Copper-aluminum composite radiator and machining method thereof

A technology of copper-aluminum composite and processing method, which is applied in the direction of heat exchanger shell, indirect heat exchanger, heat exchange equipment, etc., can solve problems such as inability to ensure sufficient contact surface, inability to completely eliminate air bubbles, inability to meet heat dissipation requirements, etc., to achieve Easy processing, faster heat transfer and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

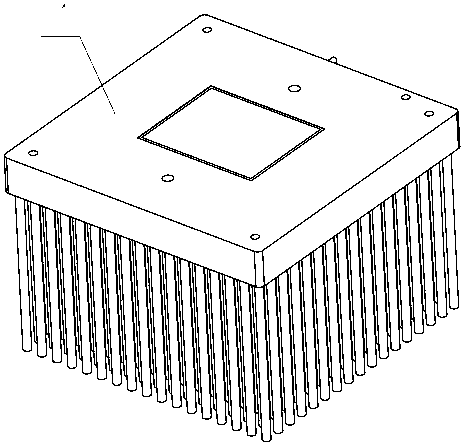

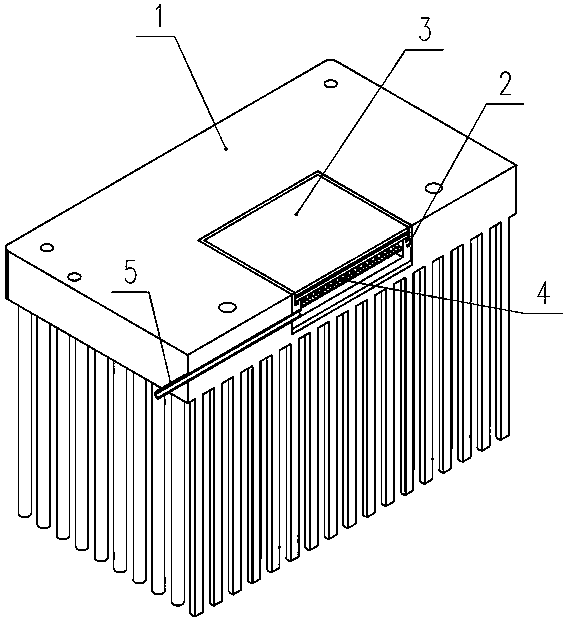

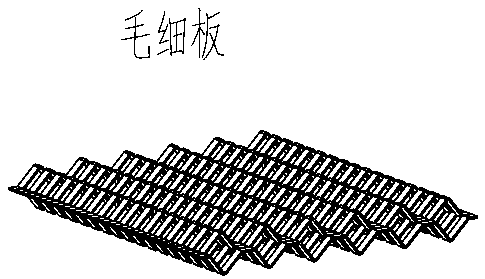

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, an embodiment of the copper-aluminum composite radiator of the present invention includes an aluminum alloy radiator main body 1, and also includes a copper substrate 2 embedded in the heat conducting surface of the aluminum alloy radiator main body and in the shape of a slot. The slot above the copper base plate 2 is open, and capillary plates 4 are laid in the slot. The capillary plates 4 are interlaced honeycomb in cross section, and the heat transfer is rapid and uniform. The slot opening is closed by the DBC board 3 through welding to form a module. In order to form a vapor chamber structure inside the copper substrate, liquid is also vacuumed and injected into the slot. Use the evaporation of liquid to absorb heat and condense to release heat to further accelerate heat transfer and further strengthen and improve the heat dissipation effect. The bottom of the copper substrate 2 has a mortise and ten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com