Liquid crystal glass packaging device

A technology for liquid crystal glass and packaging, which is applied in packaging, transportation and packaging, and packaging of vulnerable items. It can solve the problems of unfavorable energy saving and emission reduction, high cost, increased material cost and mold opening cost, etc., and achieves exquisite structural design. Production cost reduction, effect of reduced quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Preferred embodiments of the present invention will be described below with reference to the accompanying drawings.

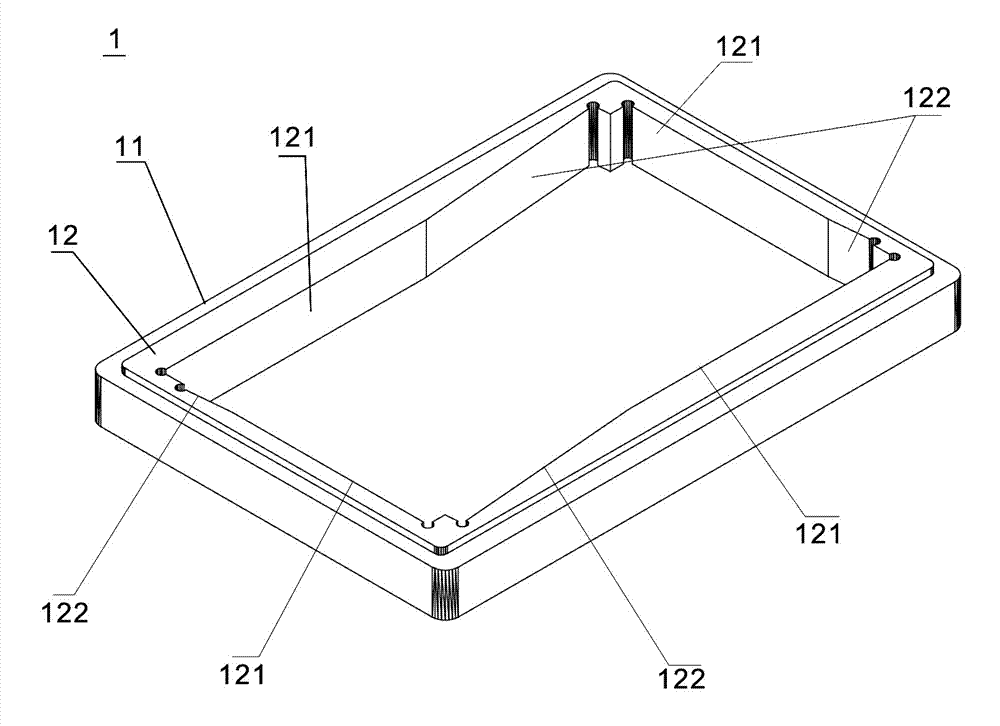

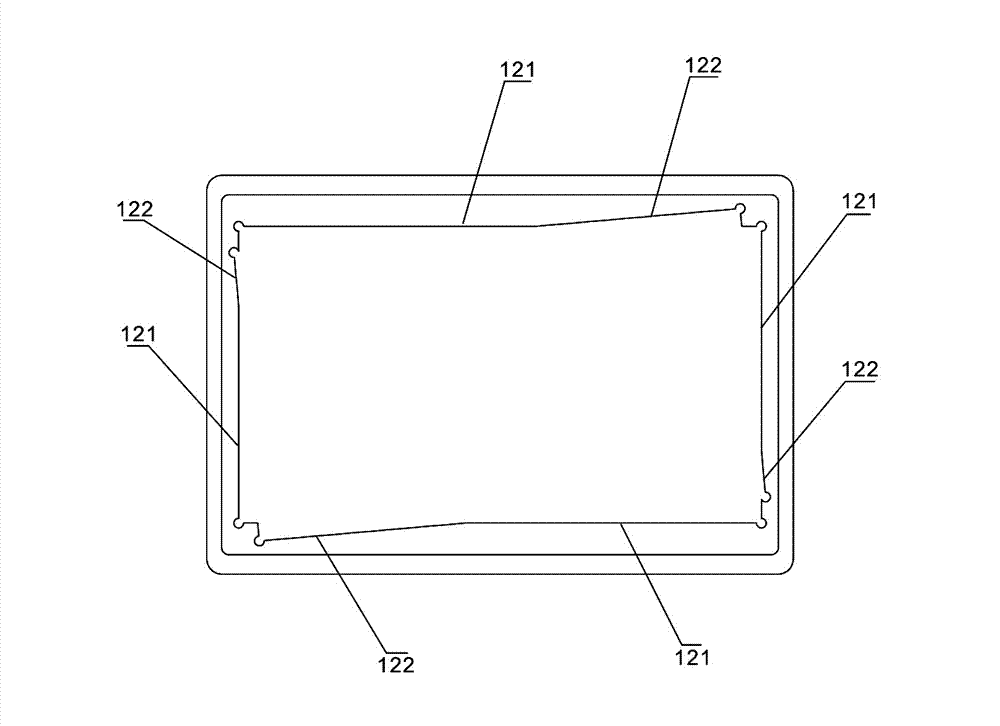

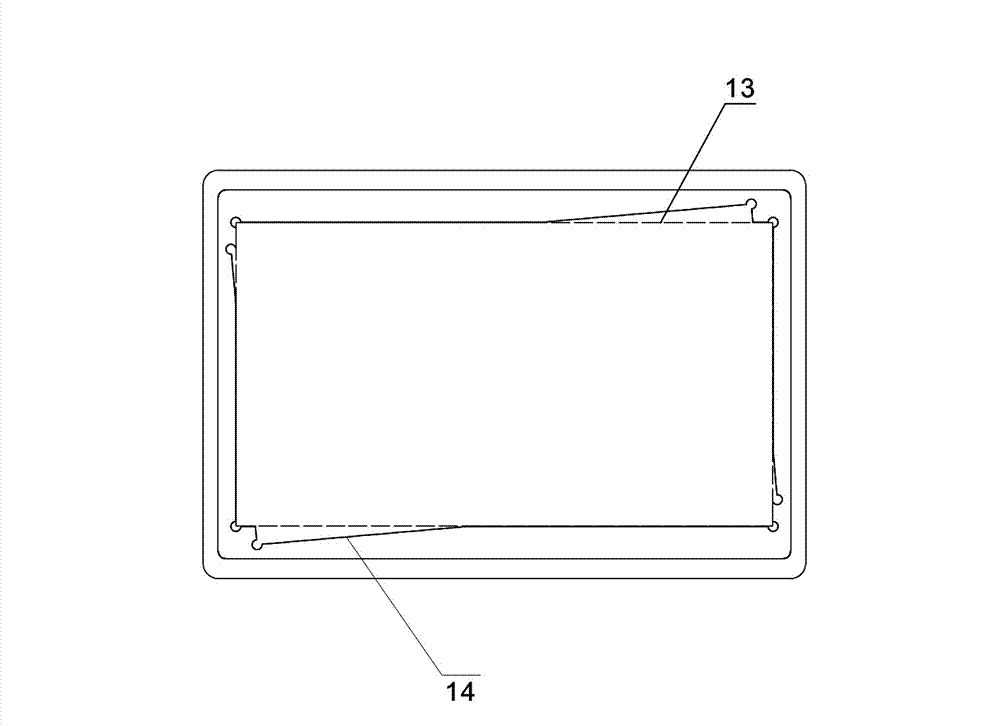

[0022] The embodiment of the present invention provides a liquid crystal glass packaging device, which is used to contain liquid crystal glasses of various sizes, including: a box body 1 and a box cover 2 correspondingly covered on the box body 1, and the box body 1 includes: an outer box 11 and the inner box 12 arranged in the outer box 11, the inner box 12 is provided with a plurality of assembly chambers that can accommodate liquid crystal glasses of various sizes, and the plurality of assembly chambers at least include the first assembly chamber 13 and the second assembly chamber 14; wherein,

[0023] The first assembly chamber 13 is formed by a plurality of first inner box walls 121 on the inner box 12, and the second assembly chamber 14 is formed by a plurality of second inner box walls 122 on the inner box 12;

[0024] The first assembly chamber 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com