Electrode leading structure and electricity storage electric element adopting thereof

A lead-out structure and electrode lead-out technology, applied in the direction of electrical components, structural parts, capacitor parts, etc., can solve the problems of limited mechanical strength, high processing precision, loose end caps, etc., and achieve saving sealing insulation materials and low processing accuracy requirements , the effect of increasing the connection strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

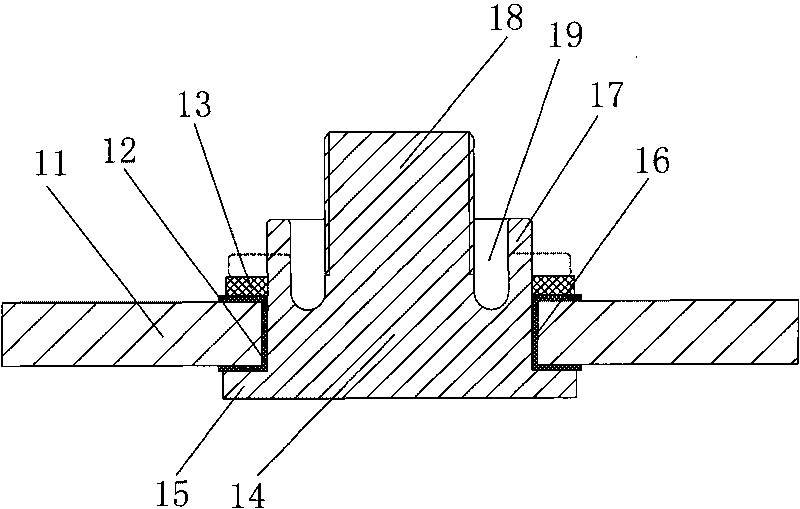

[0023] The electrode drawing structure of the present invention is as image 3 As shown, it includes an end cover 11 for sealing and fixing at the extreme opening of the battery or supercapacitor casing 21, and a lead-out hole 16 is opened in the center of the end cover 11, and a pole 14 is inserted in the lead-out hole 16. The bottom of 14 is provided with the retaining edge 15 that is used to prevent pole from falling off, and the top protrudes from the hole 16 aperture and is respectively provided with the pole lead-out 18 coaxial with the pole and the hollow around the pole lead-out 18. The flanging structure is an axial groove 19 arranged on the top of the pole 14, the outer surface of the groove wall 17 is consistent with the shape of the outer peripheral surface of the pole, and the pole lead-out 18 is in line with the concave The inner side wall of the groove 19 is a gap fit, the bottom of the lead-out end 18 of the pole is fixedly connected to the bottom of the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com