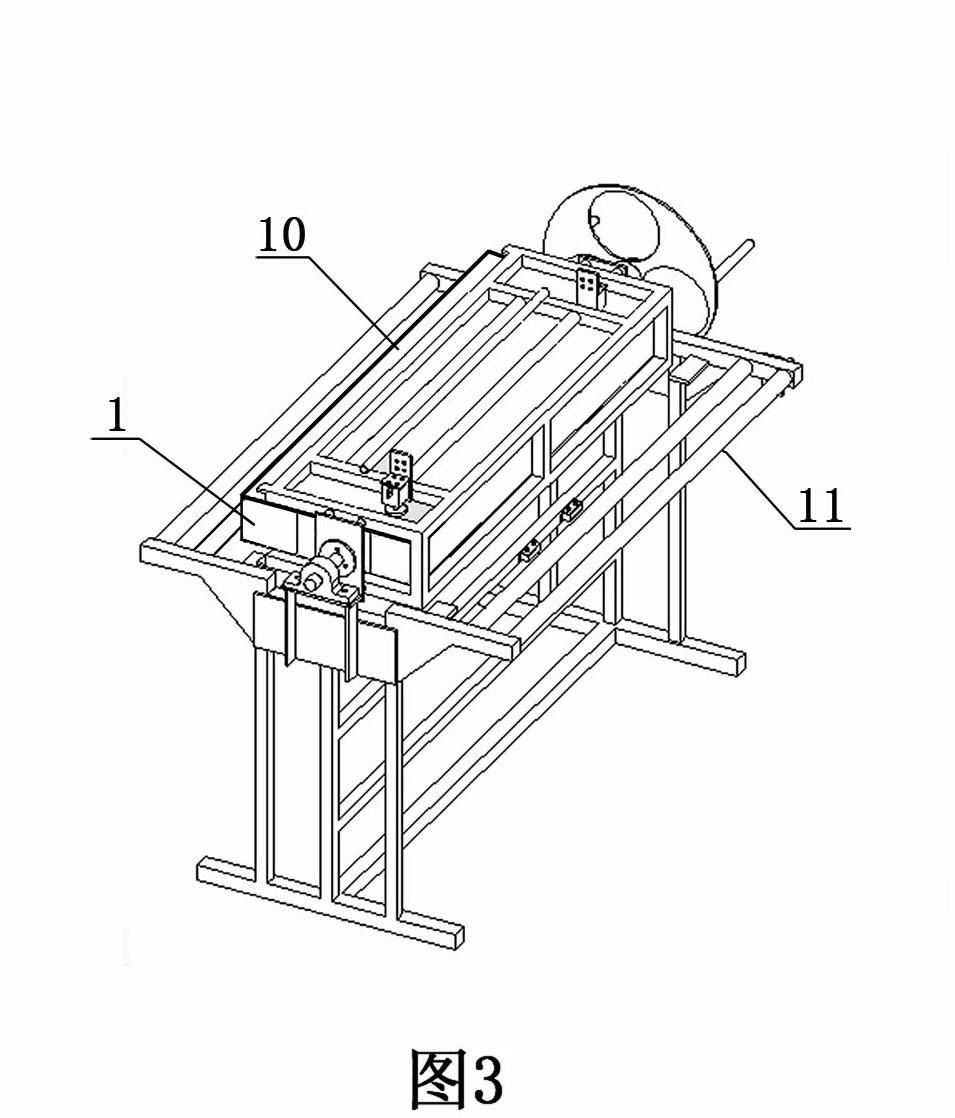

[0039] Examples see figure 1 As shown, this composite rock wool reinforced board includes a core board. The core board 1 is composed of at least two rock wool strips 1.2 arranged side by side. The fiber filaments 1.3 of the sliver 1.2 are arranged in parallel to the thickness direction of the composite rock wool reinforced board. The four sides of the core board 1 along the length direction are wrapped with a layer of reinforced fiber layer 2, and the reinforced fiber layer 2 can be made of glass fiber mesh cloth. And a layer of mortar protective layer 3 is coated on the reinforcement fiber layer 2 . The thickness of the mortar protection layer 3 is 2-6mm. The mortar protective layer can use one-component lightwei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com