Patents

Literature

101results about How to "High machining accuracy requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

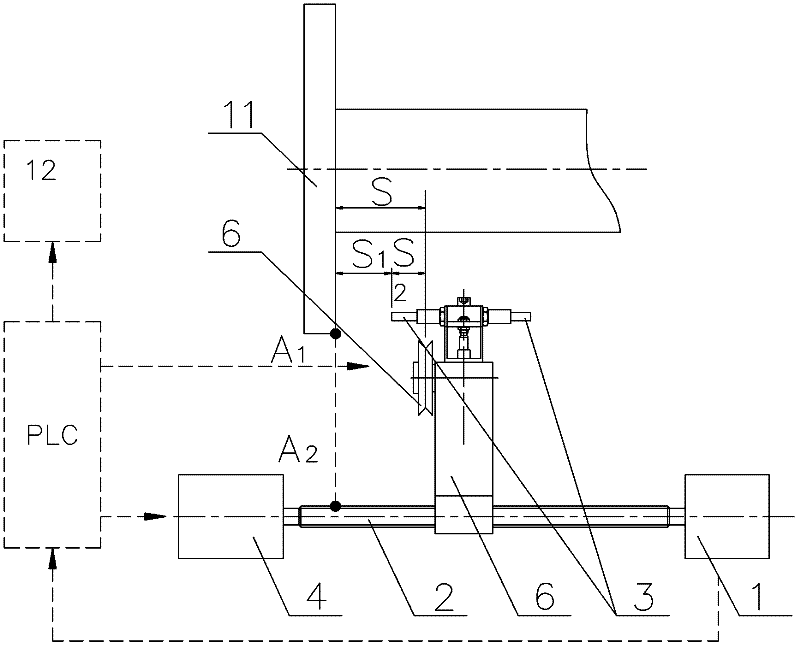

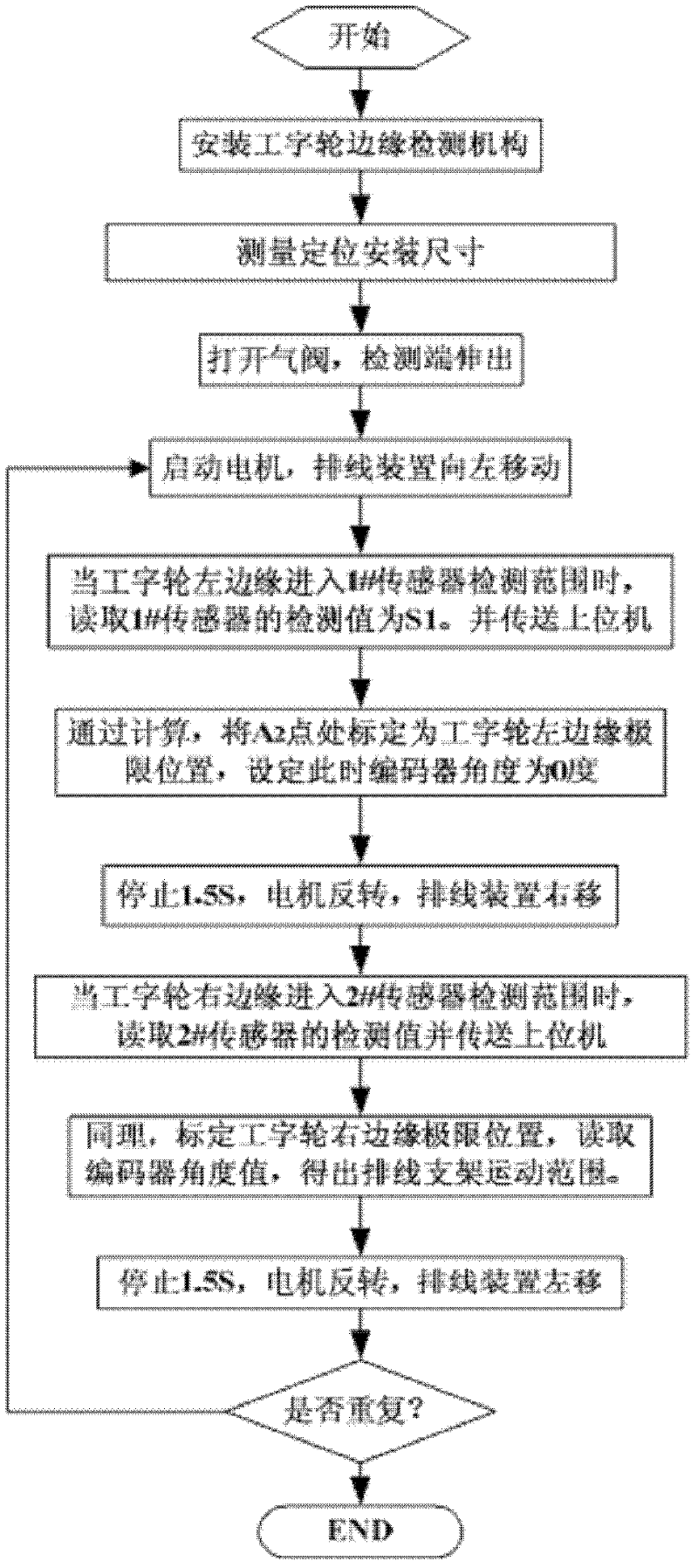

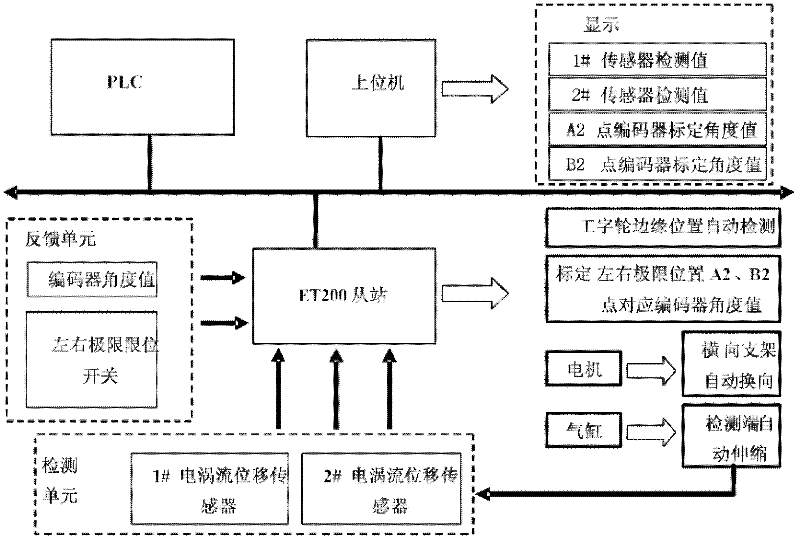

Position detecting system for edge of winding-up H-shaped wheel of wire drawing machine and control method thereof

ActiveCN102506678ASimple structureImprove detection accuracyUsing electrical meansProgramme control in sequence/logic controllersElectric machineEngineering

The invention discloses a position detecting system for the edge of a winding-up H-shaped wheel of a wire drawing machine and a control method thereof. The method comprises the following steps that: (1) two extreme positions are calibrated; in the process that a controller adopts a motor to drive a bracket to move on a lead screw, the controller acquires distances from displacement sensors to theinner edge of the H-shaped wheel by the two displacement sensors and calibrates the two extreme positions according to the distances; angle values of encoders corresponding to the two extreme positions are acquired; and (2) the bracket is controlled to do reciprocating movement between the two extreme positions, and the controller drives the bracket to move along the lead screw by the motor, and controls the motor to rotate reversely when the bracket reaches the extreme positions, so that the purpose that the bracket moves between the two extreme positions in a reciprocating manner till the wire arranging procedure on the H-shaped wheel is finished. The position detecting system has the characteristics of high detection accuracy and easiness in implementation and the like and can effectively avoid the phenomenon of wire stacking at the edge of the H-shaped wheel.

Owner:CENT SOUTH UNIV

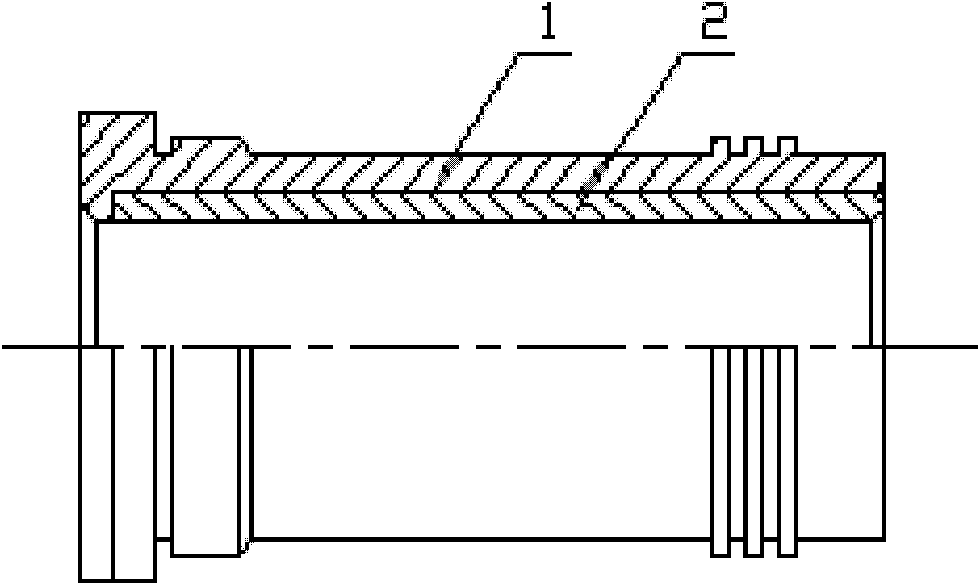

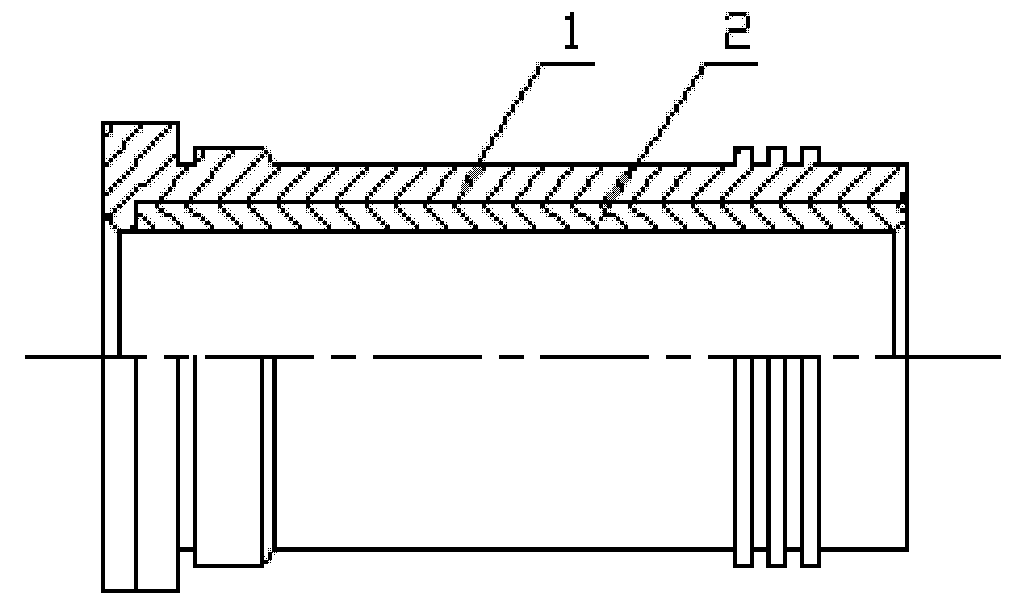

Composite prestressing force ceramic lining cylinder sleeve and manufacturing method thereof

InactiveCN102155323AHigh tensile strengthImprove heat engine efficiencyLayered productsCylinder headsNumerical controlRadiation loss

The invention discloses a composite prestressing force ceramic lining cylinder sleeve and a manufacturing method thereof; the cylinder sleeve comprises a metal outer sleeve and a ceramic lining, wherein the ceramic lining is sheathed in the metal outer sleeve by a heating assembly method, after cooling, the metal outer sleeve applies pressure stress to the ceramic lining and increases the mechanical strength of the ceramic so that the ceramic can be used for manufacturing the cylinder sleeve; wherein the inner diameter of the metal outer sleeve is identical to the outer diameter of the ceramic lining; the mismatching tolerance of the inner diameter of the metal sleeve is negative error, and the matching tolerance of the outer diameter of the ceramic lining is positive error. When the composite prestressing force ceramic lining cylinder sleeve provided by the invention is used, the exterior of the cylinder sleeve has no need to be cooled by a cooling water system, therefore, the radiation loss of the cylinder sleeve is reduced, the temperature of an air cylinder combustor is increased so that fuels are more rapidly and completely burned, and the heat engine efficiency of an internal combustion engine is improved; the manufacturing method of the composite prestressing force ceramic lining cylinder sleeve is simple, has higher requirements on the machining precision and can be realized by a modern numerical control machining technology.

Owner:WUXI INST OF ARTS & TECH +1

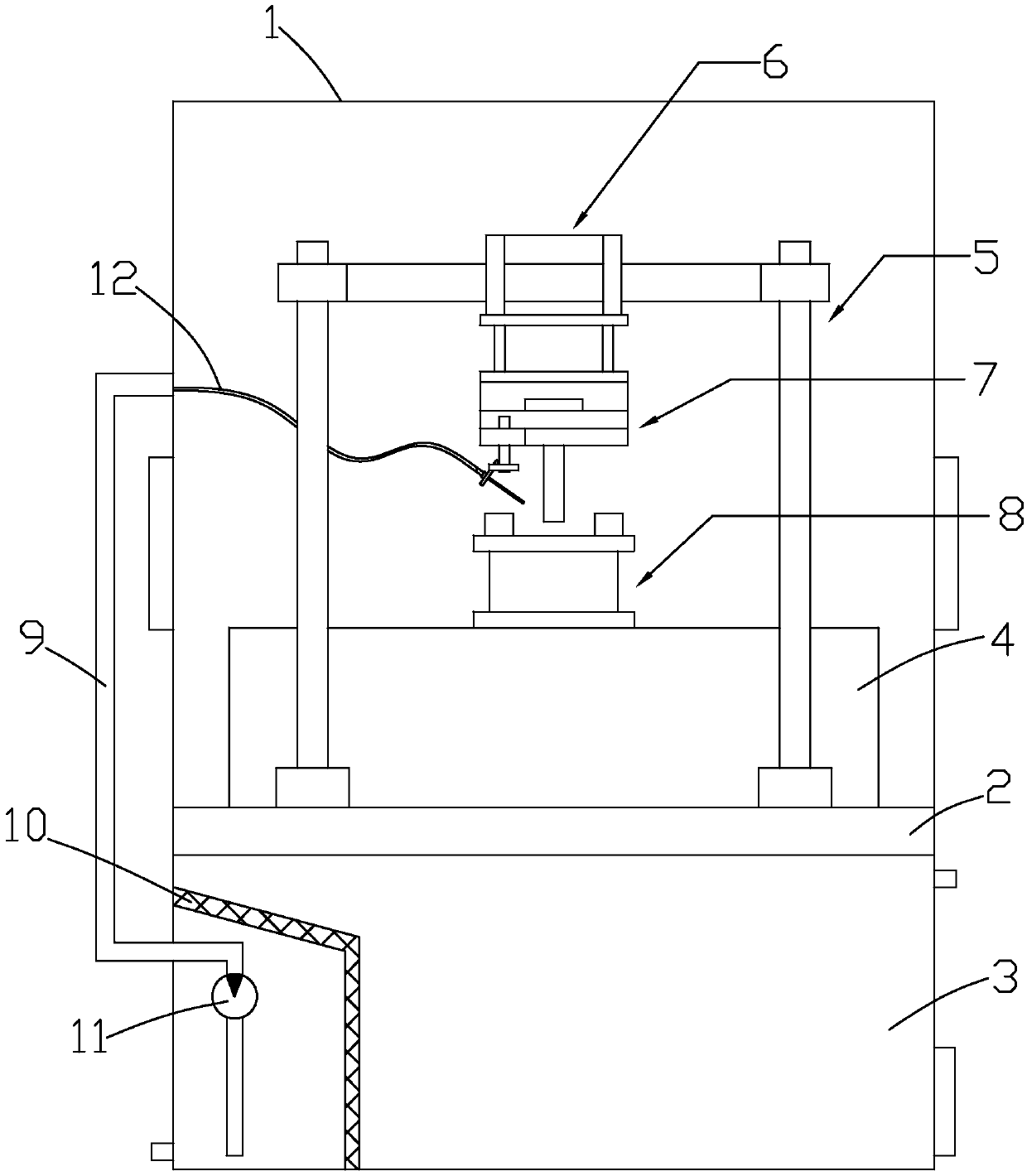

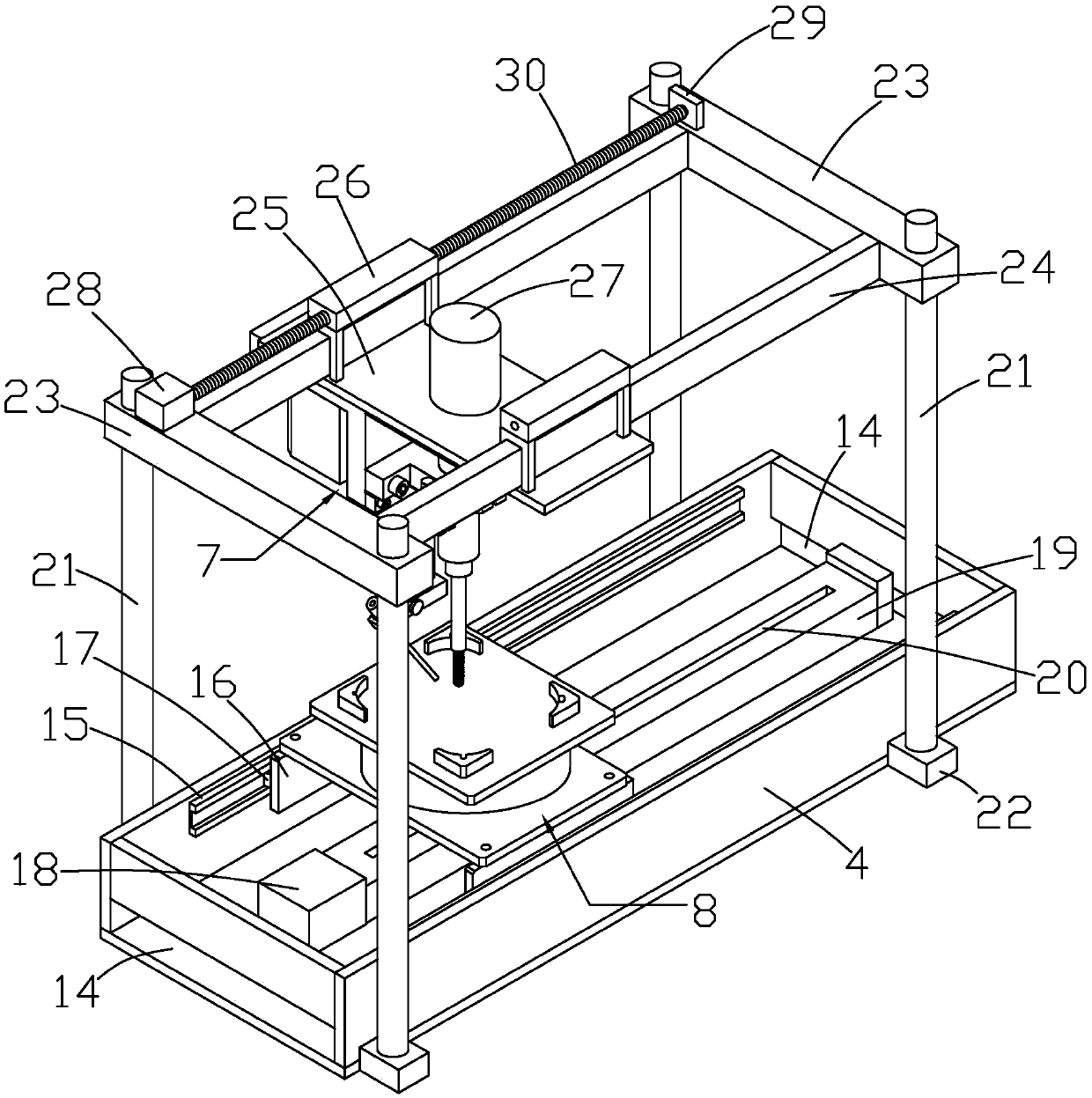

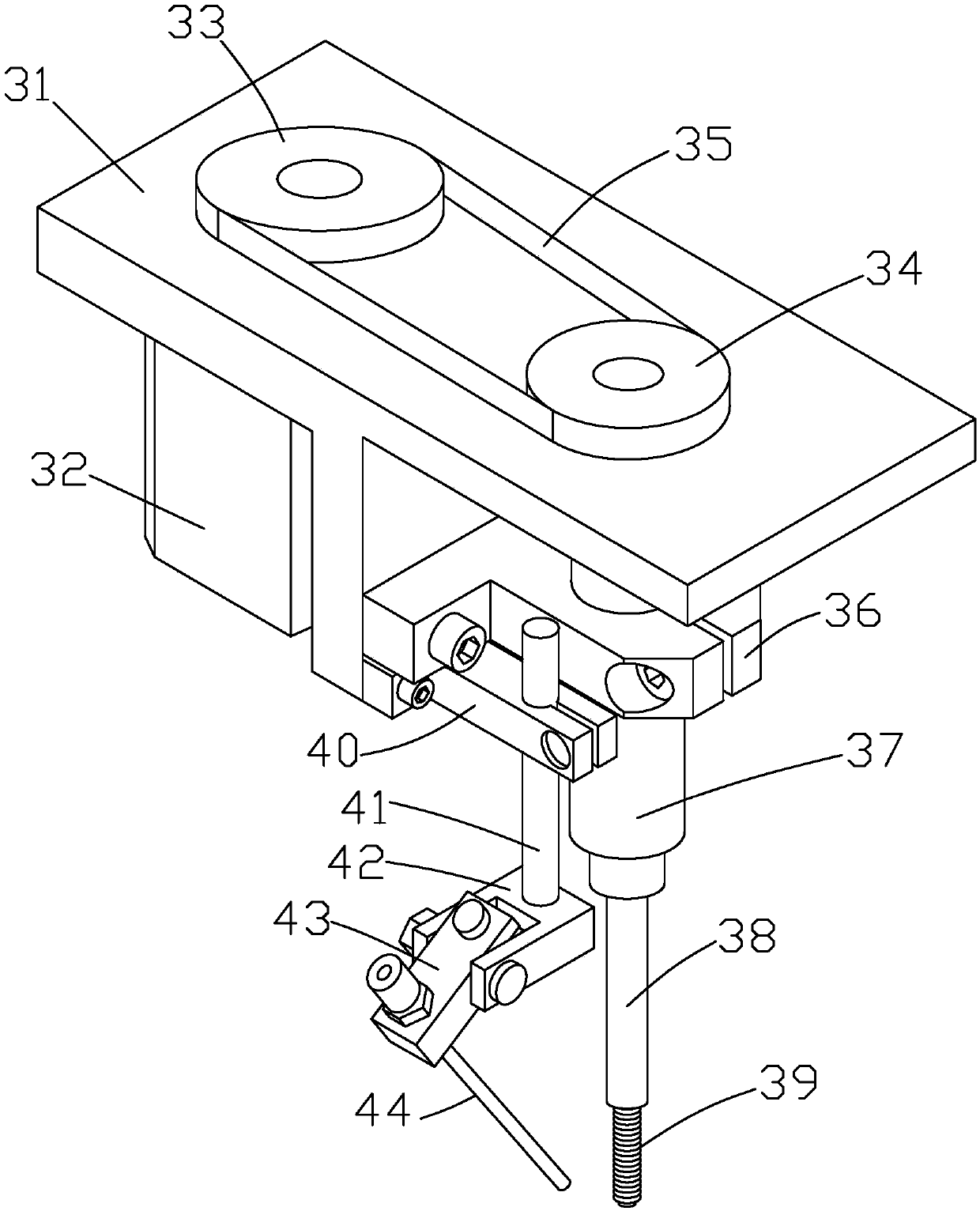

Silicon steel sheet machining device for permanent-magnet synchronous motor production and machining method of silicon steel sheet machining device

PendingCN109687659ARealize position adjustmentImprove stabilityManufacturing stator/rotor bodiesPositioning apparatusPermanent magnet synchronous motorEngineering

The invention discloses a silicon steel sheet machining device for permanent-magnet synchronous motor production and a machining method of the silicon steel sheet machining device. The silicon steel sheet machining device for the permanent-magnet synchronous motor production comprises a box body, a water tank, a spraying system and a machining assembly, the machining assembly comprises a frame body, a supporting mechanism, a horizontal moving mechanism, a permanent-magnet slot forming mechanism and a silicon steel sheet clamping platform, the silicon steel sheet clamping platform is connectedto the frame body in a horizontal moving mode, the supporting mechanism is fixedly connected to the outer side surface of the frame body, the horizontal moving mechanism is connected to the supportingmechanism, the permanent-magnet slot forming mechanism is fixedly connected below the horizontal moving mechanism, and the water tank is connected with the permanent-magnet slot forming mechanism through the spraying system. The machining method of the silicon steel sheet machining device comprises the steps of box body machining, mounting of the frame body and the silicon steel sheet clamping platform, mounting of the supporting mechanism and the horizontal moving mechanism, mounting of the permanent-magnet slot forming mechanism, mounting of the spraying system and silicon steel sheet machining. Compared with traditional silicon steel sheet punch forming equipment, according to the silicon steel sheet machining device for the permanent-magnet synchronous motor production and the machining method of the silicon steel sheet machining device, a plurality of silicon steel sheets can be machined simultaneously, no specific mould is required, the machining precision is higher, and the rejection rate is reduced.

Owner:浙江晋一特种电机有限公司

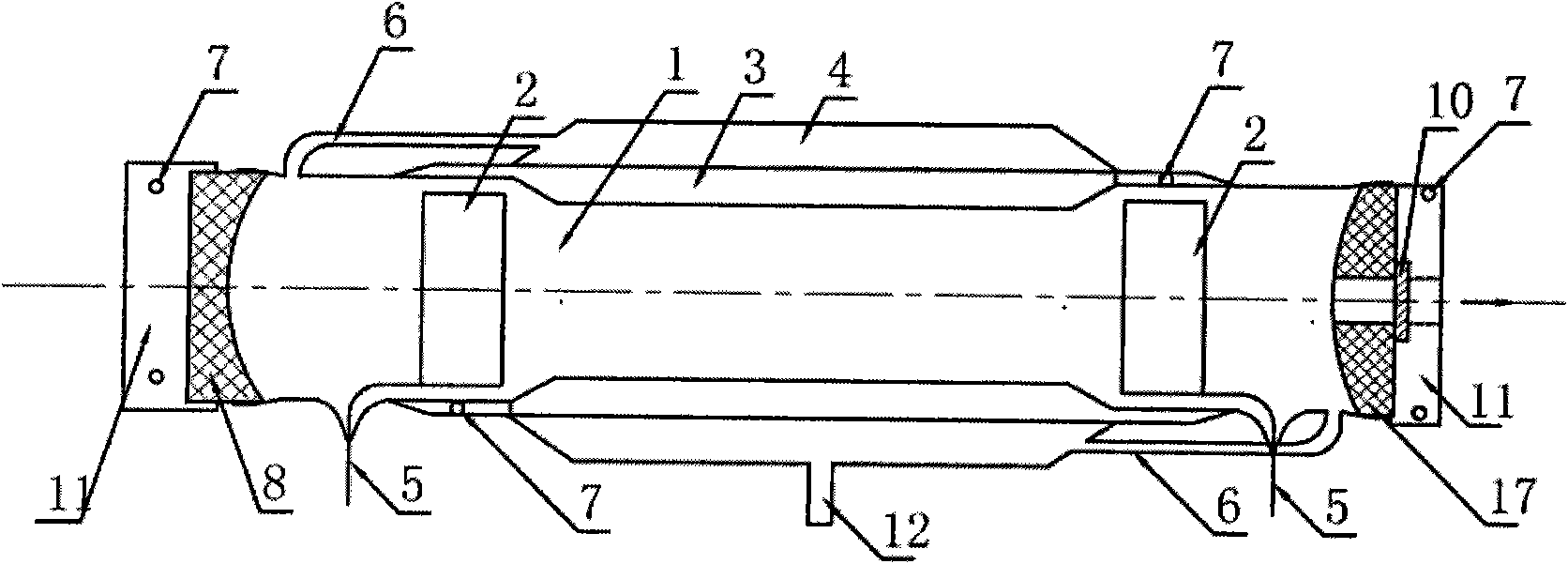

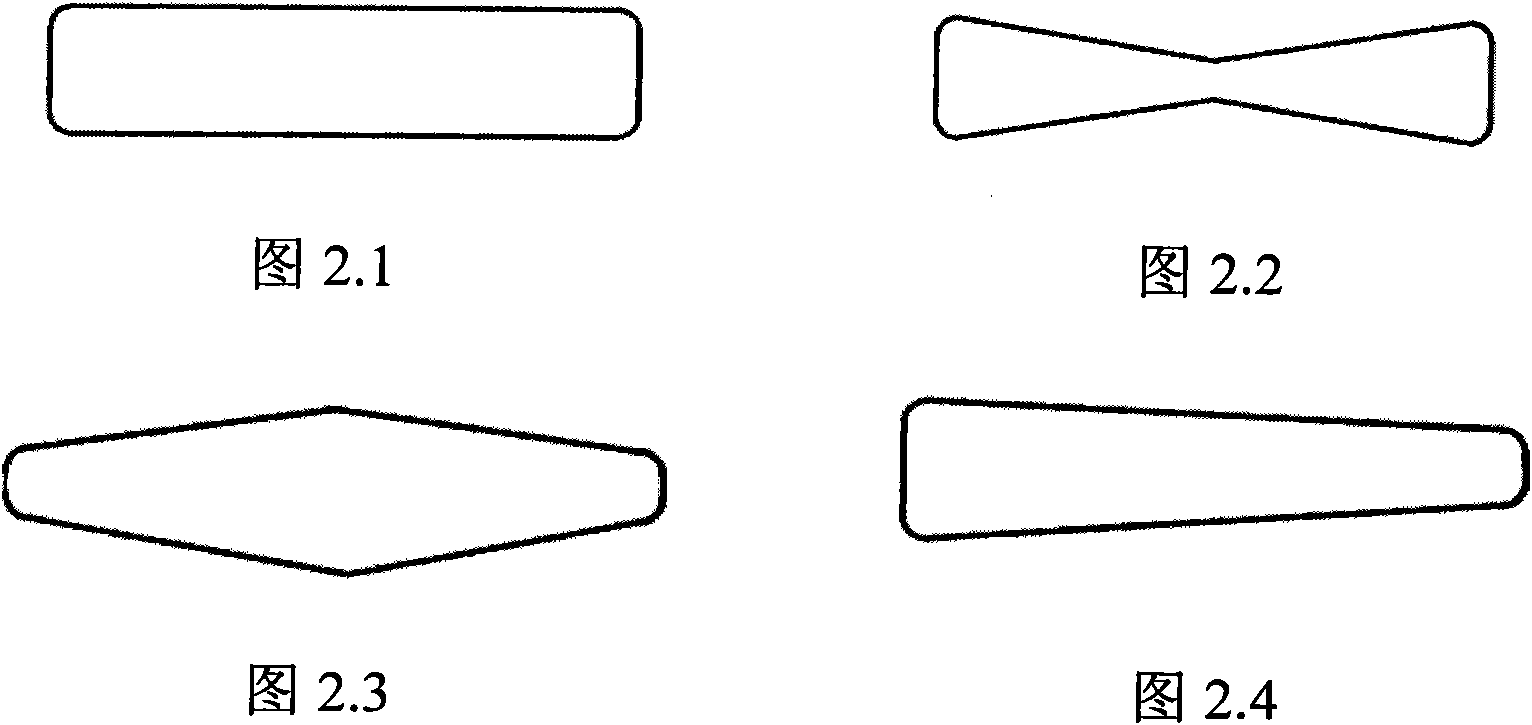

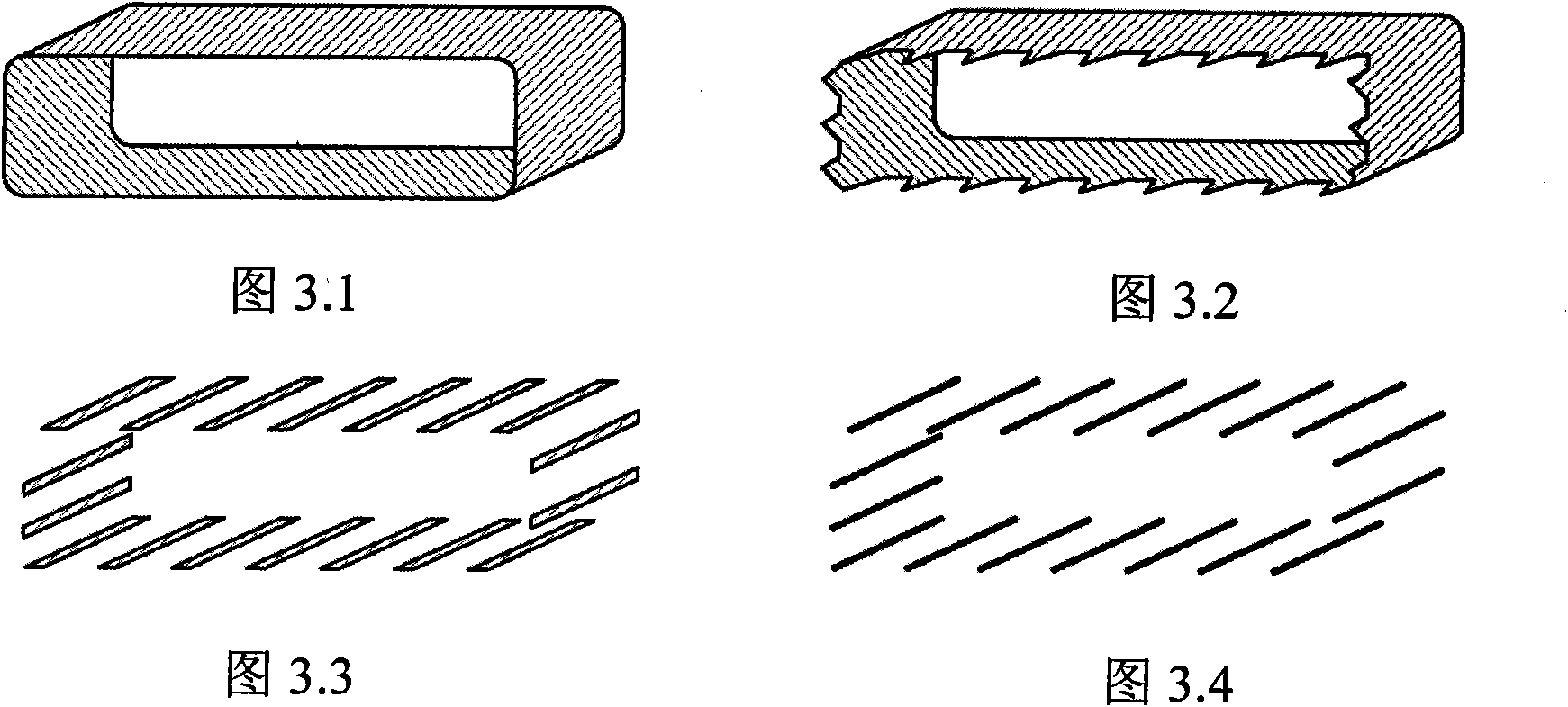

Gas laser

InactiveCN101789559ASimple structureIncrease powerActive medium materialGas laser constructional detailsLaser processingMetallic materials

The invention discloses a gas laser, which comprises a discharge chamber, a discharge electrode, a water-cooling channel and a gas storage chamber, wherein the water-cooling channel is distributed on the ektexine of the discharge chamber, the gas storage chamber is positioned outside the water-cooling channel, the discharge chamber and the gas storage chamber are communicated through a muffler, the discharge chamber is a sealed cavity which consists of a discharge cavity, a strip-shaped reflector on a tail end mirror, a strip-shaped reflector on an output end and a full-through output mirror, the discharge cavity is in a lath-shaped hollow-core structure which is made of nonmetal materials, the tail end mirror, the strip-shaped reflector on the output end are respectively positioned on the front end and the rear end of the discharge cavity, an aperture is left on the middle or one side of the strip-shaped reflector of the output end, the full-through output mirror is positioned at the position of the aperture and is used as a laser output window, and the discharge electrode is poisoned in the front end and rear end of the discharge cavity, or in the left side and the right side of the discharge cavity. The gas laser has small size, light weight, simple structure, a cooling system with good cooling effect, high output power and stable laser beam with good mode, and can be used for the laser processing industry.

Owner:HUAZHONG UNIV OF SCI & TECH

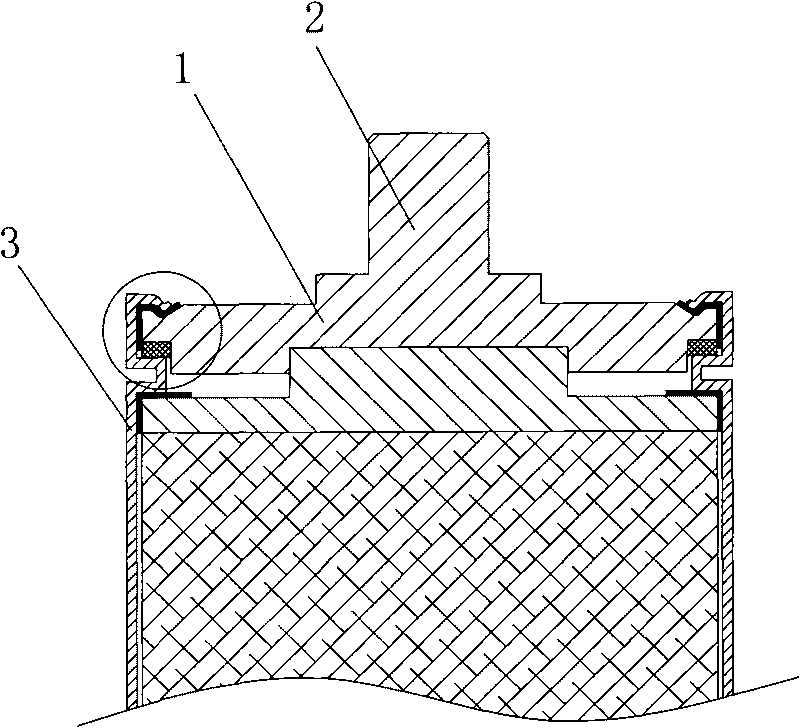

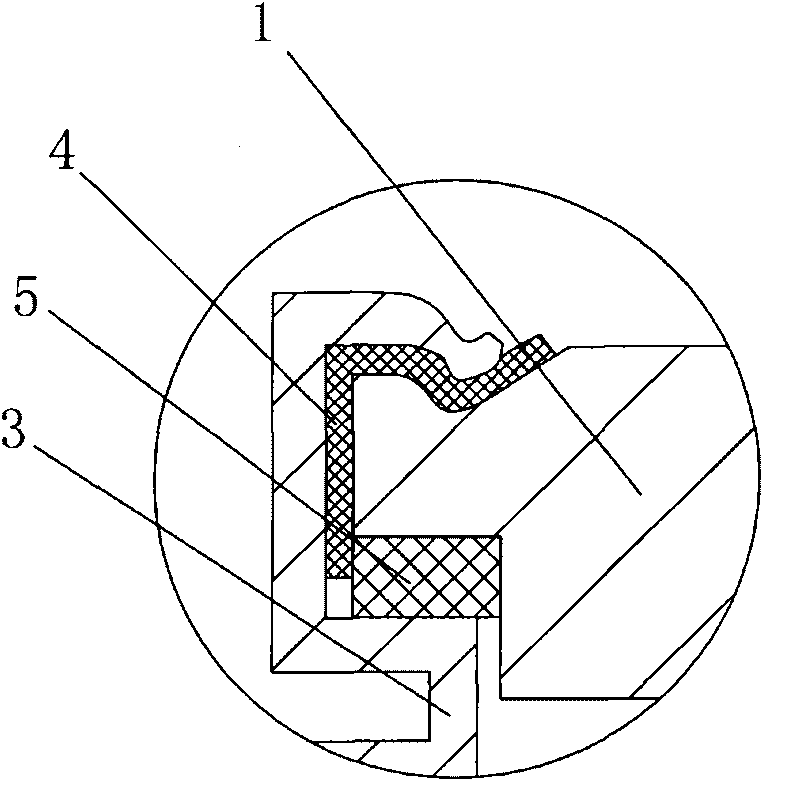

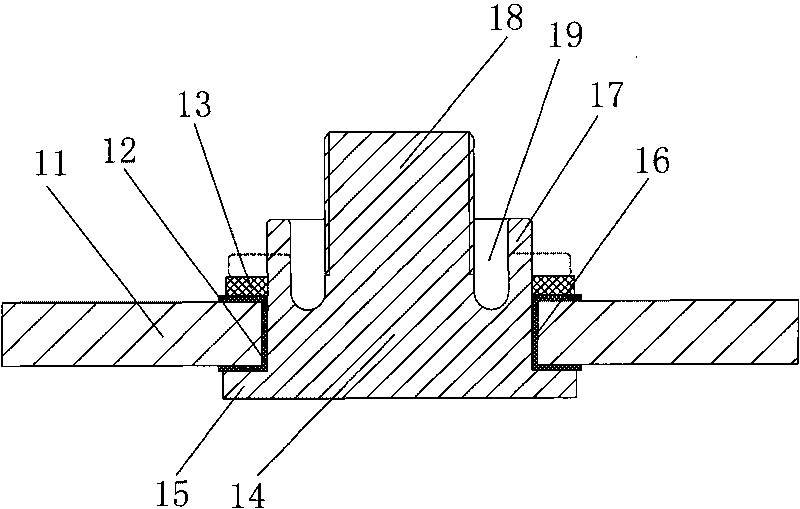

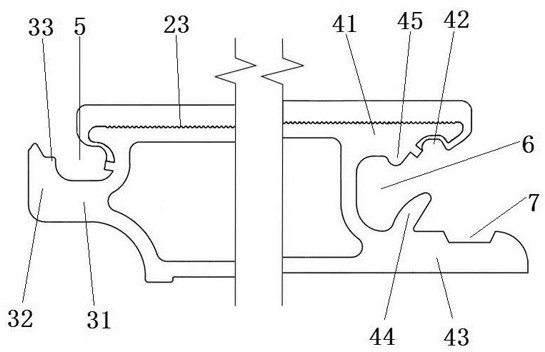

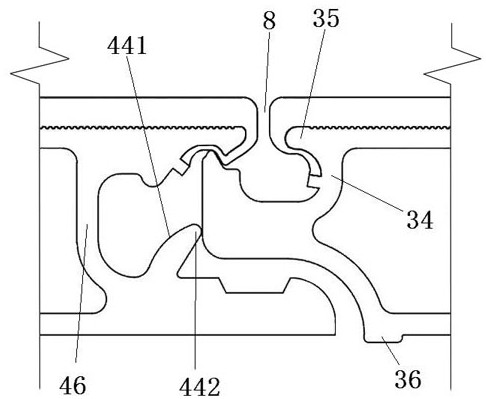

Electrode leading structure and electricity storage electric element adopting thereof

ActiveCN101714616AHigh machining accuracy requirementsLow machining accuracy requirementsCapacitor terminalsPrimary cellsCapacitanceElectricity

The invention discloses an electrode leading structure of a battery or a super capacitor, which comprises an end cover. The end cover is hermetically fixed at the opening of the electrode end of a battery or capacitor outer casing. A terminal is inserted in the middle of the end cover, and the top end of the terminal extends out of the end cover. The bottom of the terminal is fixedly provided with a stop edge which is used for preventing the terminal from falling, and the top is respectively provided with a terminal leading end and a hollow flanging structure which is arranged around the terminal leading end. An insulation and sealing sleeve is clamped between the terminal and the end cover, and is sleeved on the terminal for sealing the terminal. The invention also discloses an electricity storage electric element which adopts the electrode leading structure. The electrode leading structure adopts a split structure of the terminal and the end cover; one insulation and sealing sleeve is used for sealing and insulating when the terminal is assembled; the flanging structure is sealed and compressed after being flanged; the sealing structure is simple, and is convenient and rapid in installation; and the sealing part is arranged around the terminal, so that the sealing and insulation material is saved.

Owner:ZHENGZHOU SINO CRYSTAL DIAMOND

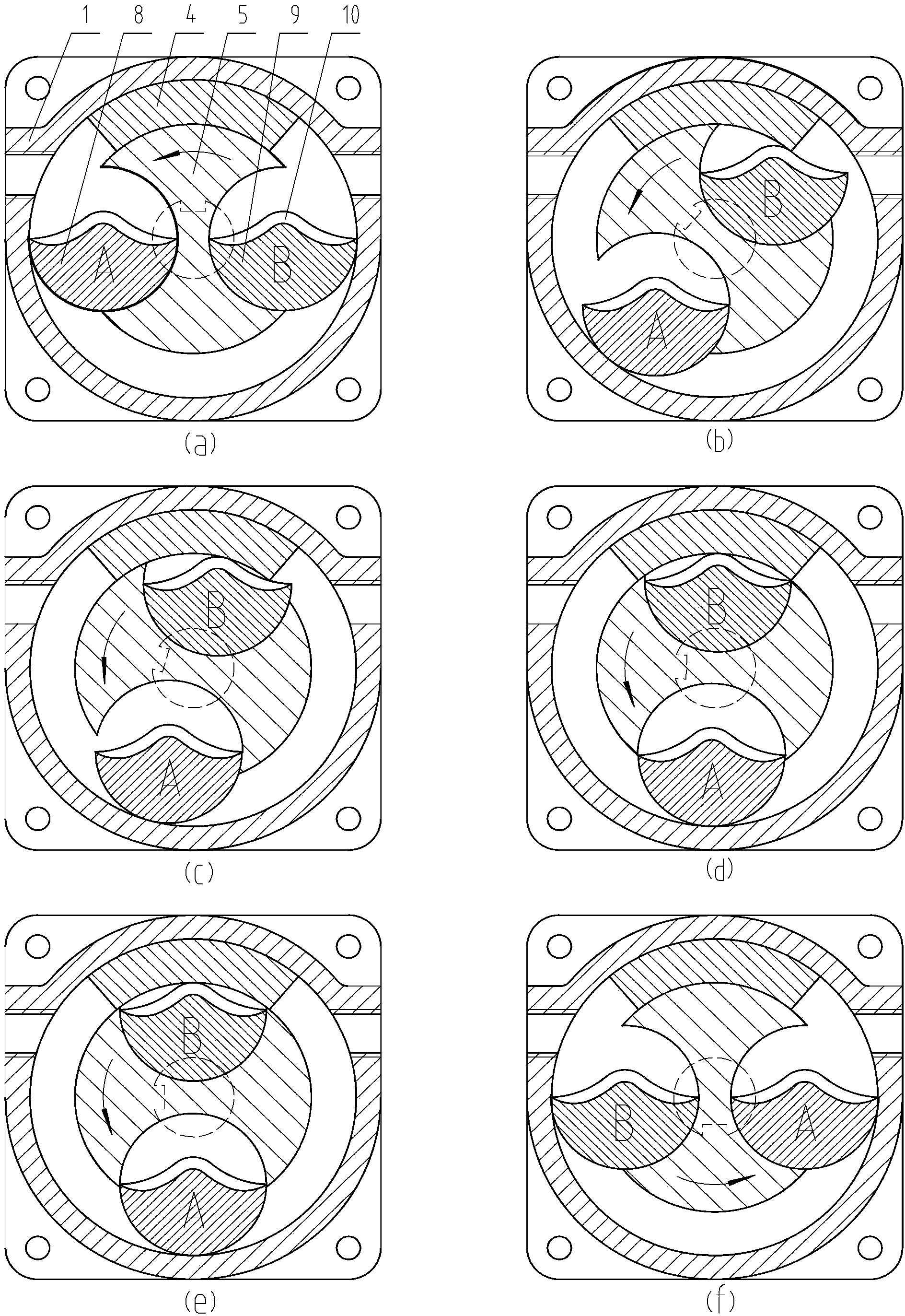

Pumps with revolving piston structure, related products and part of embodiments

InactiveCN103671087AIncrease pressureImprove self-priming performanceRotary piston pumpsRotary piston liquid enginesGear pumpHydraulic pump

The invention relates to pumps with revolving piston structures, related products and a part of embodiments. Each pump is characterized in that the pump comprises a C-shaped annular cylinder body which is composed of multiple parts, the piston of the pump is pulled and controlled through a double crank transmission mechanism and carries out circular revolving translation around the cylinder body under the driving of a rotor. The pump has the characteristics of simple structure, easy manufacturing, low wear, high rotating limit speed and direct ratio liner change of the volume. When the pumps are used for manufacturing metering pumps and flow meters, micro-metering and precision metering can be achieved; when the pumps are used for manufacturing hydraulic pumps (motors), the hydraulic pumps are smooth in flow rate, free of noise, good in hydroscopicity and low in cost and can be used to replace gear pumps (motors), centrifugal self-priming pumps, submersible pumps and the like; when the pumps are used in fluid pumps such as fire pumps, water supply pumps for buildings and the like, the fluid pumps are high in pressure and energy-saving; when the pumps are used in hydraulic water lifting pumps and dust-removing negative-pressure suction fans, the energy consumption can be greatly reduced, the energy utilization rates of power devices for hydroelectric generation can be improved. The pumps are also high in vacuum degree and can be used for manufacturing vacuum pumps. The structures of the pumps are ideal pump structures and extremely wide in application scope and market prospect.

Owner:王五一

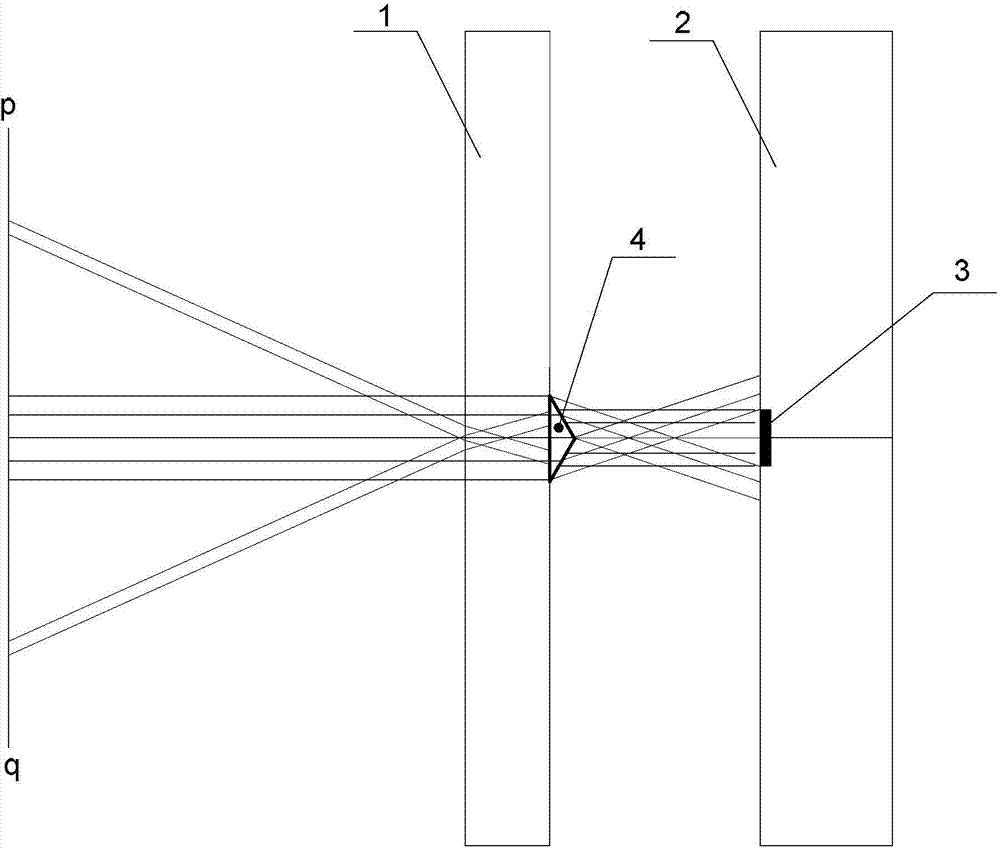

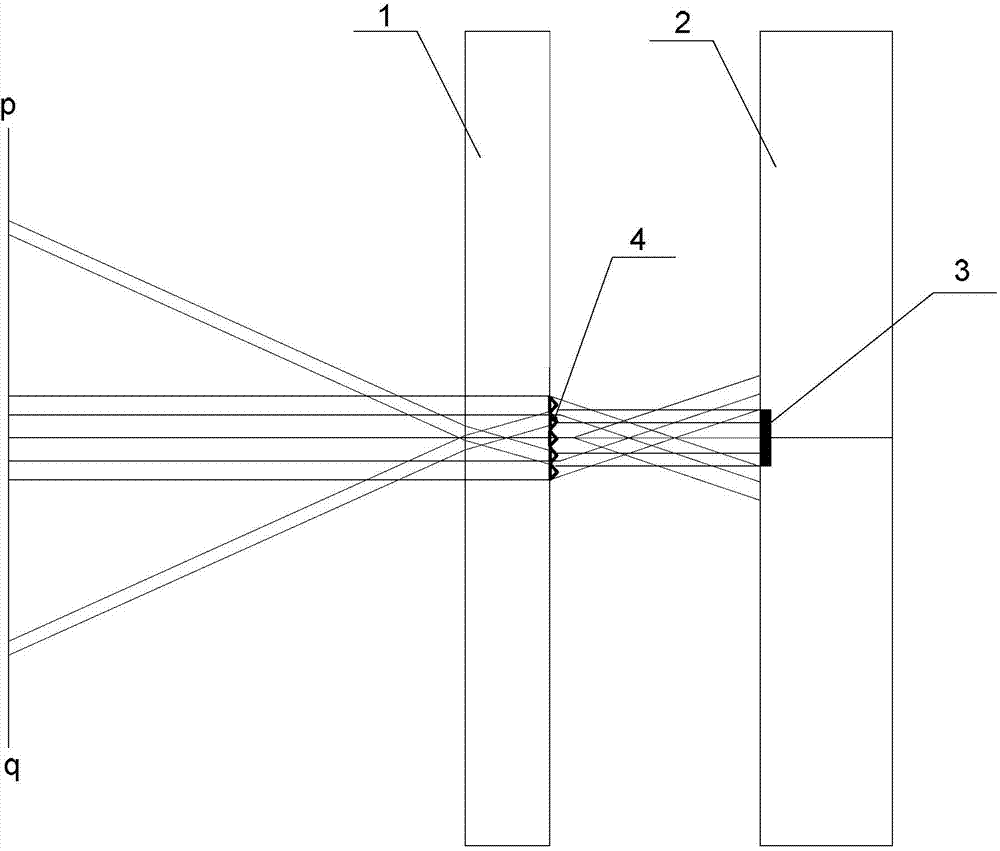

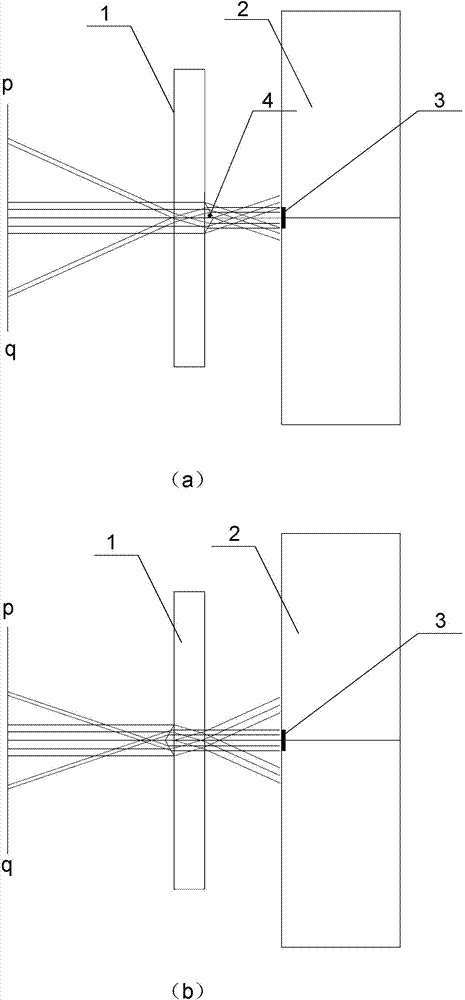

Boarder weakening method of naked-eye 3D (three dimensional) splice display screen

ActiveCN104749787ACompact designHigh machining accuracy requirementsIdentification meansOptical elementsGratingOptical axis

The invention belongs to the technical field of 3D (three dimensional) display, discloses a boarder weakening method of a naked-eye 3D splice display screen and aims to solve the problem that the two conventional boarder weakening methods adopt complicated circuit and optical path structures, causing high cost; according to the technical scheme, the boarder weakening method includes that a large-size display comprises a front glass board with grating film and a splice screen, and between every two unit screens of the splice screen, a boarder is provided; a triple prism is arranged on the surface of one side of the glass board, and the optical axis center of the triple prism and the geometric center of the boarder are on the same viewing horizontal position; length of one side opposite to the point angle of the triple prism is greater 30%-50% than width of the boarder, and length of the triple prism is equal to that of the boarder, in this way, as watching, light rays reflected by the boarder are transmitted outside a visible range under reflection action of the triple prism, and light rays of display images around the boarder are reflected in eyes, so that the boarder between the unit screens is visually weakened, and the whole splice screen displays in a seamless display way. Besides, the triple prism can be replaced by a triple prism array.

Owner:NINGBO VISION DISPLAY TECH

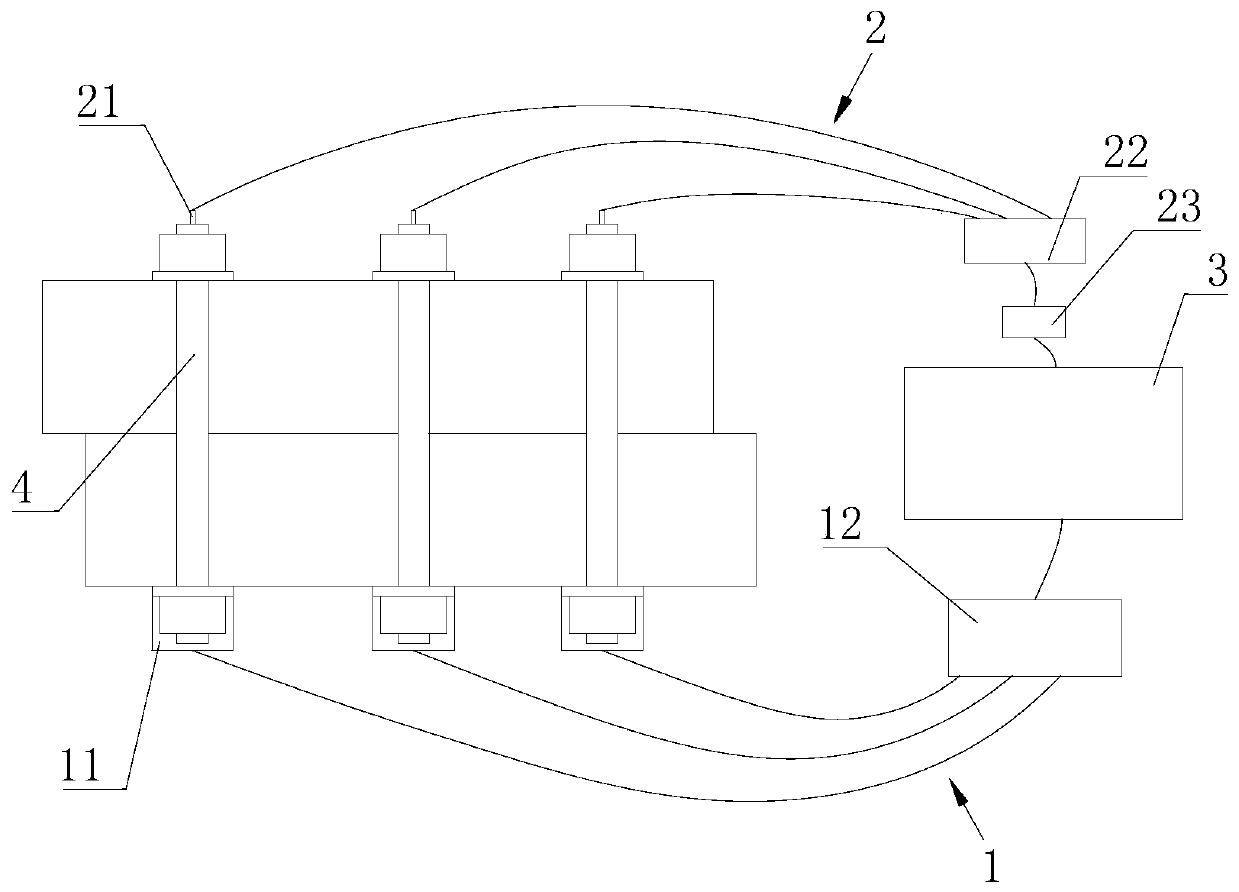

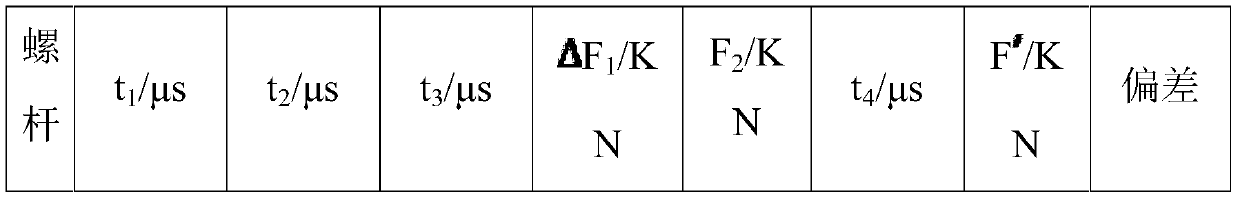

Suspension bridge cable clamp screw axial force synchronous construction system and use method thereof

ActiveCN110374003ASettle the lossSolve engineering problems with high randomnessBridge structural detailsBridge erection/assemblyBridge engineeringEngineering

The invention discloses a suspension bridge cable clamp screw axial force synchronous construction system and a use method thereof, and relates to the technical field of bridge engineering construction. The system comprises a tensioning device, an ultrasonic detection device and a control device, wherein the tensioning device is used for being connected with a to-be-tensioned screw and tensioningthe to-be-tensioned screw; the ultrasonic detection device is used for being connected with the to-be-tensioned screw, transmitting an ultrasonic signal to the to-be-tensioned screw, and detecting the transmission time of round trip of the ultrasonic signal in the to-be-tensioned screw; and the control device is connected with the tensioning device and the ultrasonic detection device and is usedfor calculating correction construction axial force F2 in the to-be-tensioned screw according to t2, t3 and a preset formula, and the tensioning device is controlled to carry out tensioning on the to-be-tensioned screw rod by adopting the correction construction axial forceF2. According to the system, a correction scheme is formulated for the retraction loss condition of single screw tensioning,and the engineering problems of large axial force loss and large randomness of the screw after a nut is screwed are well solved.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

Auxiliary positioning device and method for adjustable radar feed source

ActiveCN105425827AHigh machining accuracy requirementsDoes not reduce stiffnessWave based measurement systemsUsing optical meansRotational freedomRadar

The invention discloses an auxiliary positioning device and method for an adjustable radar feed source, and the device comprises an installation substrate, three guide rails with translational freedom degrees, and two rotating shafts with rotational freedom degrees. The installation substrate serves as a base, and the guide rails are mutually orthogonal in postures, thereby forming three translational freedom degrees. The housing of the lateral rotating shaft is installed on a sliding block on the guide rail at a tail stage, and the longitudinal rotating shaft is disposed on a step shaft on the lateral rotating shaft, and is perpendicular to the lateral rotating shaft, so as to form two orthogonal rotational freedom degrees. A fixed seat located at the tail end of the device can be directly used for target sphere measurement of a laser tracker or the electrical performance testing of a feed source through a feed source adapter board. When the device is used for measuring and adjusting the position of the feed source, the adjustment amounts of the plurality of freedom degrees can be directly read. The device can provide accurate data of the position of the feed source, and improves the efficiency of the positioning of the feed source.

Owner:THE 724TH RES INST OF CHINA SHIPBUILDING IND

Hyperbolic-curve speed reducer

ActiveCN105257786ACompact structureReduce volumeToothed gearingsPortable liftingGear driveReduction ratio

The invention discloses a hyperbolic-curve speed reducer, and belongs to the field of reduction equipment. The hyperbolic-curve speed reducer comprises an inner tooth ring, an input shaft, an input mechanism, a hyperbolic-curve speed-reducing mechanism and an output mechanism, wherein the inner tooth ring, in a peripheral direction, is provided with a plurality of inner tooth ring projecting teeth at an equal interval; the hyperbolic-curve speed-reducing mechanism comprises a first cycloidal gear and a second cycloidal gear; the first cycloidal gear and the second cycloidal gear are symmetrically and rotatably arranged in the inner tooth ring at an angle of 180 degrees; side edges of the two cycloidal gears are provided with a plurality of short-amplitude curved teeth at an equal interval in the peripheral direction; and the short-amplitude curved teeth on the two cycloidal gears are engaged with the inner tooth ring projecting teeth on the inner tooth ring. The input shaft drives the first cycloidal gear and the second cycloidal gear to rotate by virtue of the input mechanism; and the first cycloidal gear and the second cycloidal gear drive the output mechanism to rotate. The hyperbolic-curve speed reducer is in engaged transmission by virtue of the inner tooth ring projecting teeth of the inner tooth ring, and the short-amplitude curved teeth of the first cycloidal gear and the second cycloidal gear, is compact in structure, small in transmission stable vibration, high in transmission efficiency and great in reduction ratio.

Owner:四川奥斯廷科技有限公司

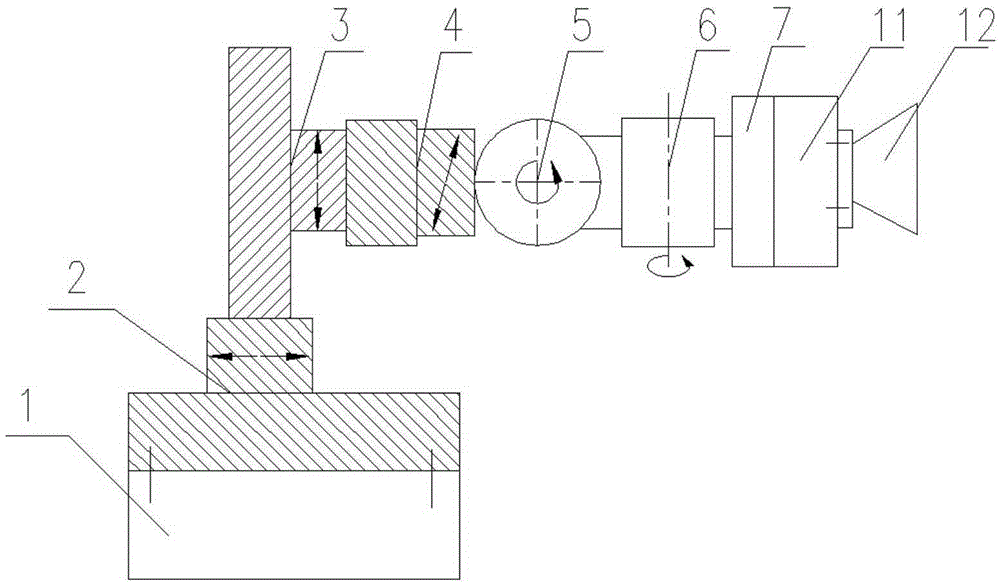

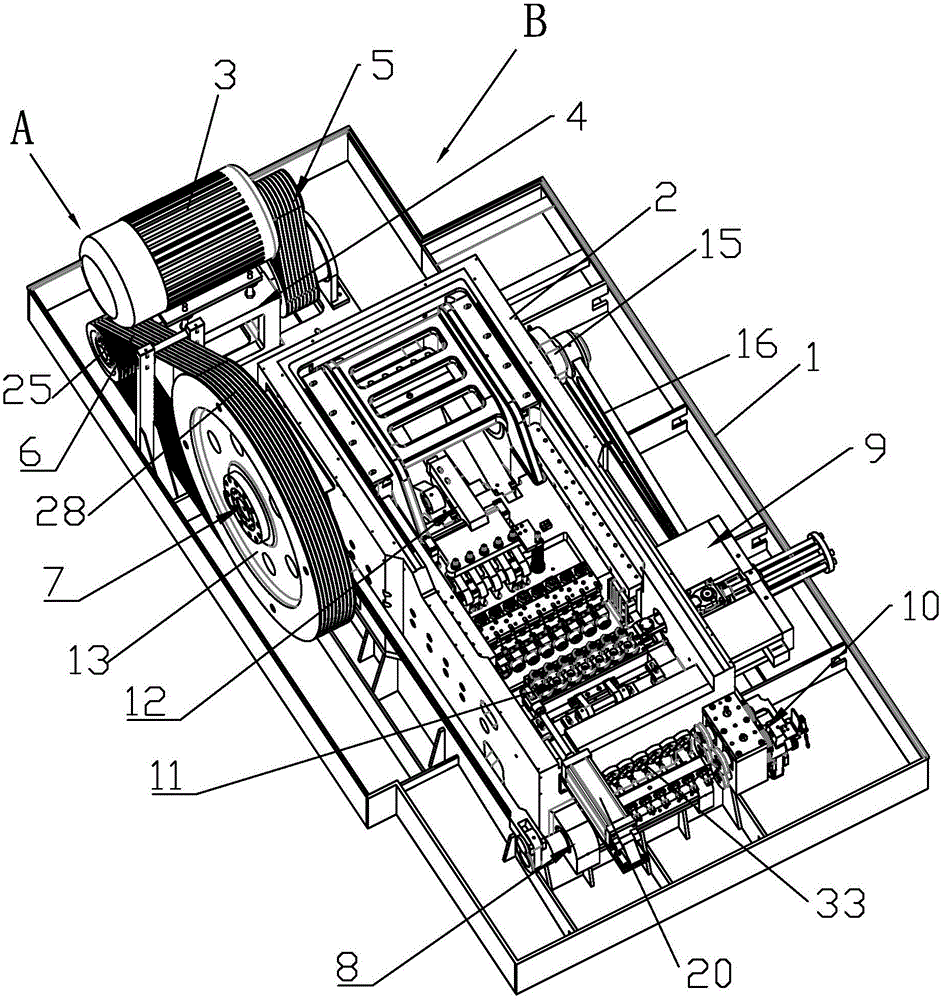

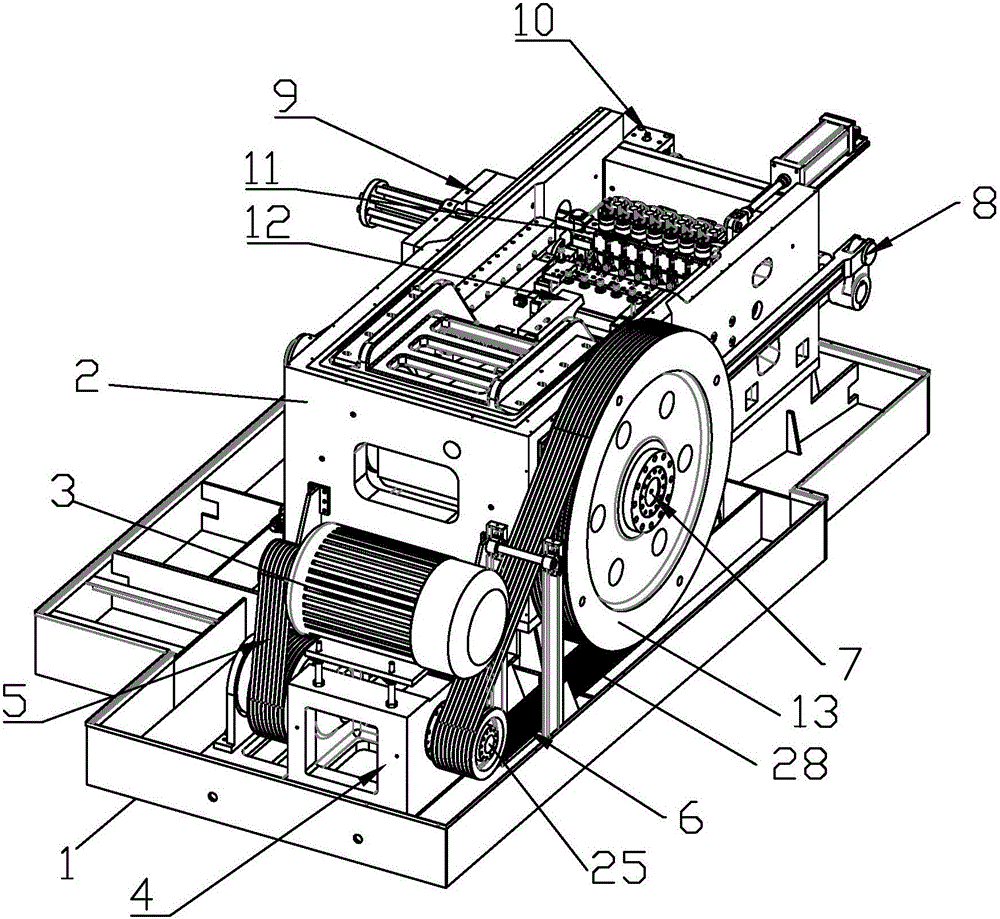

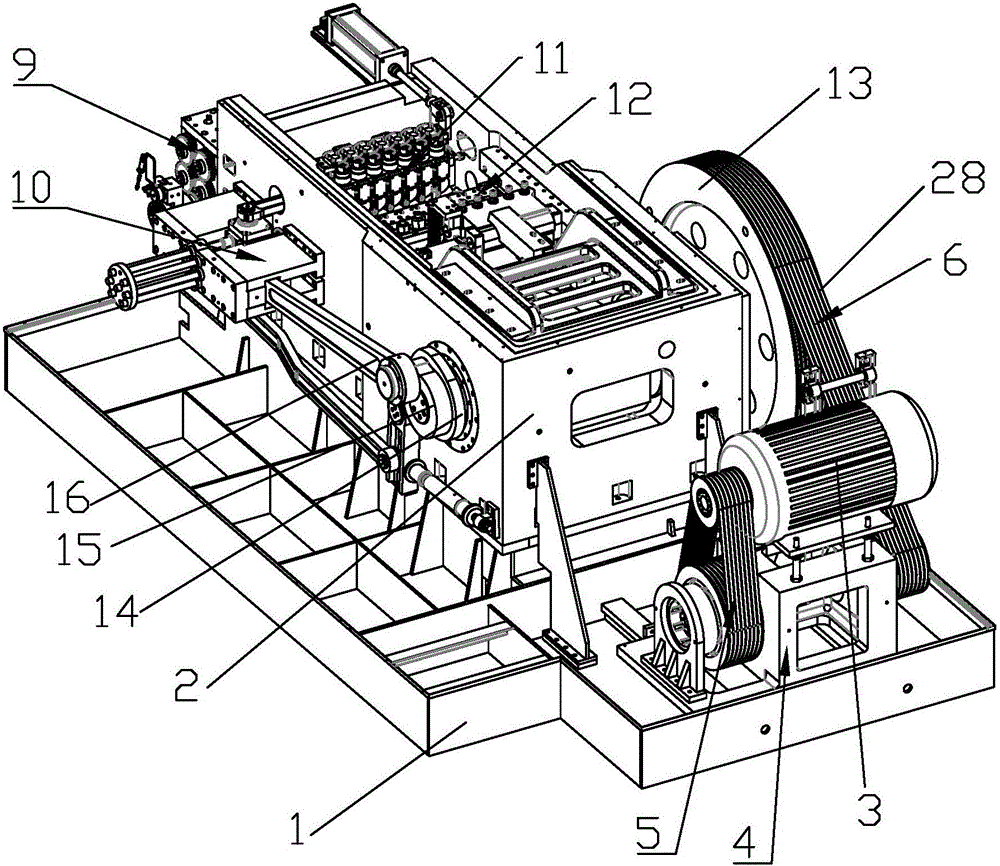

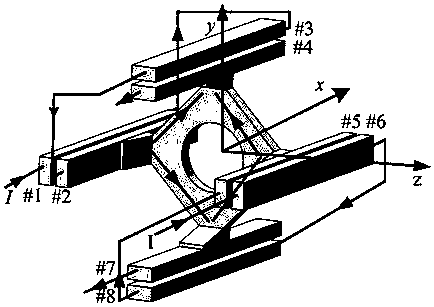

Final assembly mechanism of eight-station cold heading machine

ActiveCN105689616ASimple structureStrong targetingForging/hammering/pressing machinesForging press drivesPunchingReciprocating motion

The invention discloses a final assembly mechanism of an eight-station cold heading machine. The final assembly mechanism comprises a base and a rack, wherein a main motor and a reduction gearbox device are arranged on the base, the main motor is connected with the reduction gearbox device, a main transmission device is connected to the reduction gearbox device, a rear ejection device is connected to one end of the main transmission device, a cutting device and a feeding device are connected to the other end of the main transmission device, the feeding device is connected with the rear ejection device, a clamping device is connected to the cutting device, and a sliding block device is connected to the middle of the main transmission device. According to the final assembly mechanism, the punching operation is completed mainly in the steps that a flywheel is driven to rotate by the main motor by virtue of the reduction gearbox device, so as to drive a crankshaft to rotate, the rear ejection device, the feeding device, the cutting device and the sliding block device are respectively driven to do a reciprocating motion by the crankshaft, all motions are driven by the crankshaft, the workpiece feeding, cutting and clamping are implemented under the action of the crankshaft, and the punching steps can be continuously repeated in sequence.

Owner:浙江东雄机床有限公司

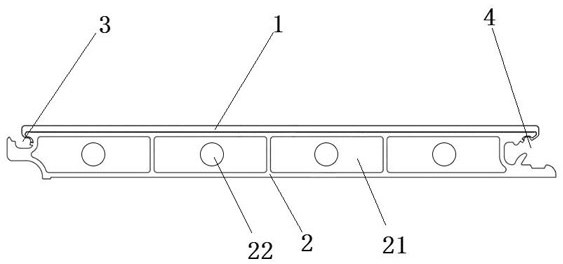

Aluminum-plastic composite floor with water accumulation prevention and snow melting functions

InactiveCN111946010AStrong chemical adhesionHigh bonding strengthCovering/liningsResiliently-mounted floorsSnowpackSnow melting

The invention provides an aluminum-plastic composite floor with water accumulation prevention and snow melting functions. The floor comprises a base layer made of aluminum alloy and an elastic surfacelayer which is attached to the base layer and mainly formed by resin, two side ends of the base layer are provided with a male splicing end with a male tenon structure and a female splicing end witha female groove structure respectively, during paving, any two adjacent floors in the length direction of the floors are connected in a matched mode through the male tenon structures and the female groove structures, a gap is formed between the upper surfaces of any two adjacent floors to form a water inlet, each of the male tenon structure and the female tenon structure is provided with a plurality of drainage grooves, one or more cavities are formed inside the base layer, and heating sources are arranged in the cavities or allowed to be arranged in the cavities. According to the aluminum-plastic composite floor with the water accumulation prevention and snow melting functions, through the design of the water inlet and the multiple drainage grooves, it is guaranteed that rainwater cannotpermeate into the lower portion of the floor and is drained as soon as possible; and when accumulated snow is generated on the surface of the floor, the accumulated snow can be quickly melted throughthe heating sources arranged in the cavities of the base layer.

Owner:ANHUI SENTAI WPC GRP CO LTD

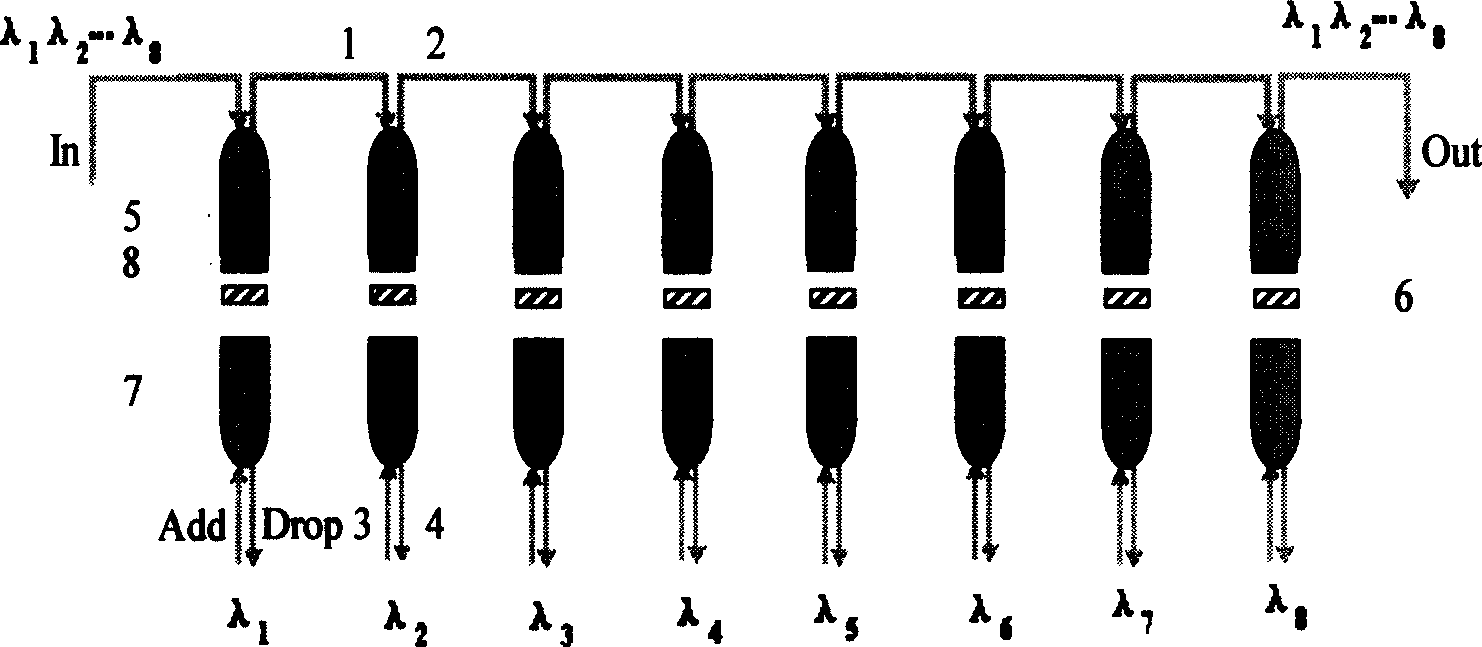

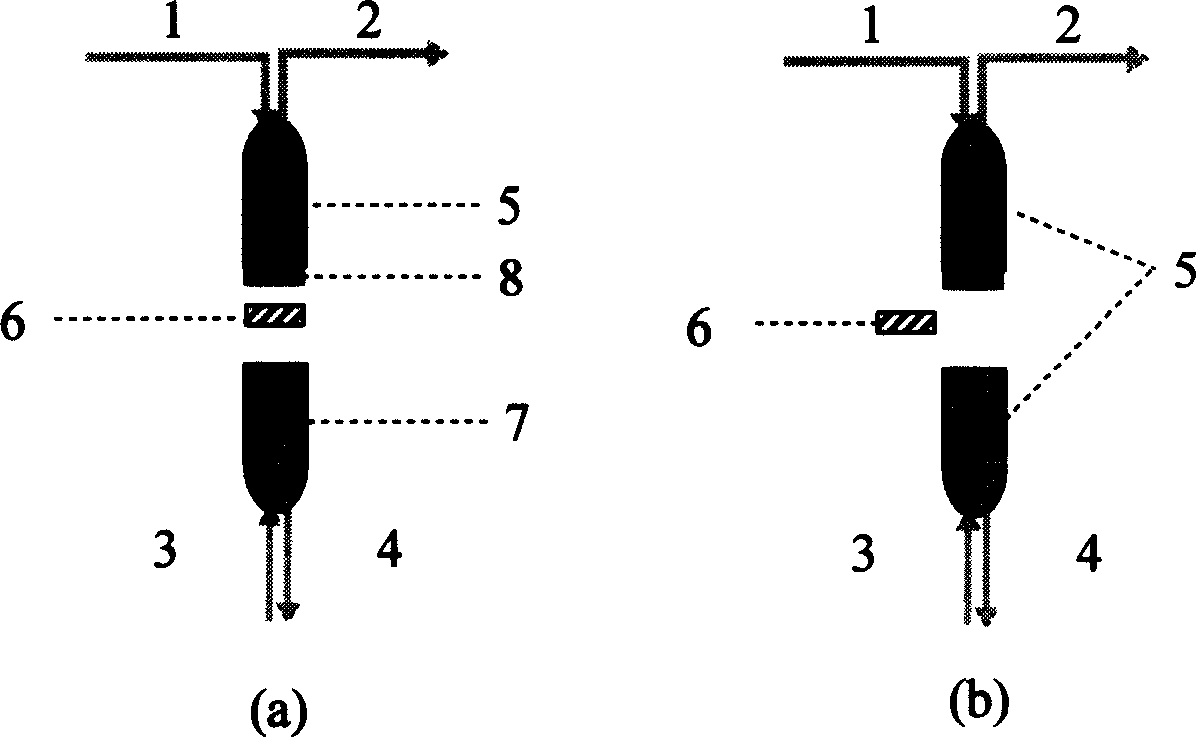

Integrated dynamic light add and drop multiplexer module based on filter wave light switch unit

InactiveCN1555147AMiniaturizationAchieve modularityOptical filtersWavelength-division multiplex systemsBandpass filteringFiber

An integrate dynamic light bifurcate multiplexing module base on filtration optical switch units is composed of wantonly multiple filter optical switch units, each having four ports of input, output, an up path and a down path with tail fibers, the output port of each is connected with the input port of the adjacent rear unit via fibers, every switch unit is composed of a fixed film filtration de-multiplexing unit including a double collimator adhered with a bandpass filter film at the front and an ordinary double core collimator and a total reflection film which position in the light channel is adjusted by a mobile device to realize that the wave lengths of the up and down path light signals are adjustable.

Owner:SHANGHAI JIAO TONG UNIV

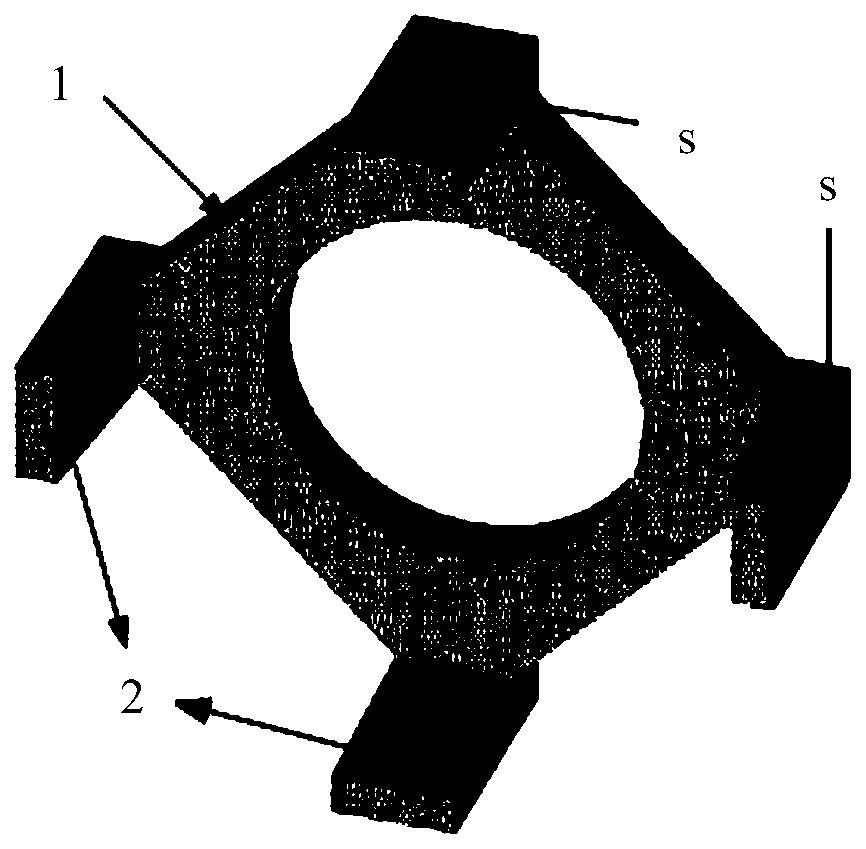

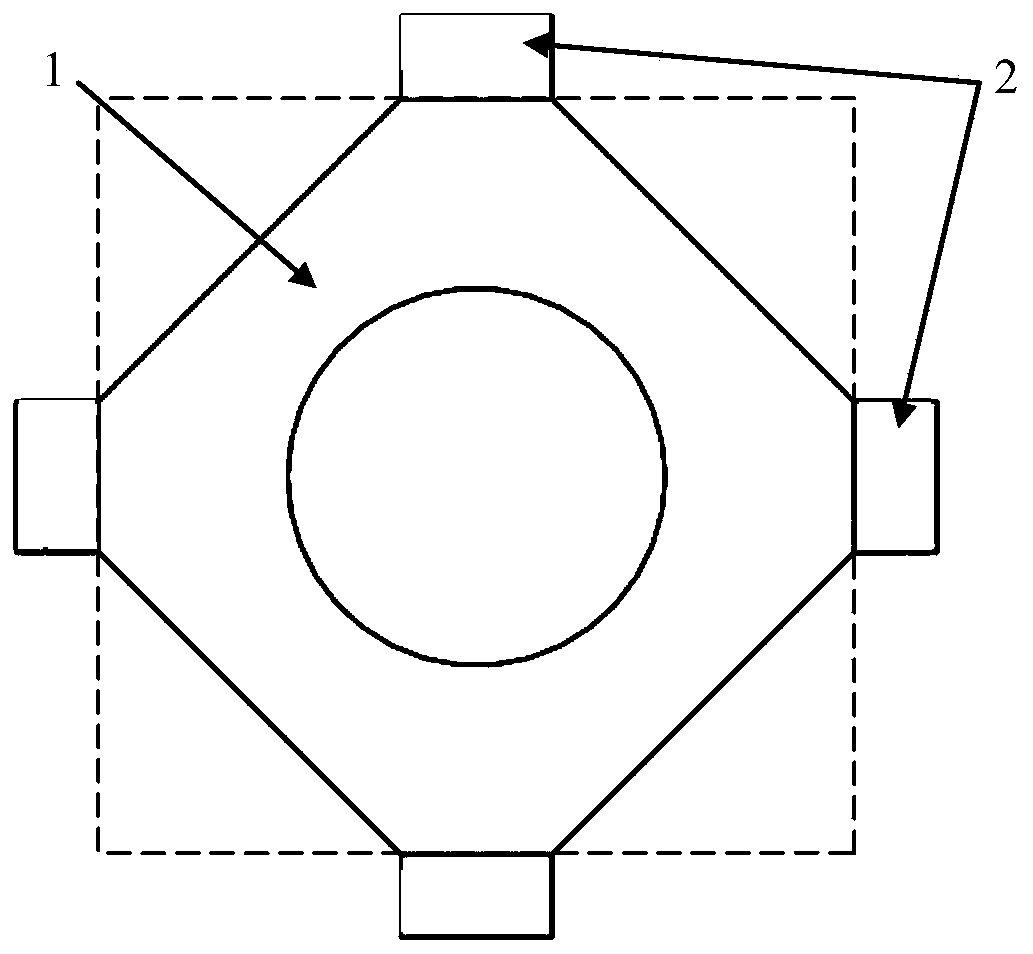

Four-pole armature

InactiveCN109827469AGuaranteed stabilityGuaranteed machining accuracy requirementsElectromagnetic launchersElectromagnetic launchInterference fit

The invention relates to a four-pole armature. The four-pole armature comprises an armature body and armature cantilevers. The armature body is a block body of which the cross section is shaped like acentrally symmetrical octagon. The armature cantilevers are connected with the armature body and are connected to four opposite lateral sides of the armature body, wherein two of the four lateral sides are opposite to the other two lateral sides correspondingly. The length of the lateral sides is the same as the width of the armature cantilevers. The armature cantilevers are flexible arms and extend backwards in the direction parallel to the armature moving direction from the armature body. The tail portions of the armature cantilevers are closer to the axis of the armature body than the headportions of the armature cantilevers. The armature cantilevers are in interference fit with a track in an electromagnetic emitter. The armature cantilevers extending outwards from the armature body are arranged, and the flexible armature cantilevers are in interference fit with the track, so that sufficient contact area and contact pressure between the armature and the track can be obtained whenthe armature is installed, the problems that the armature and the track are separated due to phenomena like abrasion and ablation of the contact surface between the armature and the track in the electromagnetic emission process are solved, and the stability of electromagnetic emission is ensured.

Owner:AIR FORCE UNIV PLA

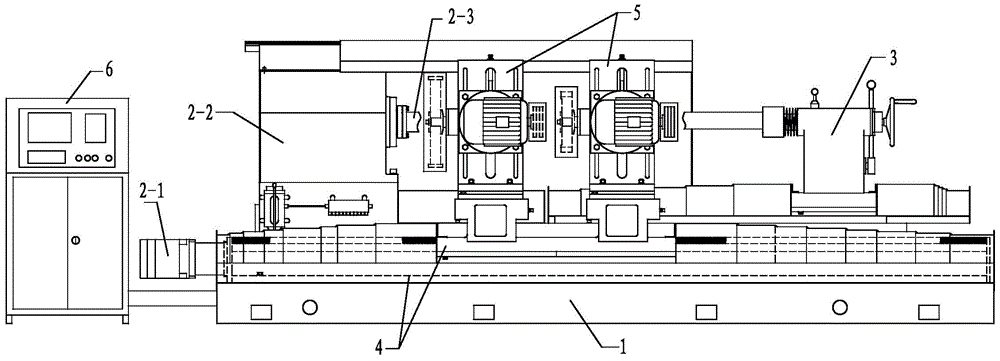

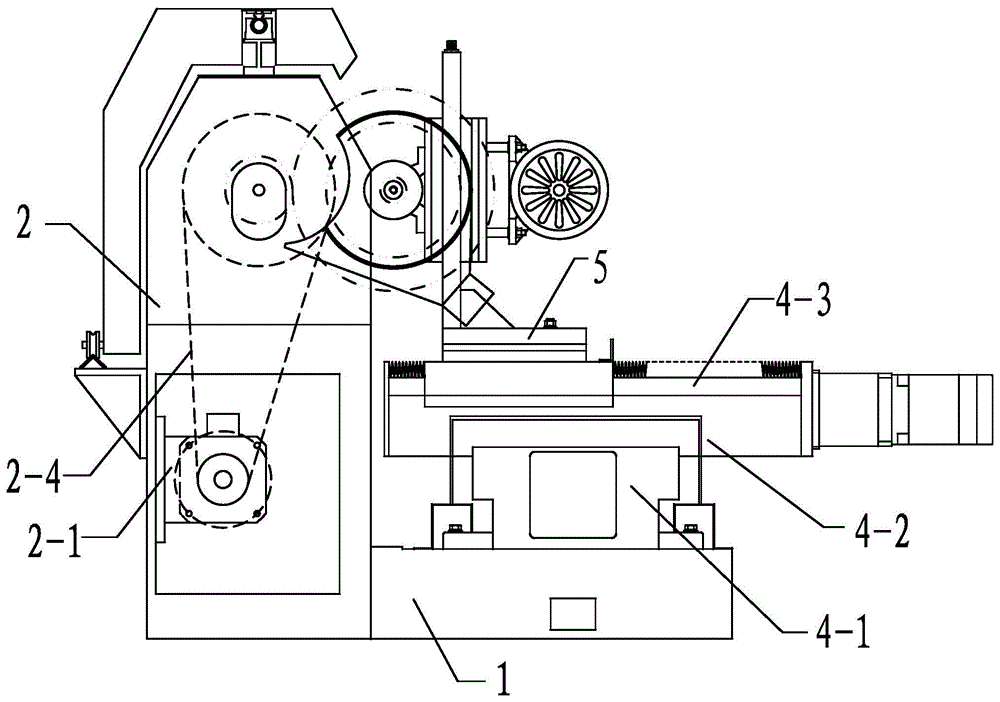

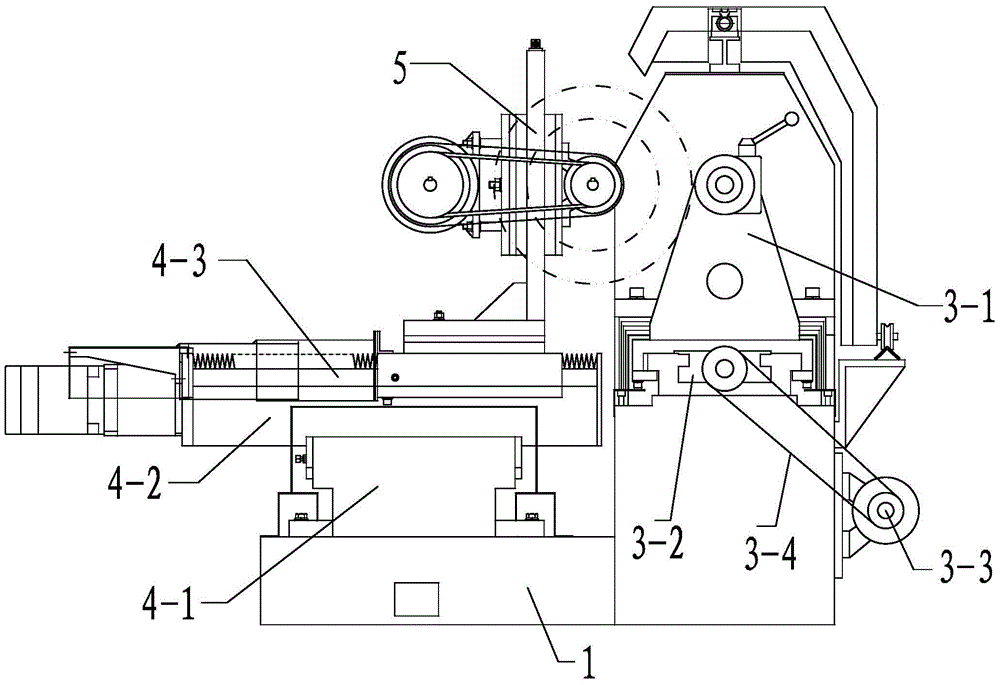

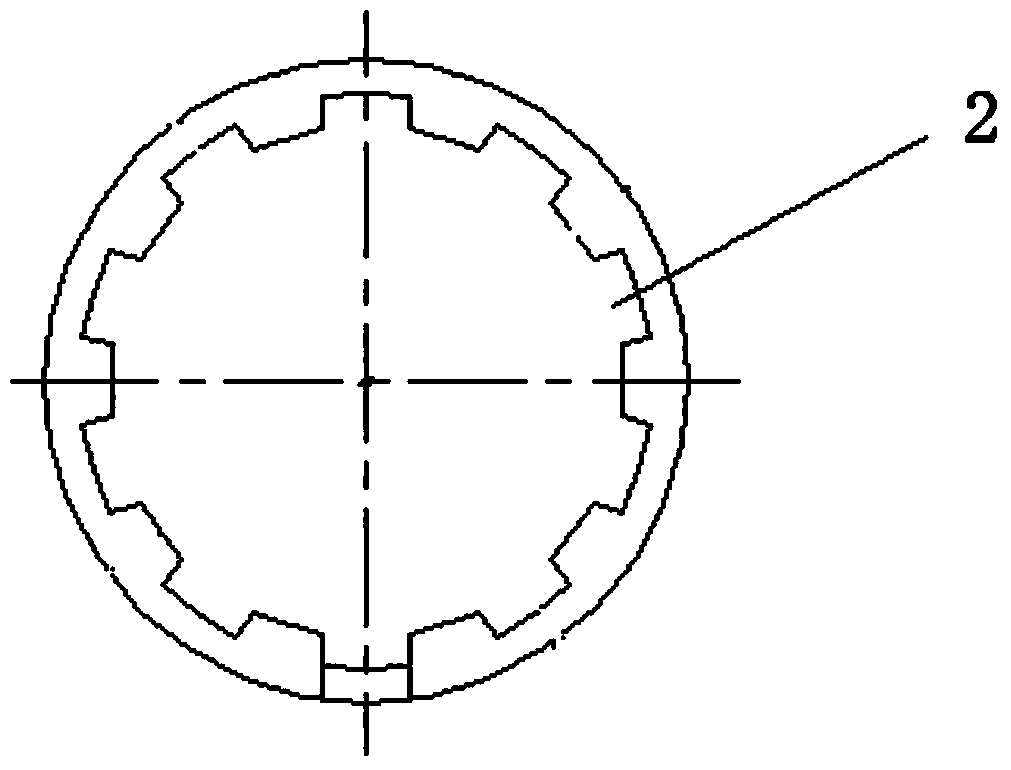

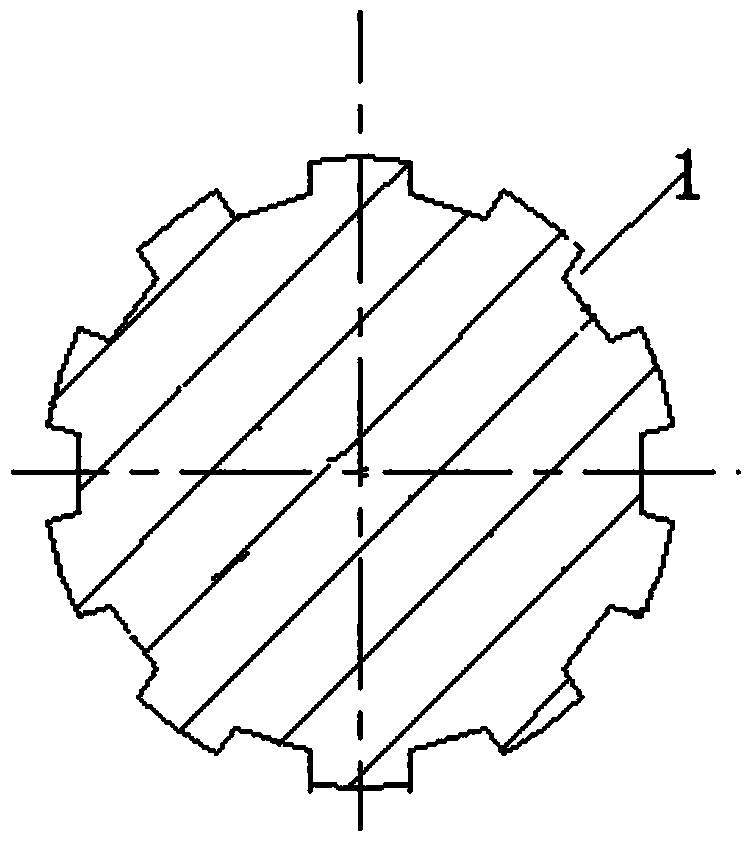

A dual-purpose CNC machining machine tool for the outer circle and spiral groove of the rice milling sand roller

ActiveCN104589124BOvercome the defect that the processing speed cannot be unifiedSpeed meetsTailstocks/centresTurning toolsNumerical controlDual purpose

Owner:湖北省鄂州市天元砂辊有限责任公司

Machining method for rectangular splines

ActiveCN103586648AHigh machining accuracy requirementsEasy to controlMachiningManufacturing engineering

The invention discloses a machining method for rectangular splines. The internal and external rectangular spline sample plate control method is used for machining, and therefore the internal and external rectangular spline machining precision is improved. The machining method for the rectangular splines is suitable for volume production, good in control over sample plates, efficient, and capable of ensuring quality and quantity.

Owner:NANJING JINXIN TRANSMISSION EQUIP

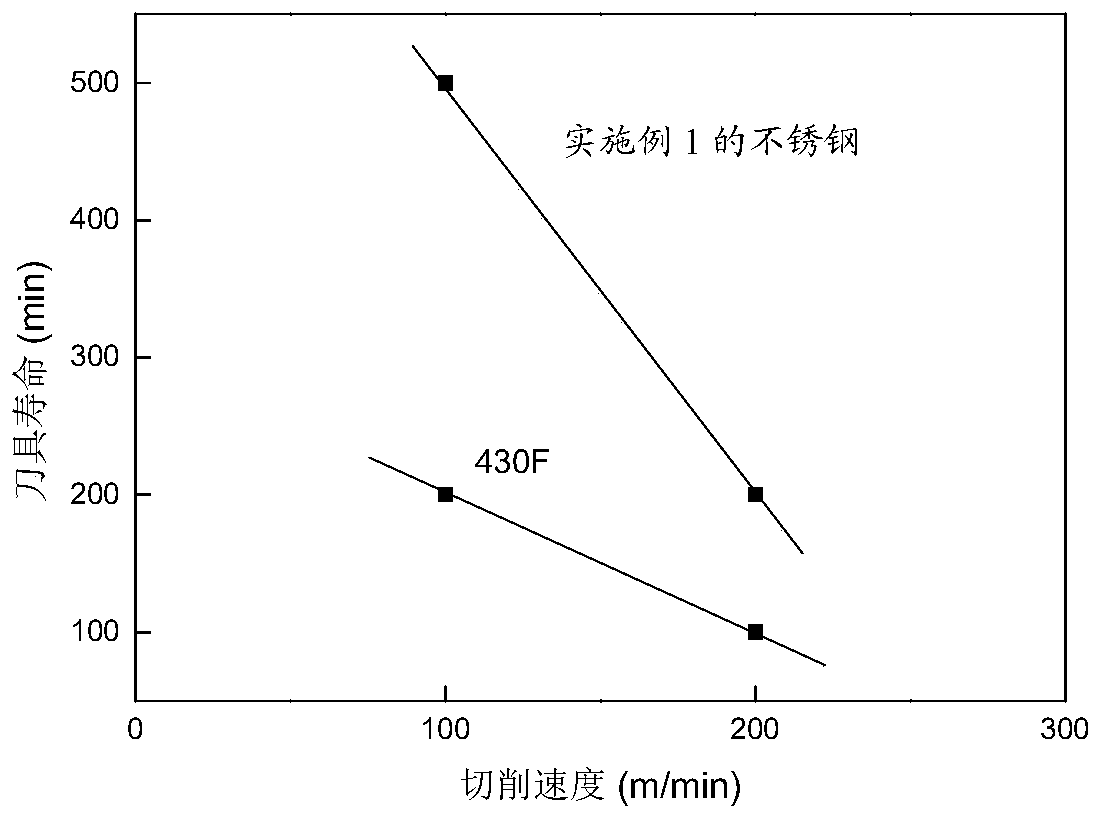

A kind of free cutting stainless steel and preparation method thereof

ActiveCN108315643BImprove corrosion resistanceNo significant change in production costsSS - Stainless steelIngot

The invention provides free-cutting stainless steel which is prepared from the following components in percentage by weight: smaller than or equal to 0.014 percent of C, 0.36-0.60 percent of Si, 0.031-0.045 percent of P, 0.02-0.36 percent of S, 10.5-15 of S / Te, 0.95-1.21 percent of Mn, 19.7-20.3 percent of Cr, 1.7-2.0 percent of Mo, 0.001-0.1 percent of Pb, larger than or equal to 0.05 percent andsmaller than or equal to 0.25 percent of Bi+Pb, 0.016-0.03 percent of N, 0.21-0.3 percent of Ni, 0.1-0.17 percent of Cu, 0.09-0.15 percent of V, 0.026-0.05 percent of Nb, 0.016-0.02 percent of O andthe balance of Fe and inevitable impurities. The invention also provides a preparation method of the free-cutting stainless steel. The preparation method comprises the following steps of (1) by takingblast furnace molten iron as a raw material, performing pretreatment; (2) performing continuous casting on the molten iron subjected to pretreatment to prepare a cast ingot; and (3) heating the castingot, and then performing rolling to prepare a finished product.

Owner:太原钢铁(集团)有限公司

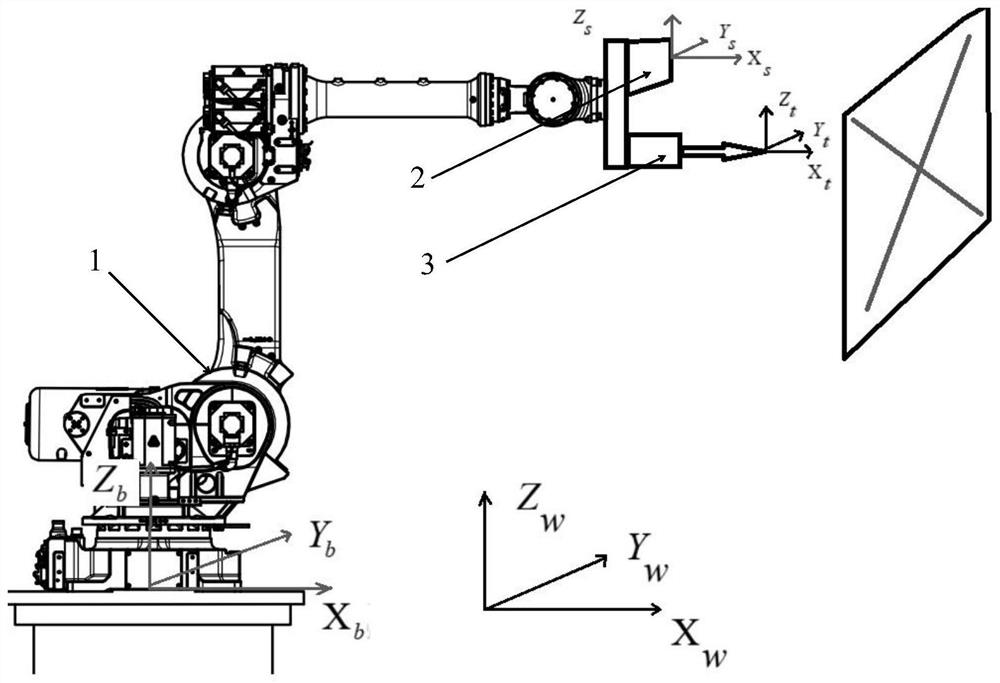

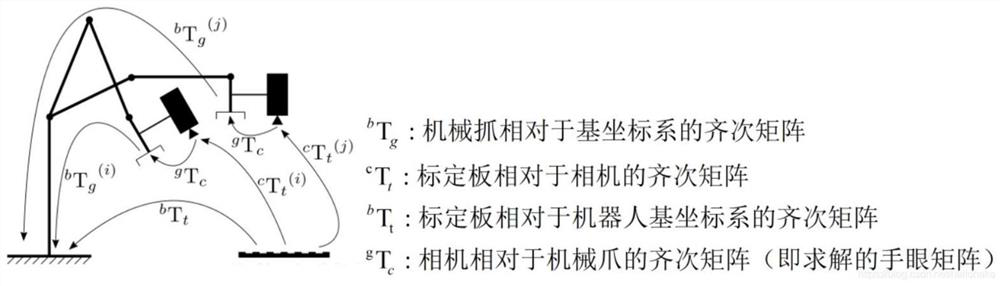

Automatic plane correction method for intelligent tube plate welding robot based on cross laser

InactiveCN112894209AHigh machining accuracy requirementsImprove fault toleranceWelding/cutting auxillary devicesAuxillary welding devicesControl engineeringControl theory

The invention belongs to the technical field of industrial welding, and particularly relates to an automatic plane correction method for an intelligent tube plate welding robot based on a cross laser. The method comprises the steps of sensor calibration, system hand-eye calibration, light strip center extraction and robot attitude angle deviation calculation. According to the method, the cross laser is directly projected to a tube plate plane to obtain three-dimensional data without being affected by the placement angle of the tube plate plane, so that the degree of freedom is larger; by adopting a gradual iteration approximation mode, the leveling precision can be well guaranteed, and the manual participation degree is greatly reduced; by means of iterative leveling, an ICP iterative algorithm based on the least square method is adopted in each leveling calculation, calculation results are converted into Euler angles, higher calculation precision is achieved, the leveling precision angle error is about 0.1 degree, and the method is suitable for most robot controllers and has high generalization performance.

Owner:常州英迈乐智能系统有限公司

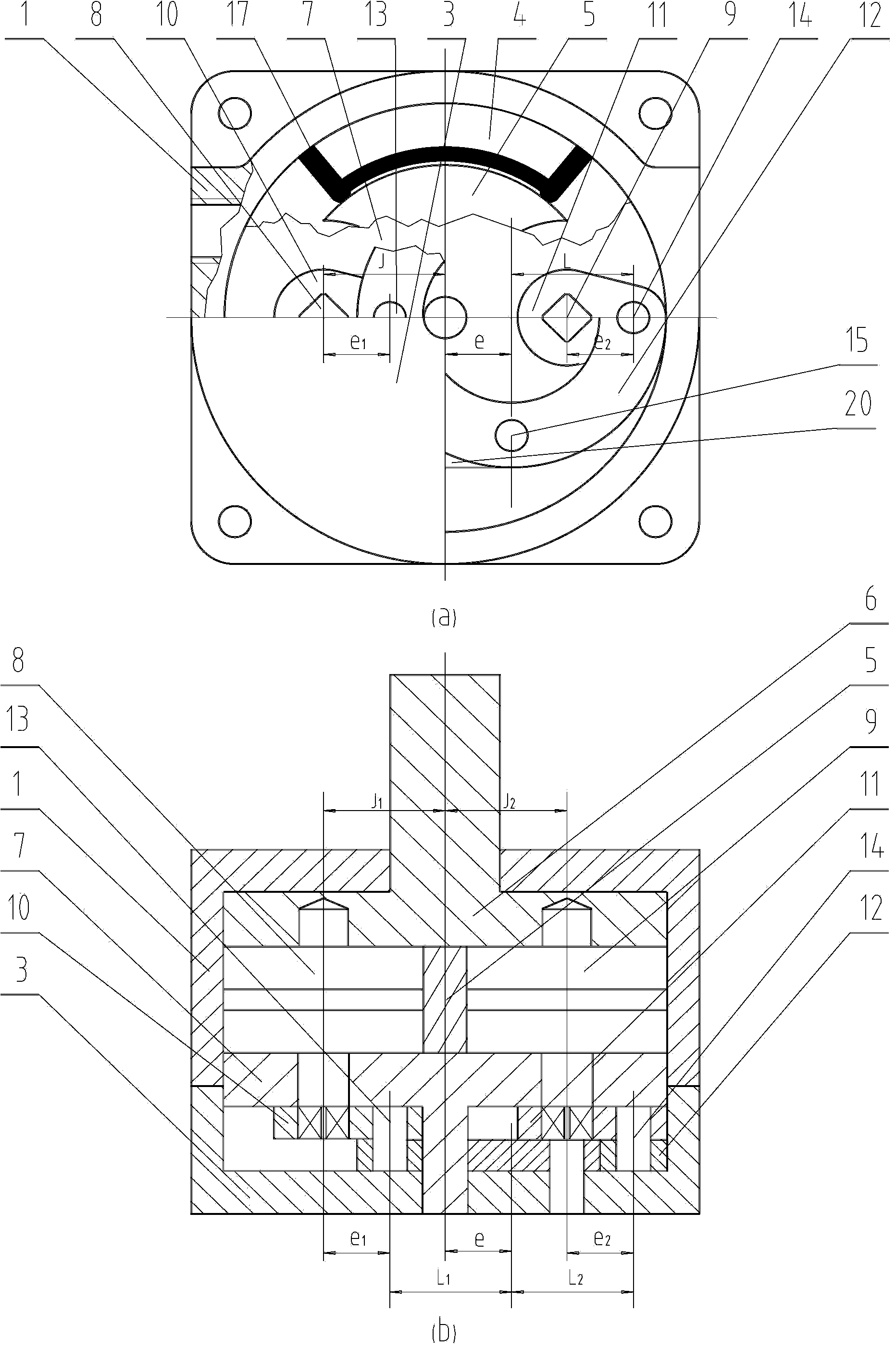

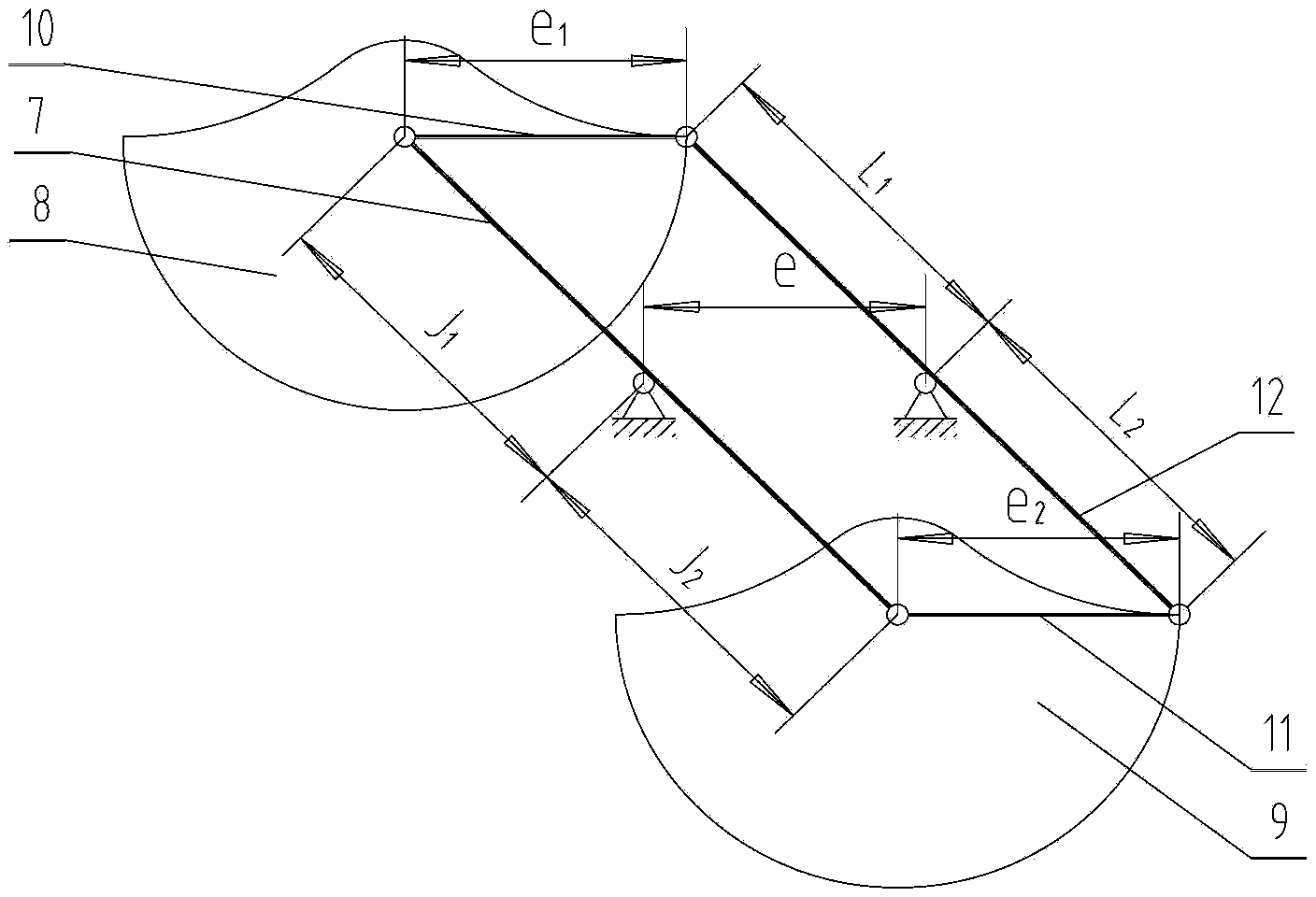

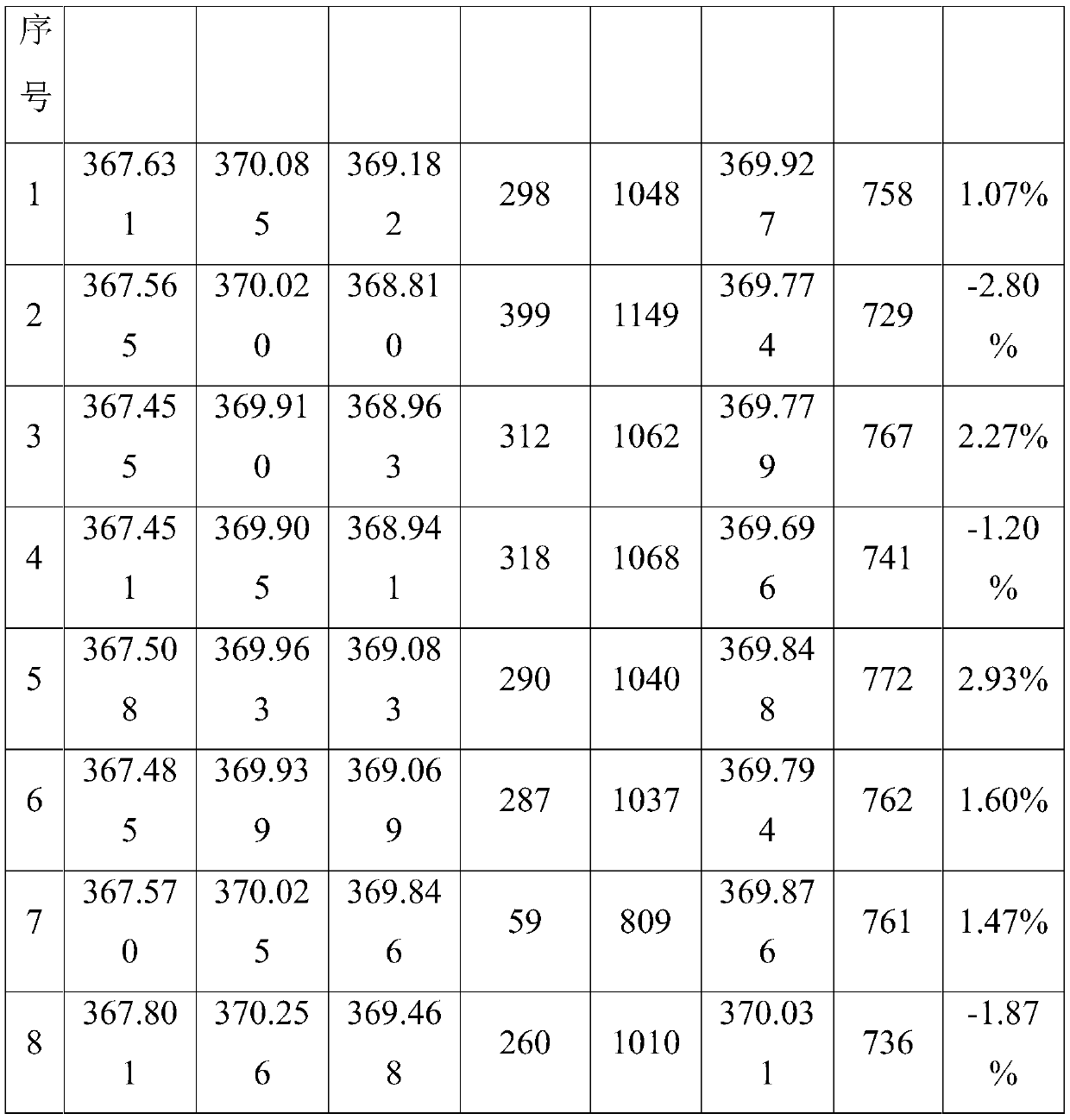

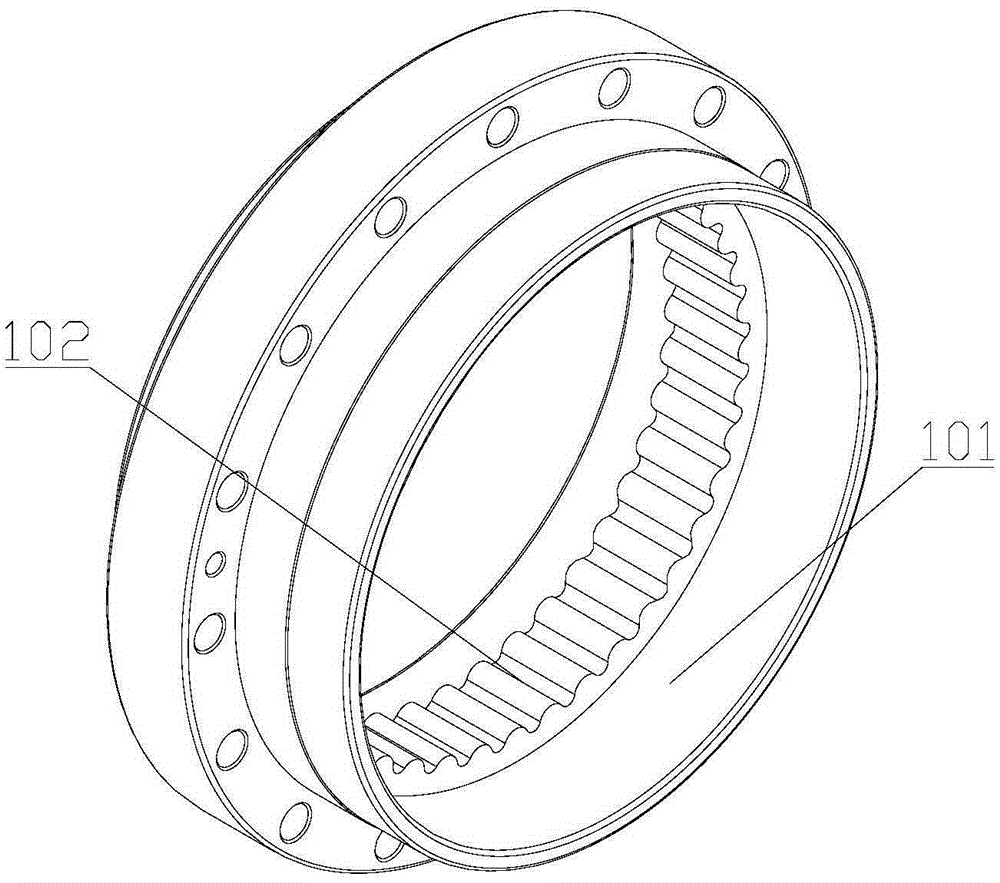

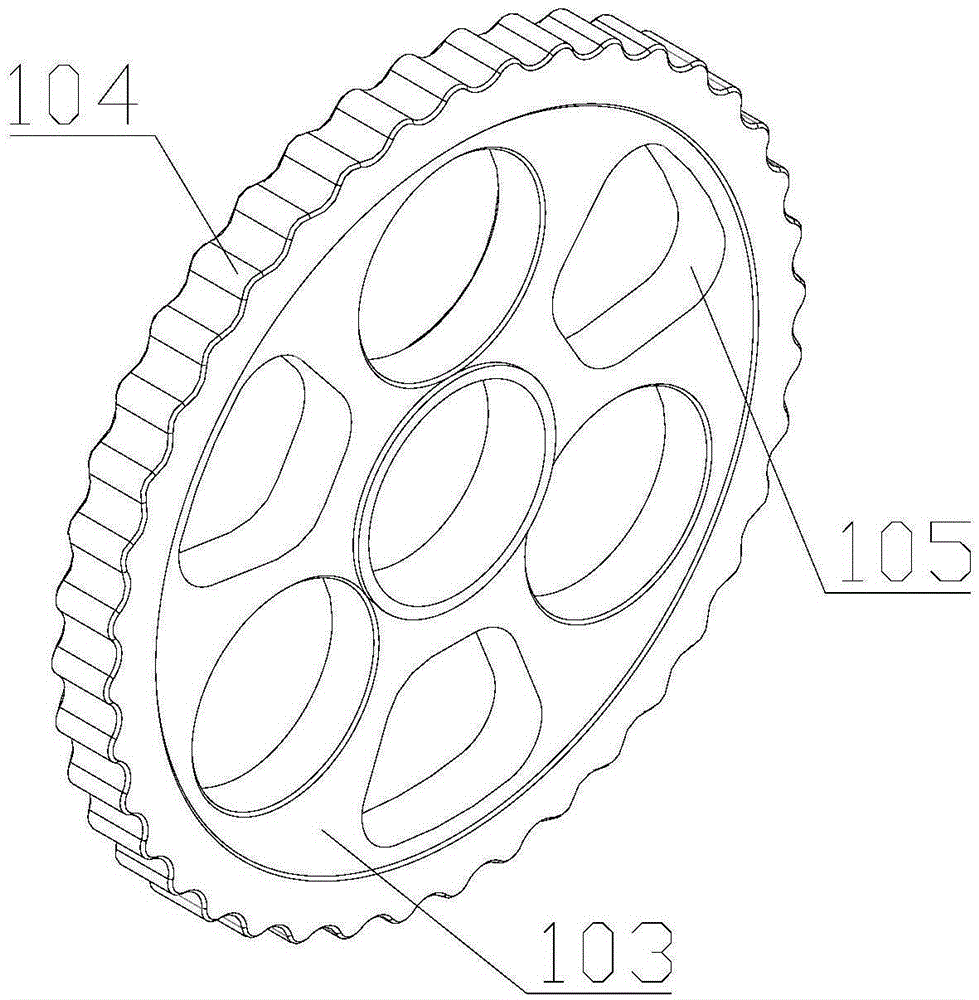

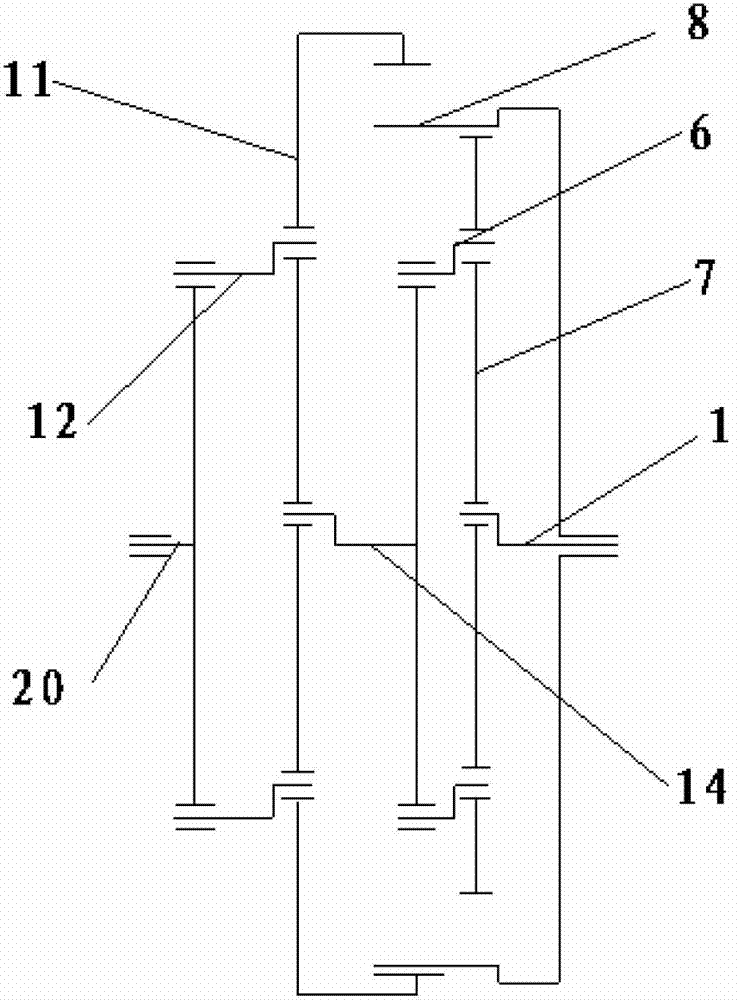

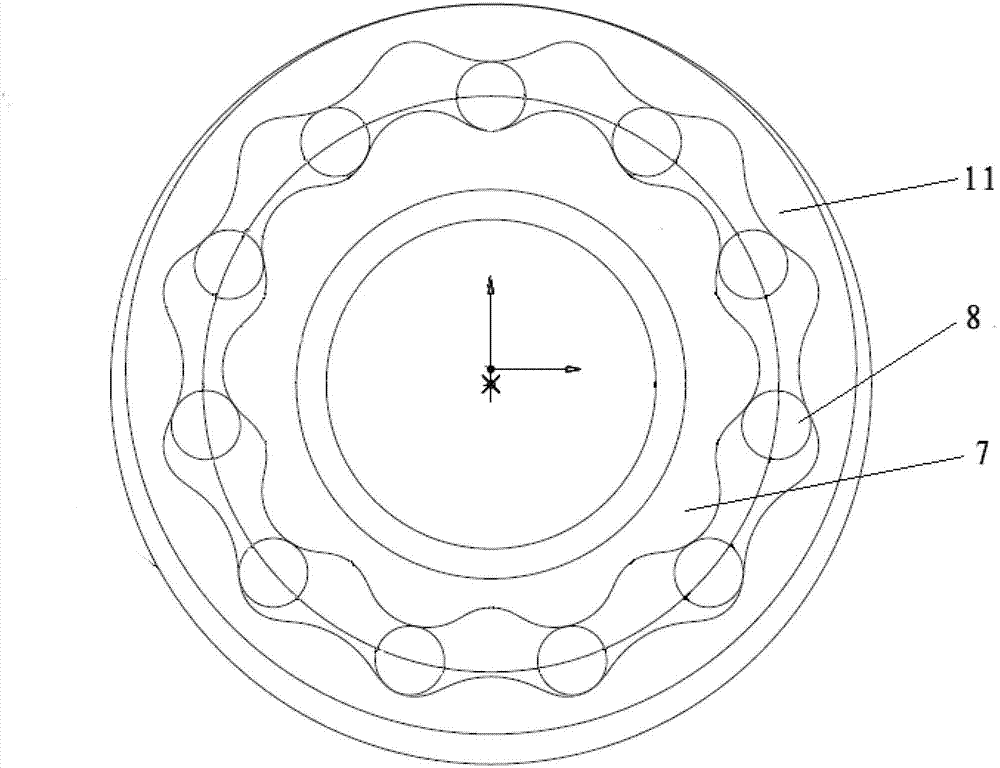

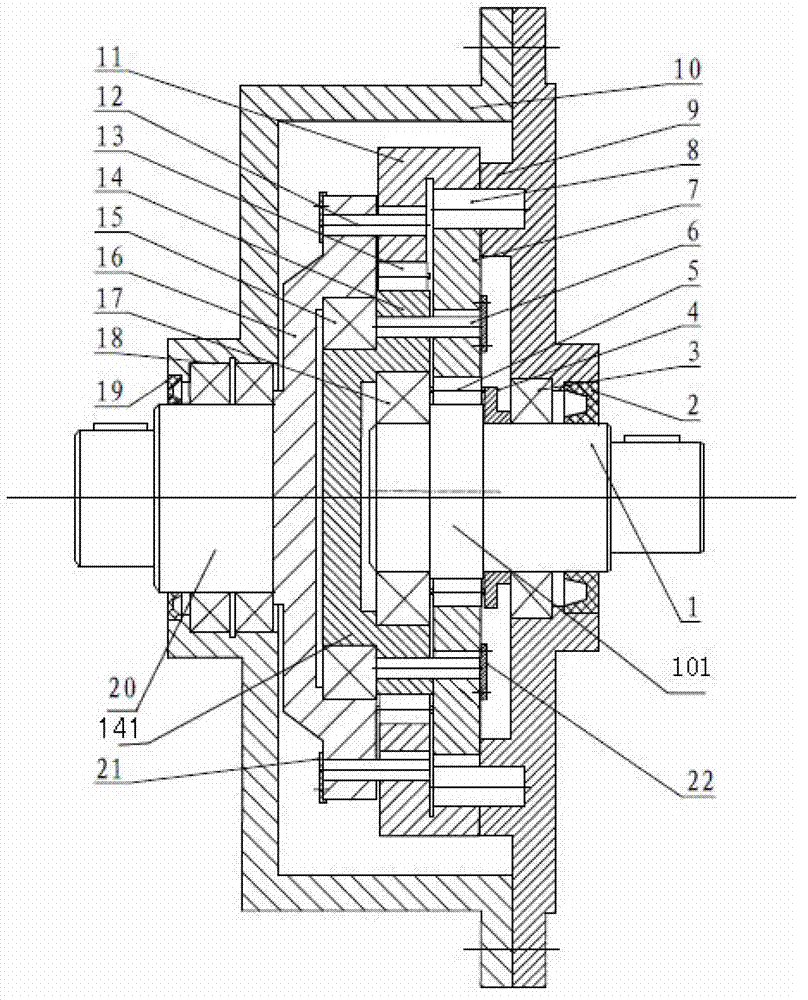

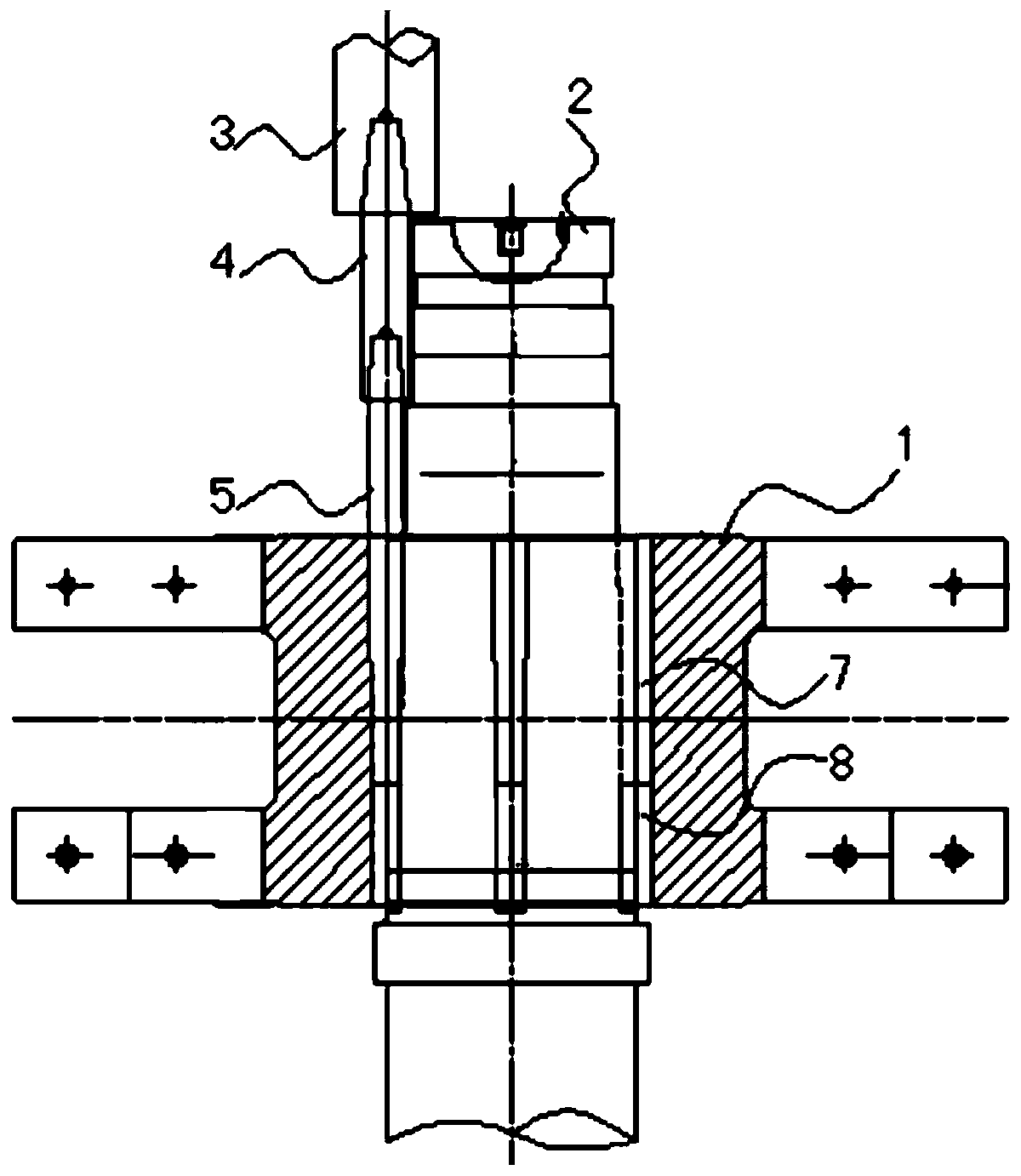

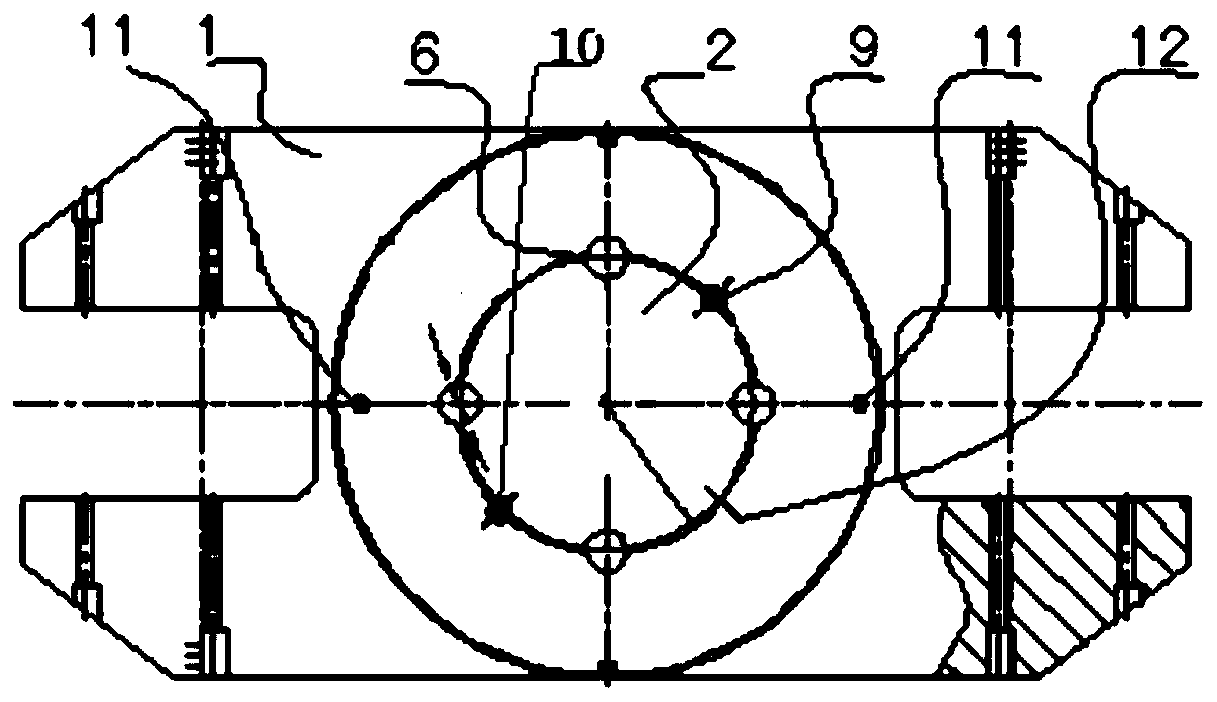

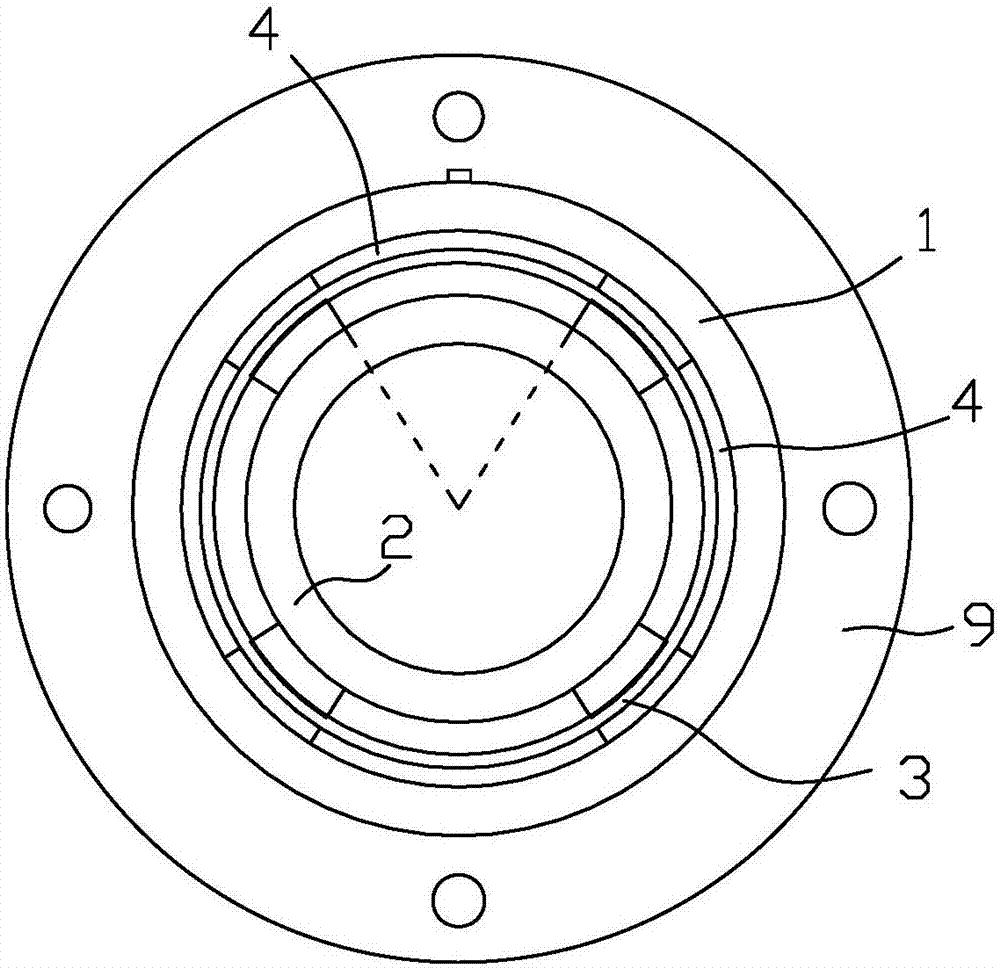

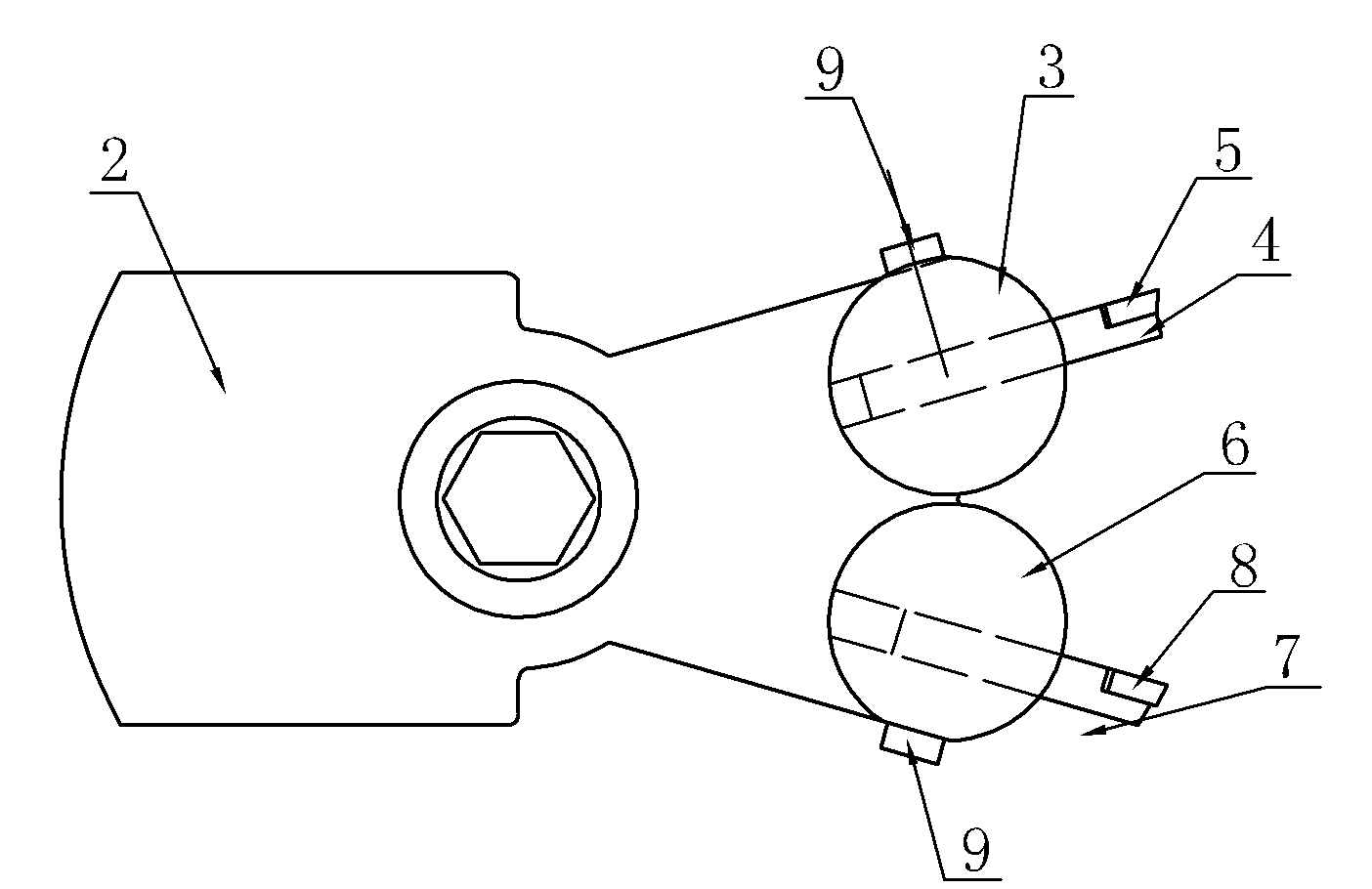

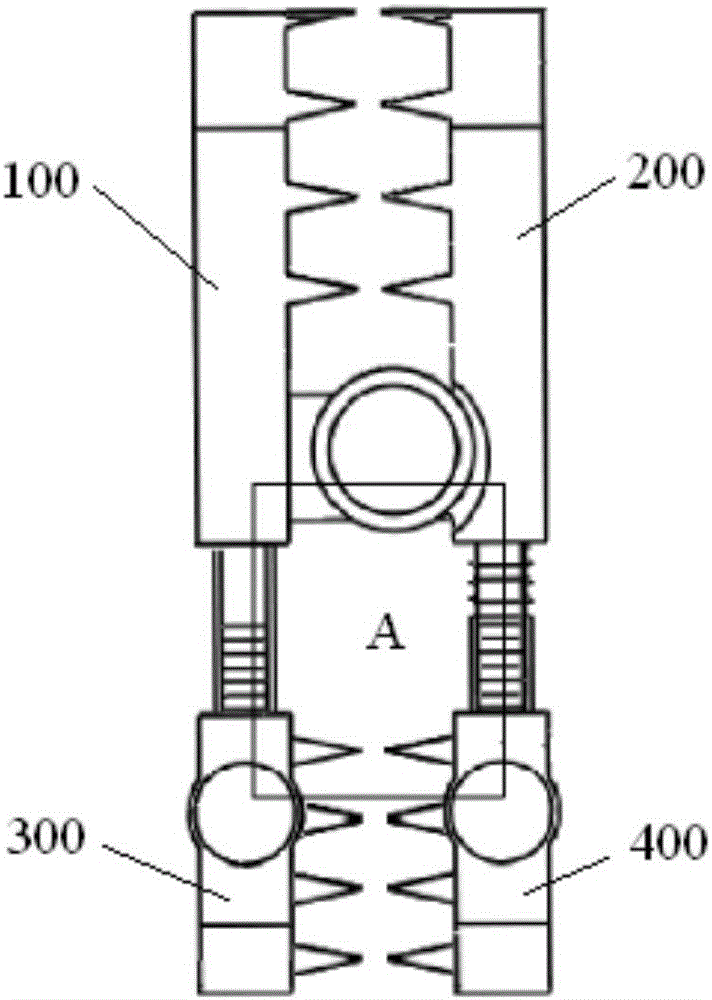

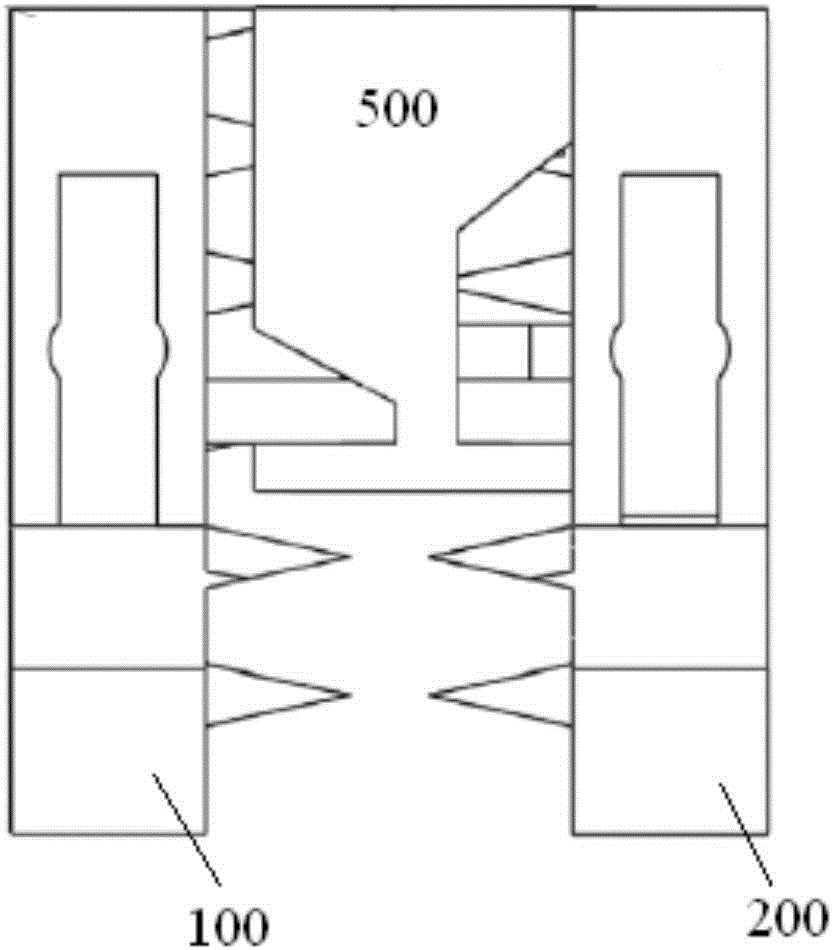

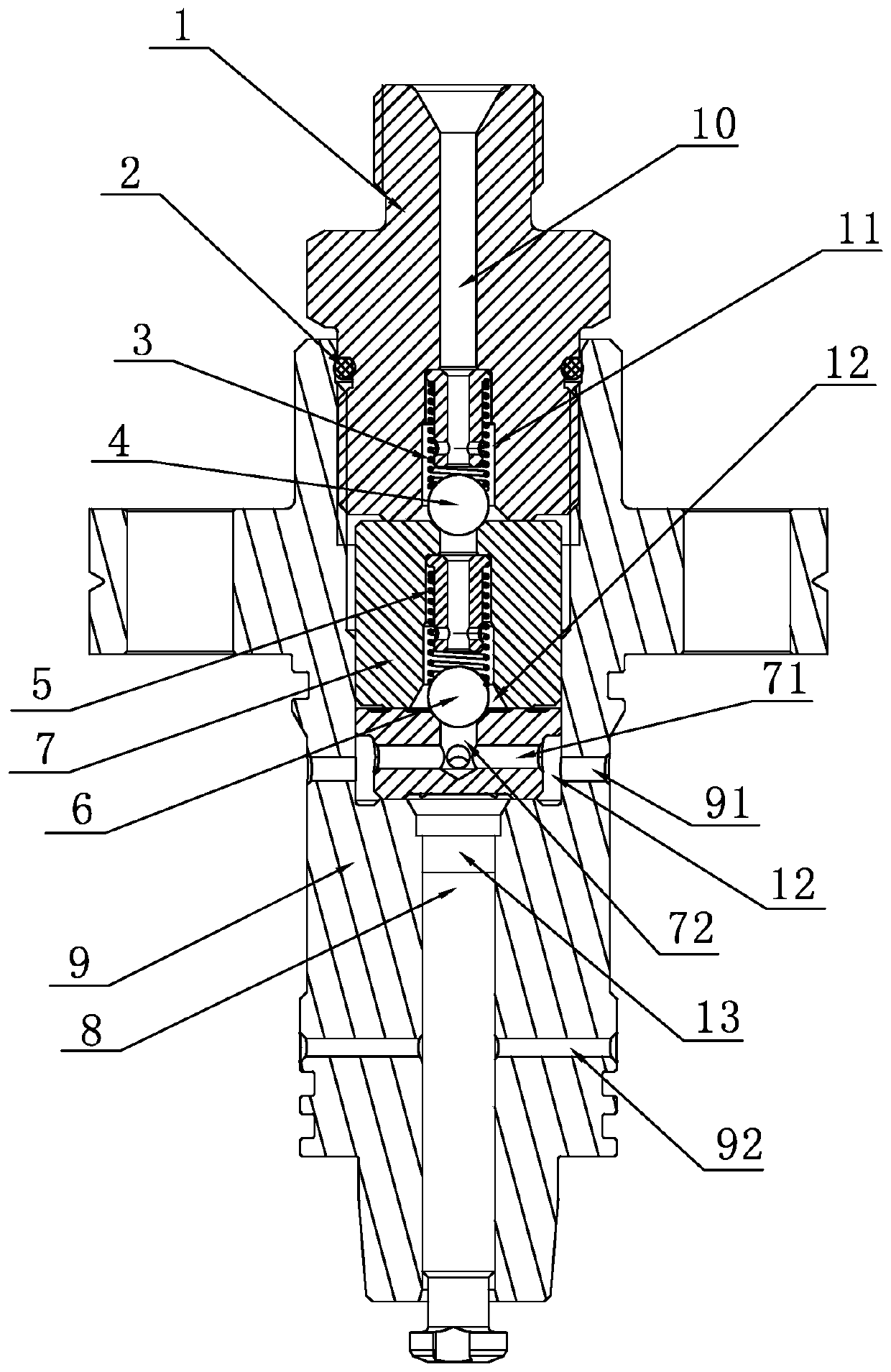

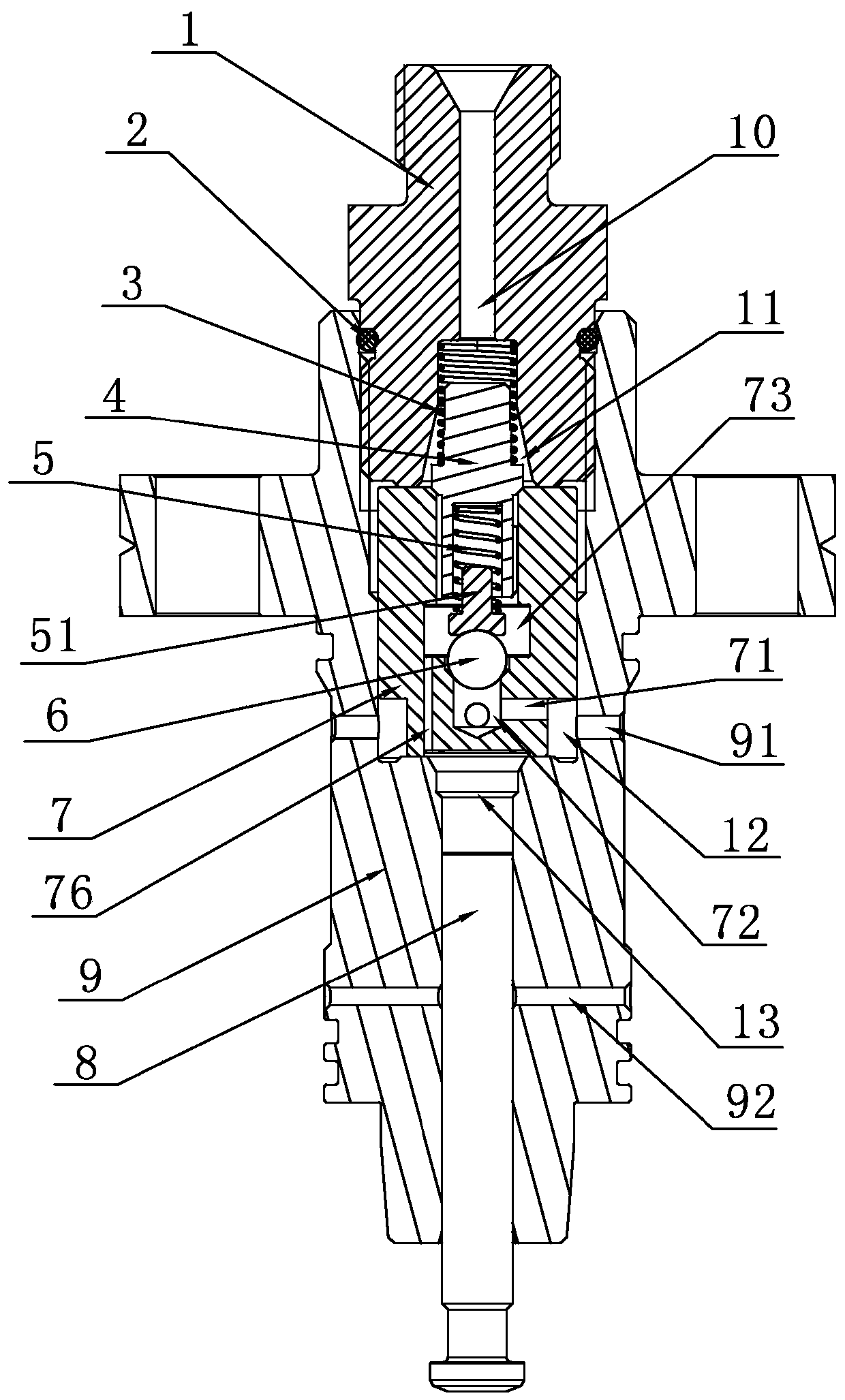

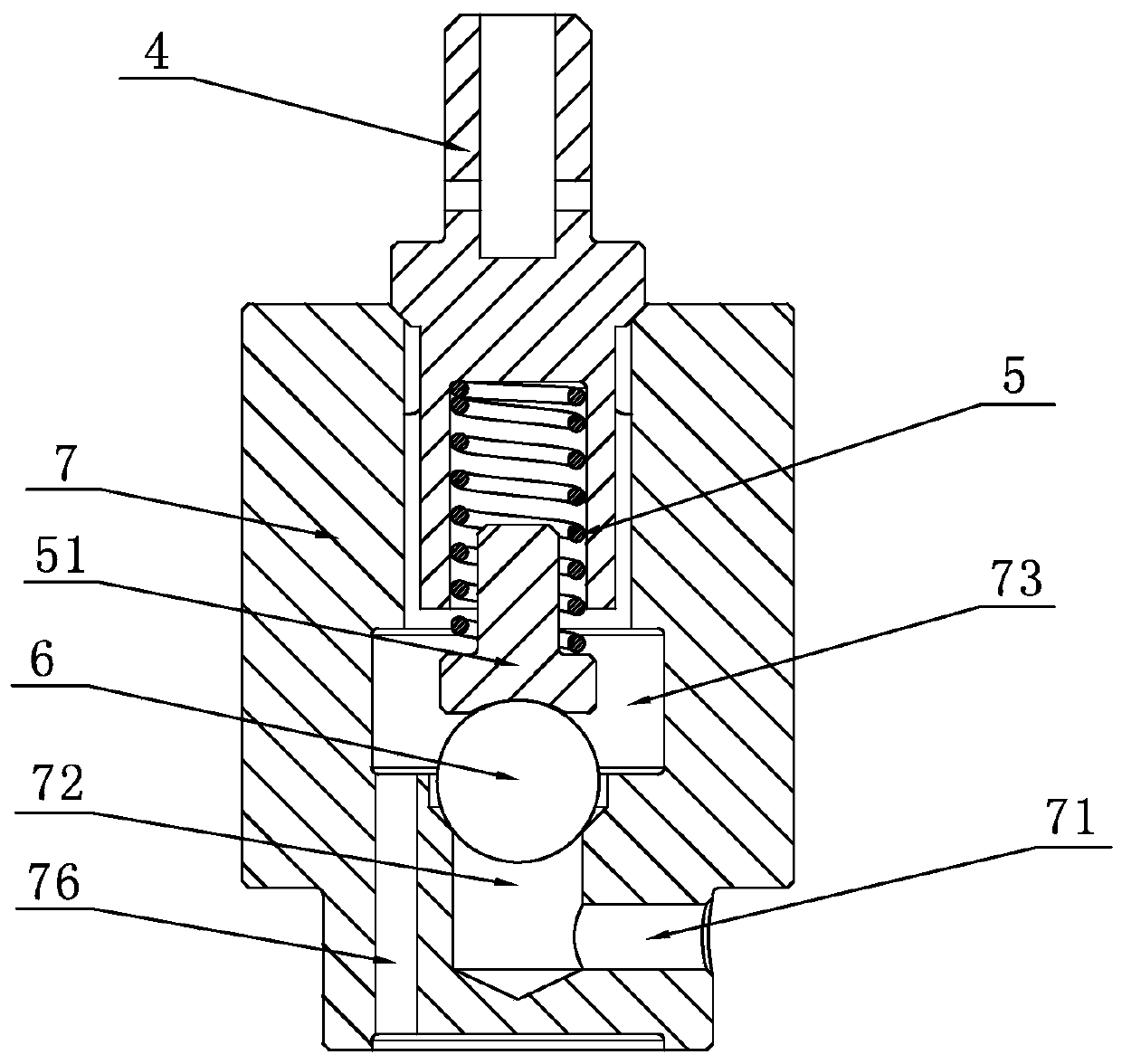

Inner and outer tooth form meshing gear reducer

ActiveCN103115112AHigh machining accuracy requirementsImprove transmission efficiencyToothed gearingsGearing detailsDrive wheelReduction drive

The invention relates to an inner and outer tooth form meshing gear reducer comprising a first-level reducing mechanism and a second-level reducing mechanism. The first-level reducing mechanism comprises an eccentric wheel (101), a first turning bearing(5), an outer-meshing curve wheel (7) and a gear pin (8); the gear pin is fixed on a first support (9) and externally meshes with the outer-meshing curve wheel (7). The second-level reducing mechanism comprises an eccentric driving wheel (14), a second turning bearing (13) sleeved on the eccentric driving wheel (14), an outer-meshing curve wheel (11), and an output plate (16) in linkage with an output shaft (20). The outer-meshing curve wheel (11) is sleeved on the second turning bearing (13) and internally meshes with the gear pin (8). The eccentric driving wheel (14) is in linkage with the outer-meshing curve wheel (7) through a pin (6), and the outer-meshing curve wheel (11) is in linkage with the output plate (16) through a driving pin (12). The inner and outer tooth form meshing gear reducer has the advantages of few tooth numbers, high speed ratio, small size, high load bearing, high efficiency and long service life, and is especially applicable to reducers by industrial robots.

Owner:ZHEJIANG HENGFENGTAI REDUCER MFG

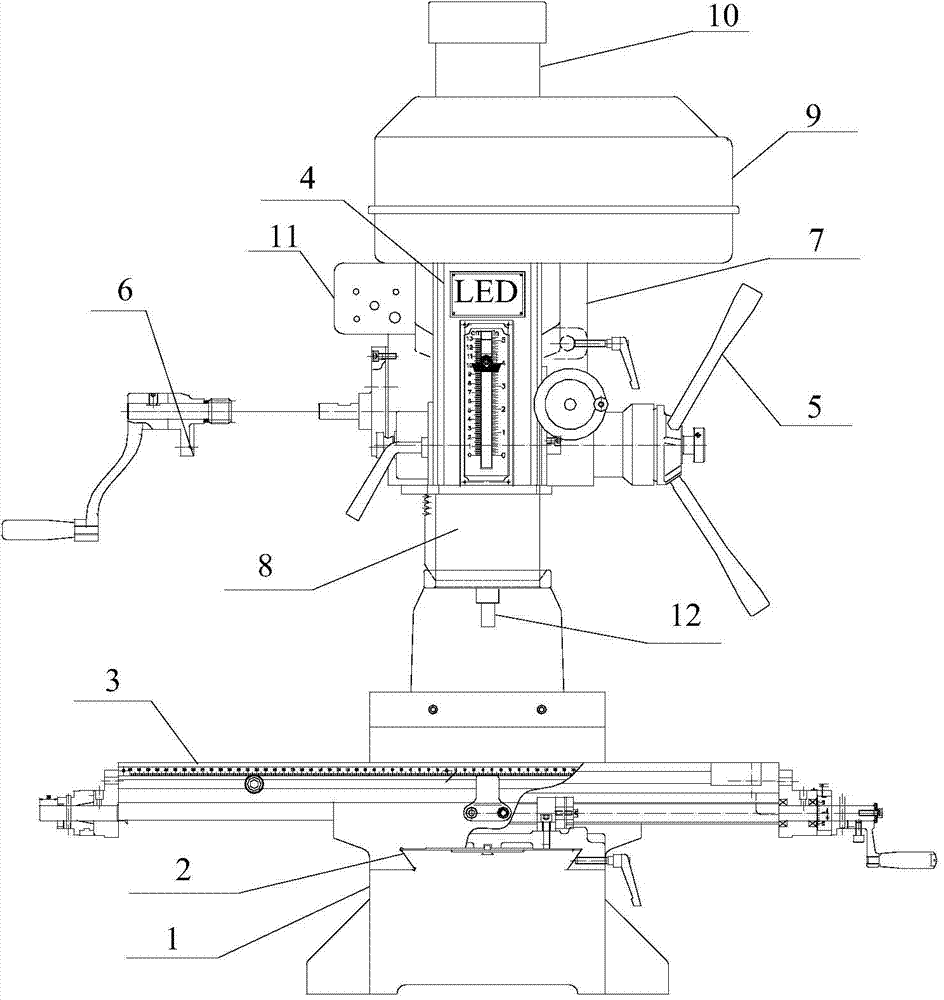

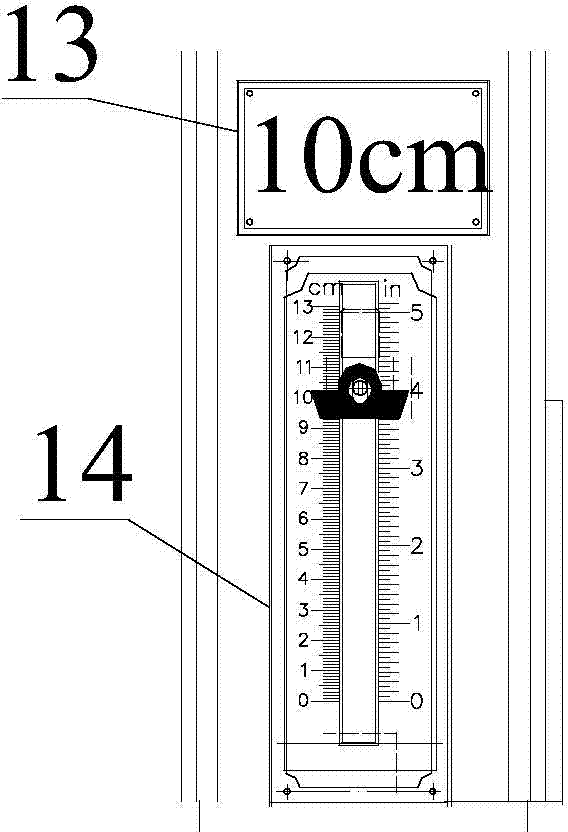

Milling machine

InactiveCN104722817AIntuitively see the scale valueHigh machining accuracy requirementsMilling machinesMilling equipment detailsEngineeringMechanical equipment

The invention provides a milling machine and belongs to the field of mechanical equipment. By adoption of the milling machine, the problems that the value of the main-shaft feeding depth of an existing milling machine can not be seen intuitively and is not accurate are solved. The milling machine mainly comprises a base, a cross-shaped towing plate, a working platform, a main-shaft lifter, a main-shaft box lifter, a main-shaft box, a main shaft, a belt-wheel protective cover, a vertical column, a motor and a milling head. The milling machine provided by the invention has the advantages that due to adoption of a digital display ruler, the scale values can be intuitively seen, accurate positioning of the feeding depth can be realized and a product with high accuracy requirement can be processed.

Owner:GAOYOU YONGFA MACHINERY

Method for machining matching tapered pin holes of tiller and rudderstock below rudder bearing and machining cutter

InactiveCN110293370ASimple processing methodRealize deep hole machiningTransportation and packagingReaming toolsEngineeringReamer

The invention discloses a method for machining matching tapered pin holes of a tiller and a rudderstock below a rudder bearing and a machining cutter. The machining cutter comprises a step reamer, a step rough rimer, a semi-finishing rimer, a finishing rimer, a boring bar and a transmission sleeve. One ends of the step reamer, the step rough rimer, the semi-finishing rimer and the finishing rimerare all provided with connection portions fixed to one end of the transmission sleeve. The other end of the transmission sleeve is fixed to the boring rod. According to the method for machining the matching tapered pin holes of the tiller and the rudderstock below the rudder bearing and the machining cutter, by means of arranging the transition sleeve, the technical problem that when an upper rudder bearing is arranged above a connection portion of the tiller and the rudderstock and the tiller and the rudderstock are connected through tapered pins, the tapered pin holes cannot be machined is solved, and under the condition that the space of a stern of a ship is limited, the means of moving the upper rudder bearing to above the connection position of the tiller and the rudderstock becomes practicable.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

Integral extrusion forming method of light alloy shell body complex inner ring rib

The invention discloses an integral extrusion forming method of a light alloy shell body complex inner ring rib. The invention relates to an integral extrusion forming mold of the light alloy shell body complex inner ring rib, the mode comprises a lower flexible filling body inner support, and the lower flexible filling body inner support adopts a soft material to be made into a sand mold according to the shape of the lower part of the inner ring rib; a light alloy cylindrical part and the mold are heated and subjected to heat preservation, then the light alloy cylindrical part is placed intothe mold, an extrusion forming inner ring rib stage is entered, when the stage is finished, a press machine drives the mold to be separated from the inner ring rib, the light alloy cylindrical part isseparated from the mold, and finally, the temperature is controlled to enable the lower flexible filling body inner support to be discretized. According to the method, a material utilization rate isgreatly improved, the problem of difficulty brought by using a valving inner support structure material when precise plastic forming is carried out is overcome, the problem of blockage during mold stripping is solved, so that the effect of protecting the mold is achieved, and the simultaneous forming of the inner ring rib during integral plastic forming of the large-scale complex light alloy shellbody component.

Owner:ZHONGBEI UNIV

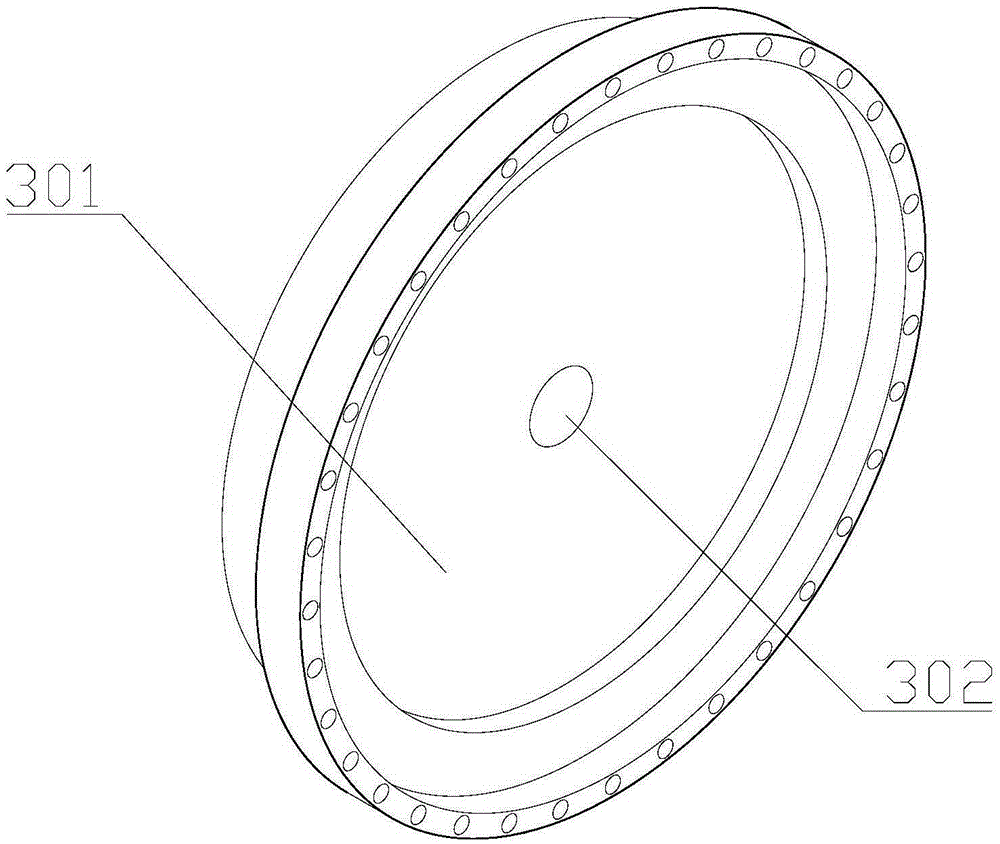

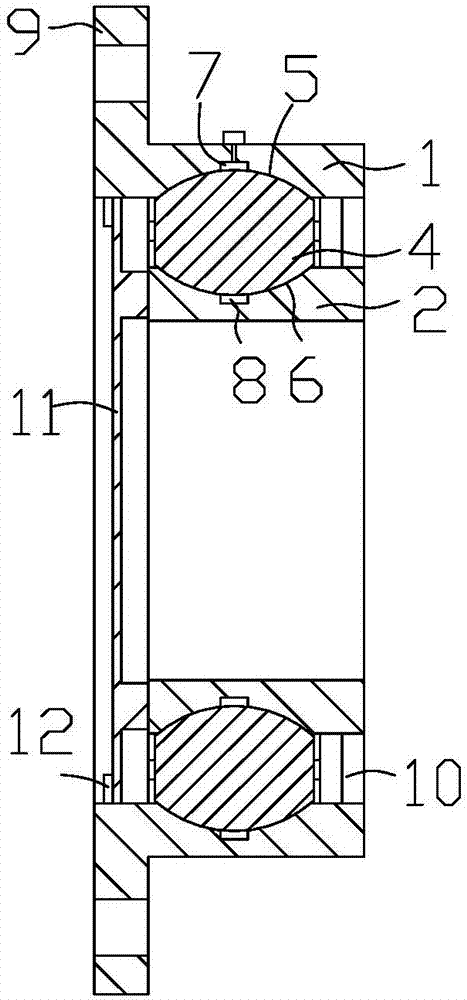

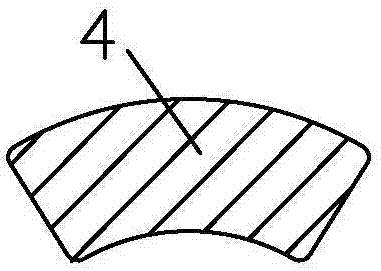

Hub module of mining equipment

InactiveCN107035774AImprove bearing capacitySatisfy the working conditions with large changes in bearing capacityBearing unit rigid supportInterference fitHeavy load

The invention discloses a hub module of mining equipment, and belongs to the technical field of bearing structures. The hub module comprises an outer ring and an inner ring for oppositely rotating; the inner ring is sleeved in the outer ring, and is coaxially arranged with the outer ring; a cage is arranged between the outer ring and the inner ring; a flange with a mounting hole is arranged at one end of the outer ring; the other end of the outer ring is leveled with the axial end surface of the inner ring; an annular inner slide way is peripherally formed in the inner side of the outer ring; an annular outer slide way is peripherally formed in the outer side of the inner ring; a slide body is arranged between the inner slide way and the outer slide way; the slide body comprises multiple slide blocks with arc structures; the slide blocks are provided with upper curved surface parts bonded corresponding to the outer slide way, and lower curved surface parts bonded corresponding to the inner slide way; a baffle plate is arranged in a shaft hole, at one end of the flange, of the outer ring; the baffle plate is extruded and pressed with the outer ring through a stop retainer ring; and the baffle plate is provided with an annular projection in interference fit with the axial end surface of the inner ring. The hub module adopts a full-contact surface rolling body, and can satisfy the use demands of a rotating part with low speed, heavy load and high load change in the process.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

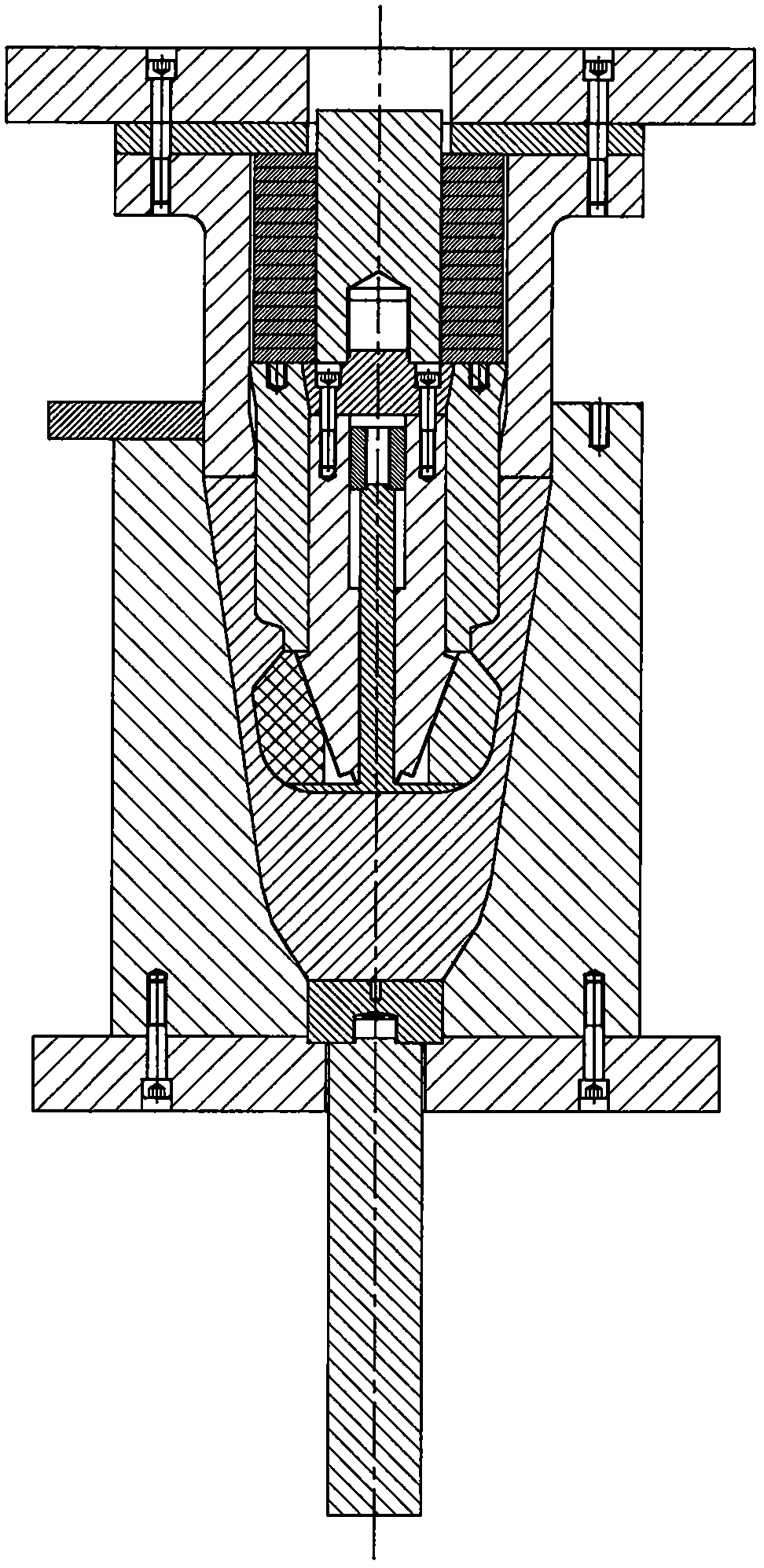

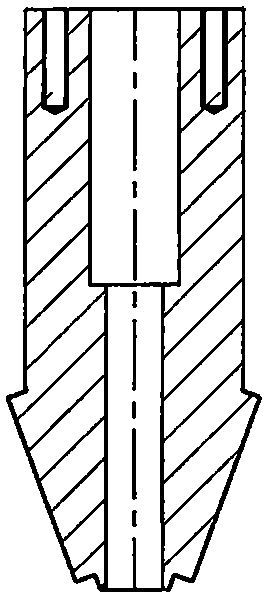

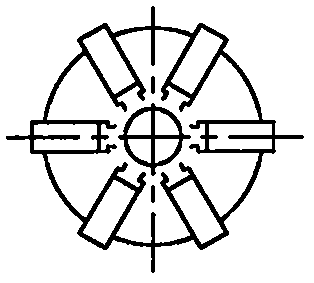

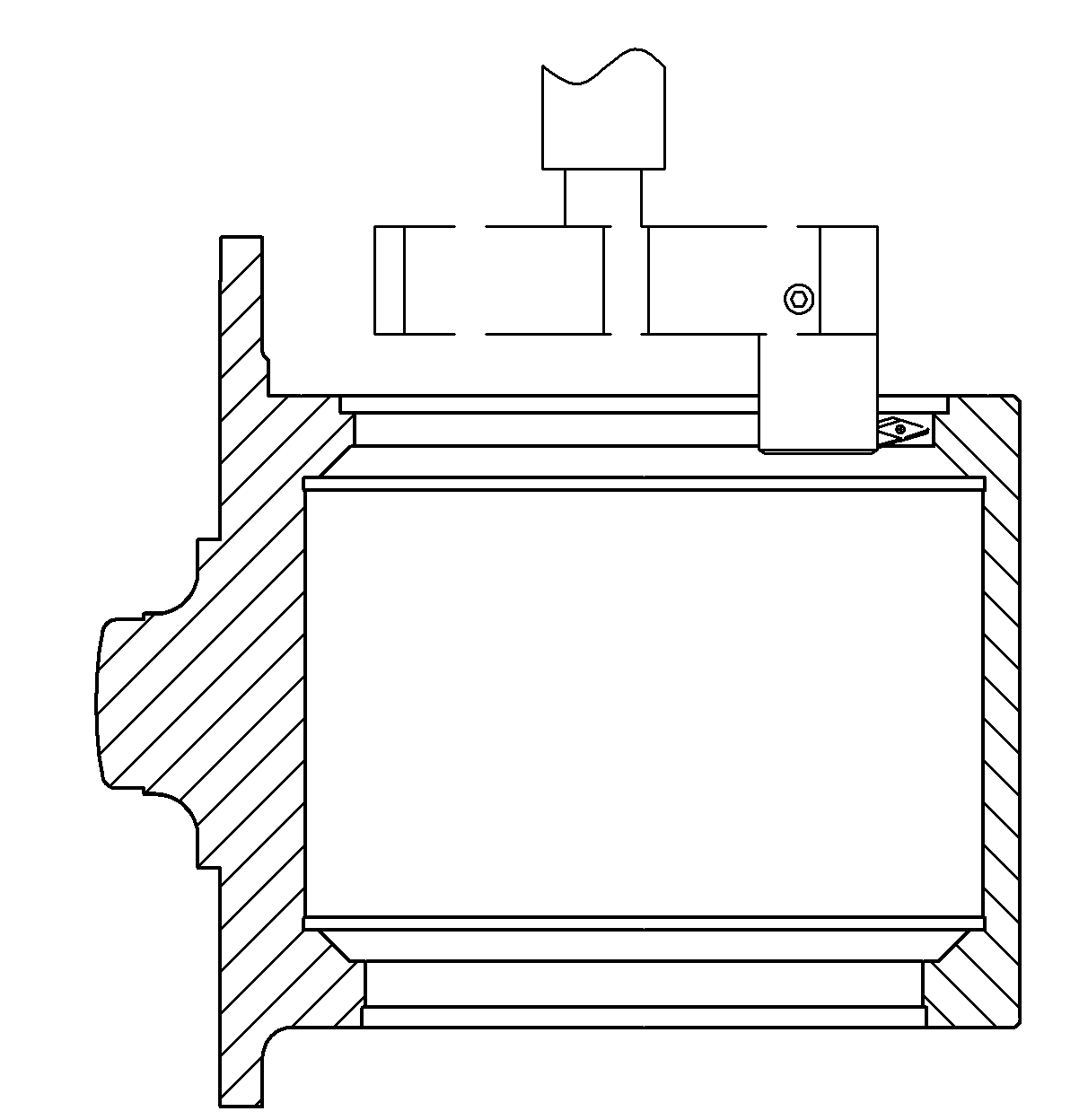

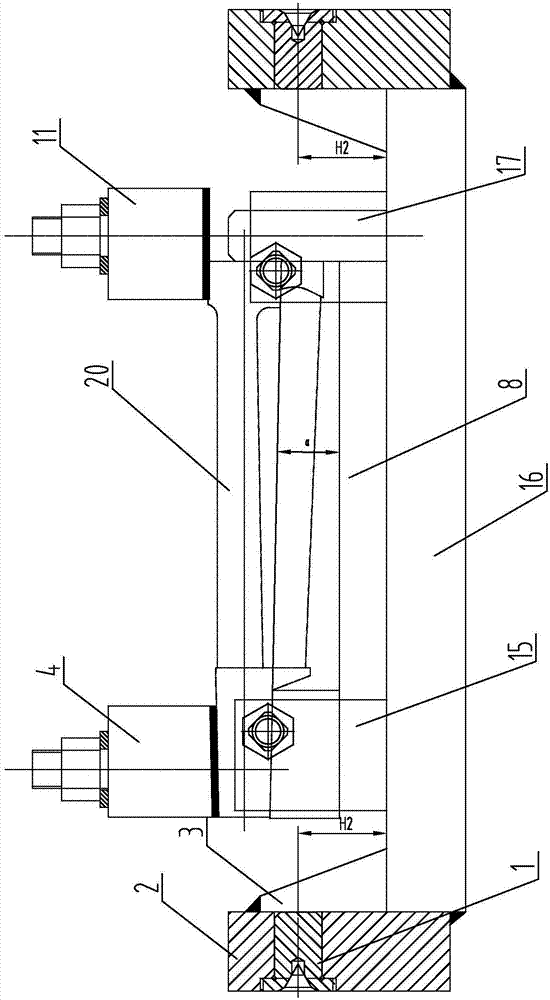

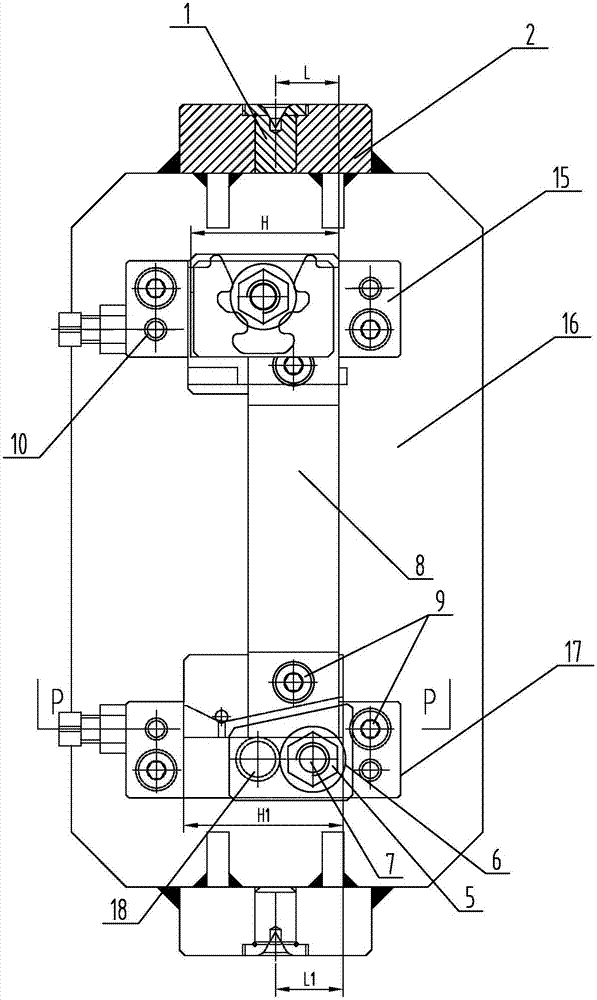

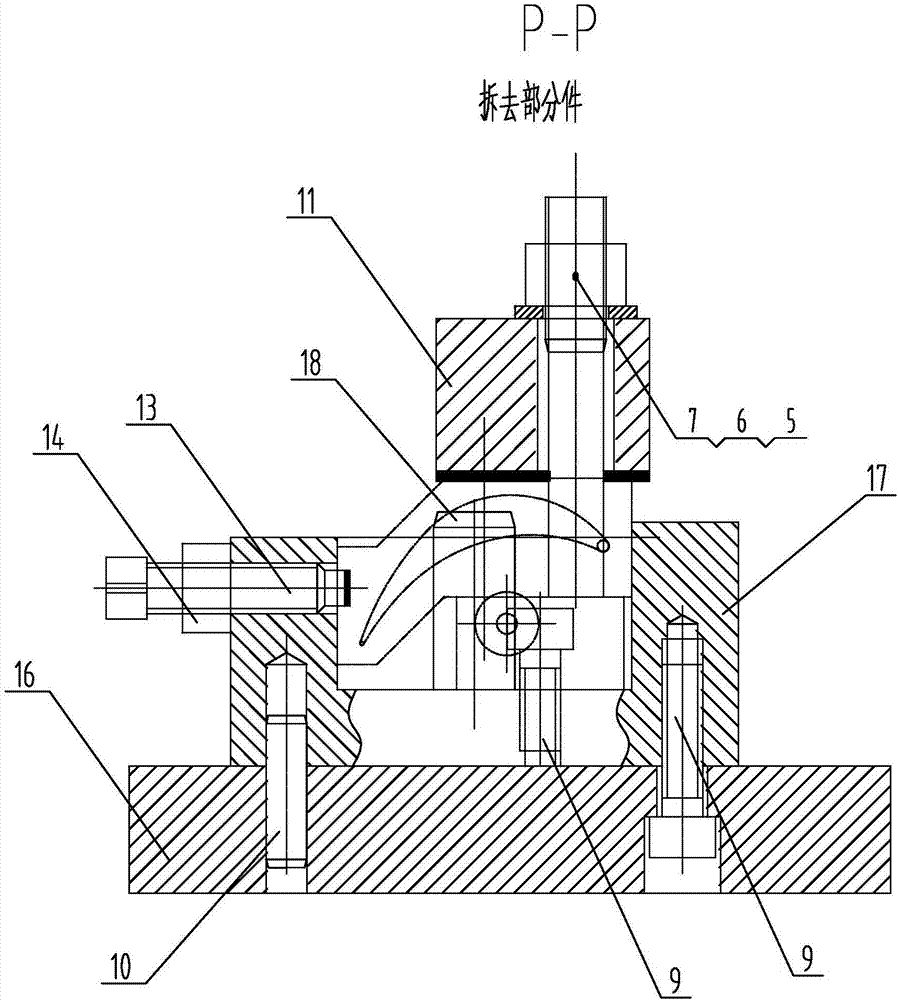

Rough and fine boring device for processing cutter bar with step holes at two ends

The invention discloses a rough and fine boring device for processing a cutter bar with step holes at two ends, which comprises a rotating main shaft, a balancing cutter bar, an adjustable rough boring holder, a rough boring cutter body, a rough boring cutter blade, an adjustable fine boring holder, a fine boring cutter body and a fine boring cutter blade, wherein the rough boring cutter body and the fine boring cutter body are respectively arranged on the adjustable rough boring holder and the adjustable fine boring holder; the adjustable rough boring holder and the adjustable fine boring holder are arranged on the balancing cutter bar, the machining allowance between a rough boring piece and a fine boring piece is 0.1-0.5 millimeter, and the whole rough and fine boring device meets dynamic balance requirements. The rough and fine boring device can be used for boring and machining a big hole while synchronously roughly boring and fine boring, and has a simple structure and low cost which is 30-40 percent of that of a standard composite tool and is only 1 / 3-1 / 2 of that of the common boring machining during machining, high machining precision up to IT4, roughness being Ra 0.2, low machining cost and remarkable labor-saving and energy-saving effects.

Owner:CHANGZHOU HUADE MACHINERY

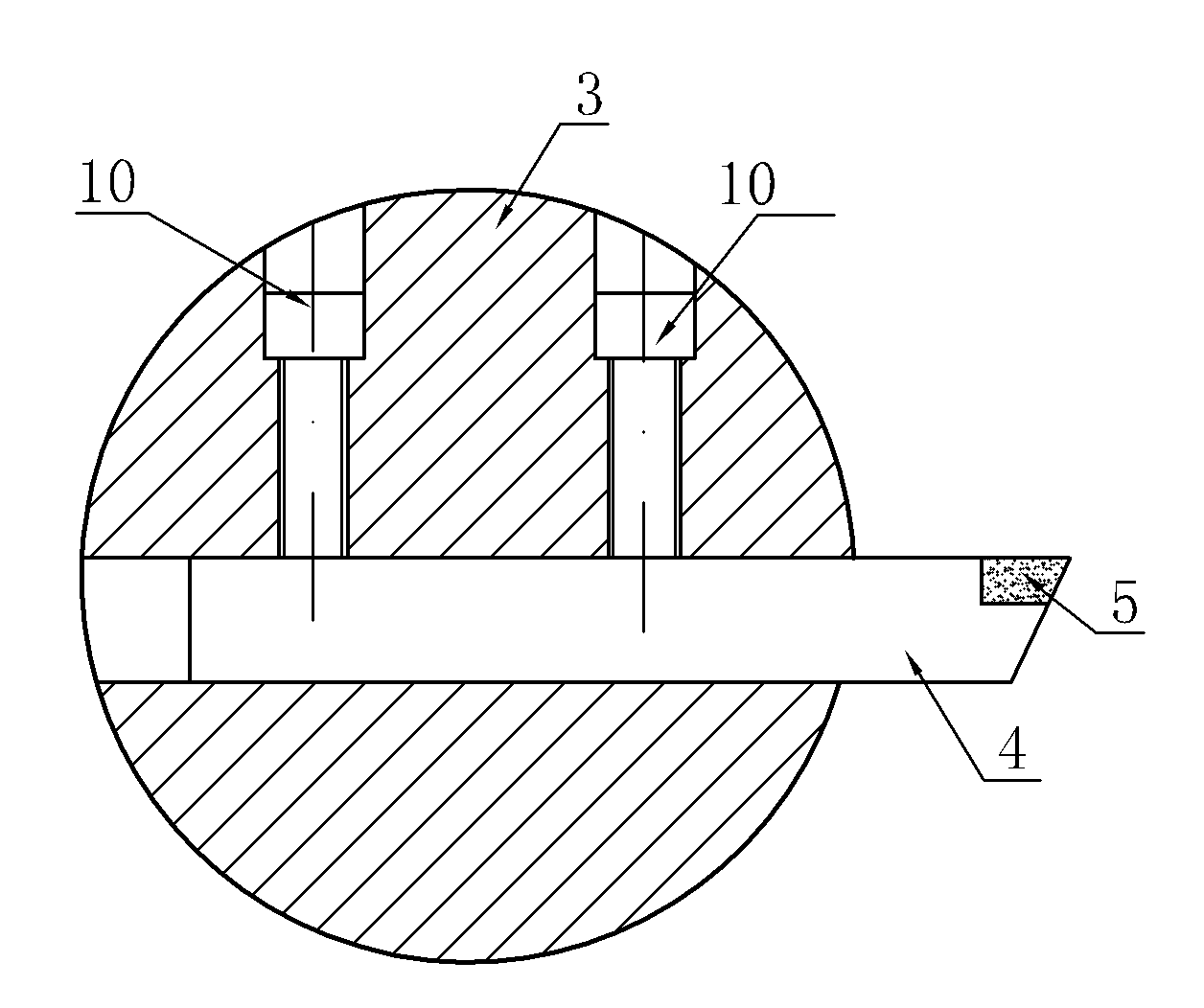

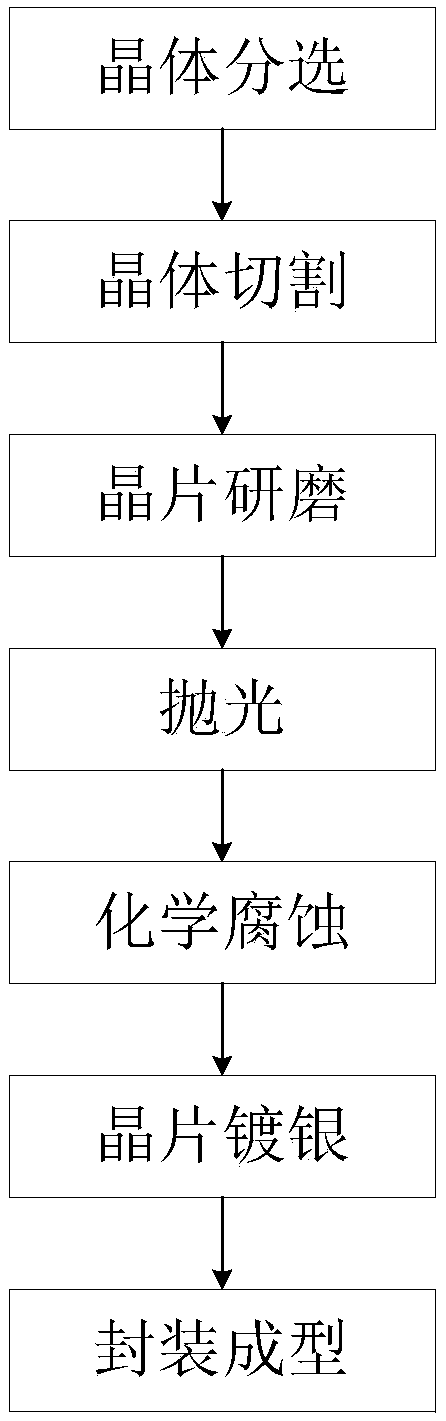

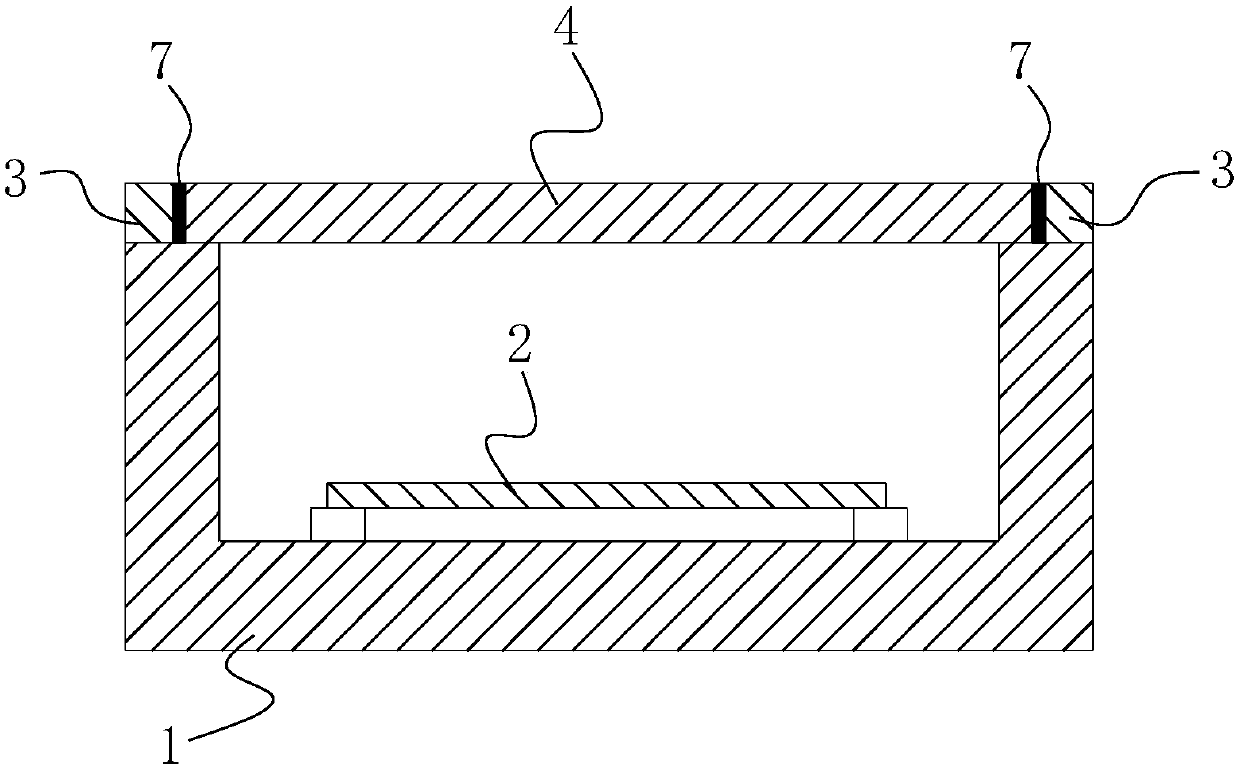

Quartz crystal resonator and processing method thereof

PendingCN107634733AReduce machining accuracyReduce processing requirementsImpedence networksQuartz crystal resonatorElectronic component

The invention belongs to the field of the electronic components, and specifically relates to a quartz crystal resonator and a processing method thereof. The quartz crystal resonator comprises a base,a wafer, a metal kovar ring and a metal cover plate, wherein the wafer is arranged in the base; the metal kovar is sintered at the gate of the base; the metal cover plate is held in an intra-ring region formed by the metal kovar ring and placed at the gate of the base; and the metal cover plate is fixedly connected with the metal kovar ring through laser slit bonding. The processing method disclosed by the invention comprises the following steps: S1, crystal sorting; S2, crystal cutting; S3, crystal grinding; S4, polishing, S5, chemical corrosion; S6, crystal silver-plating; and S7, encapsulating and forming, thereby obtaining the quartz crystal resonator. The quartz crystal resonator disclosed by the invention adopts a brand-new structure, the structure reduces the processing precision onthe metal cover plate and the metal kovar ring; the welding technology becomes simple and efficient, and the processing manufacturing cost of the resonator is obviously reduced.

Owner:HEFEI JINGWEITE ELECTRONICS CO LTD

Lathe clamp for machining blade dehumidification groove

InactiveCN107571070AHigh machining accuracy requirementsIncrease processing costPositioning apparatusMetal-working holdersLeading edgeNumerical control

The invention discloses a lathe clamp for machining a blade dehumidification groove, and relates to a clamp. The lathe clamp for machining the blade dehumidification groove aims to solve the problem that no appropriate clamp is provided aiming at a new blade dehumidification groove machining method at present, thus the blade dehumidification groove cannot be processed on a numerical control lathe,and inconvenience is brought to a new blade dehumidification groove machining technology. A blade is installed on a clamp body portion through a positioning portion and a clamping portion; two ejector pin seats are arranged in two width directions of a bottom plate respectively; the ejector pin seats are each connected with the base plate through a set of rib plates; a blade inner diameter direction surface positioning portion is installed on the bottom plate of the clamping portion of the clamp; a blade root leading edge positioning portion and a blade crown leading edge positioning portionare installed on the blade inner diameter direction surface positioning portion; the blade is positioned and installed on the blade crown leading edge positioning portion through a blade length direction positioning portion; a blade crown pressing plate and a blade root pressing plate are pressed and fitted on the blade. The lathe clamp for machining the blade dehumidification groove is used for machining the blade dehumidification groove.

Owner:HARBIN TURBINE

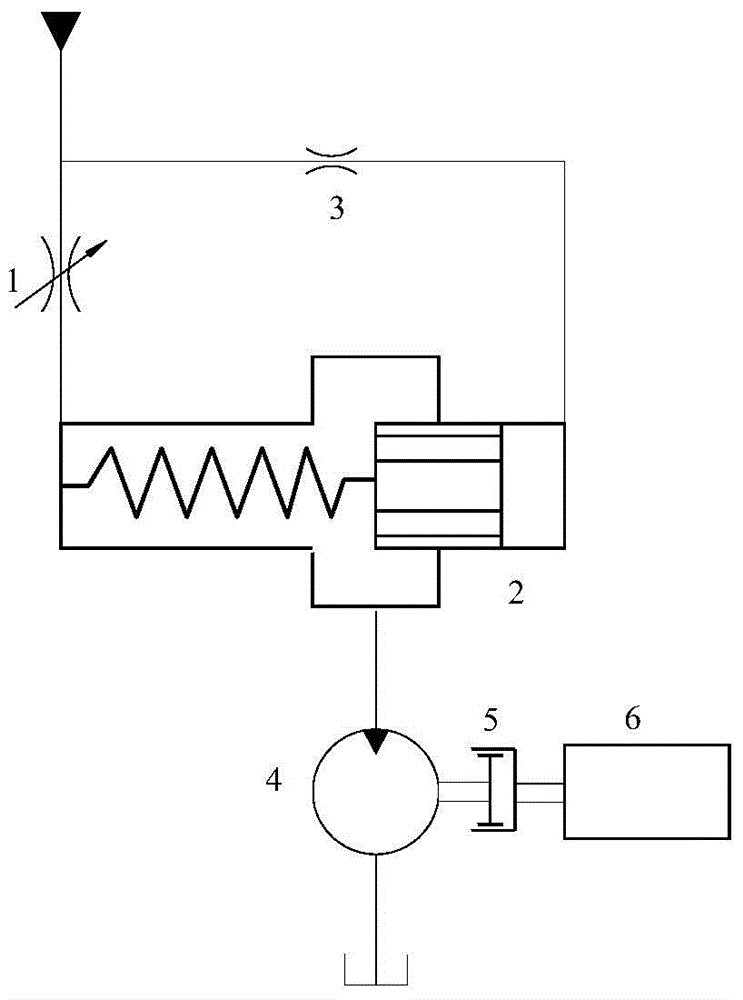

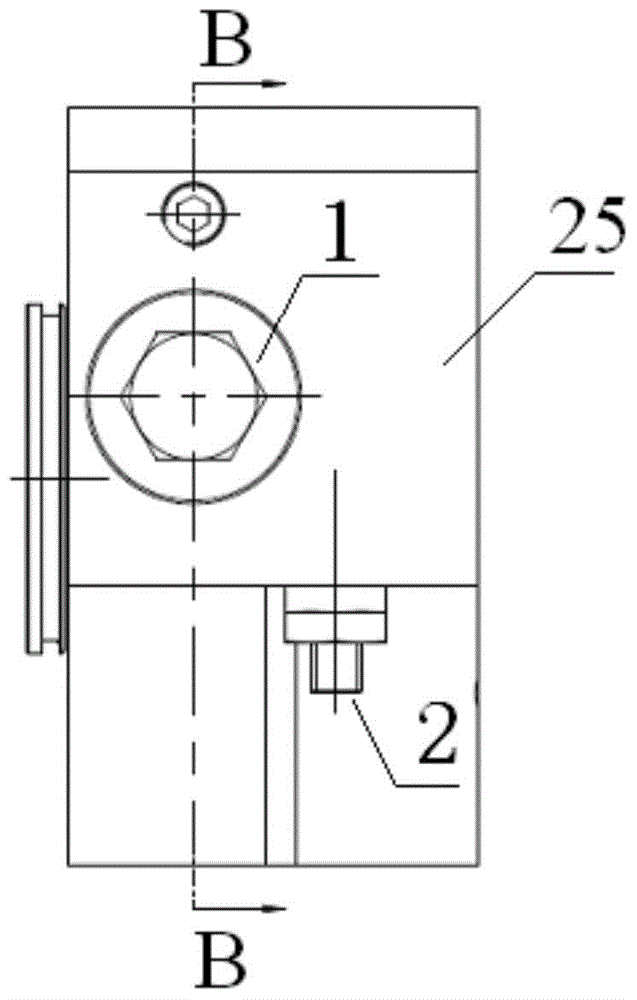

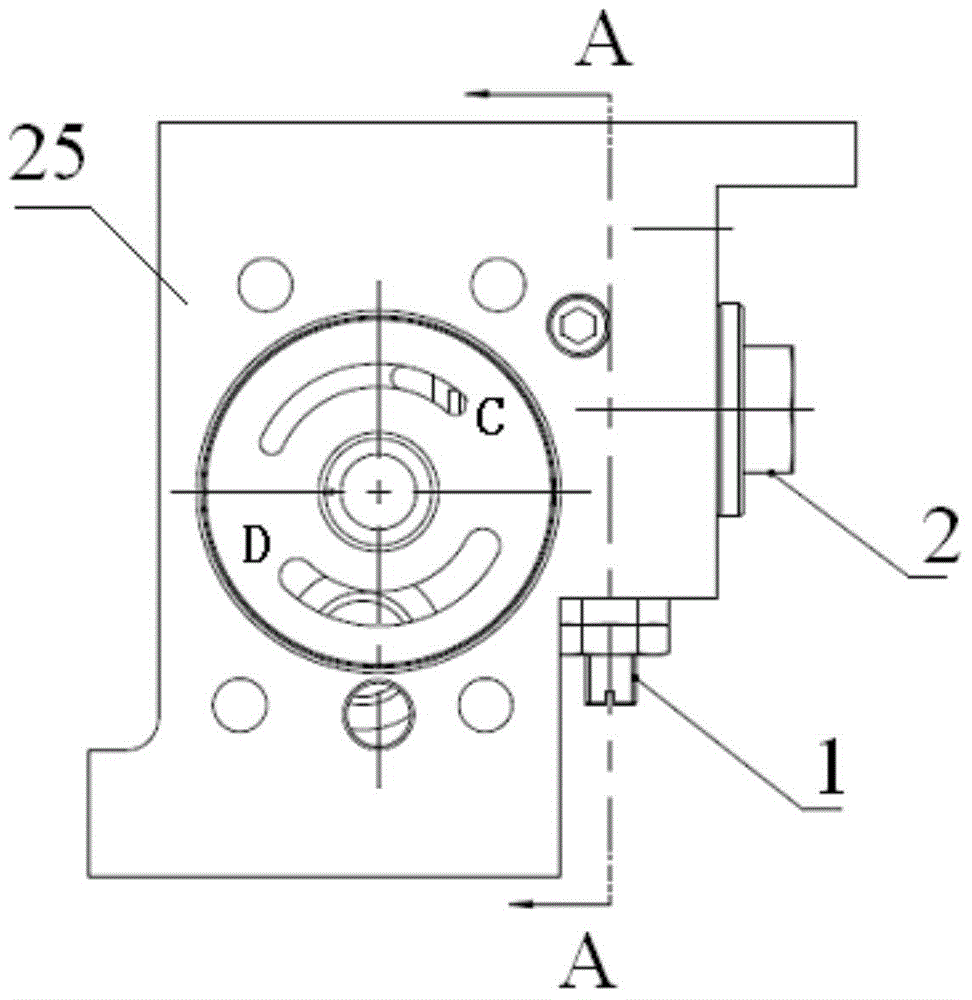

Single-stage constant-speed valve used for high-pressure kerosene constant-speed hydraulic motor

ActiveCN105626613ASimple structureImprove reliabilityServomotor componentsHydraulic motorEngineering

The invention belongs to a constant-speed valve and relates to a single-stage constant-speed valve used for a high-pressure kerosene constant-speed hydraulic motor, in particular to a high-reliability integrated large-flow single-stage constant-speed valve used for a constant-speed hydraulic motor driven by high-pressure kerosene. The single-stage constant-speed valve comprises a valve shell, a throttle valve and a compensation valve. The throttle valve is fixed in a cavity inside the valve shell. The compensation valve is fixed in the other cavity inside the valve shell. In the valve shell, an outlet of the cavity where the throttle valve is located communicates with an inlet of the cavity where the compensation valve is located. A damping hole is formed in the valve shell and enables an inlet of the cavity where the throttle valve is located to communicate with the cavity where the compensation valve is located. The single-stage constant-speed valve is simple in structure, high in reliability, low in machining cost, easy to assemble and adjust, high in integration level, capable of fixing and controlling the steady state rotation speed difference, and easy to operate.

Owner:BEIJING RES INST OF PRECISE MECHATRONICS CONTROLS +1

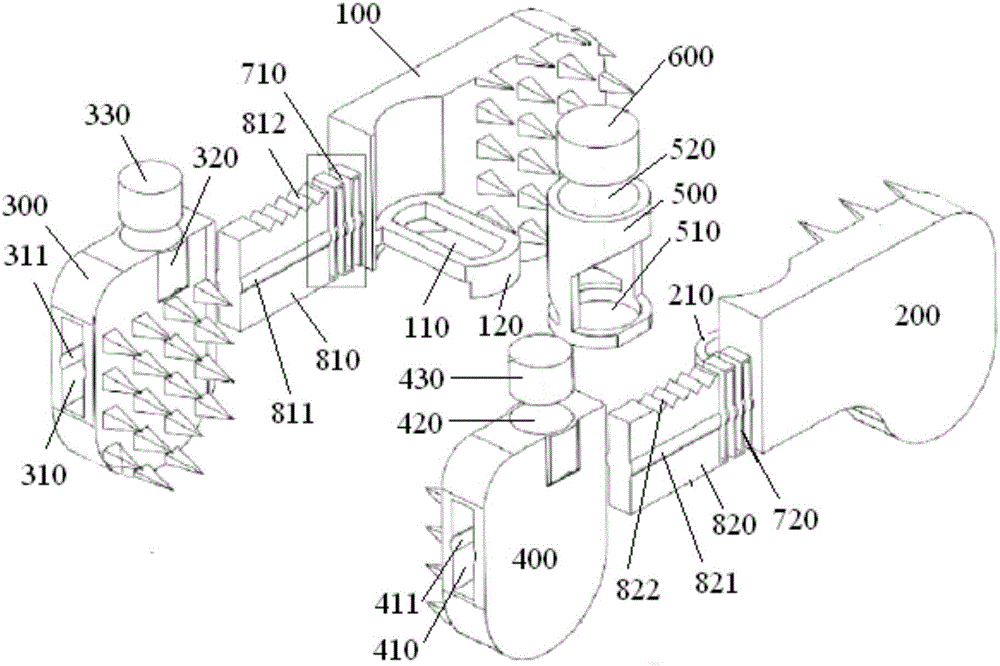

Interspinous fixation device

The invention discloses an interspinous fixation device which comprises a first side plate, a second side plate, a third side plate and the fourth side plate. The first side plate and the second side plate are arranged face to face, the third side plate and the fourth side plate are arranged face to face, the first side plate is connected with the third side plate, the second side plate is connected with the fourth side plate, and the first side plate, the second side plate, the third side plate and the fourth side plate are each provided with multiple sharp thorn protrusions; the portion between the first side plate and the third side plate and the portion between the second side plate and the fourth side plate are each provided with an adjusting structure, wherein the adjusting structure is used for adjusting the translational degree of freedom between the first side plate and the third side plate or adjusting the translational degree of freedom between the second side plate and the fourth side plate. The fixation device is mainly used for limiting the extension and flexion degree of freedom, a certain degree of freedom is kept in the lateral bending and reversing direction, and additional movement, brought by fixation of an operation segment, of an adjacent segment is reduced.

Owner:SHANGHAI KINETIC MEDICAL

Spherical-surface and tapered-surface combined opening and closing type common rail high-pressure oil injecting pump

InactiveCN109751167AHigh machining accuracy requirementsIncrease processing costMachines/enginesFuel injecting pumpsCommon railSteel ball

A spherical-surface and tapered-surface combined opening and closing type common rail high-pressure oil injecting pump comprises an oil pipe joint, an upper spring, an upper valve element, a lower spring, a lower valve element, a valve seat, a plunger piston and a pump body, wherein the upper valve element comprises an upper cylinder body, a sealing cone, a guide column and a spring seat hole; thesealing taper is in sealing fitting with the tapered surface of an upper end port of the valve seat; the valve seat is of an integrated structure and comprises a transverse oil inlet hole, a centraloil inlet hole, an oil storing chamber, a central oil outlet hole, a sealing tapered surface and a vertical oil inlet hole; the sealing tapered surface is arranged at the upper opening end of the central oil outlet hole; the transverse oil inlet hole communicates with the central oil inlet hole; the oil storing chamber communicates with a top clearance oil chamber through the vertical oil inlet hole; an oil inlet part is of an anti-rotation steel ball sealing structure; and an oil outlet part is of a guide tapered surface sealing structure. According to the spherical-surface and tapered-surface combined opening and closing type common rail high-pressure oil injecting pump, the valve seat which is of the integrated structure is capable of avoiding leaking; in addition, the pump is convenient to process and assemble; the fished product yield is high; and the service life is long.

Owner:常州博瑞油泵油嘴有限公司

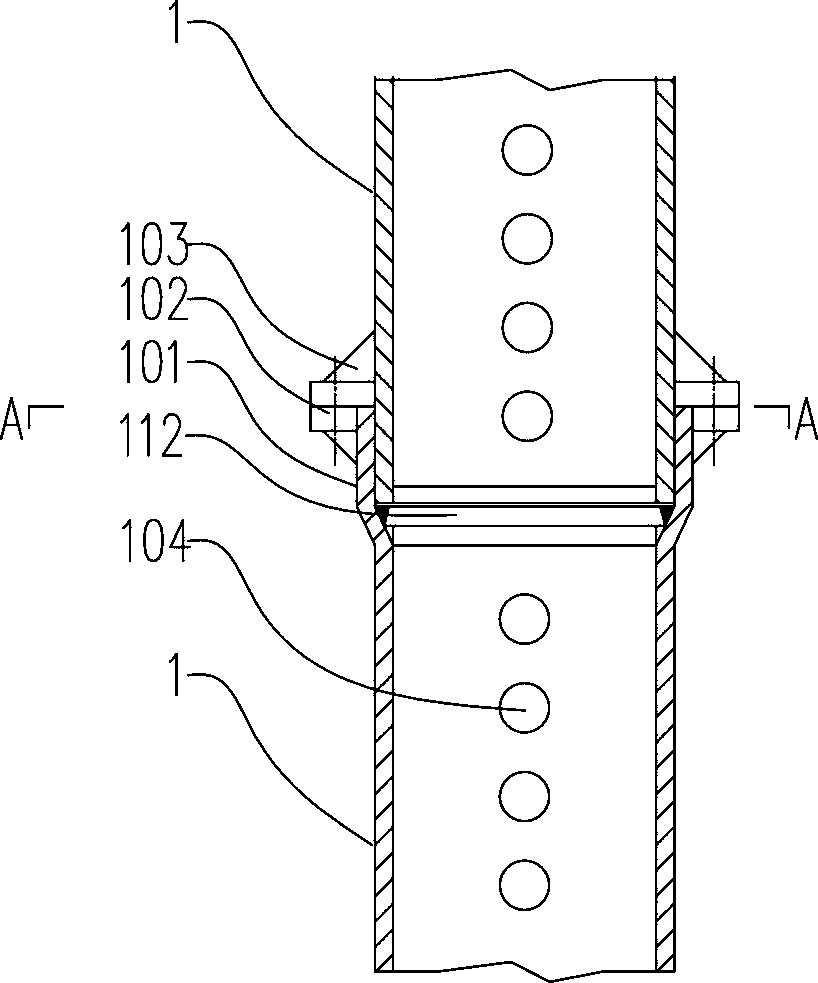

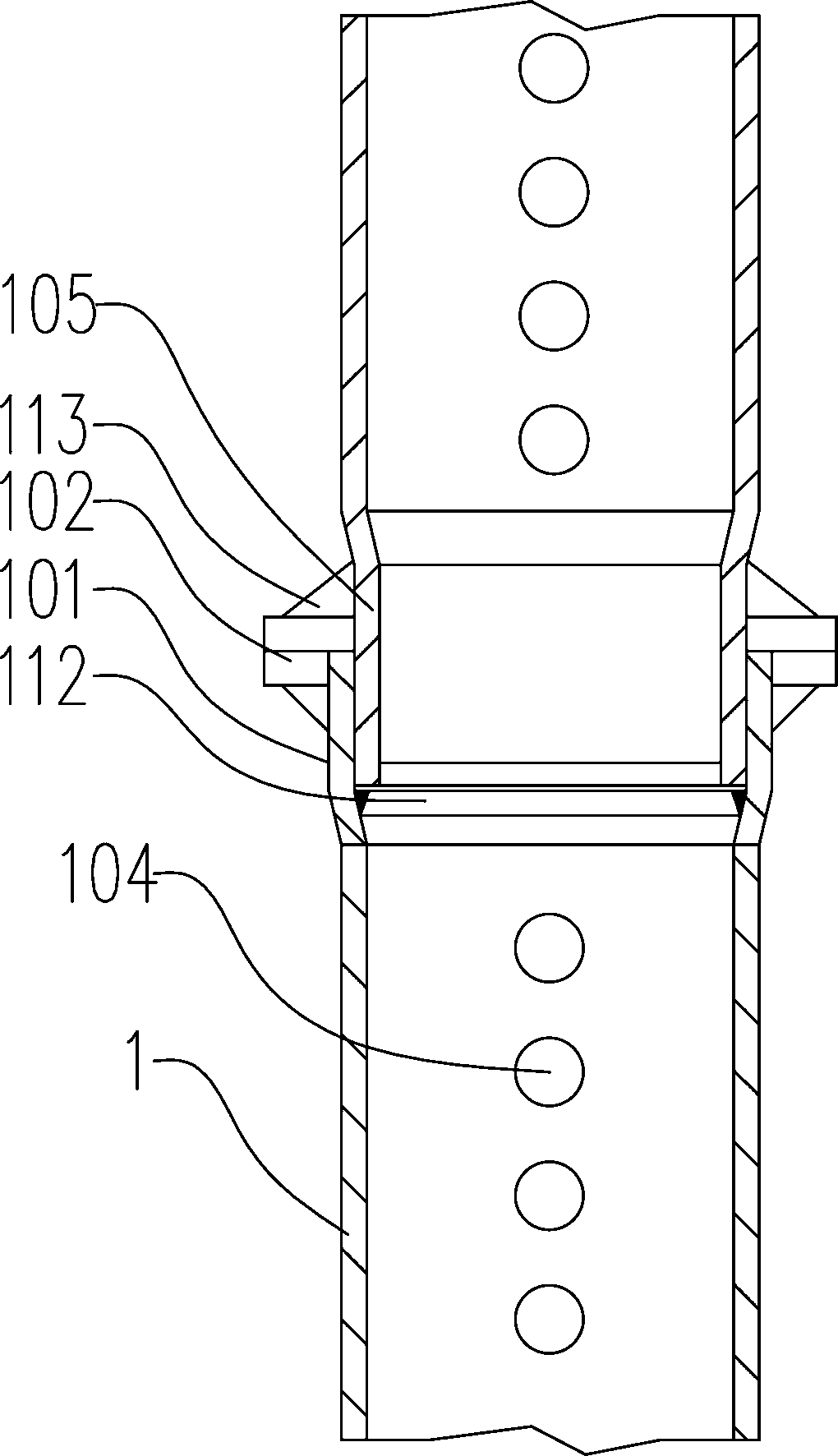

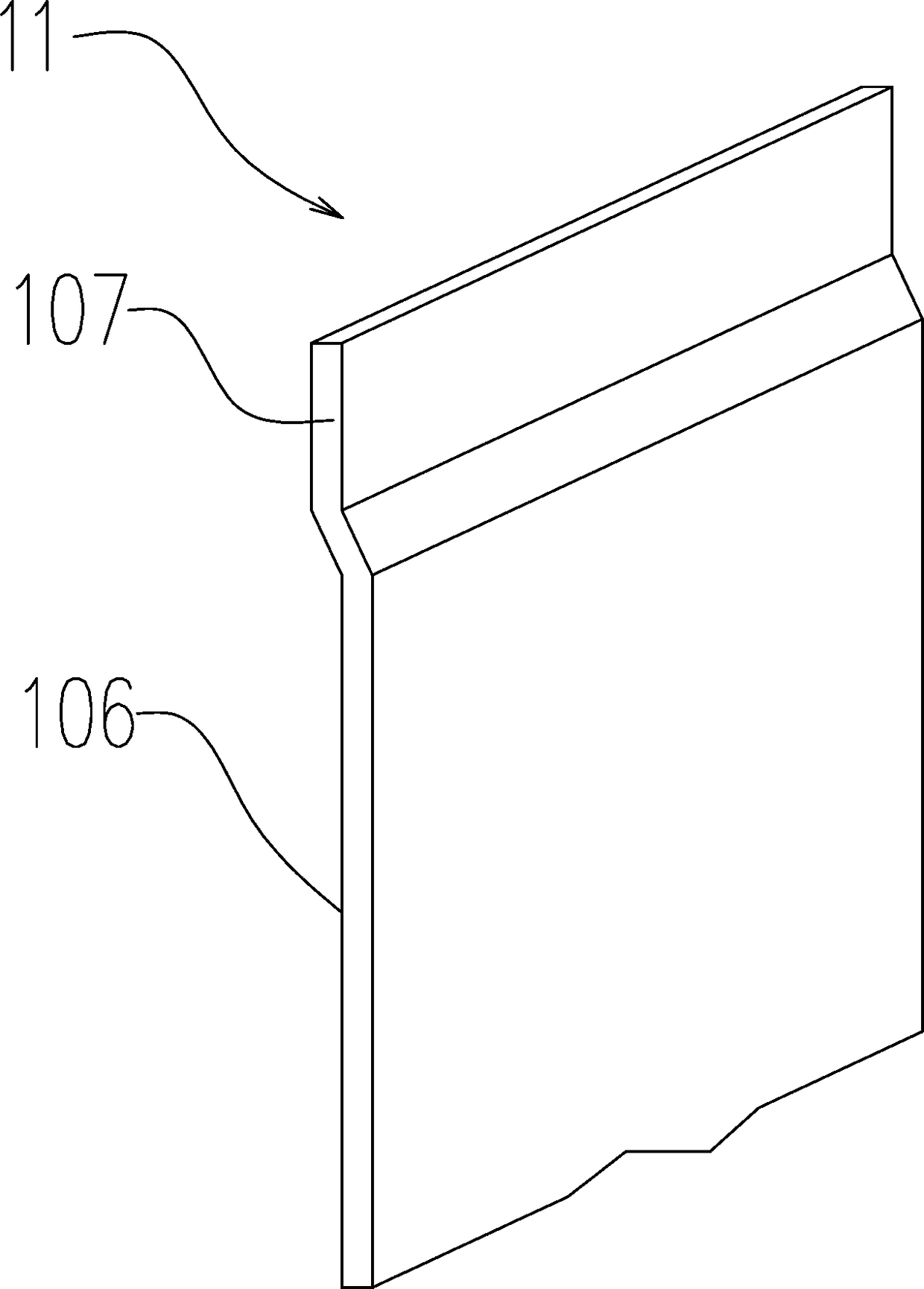

Heavy type prefabricated grouting steel tube compound column and processing method

ActiveCN108396908AImprove bearing strengthImprove lateral strengthStrutsPillarsEngineeringStress strength

The invention provides a heavy type prefabricated grouting steel tube compound column and a processing method. An edge-extending end head is arranged at one end of a tubular column, and an edge-extending end head flange is arranged on the edge of the edge-extending end head. A cavity which comprises a plurality of side walls is formed in the edge-extending end head, the other end of the tubular column can be sleeved with the cavity, and an end head flange used for connecting the edge-extending end head flange is arranged on the side wall, close to the end head, of the other end of the tubularcolumn. A vertical plate and a seam-repairing plate are bent and formed according to a preset shape. The vertical plate, an edge-extending end head plate and the seam-repairing plate are connected andformed by an edge-extending end head welding die and a middle portion locating welding die. The edge-extending end head flange is welded. The heavy type prefabricated grouting steel tube compound column is obtained by the steps. The lateral stress strength of the heavy type prefabricated grouting steel tube compound column is dramatically improved by adopting a covering-closing structure and a combined structure of flange connection, under the same load bearing requirements, the size of the heavy type prefabricated grouting steel tube compound column can be reduced.

Owner:湖北绿筑装配科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com