Construction method for artificial hole-digging grouting pile

A technology of manual digging and construction methods, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as pile center deviation, weak connection between upper retaining wall and lower retaining wall, complex engineering geology, etc., and reduce construction errors , Improve the strength and improve the effect of safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Example: such as figure 1 Shown, a kind of manual excavation hole filling pile construction method comprises the following steps:

[0027] (1) At the positioning point of the artificially dug hole grouting pile determined by the design, the hole shall be dug manually. When the depth reaches 0.8m-1m, the reinforced concrete well circle shall be poured, and the top surface of the well circle shall be 100mm-150mm higher than the site.

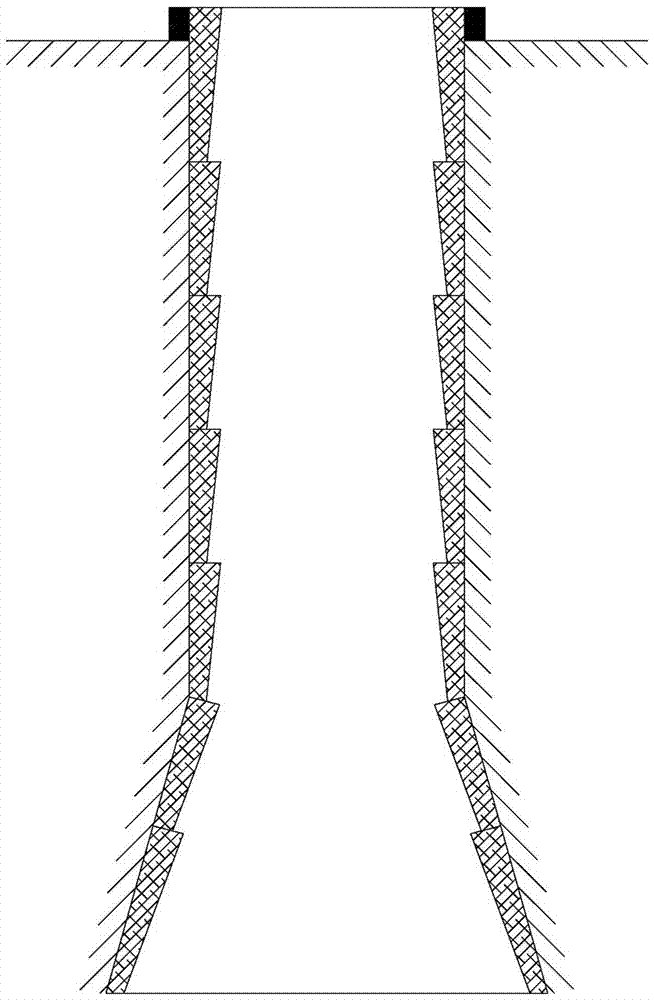

[0028] (2) For the construction of pile hole wall protection, the wall protection formwork is installed every time the pile hole is dug 1 meter deep. The wall protection formwork is repeatedly used by removing the upper section and supporting the lower section. The small end of the formwork is on the top, and the big end is on the bottom. When the retaining wall formwork is installed, the concrete retaining wall is poured.

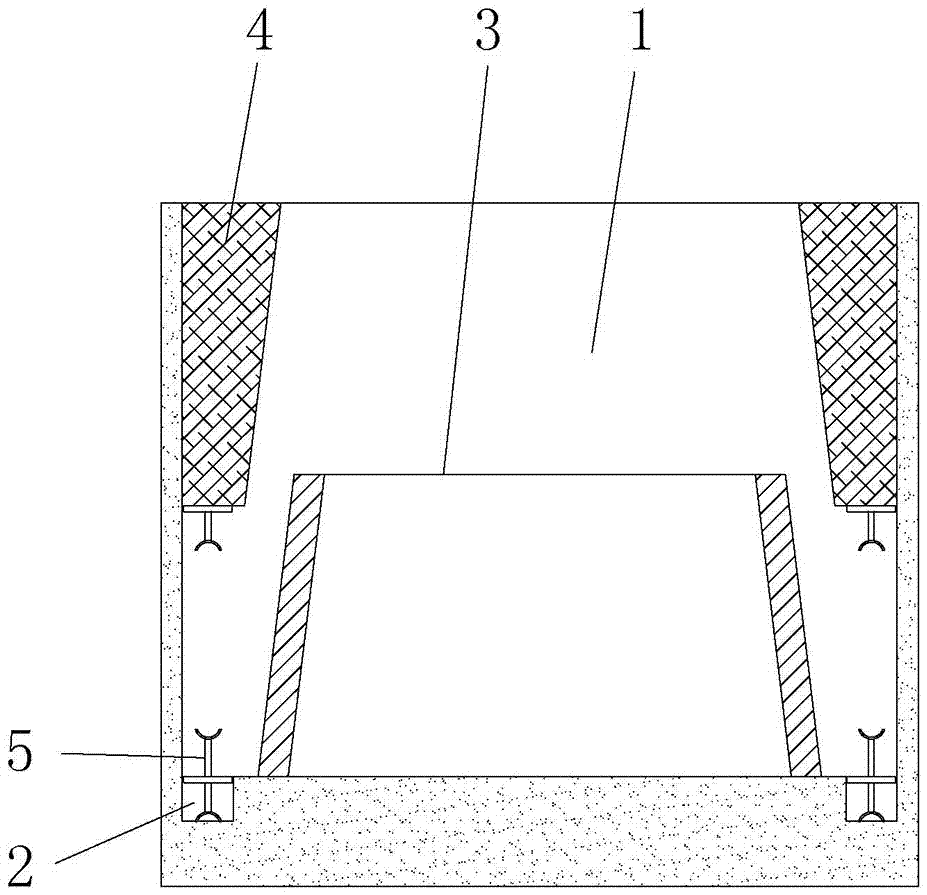

[0029] like figure 2 As shown, before installing the retaining wall template, a trench 2 is excavated downward at ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com