Suspension bridge cable clamp screw axial force synchronous construction system and use method thereof

A technology of synchronous construction and screw shaft, which is applied in the direction of bridges, bridge parts, bridge construction, etc., can solve the problems of easy delay in construction period, untimely inspection of screw axial force, and large workload, so as to save construction cost and construction time, Avoid complex pull work problems and ensure the effect of construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

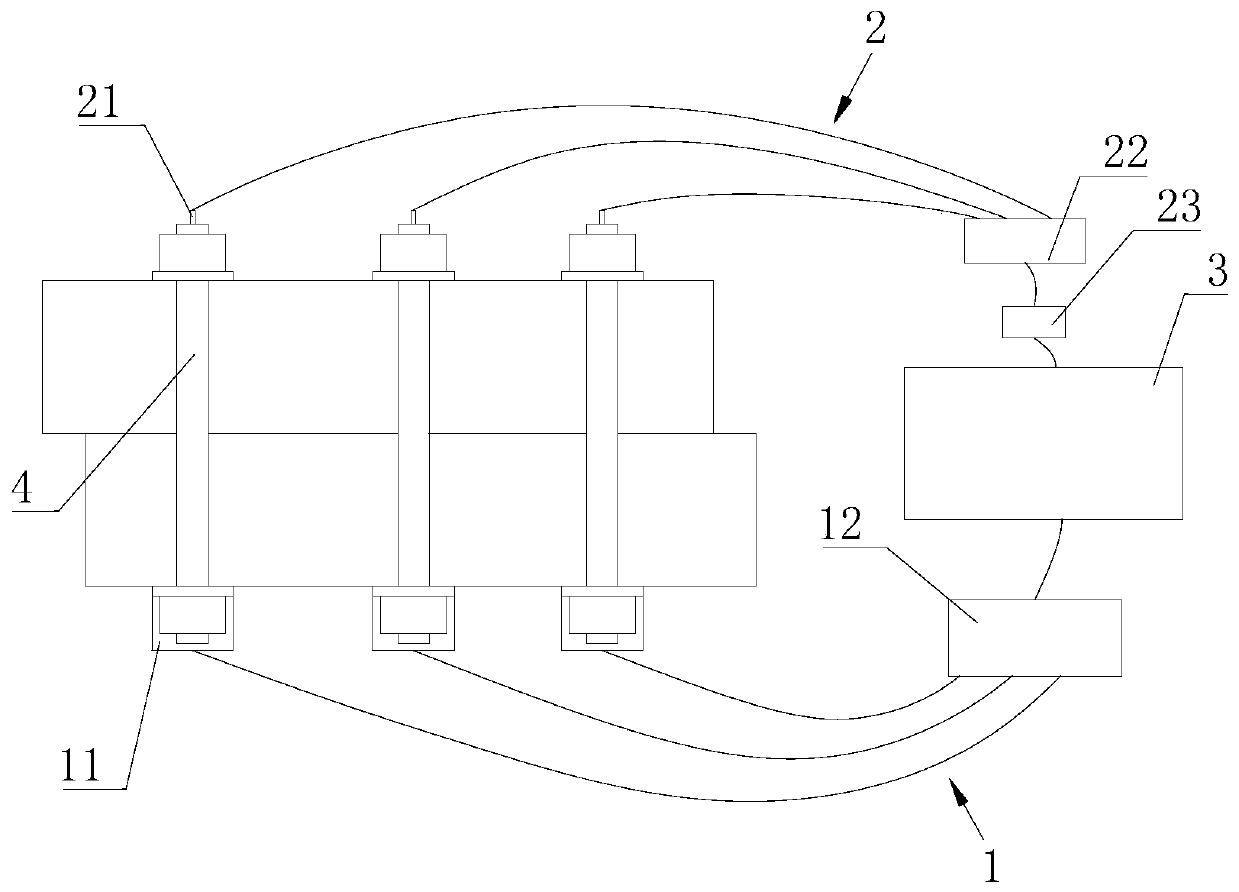

[0039] see figure 1 As shown, the embodiment of the present invention provides a suspension bridge cable clamp screw axial force synchronous construction system, including: a tensioning device 1 , an ultrasonic testing device 2 , and a control device 3 .

[0040] The stretching device 1 is used to be connected with the screw rod 4 to be stretched and to implement tension to the screw rod 4 to be stretched; the ultrasonic detection device 2 is used to be connected to the screw rod 4 to be stretched, and Ultrasonic signals are emitted in the tension screw 4, and the propagation time of the ultrasonic signal is detected to go back and forth in the tension screw 4; the control device 3 is connected to the tension device 1 and the ultrasonic detection device 2, and it is used to control the tension The pulling device 1 uses a preset axial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com