Insulated framework, motor stator and motor

A technology of insulating frame and motor stator, which is applied in the direction of electrical components, electromechanical devices, electric components, etc., can solve the problem that the insulating frame cannot realize stator winding in series and parallel at the same time, so as to reduce the probability of confusion, reduce costs, and reduce development. The effect of modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

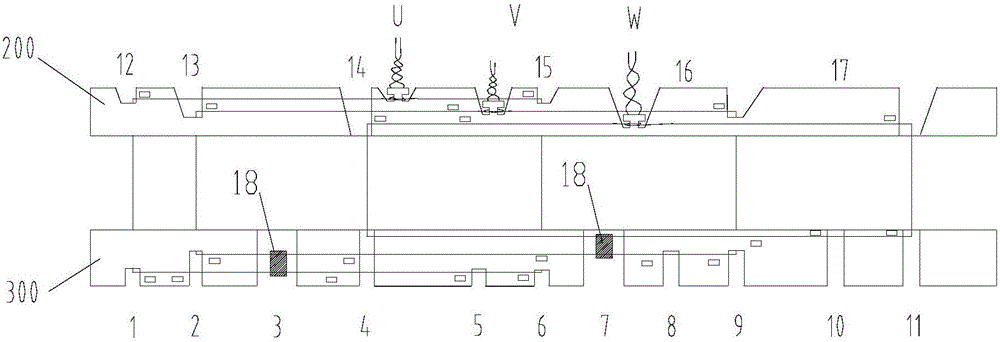

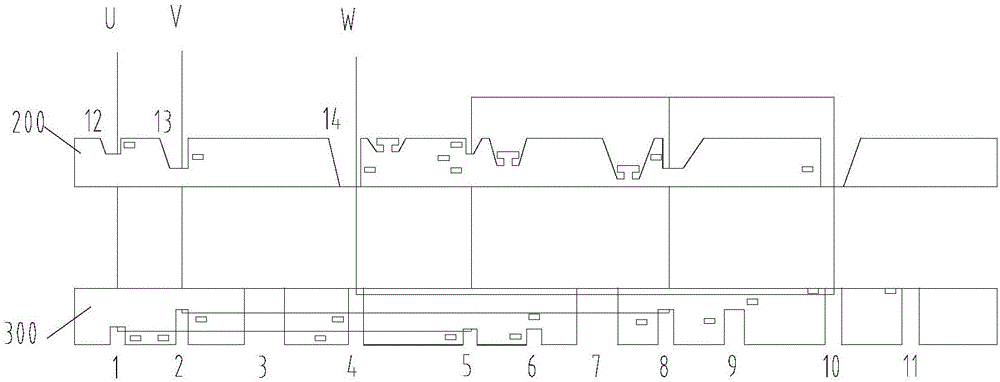

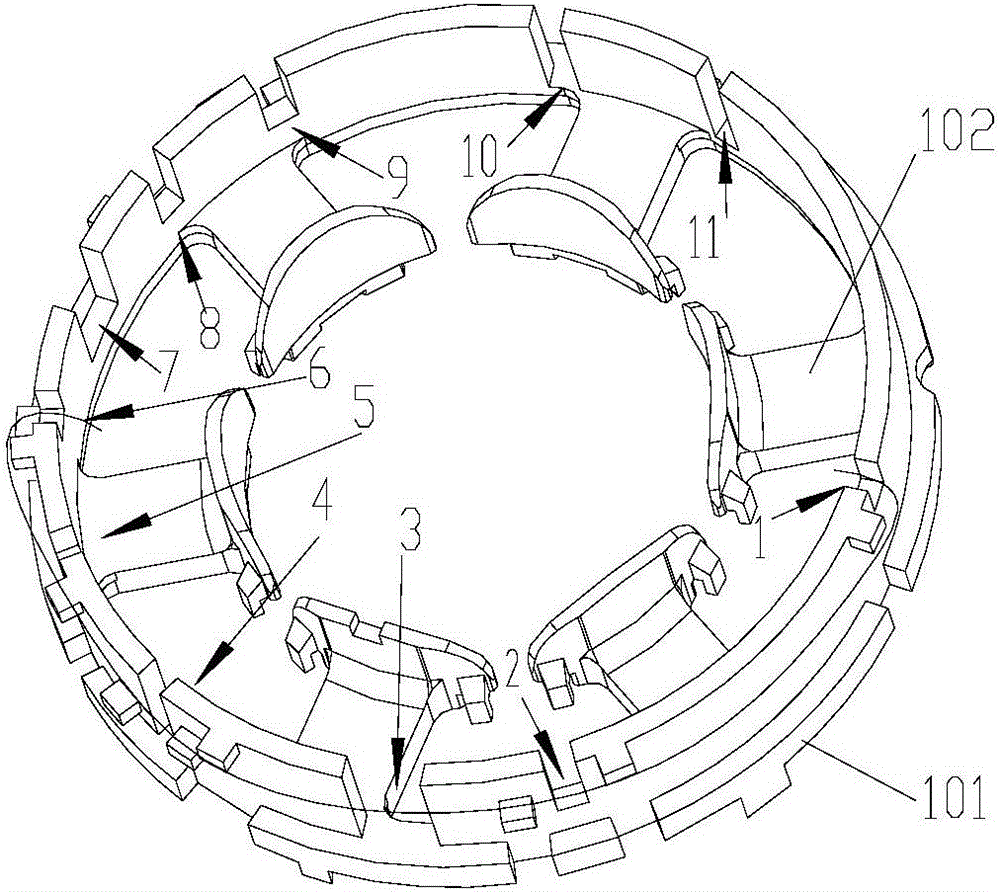

[0036] Such as Figure 1-9 As shown, the present invention provides an insulating frame, which includes an annular portion 101, a plurality of radially arranged tooth portions 102 protruding from the inner wall of the annular portion, wherein on the annular portion 101, a plurality of the tooth portions At least one of the 102 is provided with open grooves on both sides of the circumferential direction where it meets the annular part 101, and at least one of the teeth of the teeth with open grooves on both sides of the circumferential direction has two circumferential sides. The structure of the open groove on the side is the same.

[0037] 1. In the insulating framework of the present invention, the structure of the open grooves on both sides of the circumferential sides of at least one tooth portion of the tooth portion having open grooves on both sides in the circumferential direction is the same, so that one of the two above-mentioned open grooves can be adjusted as needed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com