Composite prestressing force ceramic lining cylinder sleeve and manufacturing method thereof

A technology of ceramic lining and manufacturing method, which is applied to cylinders, cylinder heads, engine components, etc., can solve problems such as lack of assembly, use strength, reduction of heat engine efficiency of internal combustion engines, difficulty in making and using cylinder liners, etc., and reduce heat loss. , Improve heat engine efficiency, increase temperature effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

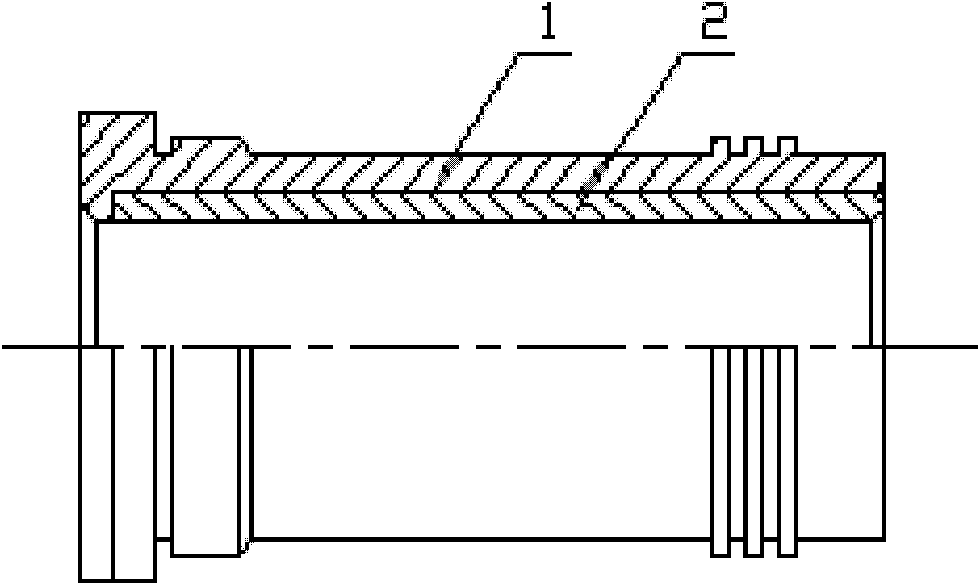

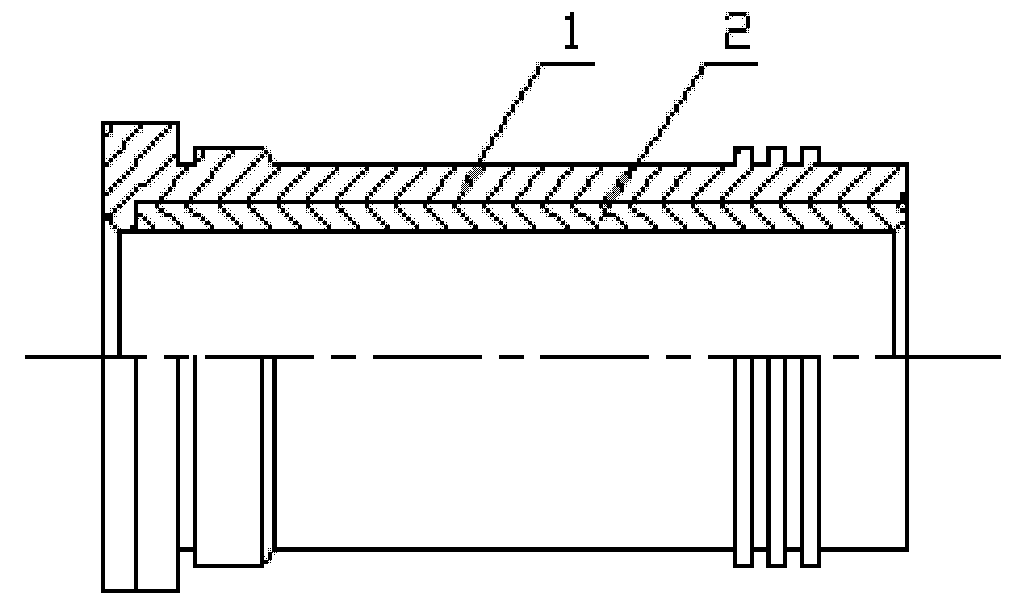

[0024] Such as figure 1 Shown is a composite prestressed ceramic-lined cylinder liner, including a metal jacket 1 and a ceramic lining 2, and the ceramic lining 2 is set inside the metal jacket 1; wherein, the inner diameter of the metal jacket 1 and the outer diameter of the ceramic lining 2 equal, and the machining error of the inner diameter of the metal jacket 1 is a negative error, and the machining error of the outer diameter of the ceramic lining 2 is a positive error; the wall thickness of the metal jacket 1 is greater than the thickness of a conventional metal cylinder liner; the ceramic lining 2 The thickness of the wall is 0.5cm to 1.0cm, and the material is one of ceramics such as silicon nitride ceramics, alumina ceramics or silicon oxide ceramics.

[0025] The manufacture of the above-mentioned composite prestressed ceramic liner specifically includes th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com