Method for producing single-pump body multi-flux submersible pump

A production method and submersible pump technology, which are applied to parts, pumps, and pump devices of elastic fluid pumping devices, can solve problems such as complex processing and management processes, reduce the number of molds, reduce production costs, Manage Simplified Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

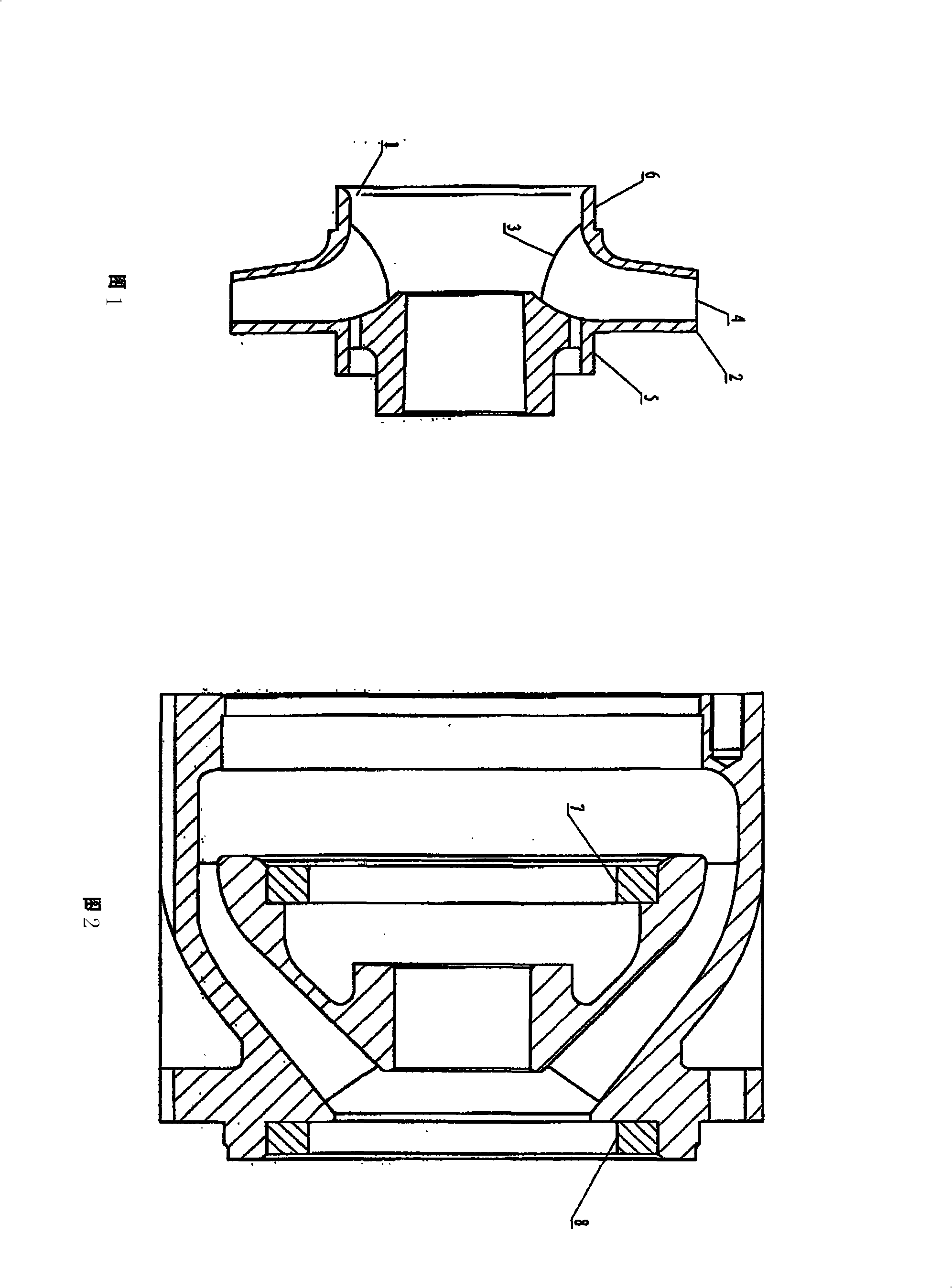

Image

Examples

Embodiment 1

[0017] Embodiment 1, the design of impeller

[0018] impeller design

[0019] The design idea is to solve the Euler equation: Ht∞=1 / g(μ 2 Cμ 2 -μ 1 Cμ 1 )

[0020] In the formula: Ht∞------------Theoretical head when the number of pump blades is infinite

[0021] mu 2 ------------Circumferential linear velocity at the largest outer diameter of the impeller outlet

[0022] Cμ 2 -----------Impeller with infinite number of blades and outlet peripheral velocity

[0023] mu 1 --------------- impeller inlet circumferential speed

[0024] Cμ 1 ------------- Inlet circumferential component velocity when the number of impeller blades is infinite

[0025] The whole process of solving Euler's equation is to design the impeller. The main requirement is to solve the parameters, and design the flow field with the graphic method, so that the flow law has a good curve, so that the actual impeller can be designed. The preliminary design is corrected by u...

Embodiment 2

[0026] Example 2: Realization of traffic transformation

[0027] In the process of water pump manufacturing, the adjustment of the impeller does not need to produce a batch of design, but after the design is completed, the impeller is finalized and produced according to the design result. In the assembly process, according to the actual flow needs, select the appropriate impeller and install it in the general pump casing, that is, choose a larger impeller when producing a pump with a larger flow rate, and select a smaller impeller when producing a pump with a smaller flow rate. Complete the production of water pumps with different flow rates. In this way, the production of water pumps requires fewer specifications of the pump casing and more specifications of the impellers, so that when pumps with different flow rates are required for the same well diameter, the same pump casing can be used to replace different impellers. For example: the water pump of model 250QJT80 was orig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com