Aluminum-plastic composite floor with water accumulation prevention and snow melting functions

An aluminum-plastic composite and anti-water technology, which is applied in the direction of elastic floor, floor, covering/lining, etc., can solve the problems of loss of sealing and waterproof effect, softening deformation, etc., so as to prevent delamination, increase contact area, and avoid physical less intense effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

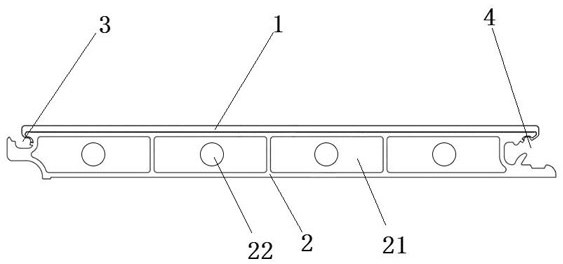

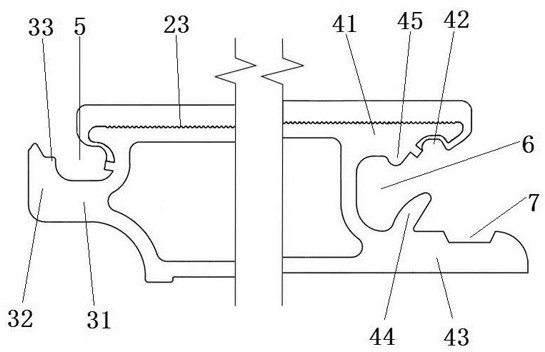

[0039] Such as Figure 1~3 , an aluminum-plastic composite floor with water-repelling and snow-melting functions, comprising a base layer 2 made of aluminum alloy and an elastic surface layer 1 mainly formed of resin attached to the base layer.

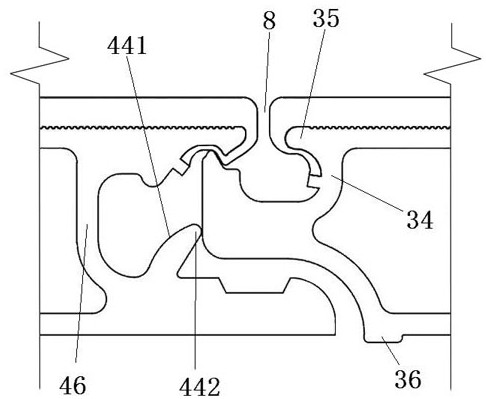

[0040] The two sides of the base layer 2 are respectively the male splicing end set as the male tenon structure 3 and the female splicing end set as the female groove structure 4; when paving, any two adjacent floors in the length direction of the floor pass through the The male tenon structure 3 and the female groove structure 4 are fitly connected, and there is a gap between the upper surfaces of any adjacent two floors to form a water inlet 8; the male tenon structure 3 includes a male tenon body part 31 and a male tenon The main body part 31 is connected to the male joint part 32 which is protruding relative to the male tenon main part 31, and the male tenon main part 31, the male joint part 32 and the side wall 34 of the male spl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com