Single-stage constant-speed valve used for high-pressure kerosene constant-speed hydraulic motor

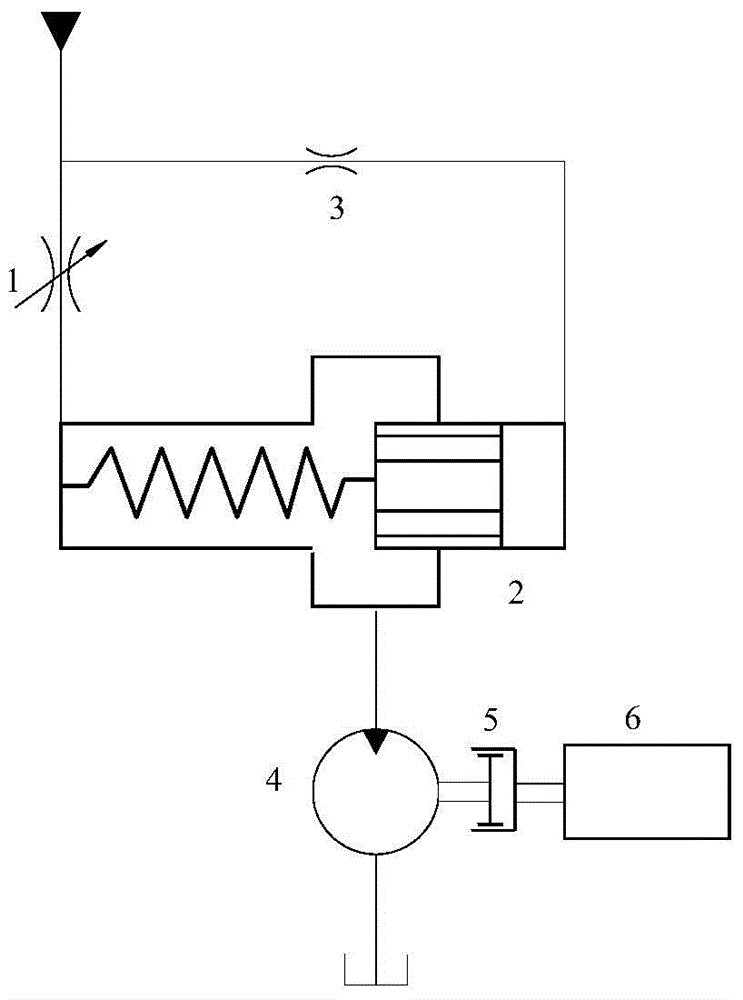

A technology of hydraulic motor and kerosene, which is applied to fluid pressure actuating devices, mechanical equipment, servo motor components, etc., can solve the problems of high processing cost and complex structure, and achieve the effect of low processing cost, easy operation and high integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

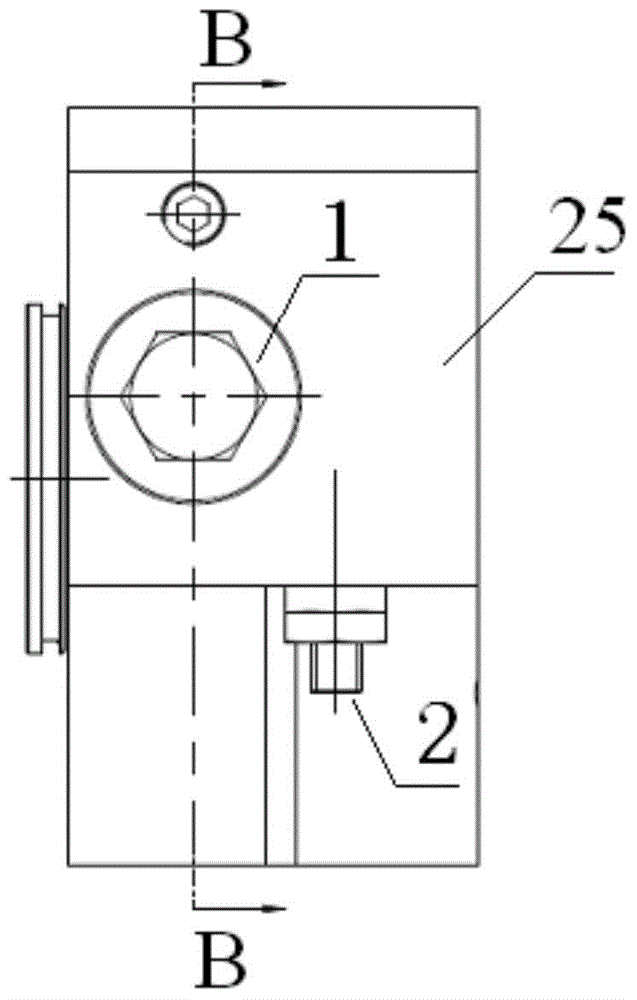

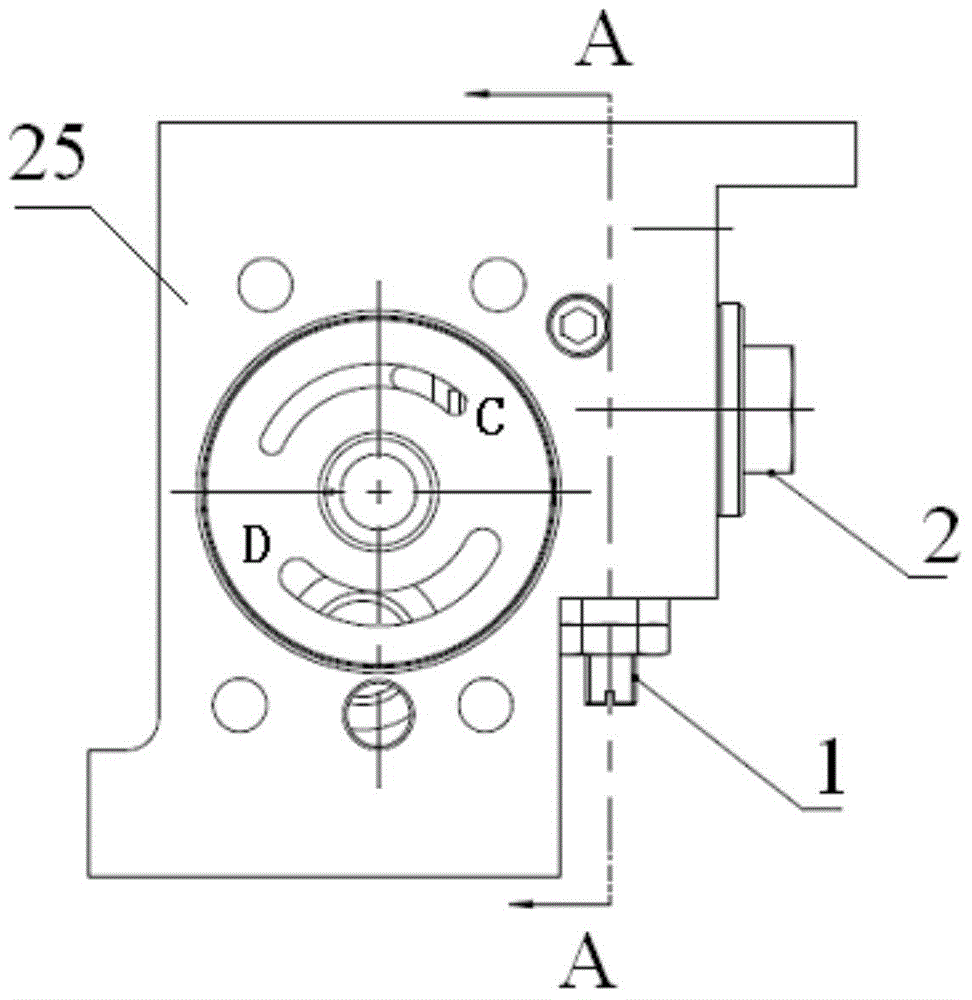

[0040] figure 2 , 3 , 4 and 5 are schematic diagrams of a single-stage constant-speed valve applied to a high-pressure kerosene constant-speed hydraulic motor with a two-valve cross-arrangement structure provided by the present invention. In this embodiment, the cavity where the throttle valve 1 is located and the compensation valve The cavities where 2 are located are perpendicular to each other. Both the throttle valve 1 and the compensation valve 2 are located in the valve housing 25 .

[0041] like Figure 4As shown, the throttle valve 1 includes an adjusting screw 7, a lock nut 8, a screw sleeve 9, a card seat 10, a guide pin 11, a throttle valve core 12, a spring I13, a spring seat I14, and an anti-rotation pin 24. The throttle valve 1 is installed in the valve housing 25 . The spring seat I14 is fixed at the end of the valve housing 25 close to the inlet H of the throttle valve 1 through threads. One end of the spring I13 is located in the spring seat I14, and the...

specific Embodiment 2

[0044] Image 6 , 7 , 8 and 9 are schematic diagrams of a single-stage constant-speed valve applied to a high-pressure kerosene constant-speed hydraulic motor provided by the two-valve parallel arrangement structure. In this embodiment, the cavity where the throttle valve 1 is located and the compensation valve The cavities where 2 are located are parallel to each other. Both the throttle valve 1 and the compensation valve 2 are located in the valve housing 25 .

[0045] like Figure 8 As shown, the throttle valve 1 includes an adjusting screw 7, a lock nut 8, a screw sleeve 9, a card seat 10, a guide pin 11, a throttle valve core 12, a spring I13, a spring seat I14, and an anti-rotation pin 24. The throttle valve 1 is installed in the valve housing 25 . The spring seat I14 is fixed at the end of the valve housing 25 close to the inlet H of the throttle valve 1 through threads. One end of the spring I13 is located in the spring seat I14, the spring I13 is sleeved on the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com