Automatic plane correction method for intelligent tube plate welding robot based on cross laser

A welding robot and cross laser technology, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., to achieve the effect of improving image processing speed, avoiding external light source interference, and high calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

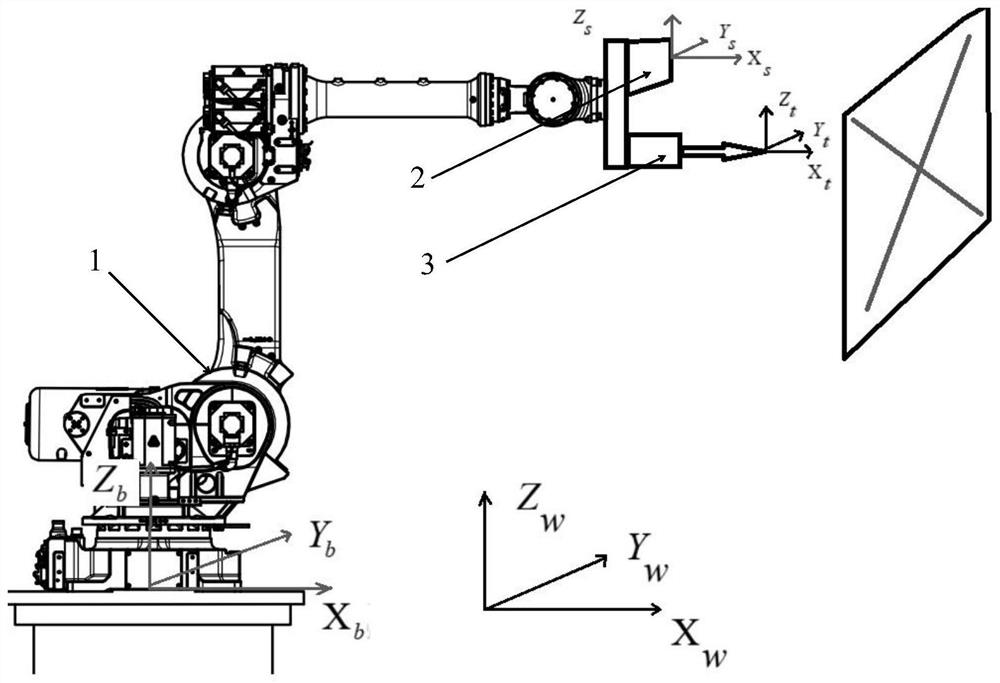

[0031] see Figure 1-3 , the present invention provides a technical solution: an automatic plane correction method for a tube-sheet intelligent welding robot based on a cross laser, comprising the following steps:

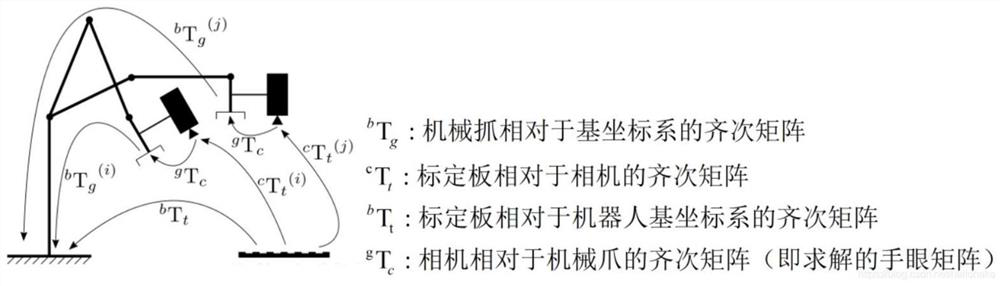

[0032] Step 1: Sensor Calibration, see figure 1 , after the installation of the cross laser three-dimensional measurement sensor 2 is completed, the internal parameters of the camera need to be calibrated, and the internal parameter matrix and distortion parameters of the camera can be obtained. The pictures taken by the camera still have certain distortions, including barrel distortion and pincushion distortion. The model includes radial distortion and tangential distortion, and the radial distortion formula is The formula for tangential distortion is Respectively, the ideal undistorted normalized image coordinates and the distorted normalized image coordinates are the distance from the image pixel to the image center point, namely r 2 =x 2 +y 2 . The seco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com