Inner/outer opening heat insulation broken bridge window screen integrated window

A heat-insulating broken bridge, integrated technology, applied in door/window applications, soundproof doors/windows, windows/doors, etc., can solve the problem that the K value coefficient cannot meet the national standard, cannot realize the conversion of internal and external openings, and increase the cost of enterprise stocking and other issues, to achieve the effect of reducing the number of molds and design costs, improving economic benefits, and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

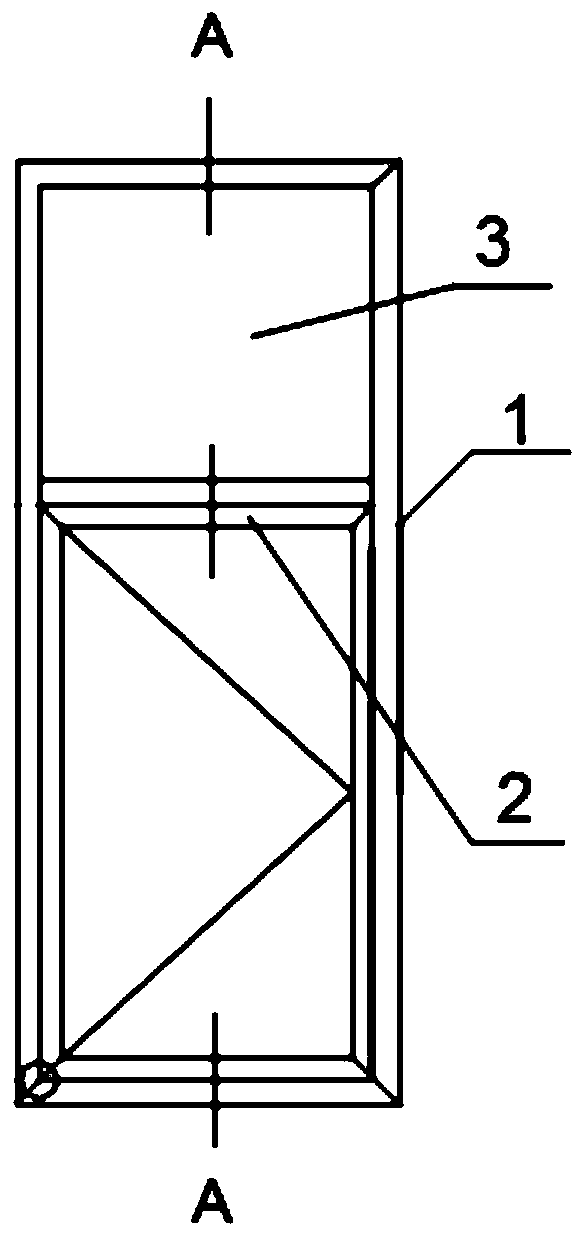

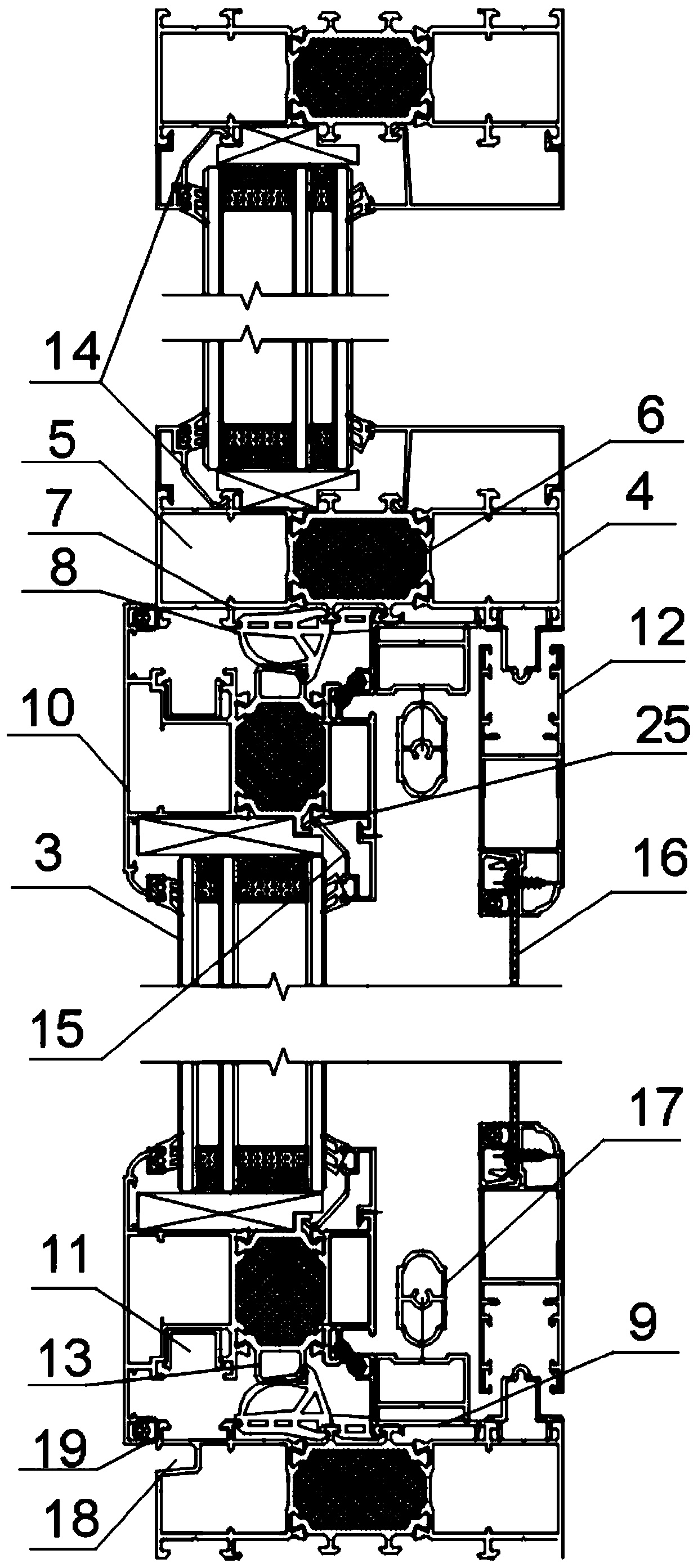

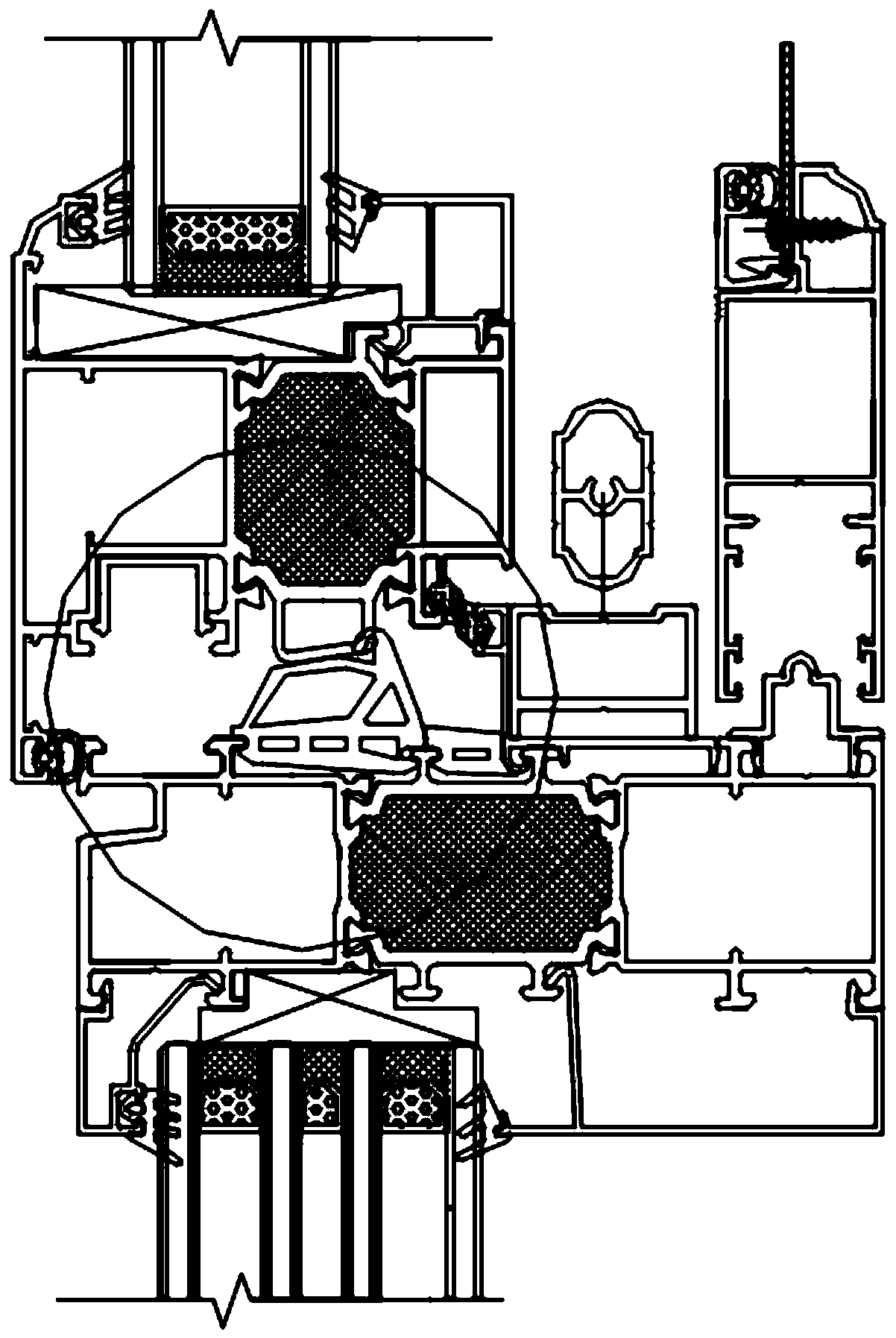

[0044] figure 1 and figure 2As shown, the integrated window of the present invention includes a frame 1 and a middle stile, and the frame is surrounded by upper and lower frames and left and right frames, wherein the frame and the middle stile are spliced by the inner frame profile 4, the outer frame profile 5 and the middle heat insulating strip 6 Forming, the frame and the middle stile adopt the same profile, and the inner frame profile, outer frame profile, and middle heat insulation strip are horizontally and vertically symmetrical to the center of the middle heat insulation strip, and the inner frame profile, outer frame profile and middle heat insulation strip are stuck together. There are equal pressure rubber strips 8 and inner / outer opening conversion parts 9 between the grooves. The equal pressure rubber strips 8, inner / outer opening conversion parts 9 and the inner / outer frame profiles and heat insulation strips form symmetrical slots with the same size. The / ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com