Vacuum-assisted fiber-reinforced metal laminate flexible medium hydroforming method and device

A fiber-reinforced, metal laminate technology, applied in the field of composite material forming, can solve the problems of resin pollution on the surface of the mold, difficulty in precise forming, and many internal pores, so as to reduce the forming process and the number of molds, high-efficiency forming, and reduce wrinkling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

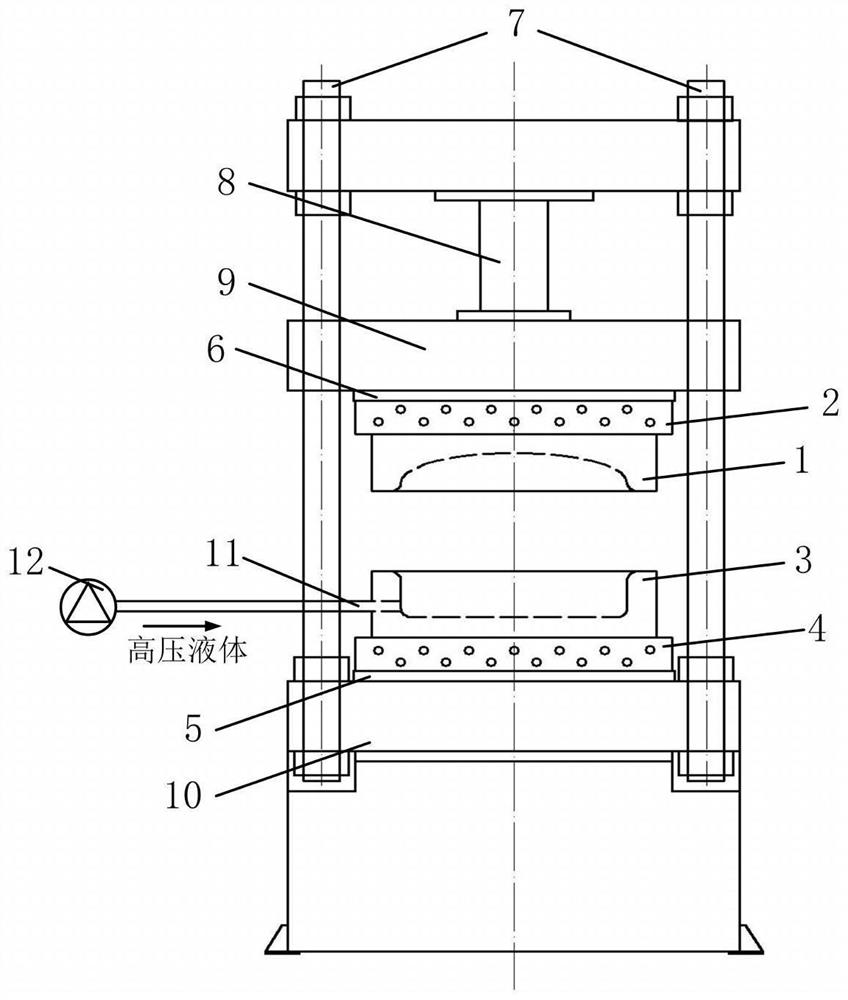

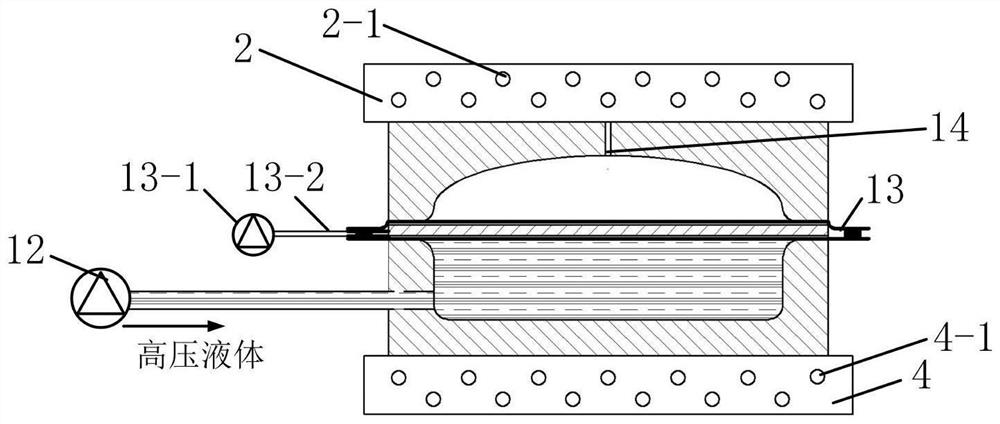

[0048] like Figure 1-Figure 6 As shown, this embodiment provides a vacuum-assisted fiber-reinforced metal laminate flexible medium liquid-filled forming method, including the following steps:

[0049] Step 1) as in figure 1 As shown, the mold is installed and debugged, the upper mold 1 is installed on the upper heating platform 2, and connected to the upper platform 9 through the upper heat insulation pad 6, the lower mold 3 is installed on the lower heating platform 4, and through the lower heat insulation The backing plate 5 is connected to the lower platform 10, and alcohol is used to wipe the cavity surfaces of the upper mold 1 and the lower mold 3 to prevent impurities from contaminating the flexible medium;

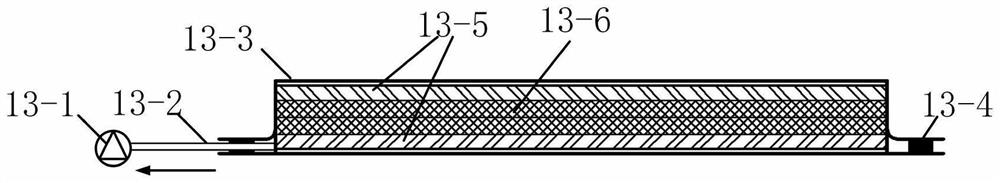

[0050] Step 2) Wipe and clean the surface of the metal sheet 13-5 in the fiber reinforced metal laminate blank, cut the fiber prepreg 13-6 according to the size of the metal sheet 13-5, and the fiber prepreg 13-6 in order paving on the surface of the metal sheet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com