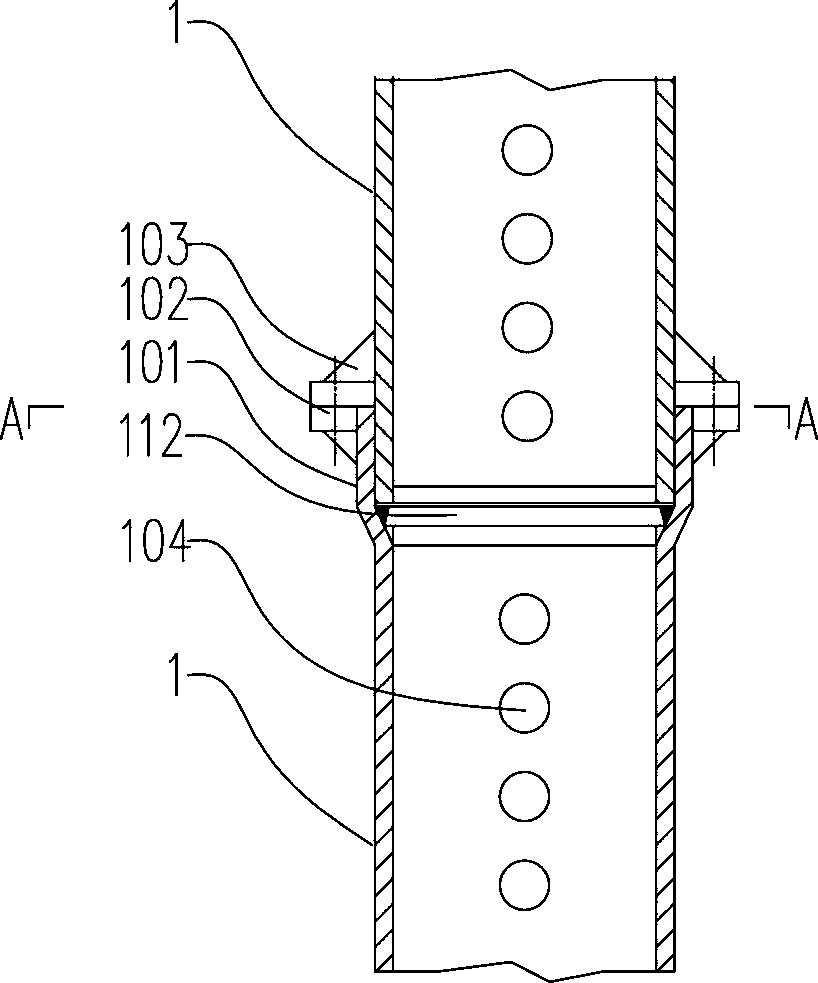

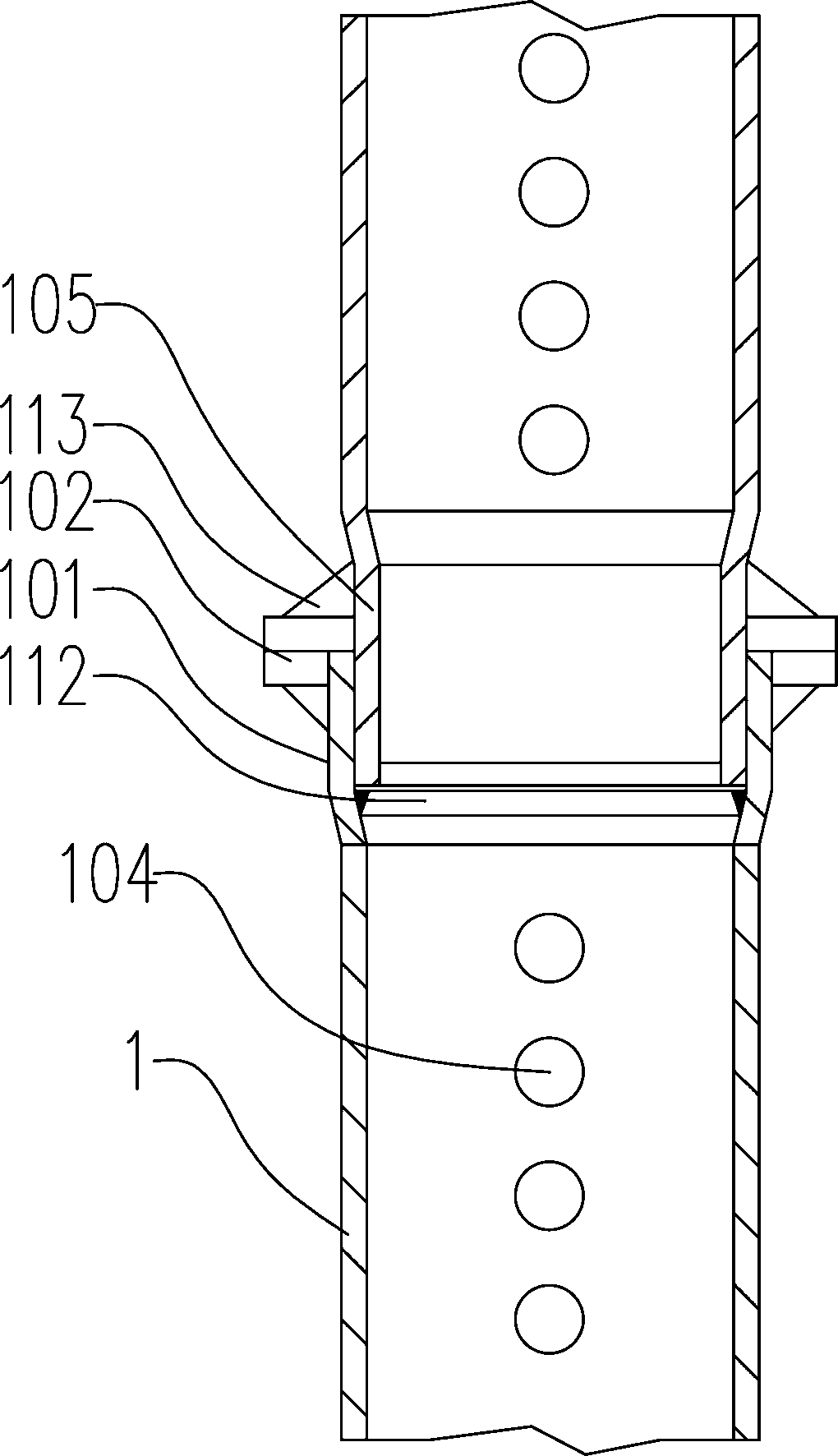

Heavy type prefabricated grouting steel tube compound column and processing method

A technology of grouting steel pipes and processing methods, which is applied in the direction of columns, pier columns, pillars, etc., can solve the problems of poor welding construction conditions, potential safety hazards, and difficult quality assurance, so as to increase processing difficulty, reduce processing difficulty, and ensure The effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0055] A processing method for the above-mentioned heavy fabricated grouted steel pipe composite column, comprising the following steps:

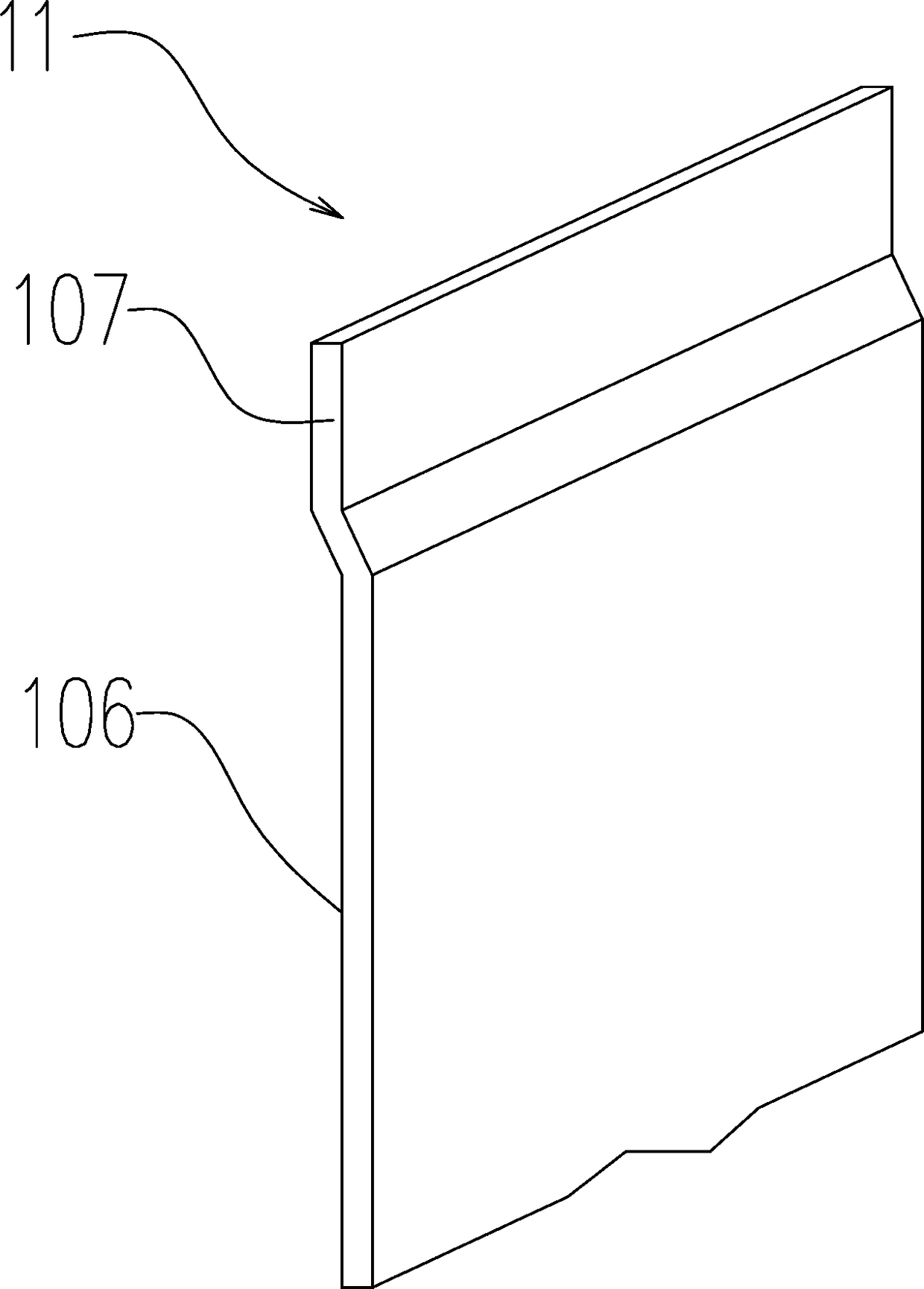

[0056] s1. Cutting the vertical board 12 and the seam repairing board 11; in this example, CNC wire cutting machine is used for cutting to ensure the dimensional accuracy.

[0057] s2, bending the vertical board 12 and the seam repairing board 11 according to the preset shape;

[0058] The preferred solution is as Figure 9 Among them, in this step, the riser 12 is heated to a predetermined temperature; the heating temperature is different according to different materials, and the heating temperature in this example is 900-1100 degrees Celsius.

[0059] The plate 100 to be processed, here the vertical plate 12 comes out of the heating furnace, and the vertical plate 12 is sent to the edge folding device 4 by the feeding trolley 41 for hemming; in a preferred solution, the feeding trolley 41 The top of the top is provided with roller table...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com