Arc corner for wallboard

A technology for wall panels and corners, applied in covering/lining, construction, building construction, etc., can solve the problems of difficult installation of screws, increased dust and dead corners, unstable corner aluminum, etc., and achieves simple disassembly and reinstallation, Guaranteed accuracy and low construction error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

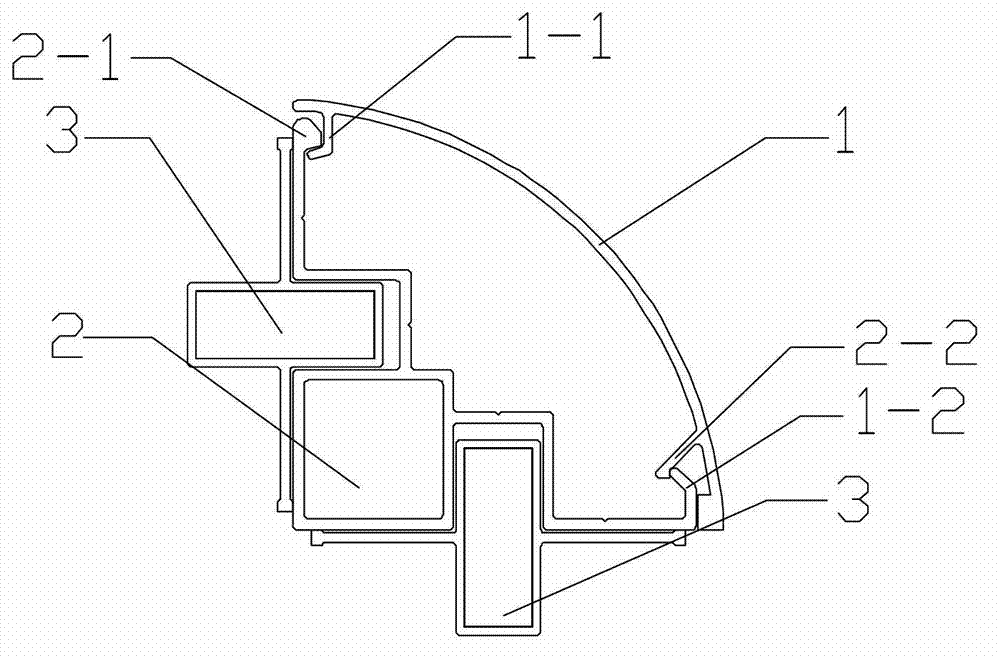

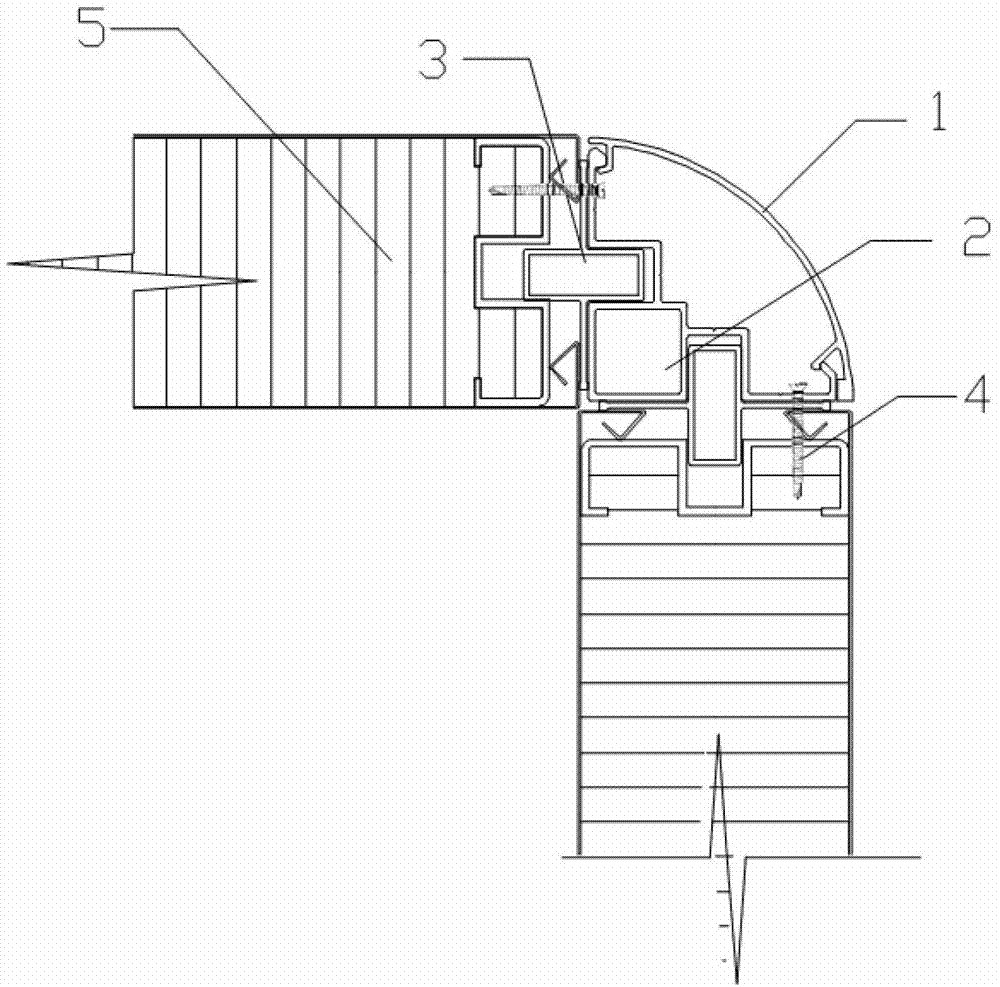

[0014] Example: such as figure 1 , 2 As shown, a wallboard arc corner, including a cylindrical arc-shaped cover plate 1 and a strip-shaped structure base 2, the two sides of the cover plate 1 are respectively provided with an insertion buckle lip 1-1 and a locking buckle lip 1-2, the base 2 The two sides are respectively provided with an insertion block 2-1 and a locking block 2-2, and the insertion buckle lip 1-1 and the locking buckle lip 1-2 are buckled with the insertion block 2-1 and the locking block 2-2 respectively, realizing the cover The inner connection between the plate 1 and the base 2 is easy to be damaged at the corner, and the cover plate 2 can be directly replaced after being damaged, and the disassembly and reinstallation are simple. The middle part of both sides of the base 2 is respectively provided with an inward groove corresponding to the longitudinal groove at the end of the wallboard 5. The positioning aluminum material 3 is placed in the correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com