Rough and fine boring device for processing cutter bar with step holes at two ends

A technology of boring bar and step hole, which is applied in the direction of boring bars, metal processing equipment, and tools used in lathes, etc. It can solve the problems of difficult high-precision machining of boring tools, long processing time, and high machining costs. Achieve the effects of high processing precision, low processing cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

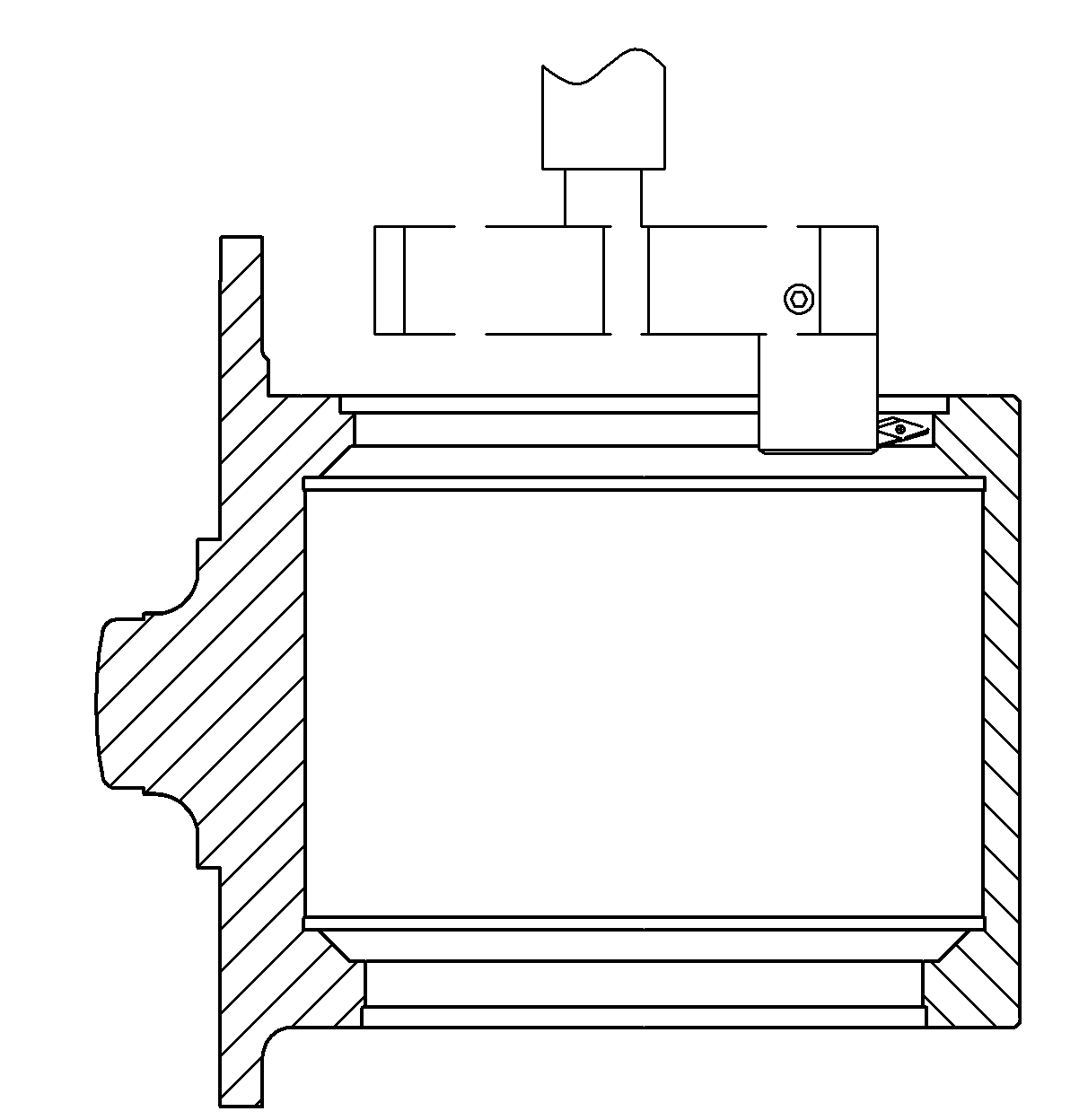

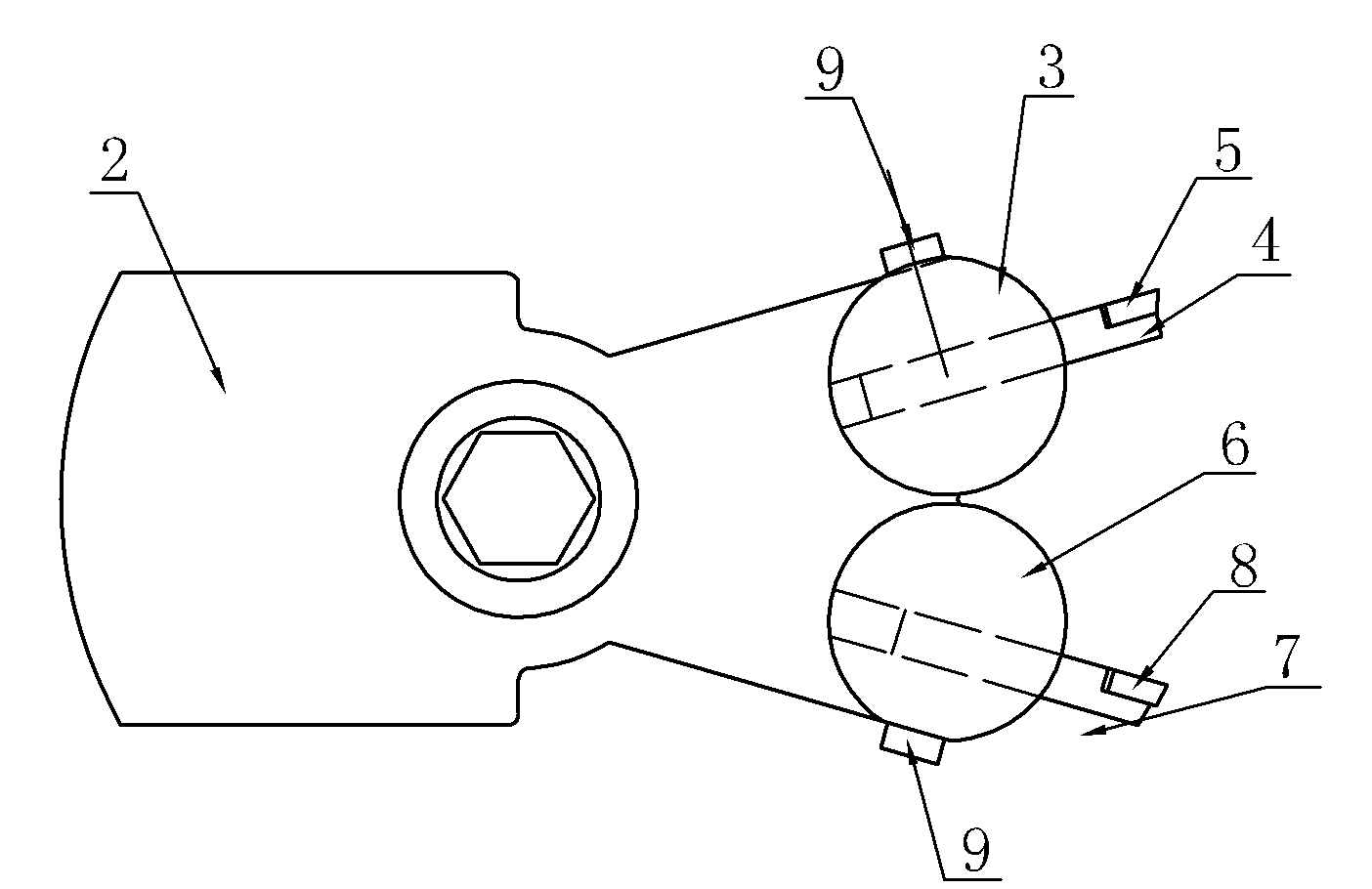

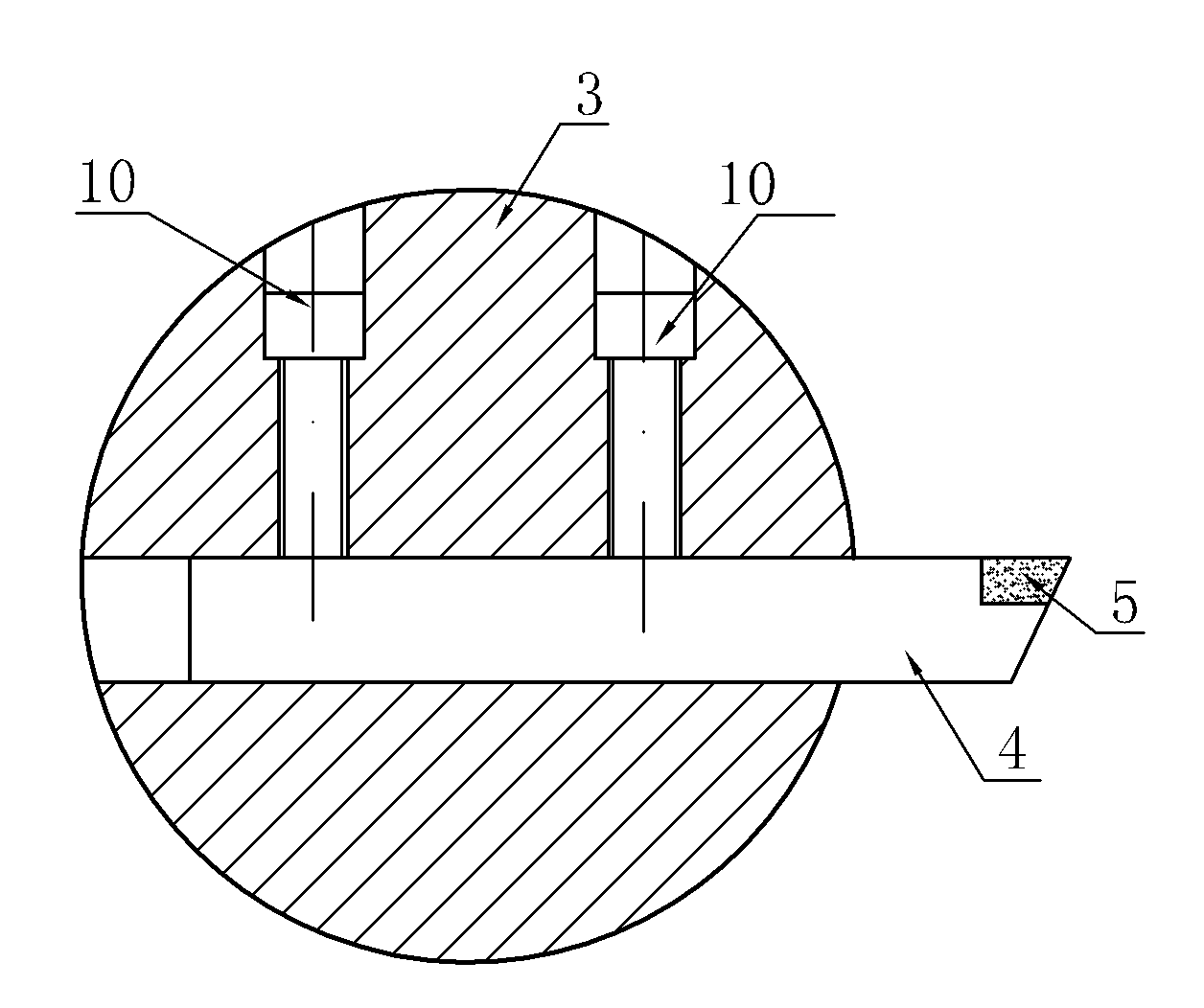

[0013] A rough and fine boring bar device for machining stepped holes at both ends, such as figure 2 , image 3 and Figure 4 As shown, it includes a rotating spindle 1, a balanced tool bar 2, an adjustable rough boring holder 3, a rough boring cutter body 4, a rough boring blade 5, an adjustable fine boring holder 6, a fine boring cutter body 7, and a fine boring blade 8. Clamp seat fastening screw 9 and cutter body fastening screw 10, the rough boring blade 5 is detachably installed on the rough boring cutter body 4, and the rough boring cutter body 4 is fixed and installed on the adjustable rough boring cutter body 4 through the cutter body fastening screw 10. On the boring holder 3, the adjustable rough boring holder 3 is installed on the balance tool bar 2 through the holder fastening screw 9, and the fine boring blade 8 is detachably installed on the fine boring cutter body 7, and the fine boring cutter body 7 passes through The cutter body fastening screw 10 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com