Manufacturing method of composite sectional bar for door and window

A technology of composite profiles and manufacturing methods, applied in the field of doors and windows, can solve the problems of complex processing, degumming, unfavorable wood protection, etc., and achieve the effects of good flexibility and extensibility, enhanced thermal insulation performance, and excellent chemical adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

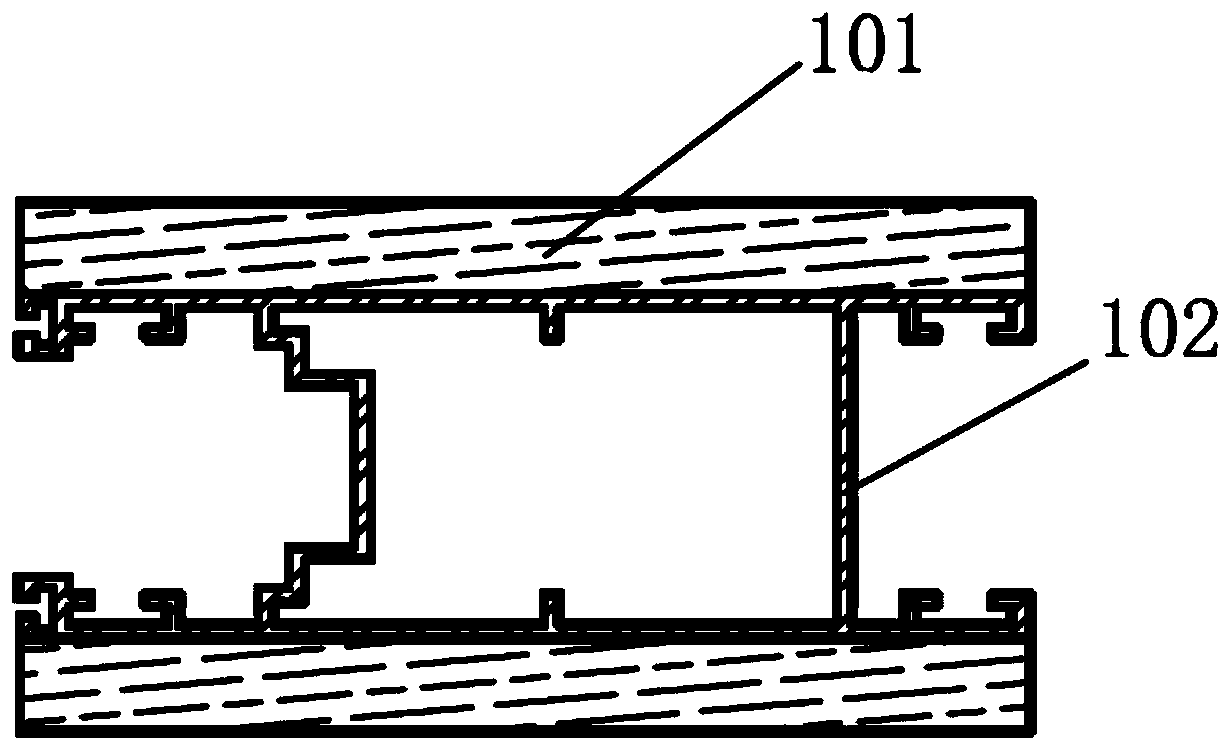

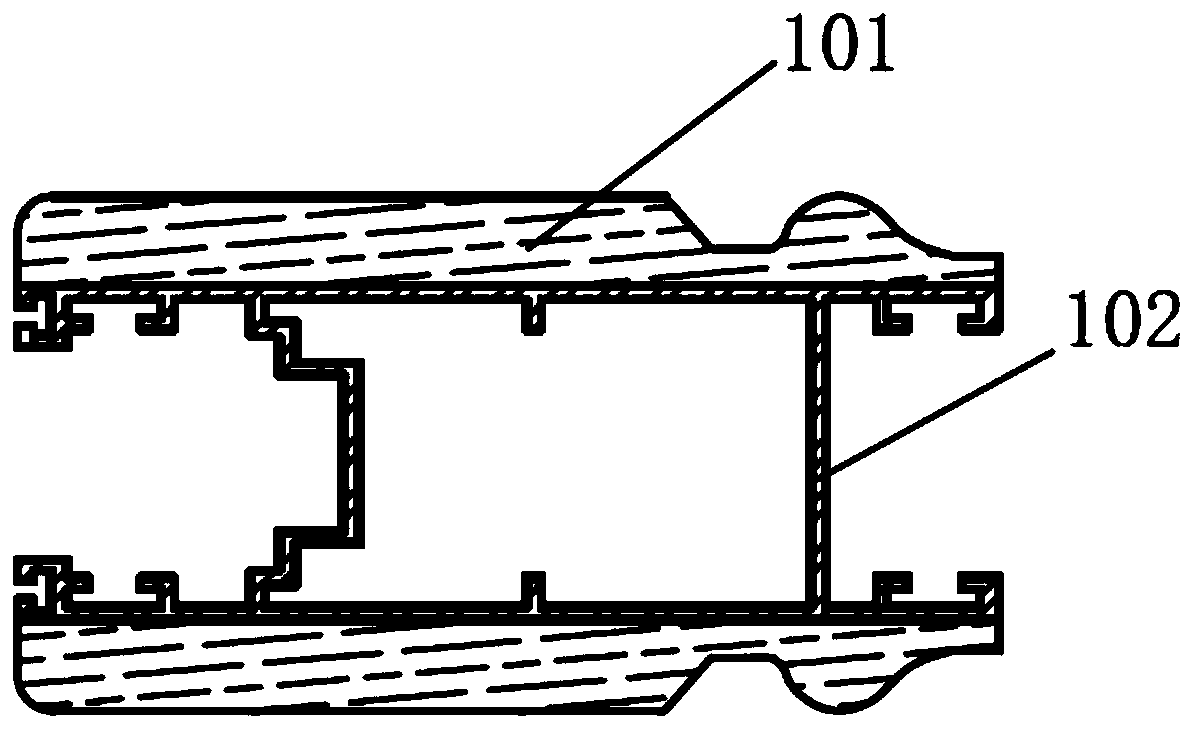

[0064] Fig. 1 (a) has shown the section of a kind of metal profile of this embodiment, and Fig. 1 (b) has shown the group blank structure of this embodiment 1; Fig. 1 (c) has shown the finished product composite of this embodiment Profile diagram. combine Figure 1(a) to Figure 1(c) As shown, this embodiment provides a kind of manufacturing method for the composite profile of door and window, comprises steps:

[0065] Prepare the non-metallic plate 101, wherein the material of the non-metallic plate 101 is wood material or wood composite material;

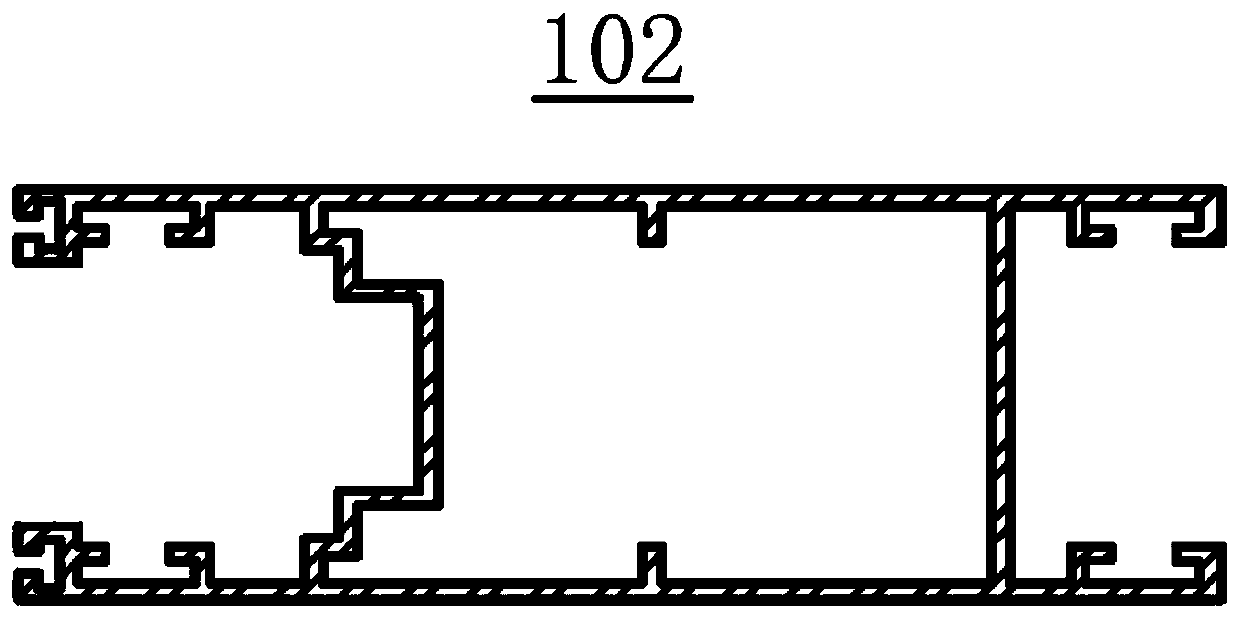

[0066] Prepare the metal profile 102, as shown in Figure 1(a), wherein the material of the metal profile 102 is a light alloy;

[0067] Adhesives are applied to the upper and lower surfaces of the metal profile 102, and the semi-finished composite profile is obtained by grouping according to the preset structure of the blanks, wherein the preset structure of the blanks is that the upper and lower sides of the metal profile 102 ar...

Embodiment 2

[0119] Fig. 2 (a) has shown the cross-section of a kind of metal profile 102 of this embodiment, and Fig. 2 (b) has shown the group blank structure of this embodiment; Fig. 2 (c) has shown the finished composite of this embodiment Profile diagram. combine Figure 2(a) to Figure 2(c) As shown, the present embodiment provides a method for making a composite profile for doors and windows, comprising steps:

[0120] Prepare the non-metallic plate 101, wherein the material of the non-metallic plate 101 is wood material or wood composite material;

[0121] Prepare a metal profile 102, wherein the material of the metal profile 102 is a light alloy;

[0122] Adhesive is applied to the upper surface of the metal profile 102, and the semi-finished composite profile is obtained by grouping according to the preset billet structure, wherein the preset billet structure is that the upper surface of the metal profile 102 is provided with The non-metal plate 101;

[0123] Pressing the semi...

Embodiment 3

[0151] Fig. 3 (a) shows a schematic cross-sectional view of a metal profile of this embodiment; Fig. 3 (b) shows a schematic cross-sectional view of a heat insulating member of this embodiment; Fig. 3 (c) shows a schematic cross-section of a metal profile of this embodiment Schematic diagram of the assembly of the metal profile and the heat insulating member; FIG. 3( d ) shows a schematic diagram of the billet structure of this embodiment; FIG. 3( e ) shows a schematic diagram of the finished composite profile of this embodiment. combine Figure 3(a) to Figure 3(e) As shown, the present embodiment provides a method for making a composite profile for doors and windows, comprising steps:

[0152] Prepare the non-metallic plate 201, wherein the material of the non-metallic plate 201 is wood material or wood composite material;

[0153] Prepare two pieces of metal profiles 202, wherein the material of the metal profiles 202 is light alloy;

[0154] Prepare a heat insulating part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com