Silicon steel sheet machining device for permanent-magnet synchronous motor production and machining method of silicon steel sheet machining device

A permanent magnet synchronous motor and processing device technology, applied in the direction of electromechanical devices, positioning devices, metal processing equipment, etc., can solve the problems of inability to manufacture high-precision silicon steel sheets, mold waste, etc., to prevent clogging, improve stability and reliability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

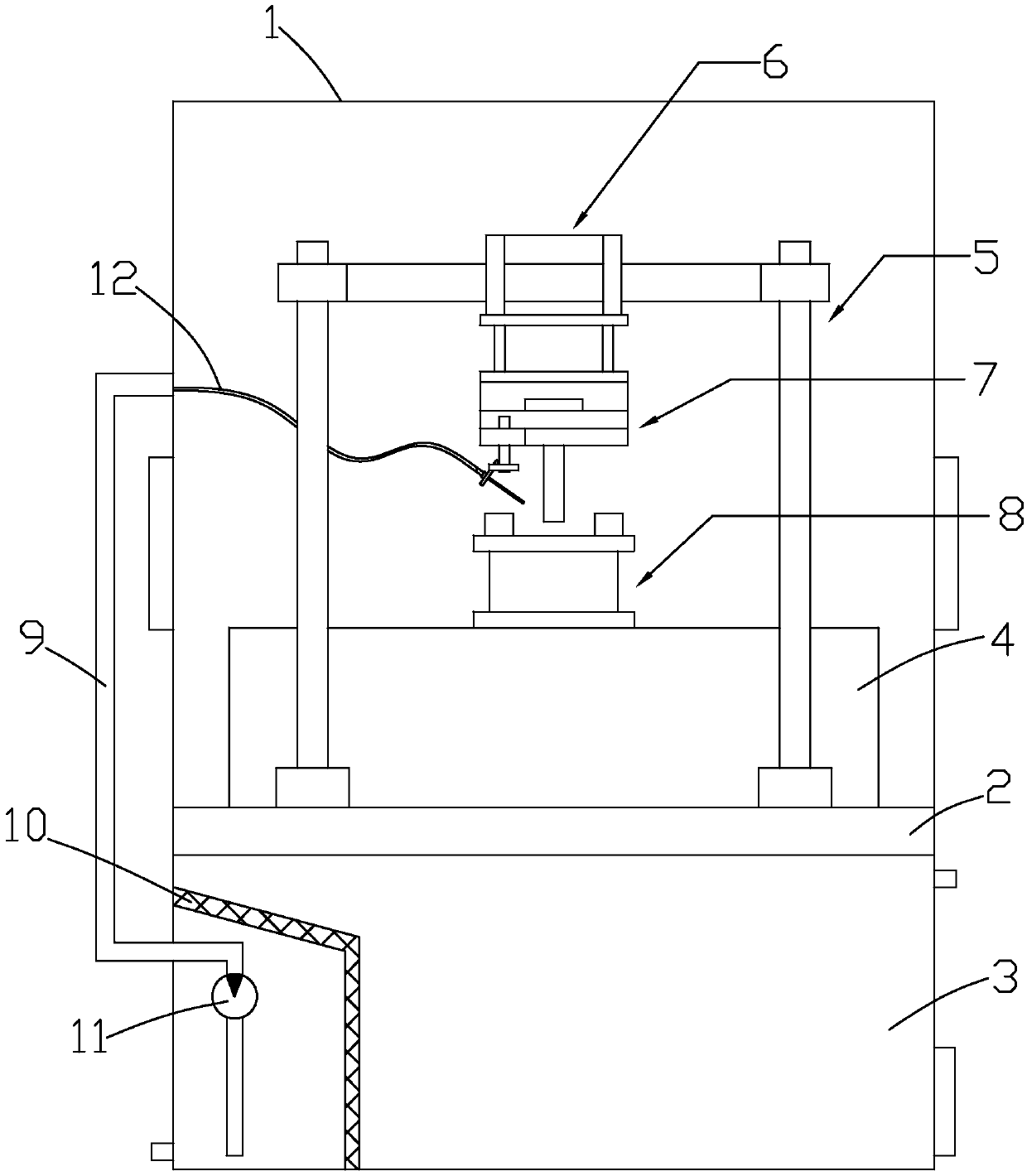

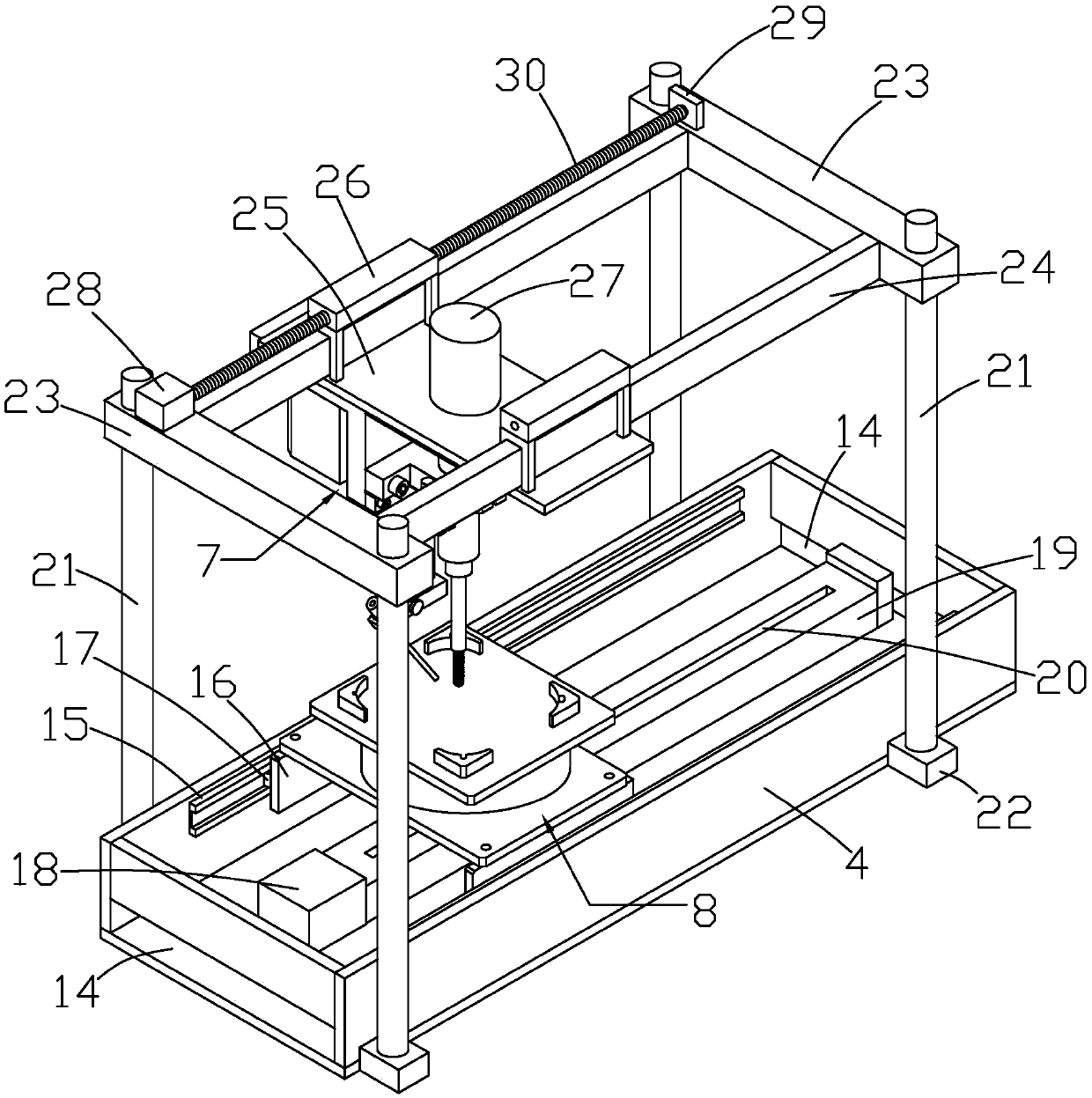

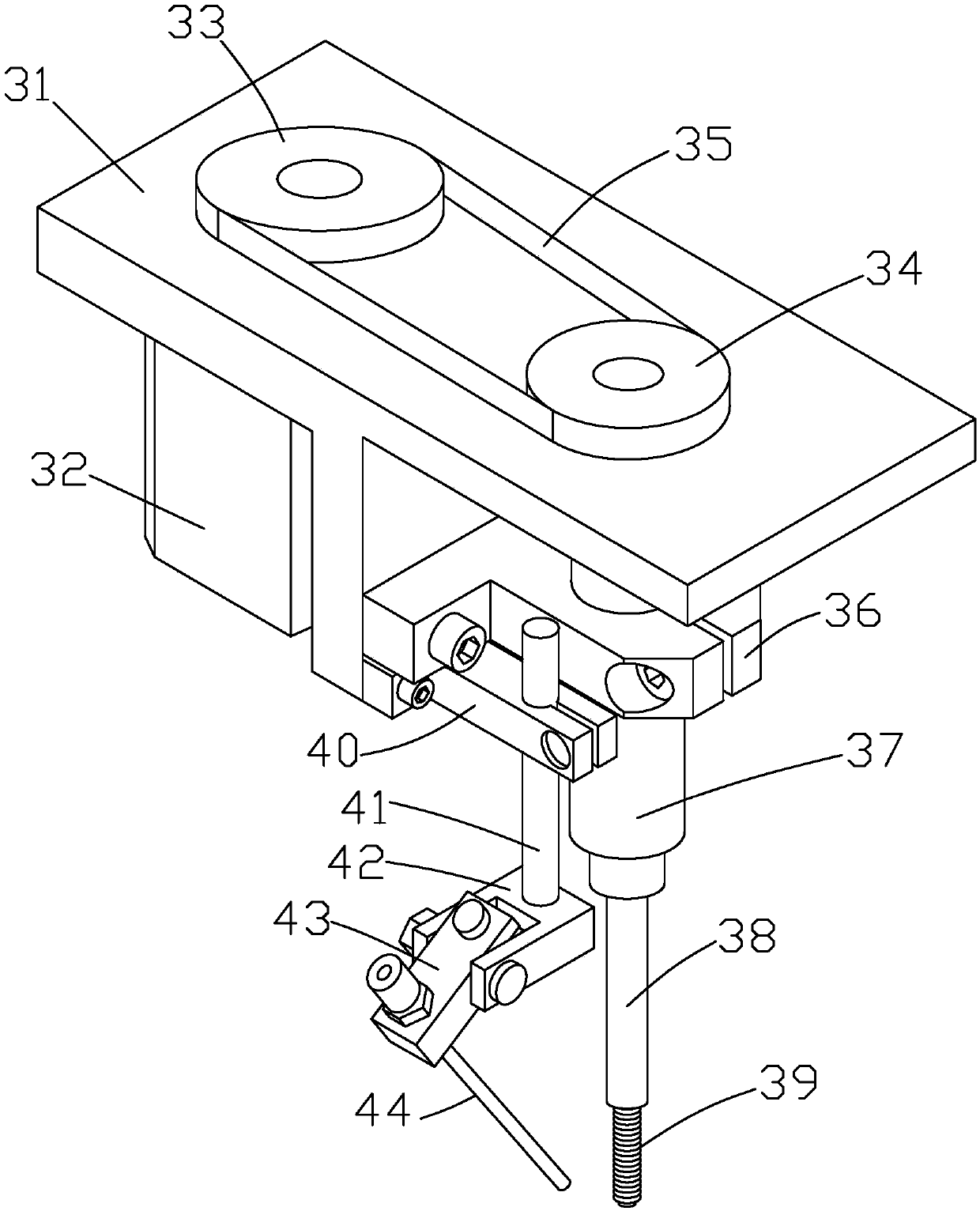

[0054] Such as Figure 1 to Figure 6 As shown, it is a silicon steel sheet processing device for permanent magnet synchronous motor production according to the present invention, which includes a box body 1, a water tank 3, a spray system and a processing assembly, and the processing assembly includes a frame body 4, a support mechanism 5, a horizontal movement mechanism 6, The permanent magnet tank is provided with a mechanism 7 and a silicon steel sheet clamping platform 8. The frame body 4 is horizontally fixedly connected in the box body 1 through the support 2. The water tank 3 is located under the support 2. A filter screen 10 is arranged in the water tank 3. Two parts of the water tank 3 The water inlet pipe, outlet pipe and protective door are respectively arranged on the side, and the protective door is located under the water inlet pipe. The design of the filter screen 10 can filter the silicon steel sheet debris after washing, and prevent the silicon steel sheet debr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com