Universal prefabricated concrete wallboard mold

A technology of prefabricated concrete and moulds, which is applied in the direction of moulds, mold fixing devices, mold auxiliary parts, etc., can solve the problems of inconvenient production, non-universal use, and increased production costs, so as to save production costs, improve flexibility and versatility, and improve quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

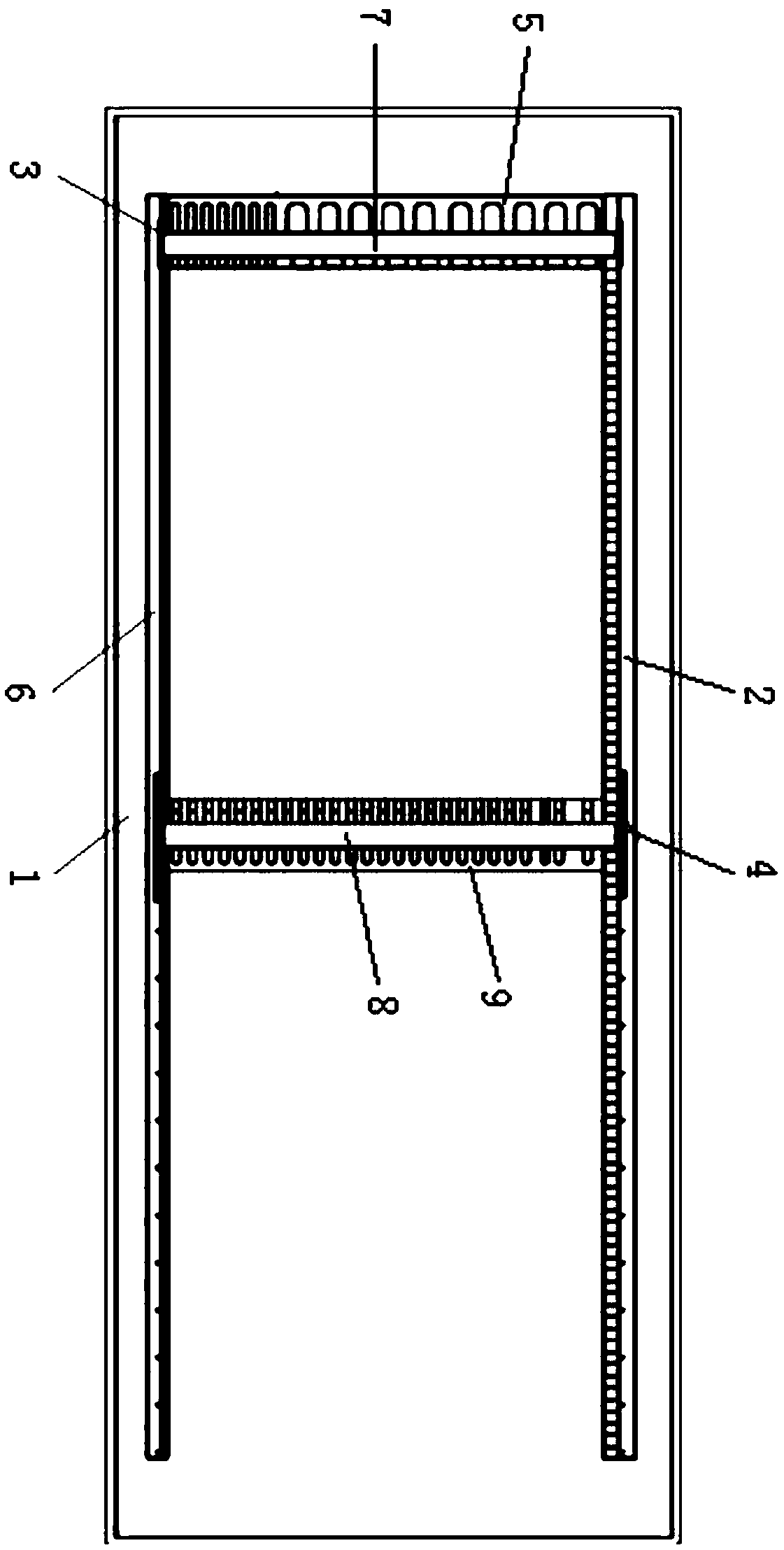

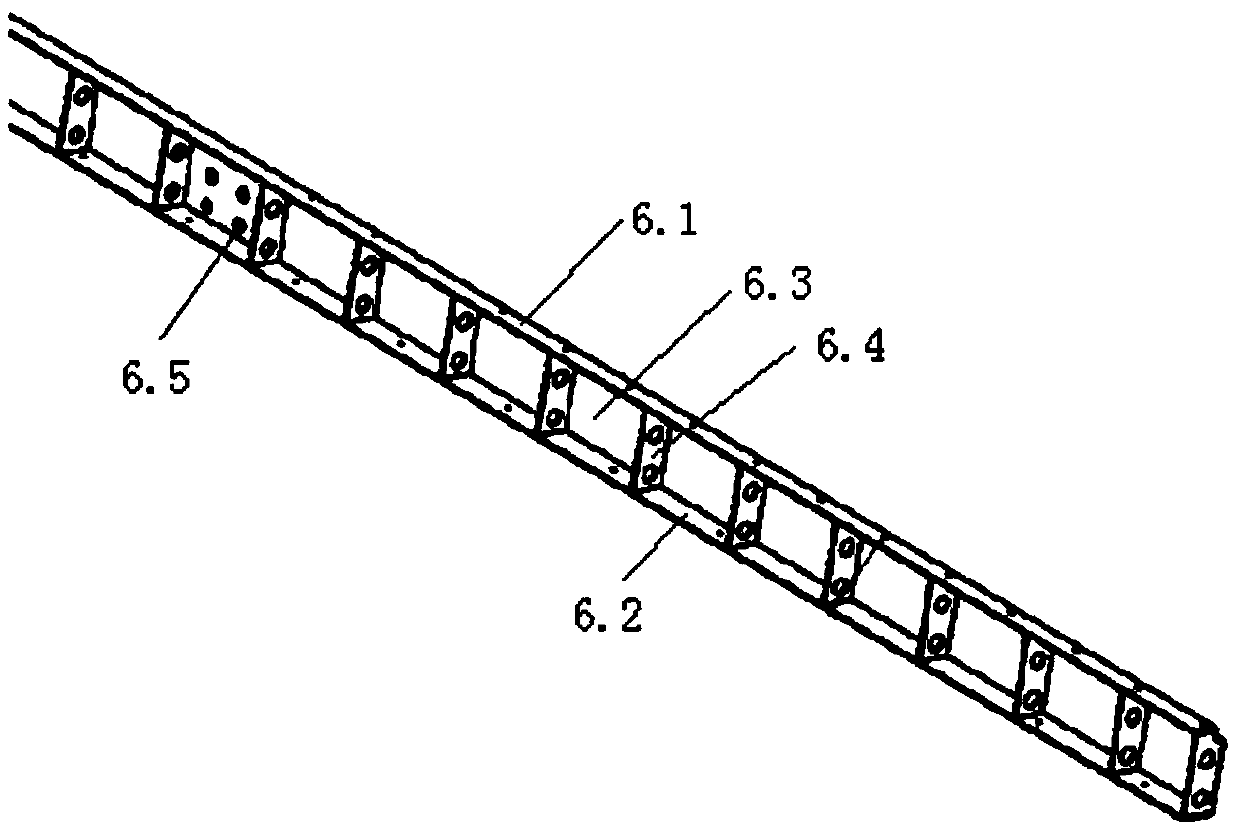

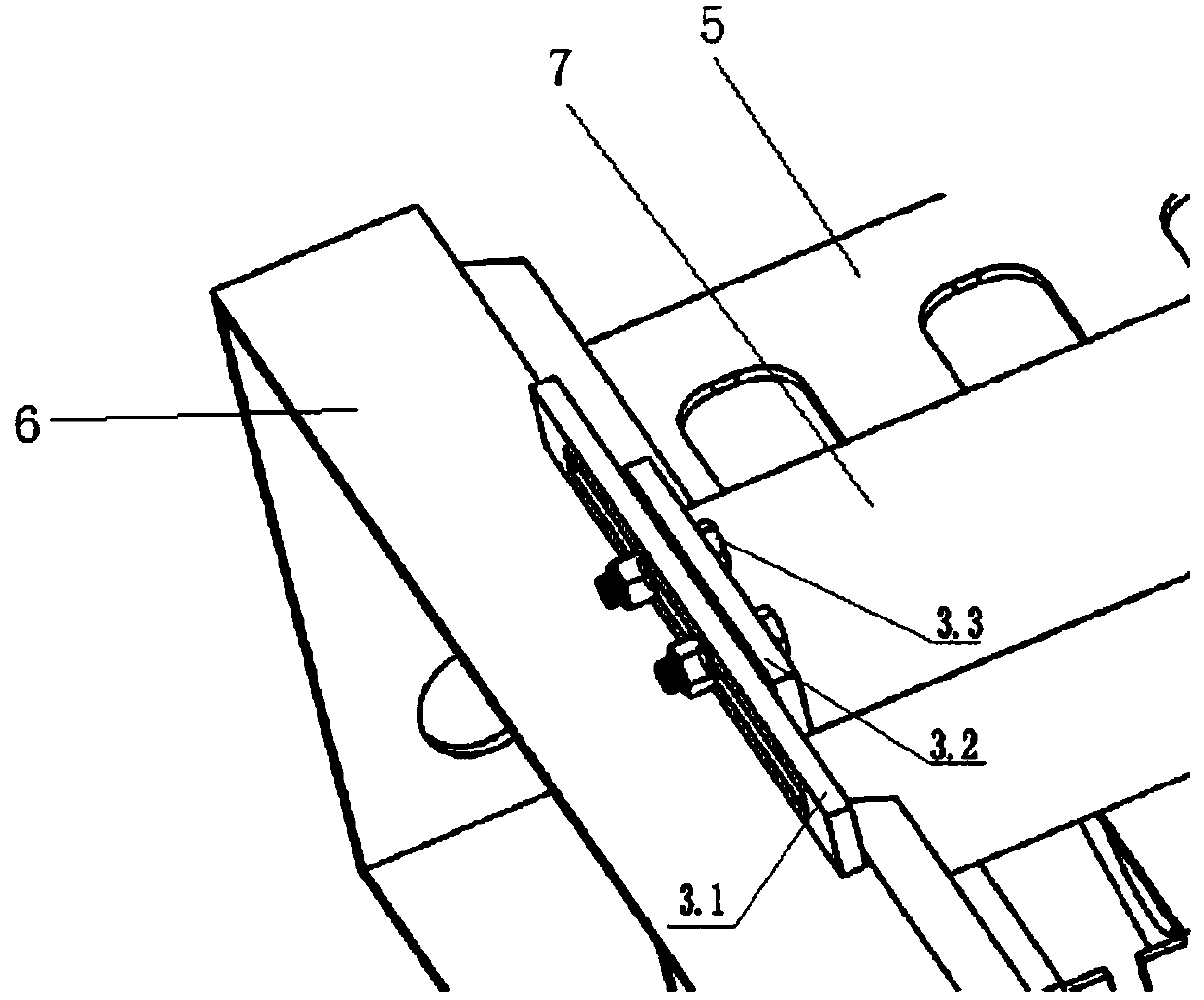

[0024] like figure 1 A general prefabricated concrete wall panel mold is shown, including a mold table 1, a front formwork 2, a rear formwork 6, a left formwork and a right formwork, and the front formwork 2 and the rear formwork 6 are relatively arranged and fixed to the formwork by bolts 1, the left template and the right template are respectively movably installed between the front template 2 and the rear template 6, and the right template can slide along the length direction of the front template 2 / back template 6; the front template 2, the rear template 6, the left The template and the right template are enclosed to form a mold cavity.

[0025] Preferably, the left formwork includes a left lower formwork 5 and a left upper formwork 7, the left lower formwork 5 is fixedly connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com