Electric heating water boiler

A technology of electric water boiler and electric heating tube, which is applied in the direction of fluid heater, lighting and heating equipment, etc., which can solve the problems of inability to drink tea, inability to realize instant heating, and affecting drinking of boiled water, so that it is not easy to burst and be affected. Low coefficient of thermal expansion, excellent taste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

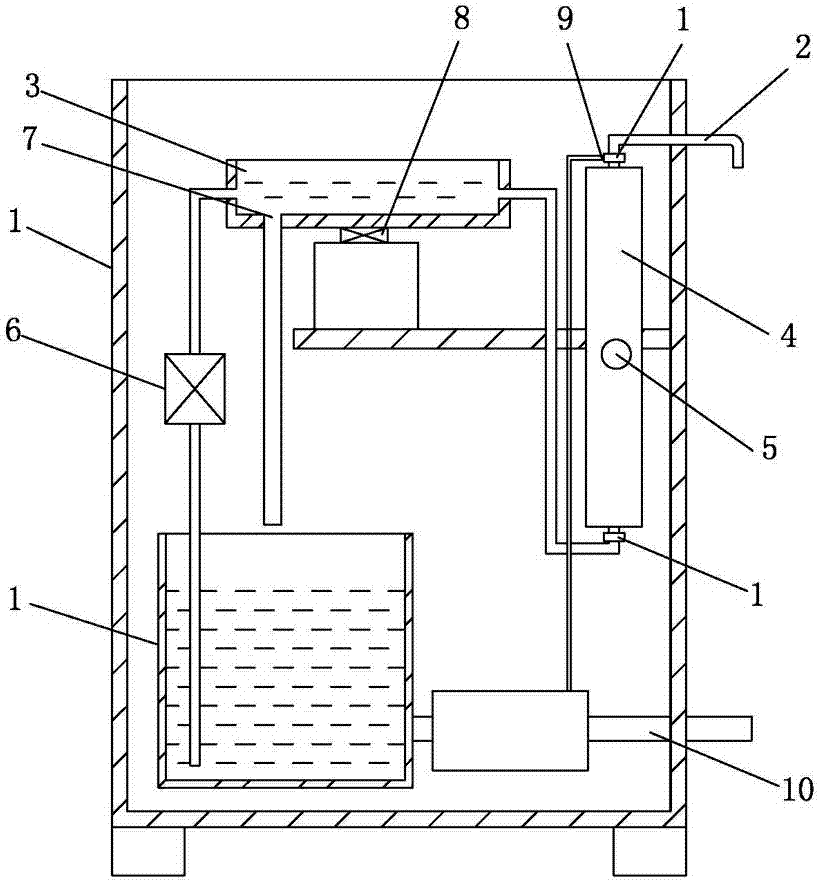

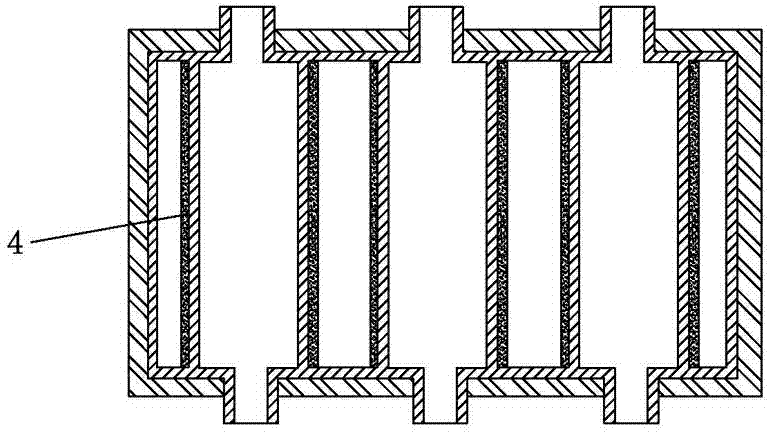

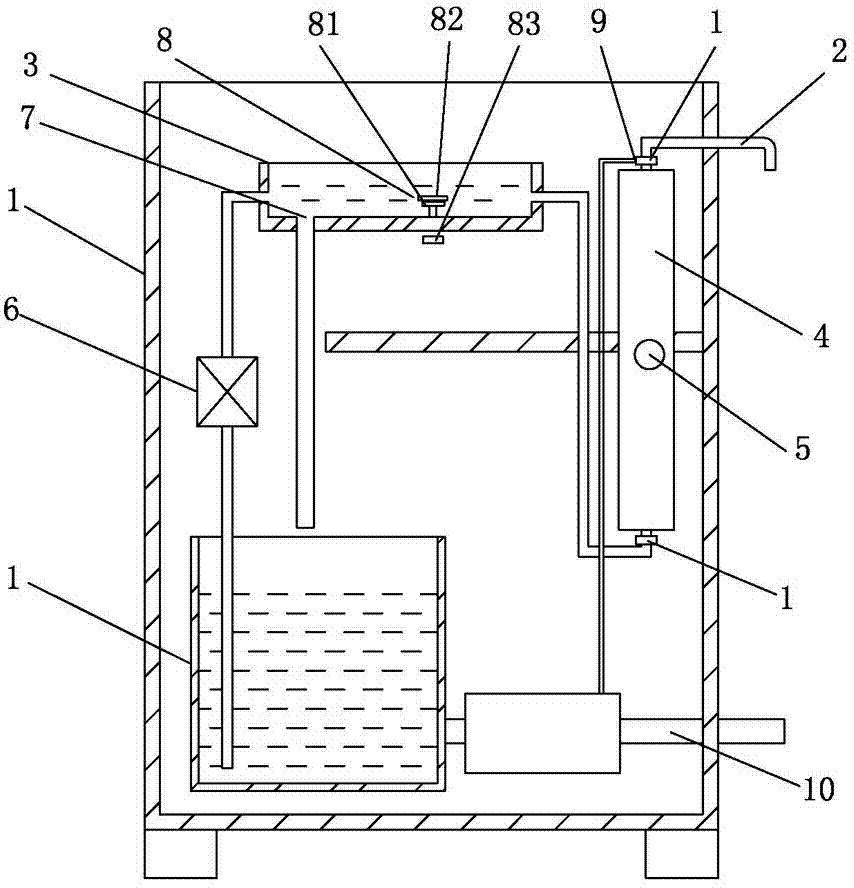

[0028] Such as Figure 1 to Figure 2 As shown, an electric water boiler includes a water storage tank 1 and a water outlet 2, and is characterized in that it also includes a balance water tank 3 and a glass-coated electric heating tube 4, the water outlet of the water storage tank 1 is connected to the water inlet of the balance water tank 3, and the balance The water inlet of the water tank 3 is connected to the water inlet of the glass-coated electric heating tube 4, and the water outlet 2 is connected to the water outlet of the glass-coated electric heating tube 4, and a temperature controller and / or a fuse to prevent dry burning are installed beside the glass-coated electric heating tube 4 Device 5; the water level of the balance water tank 3 is lower than the level of the water outlet of the glass-coated electric heating tube 4 by 2mm to 15mm.

[0029] It also includes a water pump 6, the water storage tank 1 is below, the balance water tank 3 is above, and the electric p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com