Wind electricity tower spoiler

A technology for wind power towers and spoilers, which is applied in wind power generation, wind engines, machines/engines, etc. It can solve the problems of limited service life, inability to use, and difficulty in installation, so as to prevent paint damage and reduce The effect of the number of molds and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

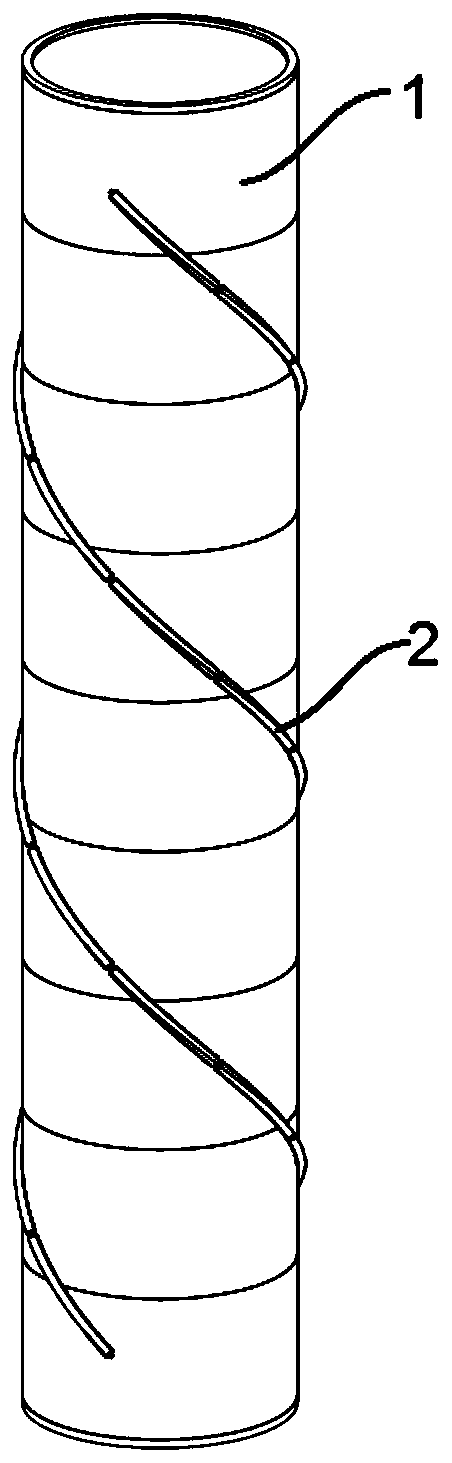

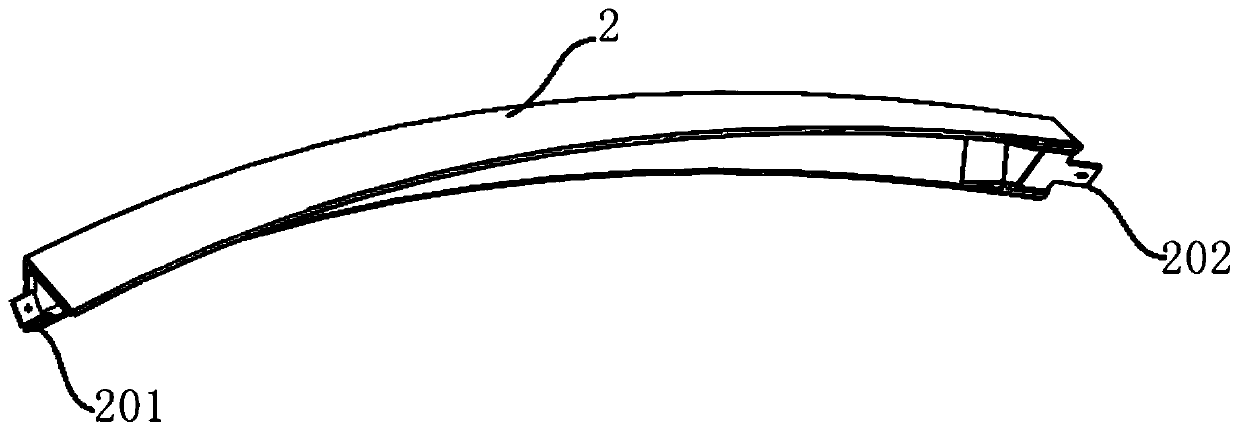

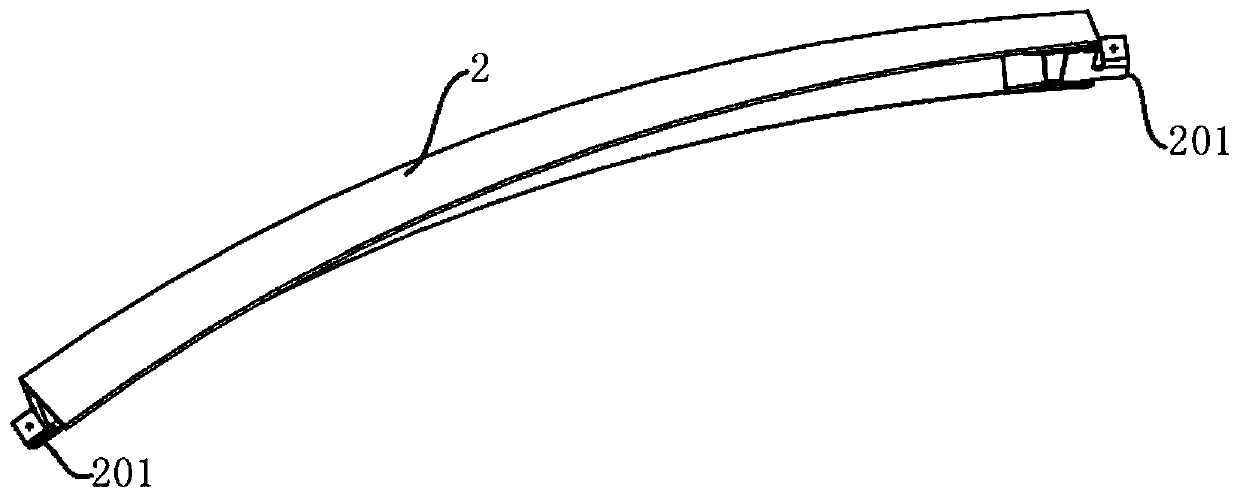

[0034] Such as Figure 1 to Figure 6 As shown, the wind power tower spoiler described in this embodiment is composed of a plurality of spoiler units 2, and the plurality of spoiler units 2 are connected in sequence to form a continuous helical line arranged on the wind power tower 1 on the outer wall (2 to 4 strands can be installed according to the actual situation, figure 1 is the effect of two strands), and is fixed on the outer wall of the wind power tower 1 through the spoiler unit 2 at the end, and the helical structure spoiler "breaks up" and "disturbs" the airflow flowing through the tower, so that Its back flow surface will not produce regular shedding vortices to destroy the components of the Karman vortex street, thereby preventing vortex-induced resonance during the entire life cycle of the fan. The pitch of the continuous helix is 2D to 5D, where D is Outer diameter of the tower tube 1, wherein the material of the spoiler unit 2 is one of glass fiber resin comp...

Embodiment 2

[0038] Such as Figure 7 As shown, the difference between the structure of this embodiment and the first embodiment is that a plurality of spoiler units 2 form a discontinuous helix and are arranged on the outer wall of the wind power tower 1, that is, each spoiler unit 2 is independently fixed on the outer wall of the wind power tower 1, and the distance between two adjacent spoiler units 2 is set.

Embodiment 3

[0040] Such as Figure 8 As shown, the structure of this embodiment is similar to Embodiment 1, the difference is that every 2 to 10 spoiler units 2 are connected into a group, and multiple groups of spoiler units 2 form a non-continuous helical row It is arranged on the outer wall of the wind power tower 1, and a distance is kept between two adjacent groups.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com