Gear box structure with variable center distance and method thereof

A technology of gear box structure and center distance, which is applied in the direction of transmission boxes and components with teeth, etc., can solve the problems of insufficient application, reduce storage volume and mold quantity, improve product quality, and enhance competitiveness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

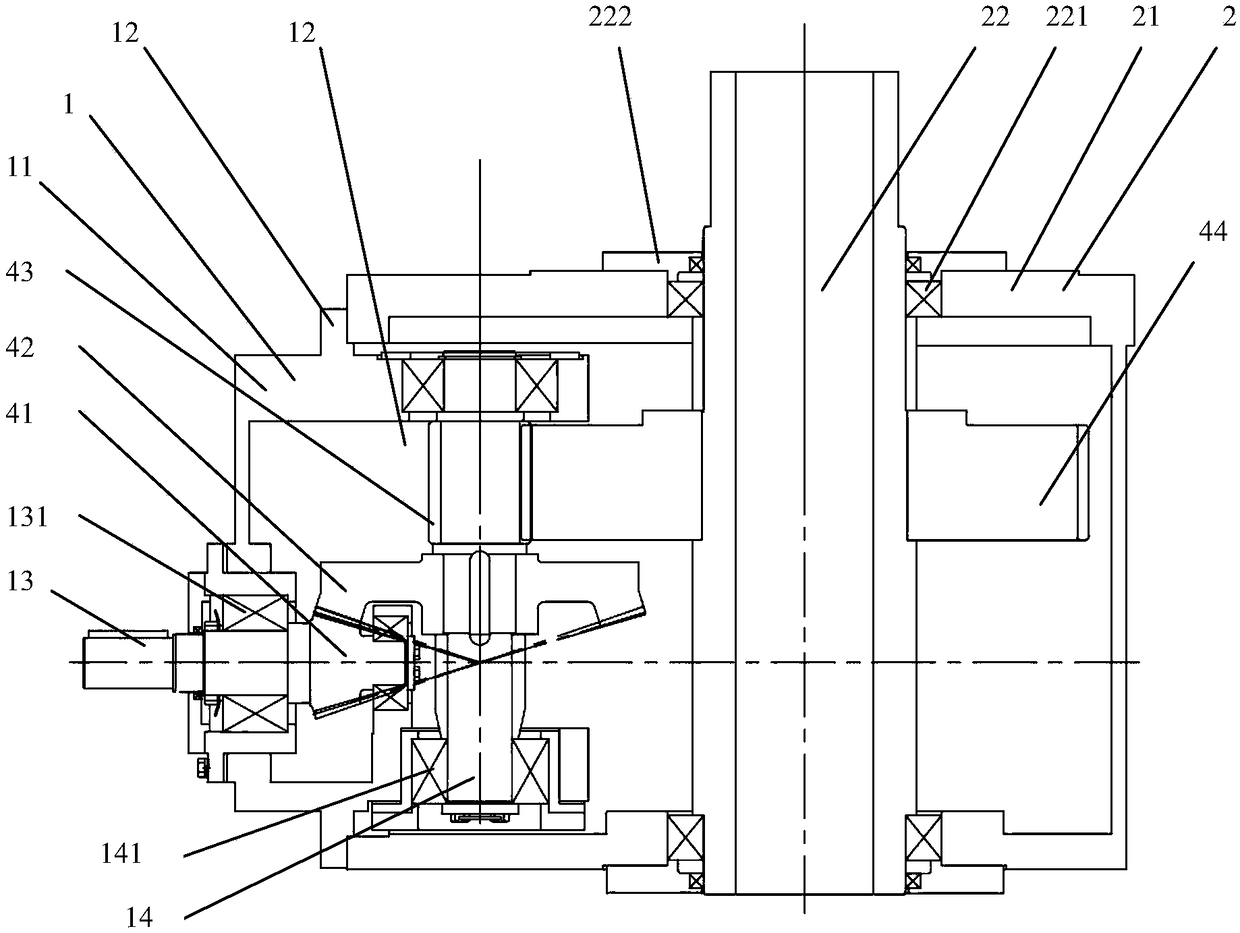

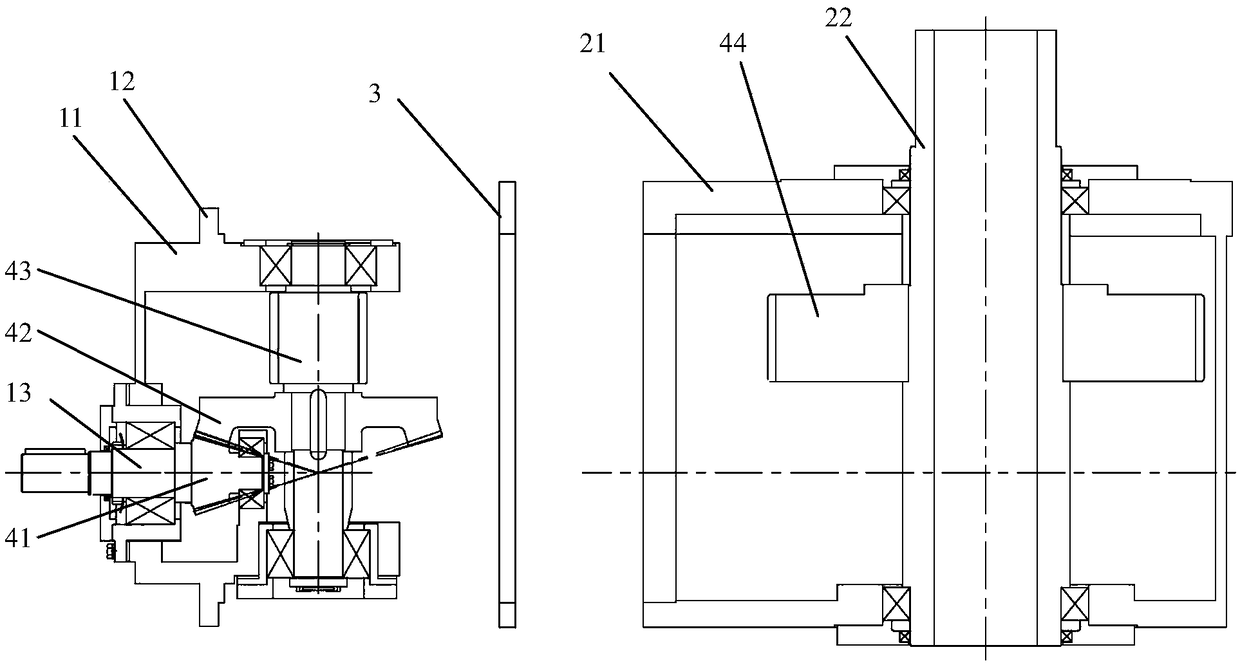

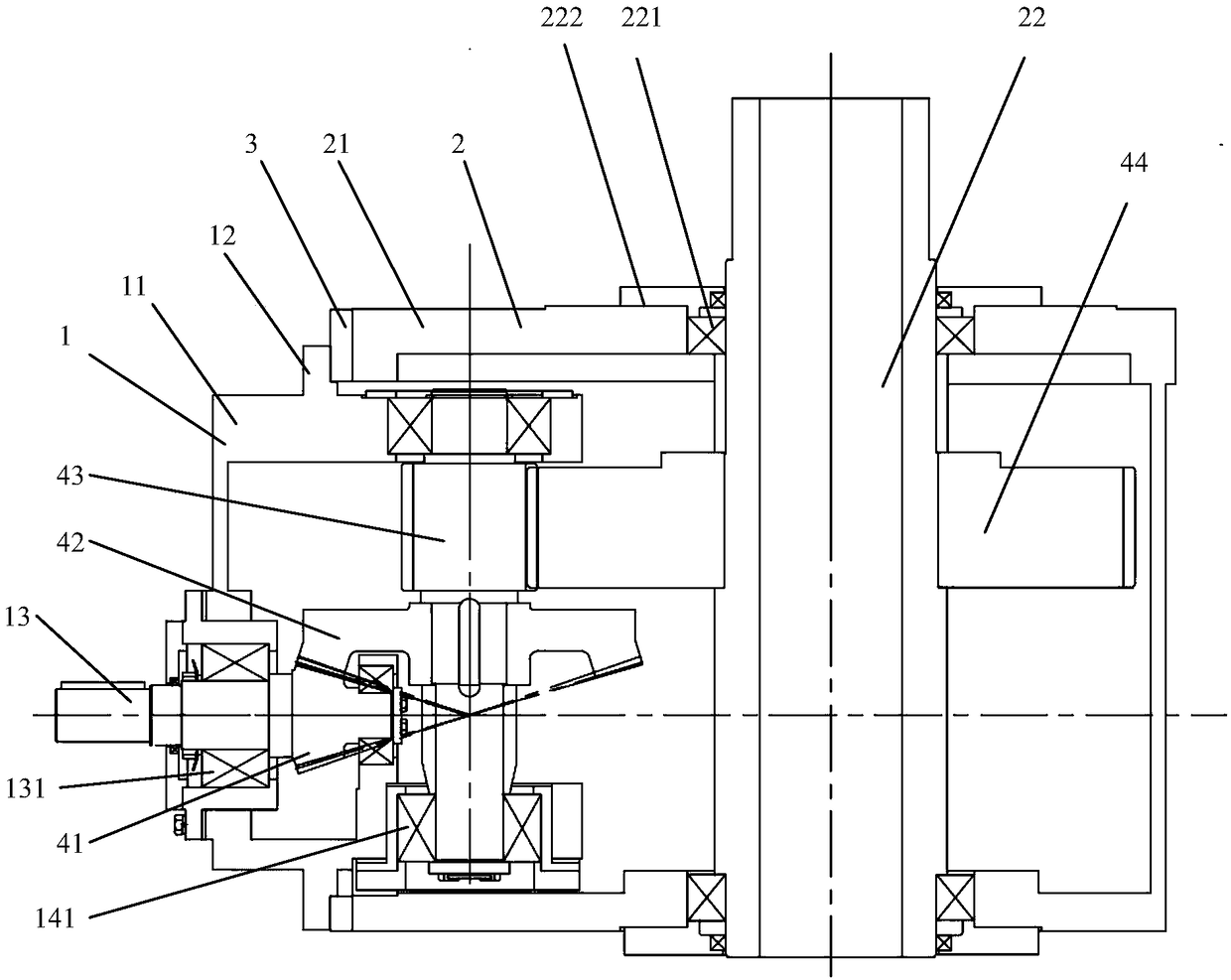

[0037] In further embodiments of the present invention, please continue to refer to Figure 1 to Figure 3 As shown, both ends of the output shaft 22 pass through the side wall of the second housing 21 , and both ends of the output shaft 22 are provided with shaft seats 221 , and the shaft seats 221 are fixedly connected to the outer wall of the second housing 21 .

[0038] In a further embodiment of the present invention, an input shaft bearing 131 is provided between the input shaft 13 and the first housing 11 .

[0039] In a further embodiment of the present invention, a transmission shaft bearing 141 is provided between both ends of the transmission shaft 14 and the first housing 11 .

[0040] In a further embodiment of the present invention, output shaft bearings 222 are provided between both ends of the output shaft 22 and the second housing 21 .

[0041] The using method of the present invention is illustrated below:

[0042] Step S1: Calculate the thickness a of the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com