High-precision high-speed glass rotary disc visual inspection machine

A visual inspection, high-precision technology, applied in the field of visual inspection, can solve the problems of high-speed inspection of the inspection machine, no open and efficient operation method, etc., to achieve the effect of reducing follow-up processes, optimizing working procedures, and improving inspection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

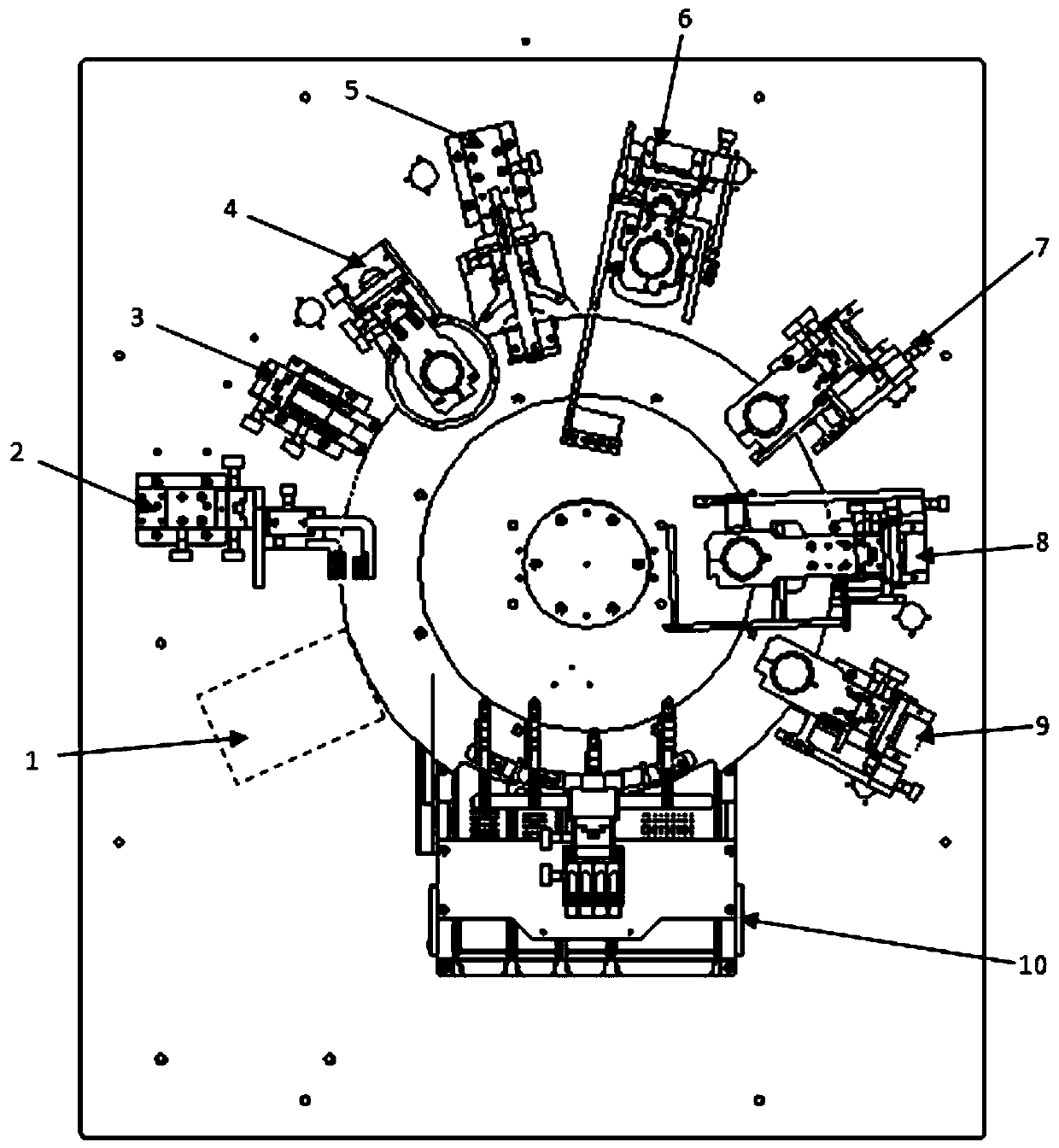

[0018] Such as figure 1 As shown, a high-precision and high-speed glass turntable visual inspection machine includes a cabinet and a detection device installed in the cabinet. Visual detection camera and unloading mechanism, the center of the bottom plate is installed with a rotating glass plate through a rotating shaft, and the rotating shaft is connected to a motor through a transmission mechanism. The feeding mechanism, the sensor, the first visual detection camera, the second visual detection camera, the third visual detection camera, the fourth visual detection camera, the fifth visual detection camera, the sixth visual detection camera and the unloading mechanism, wherein the fifth visual detection camera The lens of the detection camera extends into the bottom surface of the rotating glass disk and the lens is vertically facing upwards. One side of the fifth visual inspection camera is equipped with a reflector through an adjustment bracket, and the reflector is located...

Embodiment 2

[0025] A high-precision and high-speed glass turntable visual inspection machine, which includes a cabinet and a detection device installed in the cabinet, is characterized in that: the detection device includes a bottom plate, a rotating glass disk, an array feeding mechanism, a sensor, and multiple visual detection cameras As well as the unloading mechanism, the center of the bottom plate is equipped with a rotating glass plate through a rotating shaft, and the rotating shaft is connected to a motor through a transmission mechanism. The bottom plate is located on the outer periphery of the rotating glass plate and is surrounded by an entire row of feeding mechanisms in a clockwise direction. , sensor, the first visual detection camera, the second visual detection camera, the third visual detection camera, the fourth visual detection camera, the fifth visual detection camera, the sixth visual detection camera and the blanking mechanism, wherein the fifth visual detection camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com