A kind of free cutting stainless steel and preparation method thereof

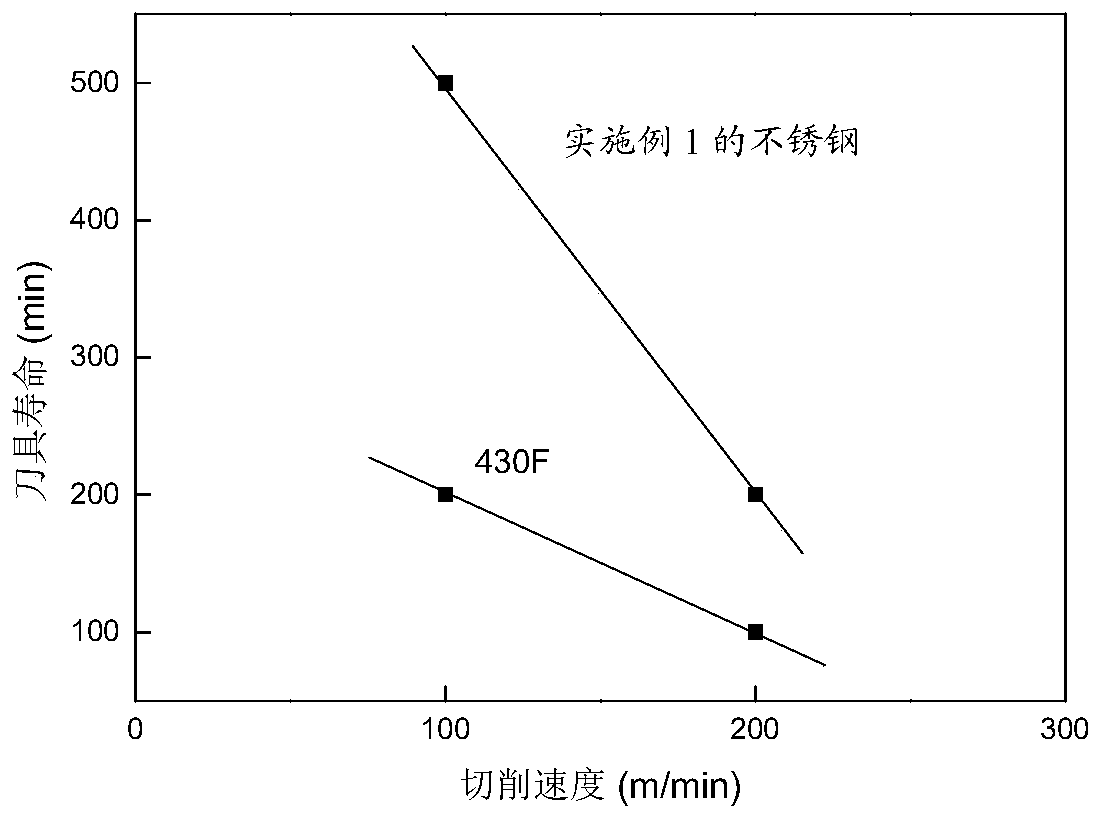

A stainless steel, easy-cutting technology, applied in the field of metallurgy, can solve problems such as human hazards and environmental pollution, and achieve the effects of large cutting volume, high corrosion resistance and excellent cutting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0091] In a second aspect, the present invention provides a method for preparing free-cutting stainless steel, comprising: (1) using blast furnace molten iron as a raw material to pretreat it; (2) continuously casting the pretreated molten iron into an ingot; (3) The ingot is heated and then rolled into the finished product.

[0092] In step (1), blast furnace molten iron is prepared by reacting iron ore and coke in a blast furnace.

[0093] In step (1), the pretreatment includes dephosphorization, desiliconization, and desulfurization of the blast furnace molten iron. Specifically, iron oxide balls and lime are added to molten iron to remove phosphorus, silicon and sulfur. P≤0.04, Si≤0.1%, and S≤0.02% in the stainless steel mother liquor after triple removal.

[0094] In step (2), before continuous casting, decarburization and denitrogenation roughing and LF furnace refining are performed on the pretreated molten iron, specifically, the molten iron is decarburized to 0.02-0....

Embodiment 1

[0101] The chemical composition of stainless steel is:

[0102] element symbol C Si mn P S Cr Mo Bi mass percentage 0.011 0.39 1.20 0.031 0.33 20.04 1.82 0.15 element symbol Pb Te Ni Cu V Nb N O mass percentage 0.01 0.027 0.2 0.1 0.1 0.03 0.02 0.016

[0103] Manufacturing method: After the molten steel has undergone three decarburization treatments, it is decarburized to 0.022% and nitrogen to 0.028% in the K-OBM-S furnace, and then undergoes deep decarburization to 0.008% and nitrogen to 0.020 in the VOD furnace, and is carried out in the LF furnace. The refining temperature is adjusted to 1585°C, and then the ladle is out of the station, and the molten steel is cast into ingots.

[0104] The temperature of the soaking section is 1120°C, and the holding time of the soaking section is calculated as 0.6min / mm; the heating rate of the heating section is 120°C / h; the temperature of the holding section is 1180°C...

Embodiment 2

[0110] The chemical composition of stainless steel is:

[0111] element symbol C Si mn P S Cr Mo Bi mass percentage 0.009 0.40 1.10 0.036 0.31 20.01 1.80 0.12 element symbol Pb Te Ni Cu V Nb N O mass percentage 0.05 0.025 0.23 0.11 0.09 0.03 0.022 0.017

[0112] Manufacturing method: After the molten steel has been subjected to three decarburization treatments, it is decarburized to 0.020% and nitrogen to 0.030% in the K-OBM-S furnace, and then goes through the VOD furnace for deep decarburization to 0.007%, and nitrogen to 0.024, and then goes through the LF furnace. The refining temperature is adjusted to 1590°C, and then the ladle is out of the station, and the molten steel is cast into ingots.

[0113] The temperature of the soaking section is 1150°C, and the holding time of the soaking section is calculated according to 0.8min / mm; the heating rate of the heating section is 150°C / h; the temperature of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com