Automotive pipeline three-dimensional blow molding glass fiber reinforced polyamide 6 composition and preparation method thereof

A technology of three-dimensional blow molding and automobile pipeline, which is applied in the field of three-dimensional blow molding glass fiber reinforced polyamide 6 composition and its preparation of automobile pipeline, which can solve the problem of not meeting the wall thickness requirement, difficulty and blow molding pipe body wall Uneven thickness and other problems, to achieve the effect of improving wall thickness uniformity, uniform thickness, and good appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

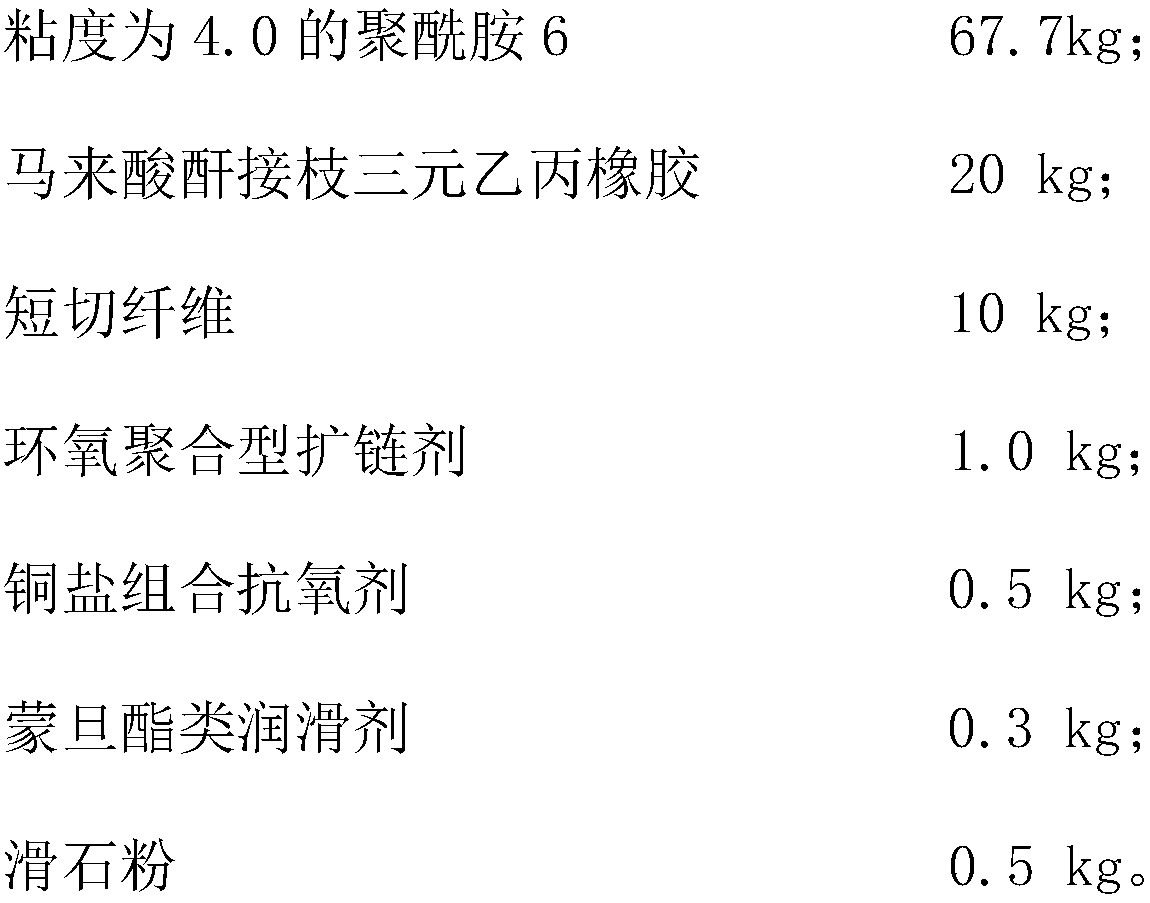

[0027] A three-dimensional blow-molded glass fiber reinforced polyamide 6 composition for automobile pipelines, comprising the following components:

[0028]

[0029] Among them, the polyamide 6 with a viscosity of 4.0 is B 40LN 01 of BASF Group; the maleic anhydride grafted EPDM rubber is 4785HM of Dow; the chopped fiber is 560A of Jushi Group; the epoxy polymer chain extender is BASF Group's 4385; copper salt combined antioxidant is Bruggemann's TP-P-H8017; montan ester lubricant is Clariant's LICOWAX E; talcum powder is IMIFABI's HTP Ultra5L.

[0030] Table 1 shows the performance test results of the three-dimensional blow-molded glass fiber reinforced polyamide 6 composition for automobile pipelines in this embodiment.

Embodiment 2

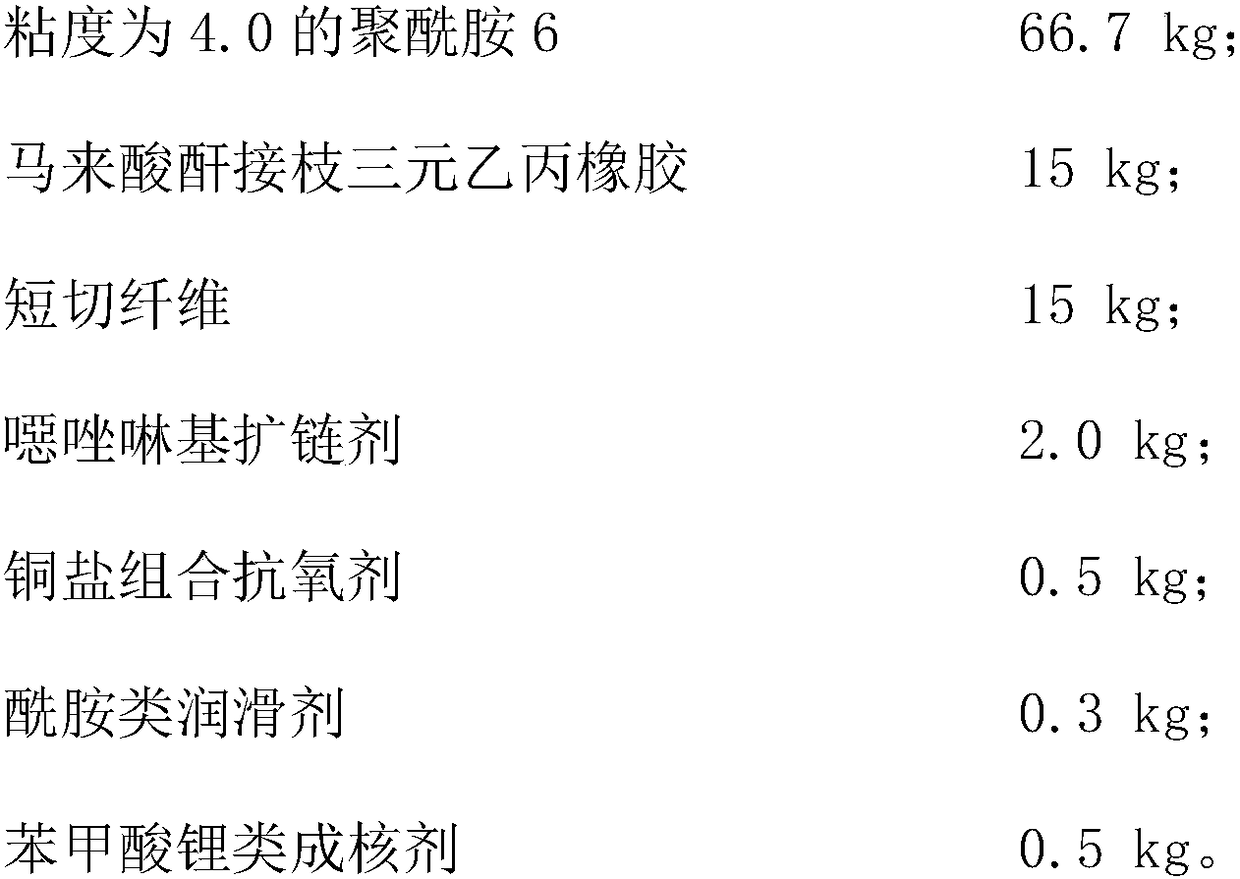

[0032] A three-dimensional blow-molded glass fiber reinforced polyamide 6 composition for automobile pipelines, comprising the following components:

[0033]

[0034] Among them, the polyamide 6 with a viscosity of 4.0 is B 40LN 01 of BASF Group; the maleic anhydride grafted EPDM rubber is 4785HM of Dow; the chopped fiber is 560A of Jushi Group; the oxazoline-based chain extender is Nippon Shokubai’s RPS 1005; copper salt combination antioxidant is Bruggemann’s TP-P-H8017; amide lubricant is Struktol’s TR016; and lithium benzoate nucleating agent is Guangzhou Chenghe’s NAA-325.

[0035] Table 1 shows the performance test results of the three-dimensional blow-molded glass fiber reinforced polyamide 6 composition for automobile pipelines in this embodiment.

Embodiment 3

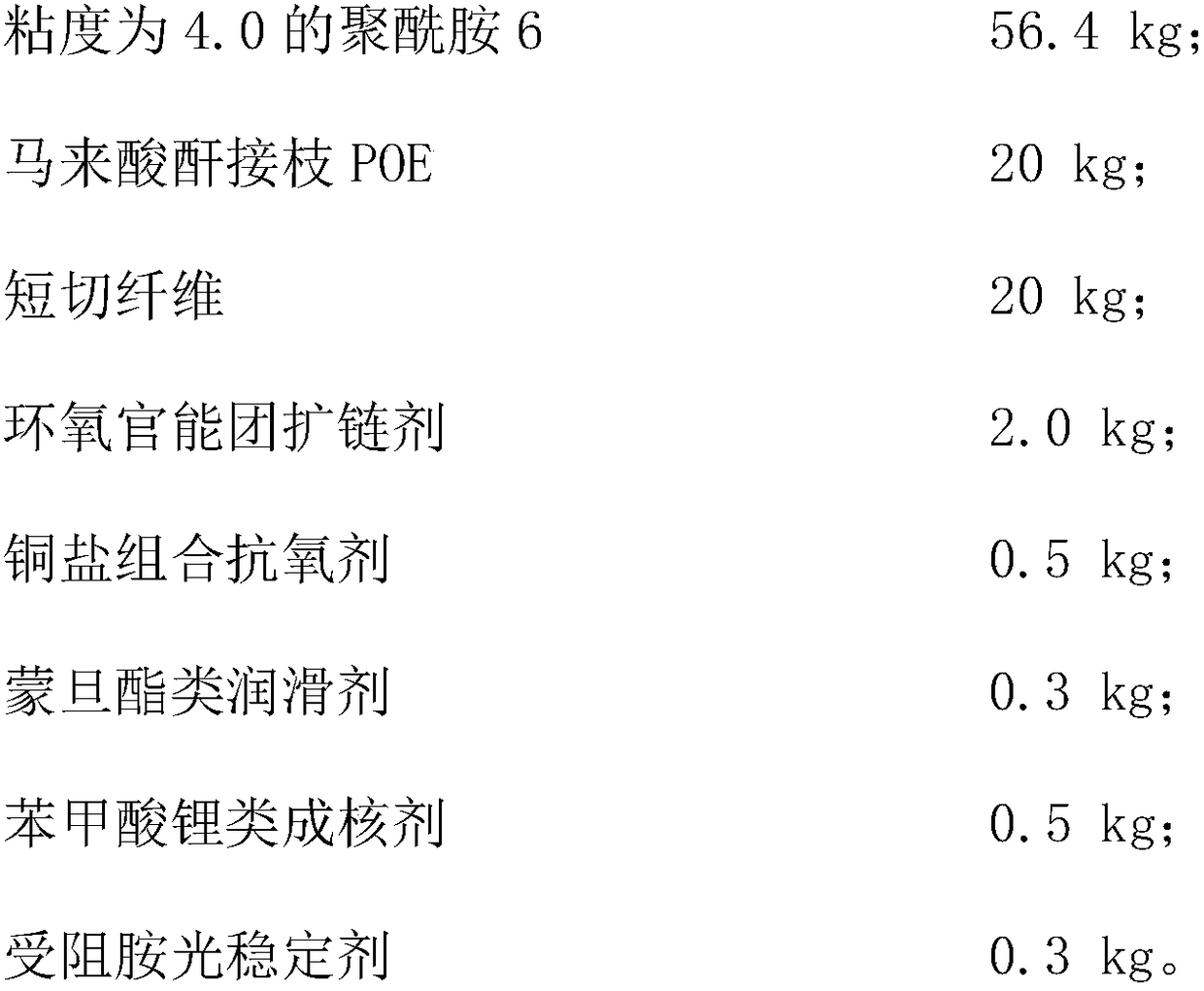

[0037] A three-dimensional blow-molded glass fiber reinforced polyamide 6 composition for automobile pipelines, comprising the following components:

[0038]

[0039] Among them, the polyamide 6 with a viscosity of 4.0 is B 40LN 01 of BASF Group; the maleic anhydride grafted POE is DF110 of Mitsui Chemicals; the chopped fiber is 560A of Jushi Group; the epoxy functional chain extender is TDE 85 (that is, 4,5-epoxyhexane-1,2-dicarboxylic acid diglycidyl ester); the copper salt combination antioxidant is Brüggemann’s TP-P-H8017; the montan ester lubricant is Clariant’s LICOWAX E; The lithium benzoate nucleating agent is NAA-325 from Guangzhou Chenghe; the hindered amine light stabilizer is UV-3808PP5 from Cytec.

[0040] Table 1 shows the performance test results of the three-dimensional blow-molded glass fiber reinforced polyamide 6 composition for automobile pipelines in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com