Milling machine

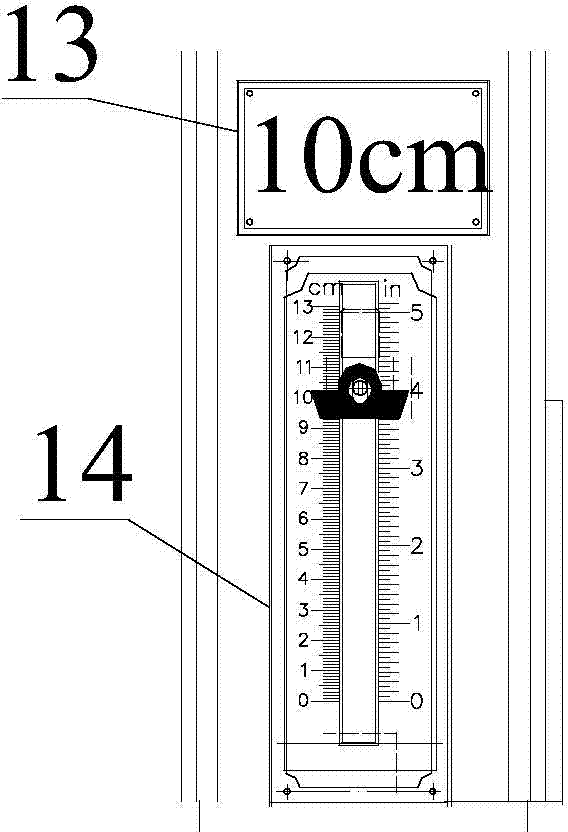

A milling machine and spindle technology, applied in the field of milling machines, can solve the problem that the depth of the spindle cannot be visually and accurately seen and set.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

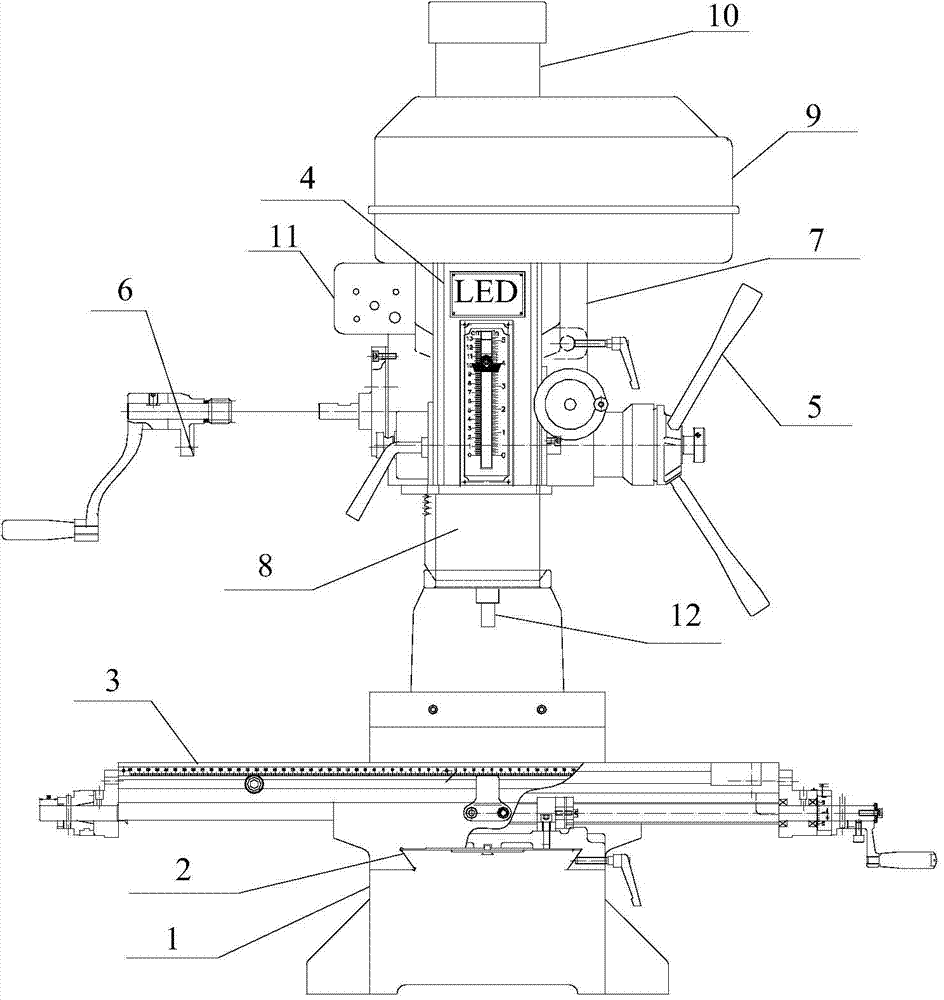

[0013] Such as figure 1 As shown, the present invention provides a milling machine, including a base 1, a cross carriage 2, a workbench 3, a spindle lifting handle 5, a spindle box lifting handle 6, a spindle box 7, a spindle 8, a pulley shield 9, a column 10, Motor 11, milling head 12. There is a dovetail between the base 1 and the cross carriage 2, the workbench 3 and the upper part of the cross carriage 2 are connected by a dovetail, the lower part of the column 10 is connected with the base 1 by four screws, the headstock 7 is located on the upper part of the column 10, and the motor 11 is installed On the motor plate located on the outside of the headstock.

[0014] Three belt pulleys are housed in pulley guard 9 inside, main shaft 8 is installed with main shaft box 7 inside, is connected with milling head 12 on main shaft 8, and motor 11 drives main shaft 8 by the transmission of belt pulley thereby controls milling head work.

[0015] Shaking the spindle box lifting h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com