Integrated gas dispenser detection device through standard meter method

A detection device, a technology of standard table method, applied in mechanical equipment, container filling method, container discharge method, etc., can solve the problems of inability to verify the gas dispenser in the laboratory, narrow flow device range, verification and other problems, and achieve easy operation and reliability. Controllability and accuracy, avoid inconvenience of operation, enhance the effect of flow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

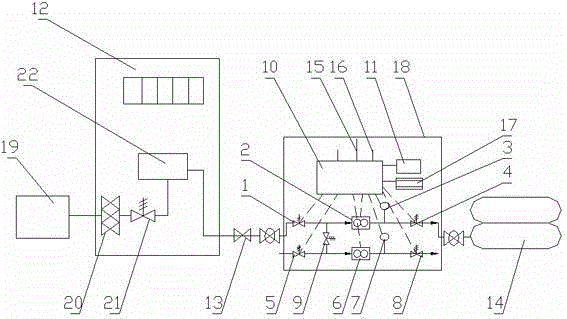

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0024] Such as figure 1 As shown, the integrated standard table method gas filling machine detection device includes gas filling machine inlet valve 1, flow meter I2, gas filling machine pipeline pressure sensor 3, gas filling machine outlet valve 4, gas filling column inlet valve 5, Flow meter Ⅱ6, pressure sensor 7 of gas filling column pipeline, gas filling column outlet valve 8, intake switching valve 9, embedded ARM main board 10, LCD display 11, box body 18 and lithium battery with external charging power supply (in the figure not shown). In this embodiment, flowmeter I2 and flowmeter II6 use CNG050 mass flowmeters. The lithium battery is placed in an explosion-proof box, explosion-proof box, gas dispenser inlet valve 1, flow meter Ⅰ2, gas dispenser pipeline pressure sensor 3, gas dispenser outlet valve 4, gas column inlet valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com