Position detecting system for edge of winding-up H-shaped wheel of wire drawing machine and control method thereof

A technology of edge position and detection system, applied in the direction of electrical program control, program control in sequence/logic controller, measuring device, etc., can solve the problems of demanding machining accuracy, low precision, complex structure, etc., and achieve machining accuracy Low requirements, high-precision position detection, and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

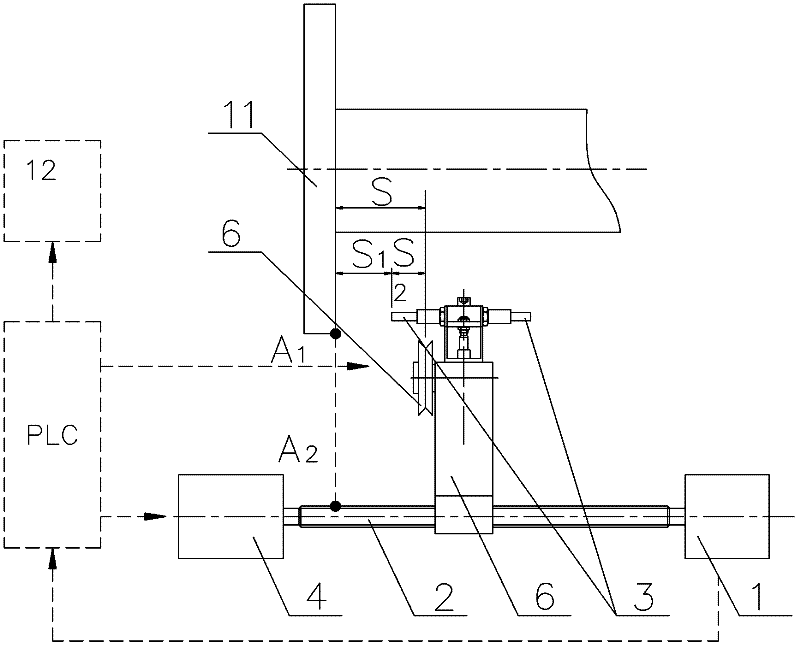

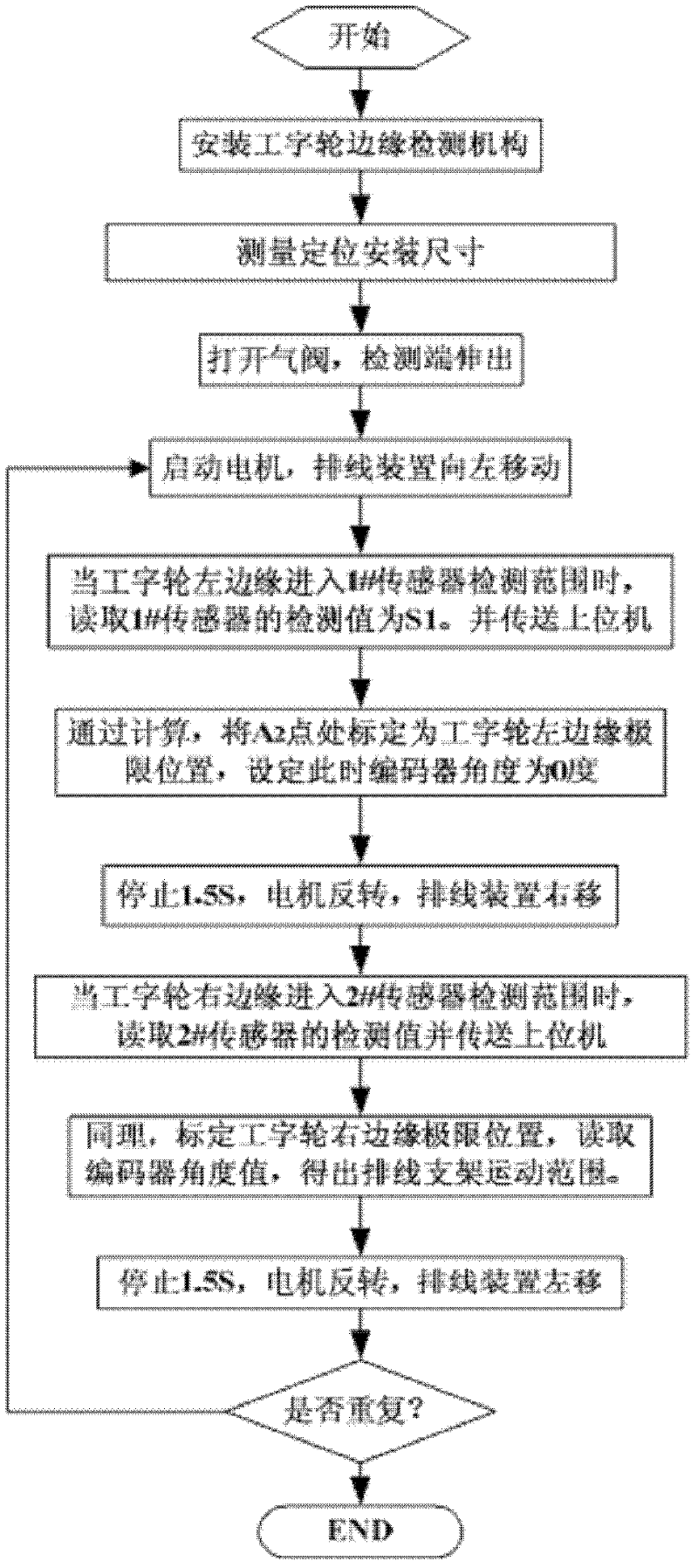

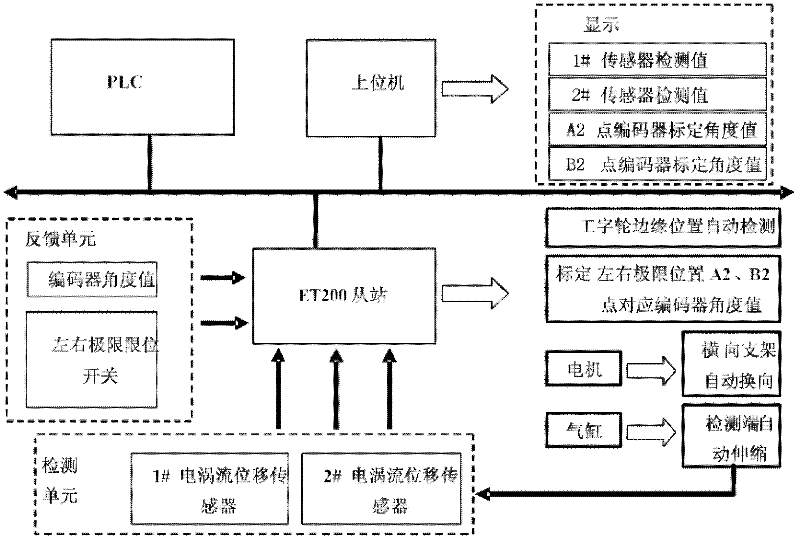

[0041] Such as figure 1As shown, the edge position detection device of the take-up I-shaped wheel includes an encoder, a screw, a displacement sensor, a motor, a bracket, and an I-shaped wheel. The motor is connected with the screw drive, and the support is driven to move laterally through the rotation of the screw. The guide wheel, cylinder, guide rail and slider installed on the guide rail are installed on the support. The position detection end is respectively connected with the front end of the cylinder and the slider. There are two displacement sensors to detect the position of the edge of the I-shaped wheel. The system control is composed of PLC control unit, upper computer display unit, feedback unit, detection unit and output unit. Among them, the PLC control unit is the core of the whole system control; the upper computer displays the detection value of the left and right sensors and the setting value of the encoder; the feedback unit feeds back the information of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com