Patents

Literature

82results about How to "Eliminate quality impact" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

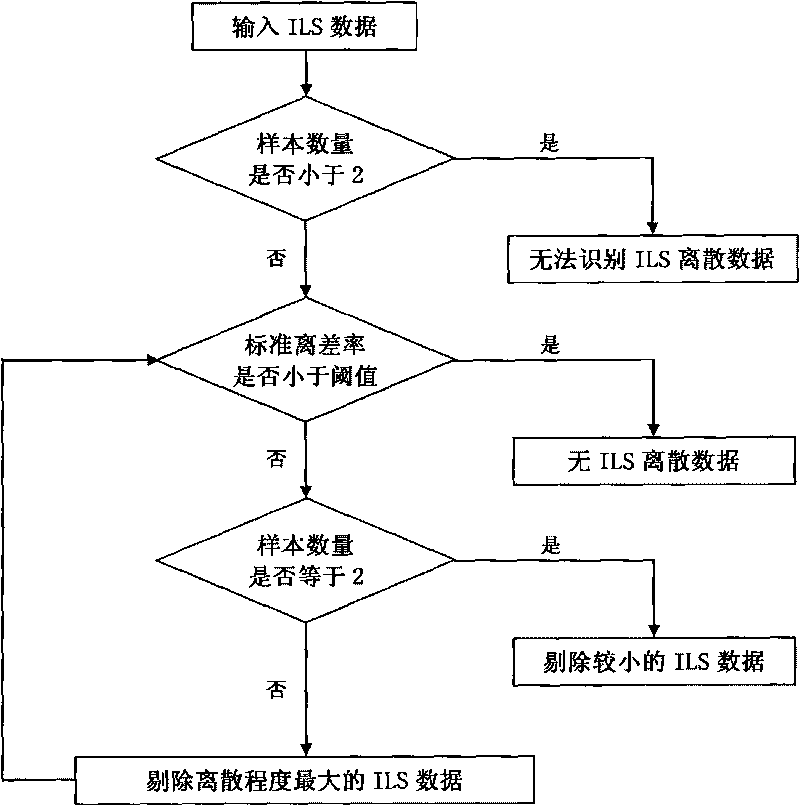

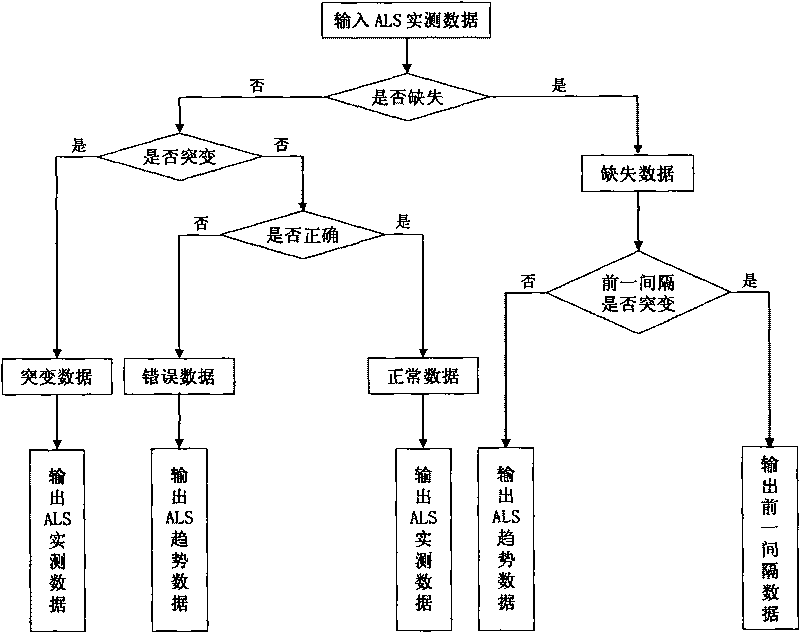

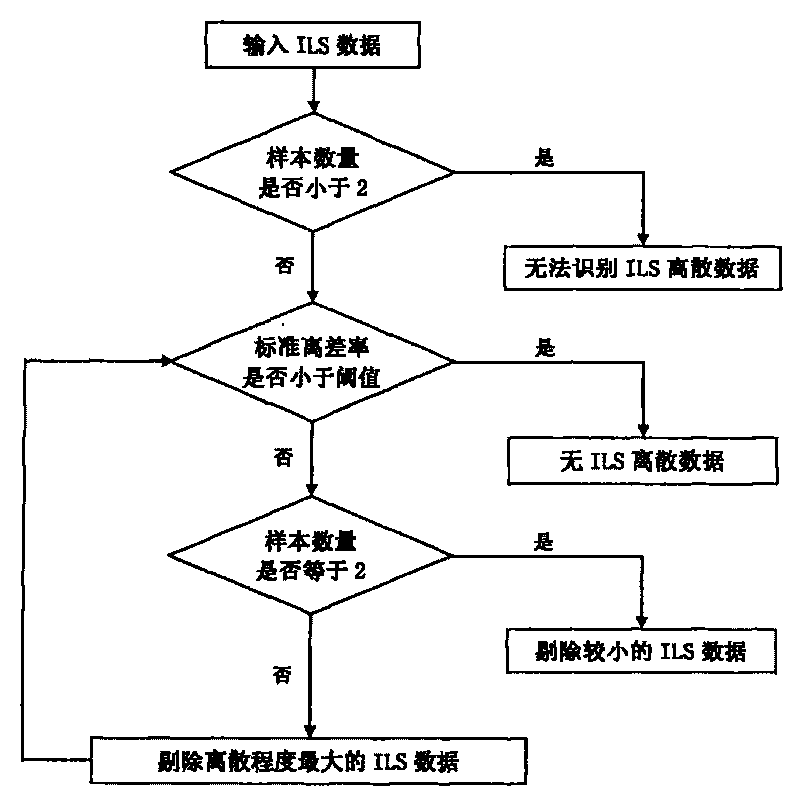

GPS floating vehicle-based traffic data fault identification and recovery method

InactiveCN101739825AEliminate quality impactQuality improvementDetection of traffic movementRecovery methodInformation processing

The invention discloses a GPS floating vehicle-based traffic data fault identification and recovery method, which relates to a traffic information processing method. In the method, the shutdown condition of a floating vehicle is identified in real time to obtain the continuous shutdown time of the vehicle; in combination with intersection control signal timing data, the validity of the single road section travel speed data of the vehicle is identified; and the discreteness and discontinuity of the single road section travel speed data of the vehicle are identified through the real-time judgment of a processor of a computer to recover missing data so that the accuracy of the single road section travel speed data of the vehicle is identified.

Owner:JILIN UNIV

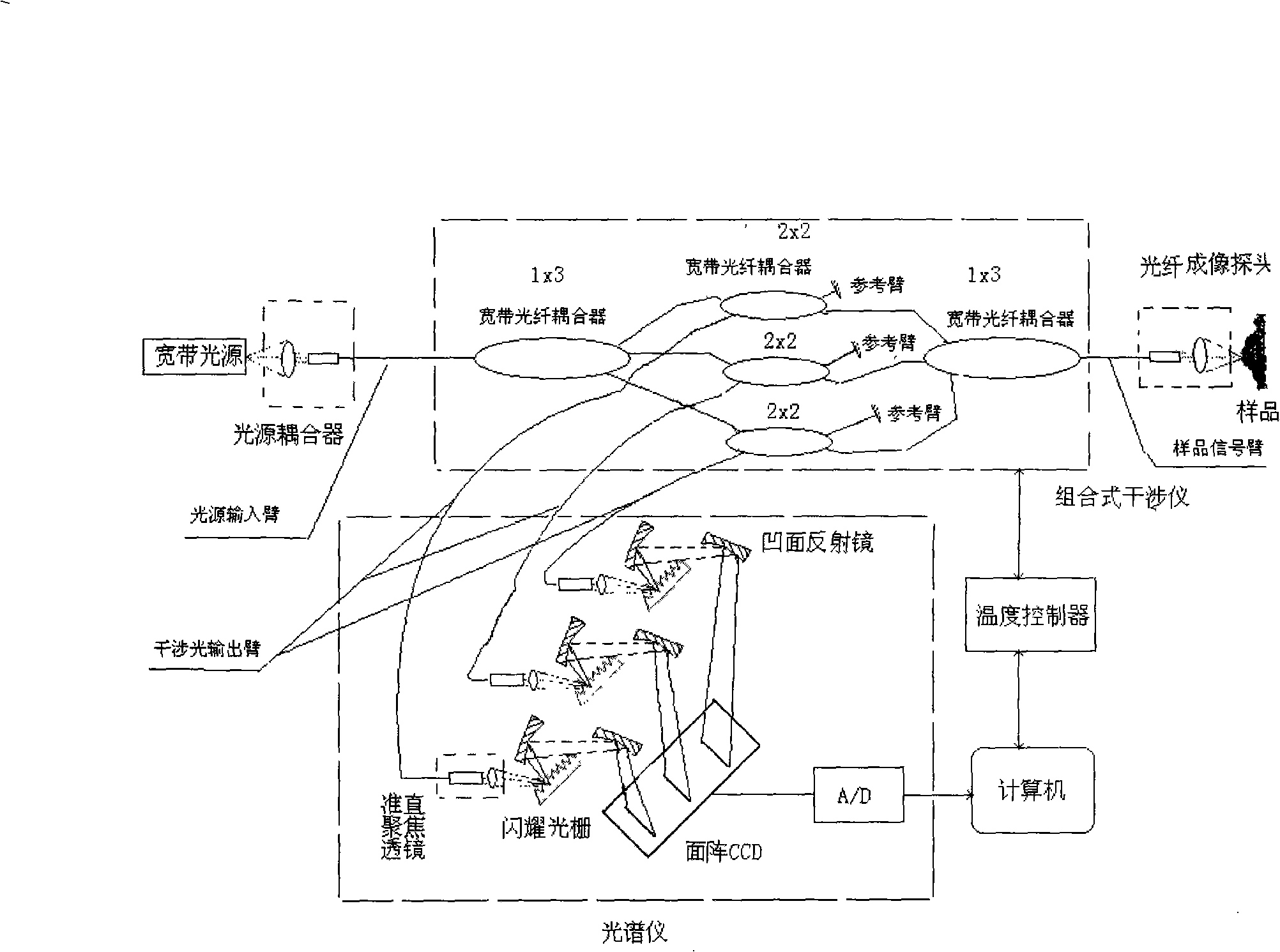

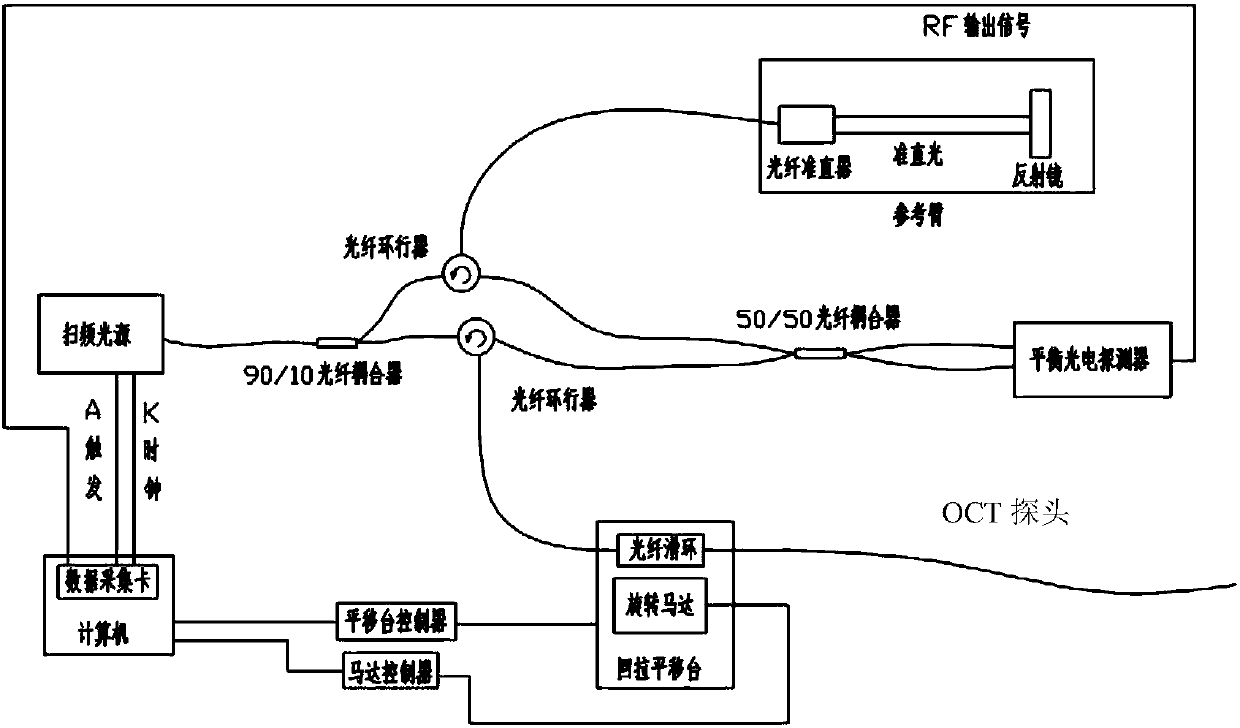

Complex spectral domain optical coherence tomography method and system

InactiveCN101297750ASimple system structureLarge dynamic rangeDiagnostic recording/measuringSensorsFull scaleTomography

The invention provides a tomographic method and a system for coherent optics in complex spectrum frequency domain, comprising a broadband light source, a light source coupling mechanism, a combined interferometer, a fiber-optics imaging probe, a spectrograph, a temperature controller and a computer; the method comprises the following steps of: firstly, measuring three groups of interference spectrum in state of three different phases of reference light; secondly, calculating two groups of differential interference spectrums; thirdly, taking the sum and the remainder of the two groups of differential interference spectrums as a real part and an imaginary part for a complex amplitude so as to reconstruct the interference spectrum of the complex amplitude in a wave number space; finally, making an inverse Fourier transform for the interference spectrum of the complex amplitude and obtaining depth-scanning information of a measured sample along an optical axis, that is chromatogram. Under the condition that a regulating device for the phase of the reference light is not used, the tomographic method and the system eliminate the effect for chromatogram quality caused by a parasitic image and a hetero conjugation image, and can realize the tomography which reflects the real structure of the measured sample with the advantages of simple system structure, wide dynamic scope and deep measurement in full scale.

Owner:SHENZHEN POLYTECHNIC

Terpene resin and preparation method thereof

The invention discloses a terpene resin and a preparation method thereof. The preparation method comprises steps as follows: terpene substances are used as a raw material, AlCl3 in the presence of an aromatic solvent is used as a main catalyst, and a cocatalyst is used in the reaction; polymerization is carried out at low temperature to prepare the crude terpene resin product; and the crude terpene resin product is washed and distilled under reduced pressure to obtain the terpene resin product. The cocatalyst is trimethylchlorosilane, triethylchlorosilane, tripropylchlorosilane or tributylchlorosilane, and accounts for 1-5% of the total mass of the terpene substance raw material; the main catalyst AlCl3 accounts for 4-12% of the total mass of the terpene substance raw material; the elemental chlorine content in the prepared terpene resin product is less than 100mg / kg, and the metallic aluminum content is less than 10mg / kg; the terpene resin product does not contain metallic antimony; and the residue level of the volatile solvent is less than 25mg / kg. The product reaches to the food level.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY +1

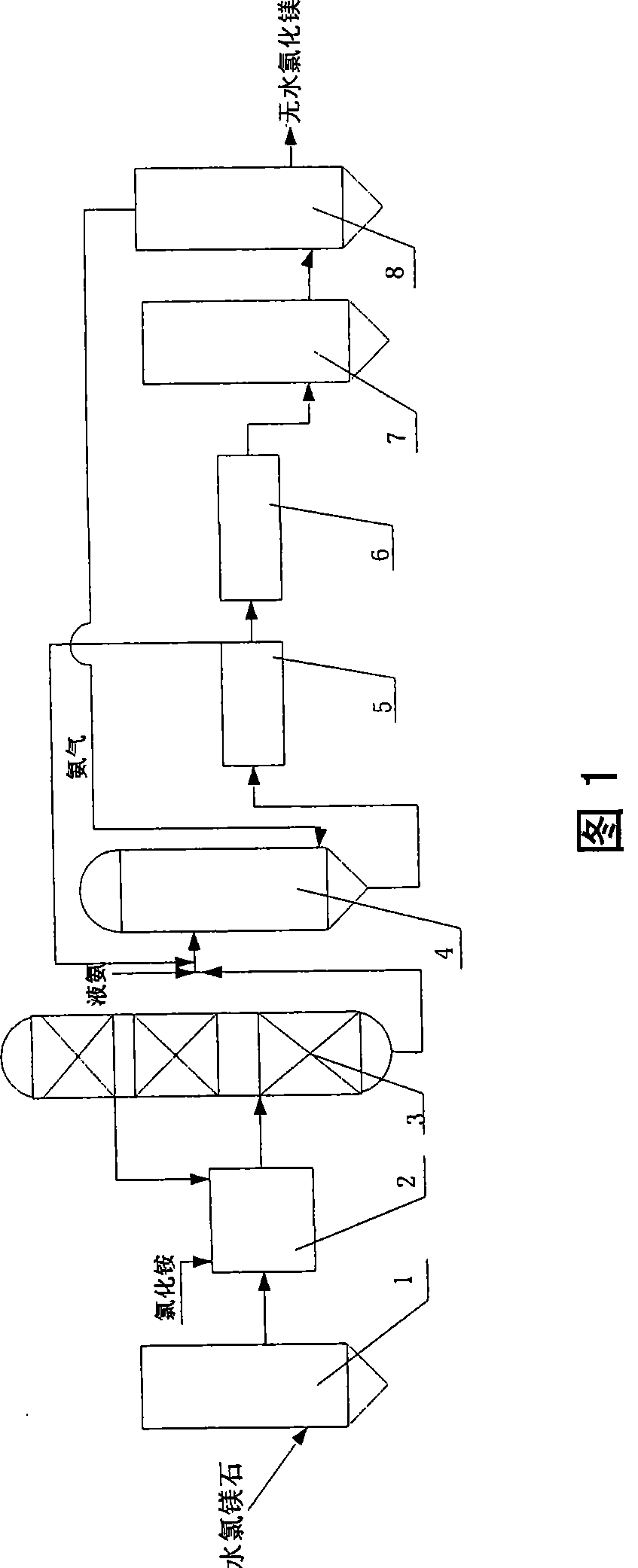

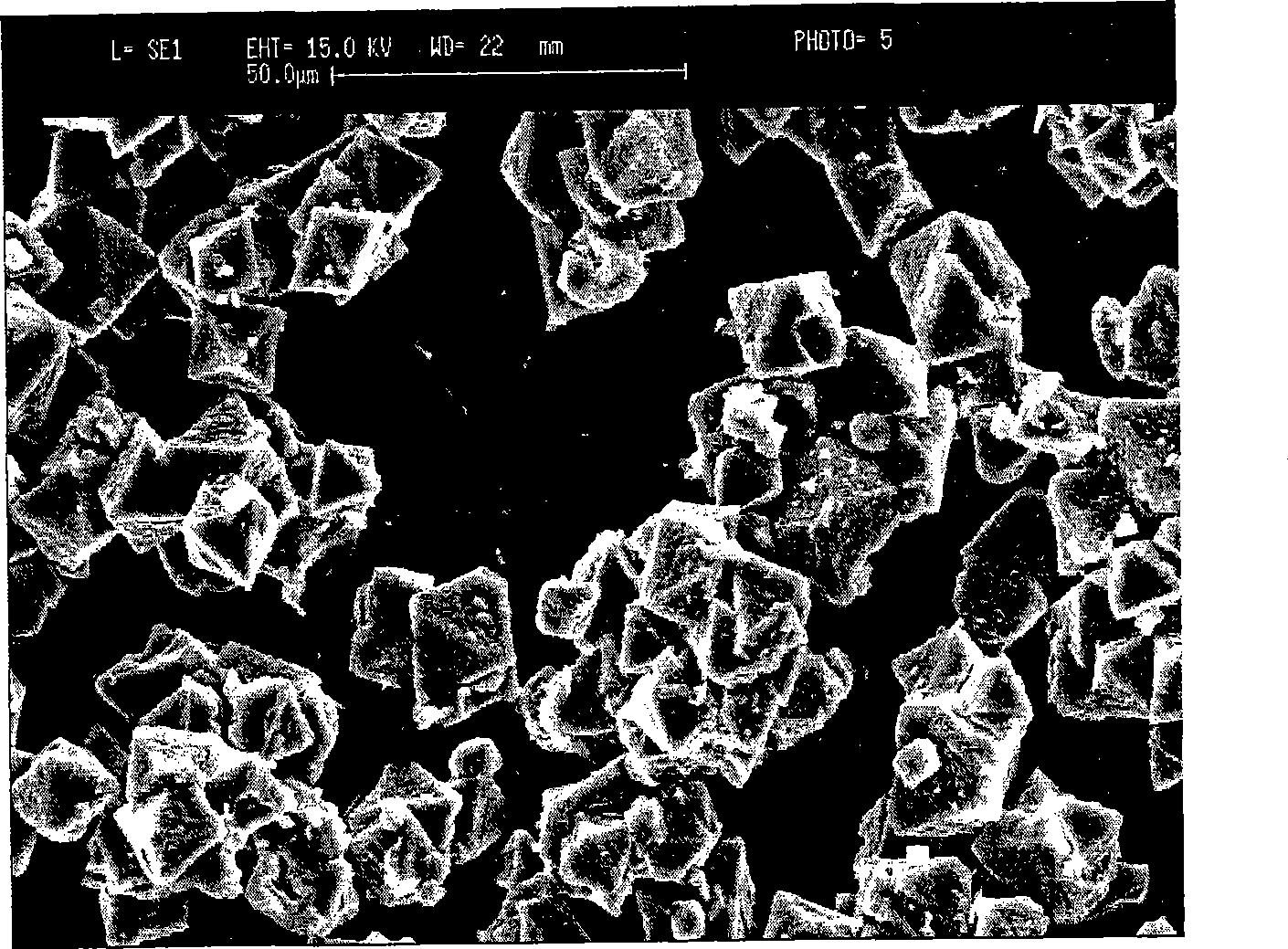

Method for preparing anhydrous magnesium chloride from bischofite

The invention relates to a method for preparing anhydrous magnesium chloride from bischofite, which uses the bischofite as a raw material for preparing the anhydrous magnesium chloride. The method comprises the following technical processes: (1) firstly, drying the bischofite for dewatering most crystallization water; (2) dissolving the dried magnesium chloride in glycol for preparing a glycol solution of the magnesium chloride and using a vacuum distillation method for dewatering water in the glycol solution of the magnesium chloride; (3) reacting the dewatered glycol solution of the magnesium chloride with ammonia for crystallizing so as to generate magnesium chloride hexammoniate crystals; (4) washing, filtering and drying for obtaining the magnesium chloride hexammoniate crystals; and (5) heating, decomposing and deaminating the dried magnesium chloride hexammoniate crystals for preparing the anhydrous magnesium chloride. In each process, ammonia gas, detergent and a crystallization mother liquor are recycled. The process has the characteristics of convenient operation, easy large-scale production, low energy consumption, low product cost and no pollution to environment and the prepared anhydrous magnesium chloride can be used as a raw material for producing magnesium metal by an electrolysis method.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

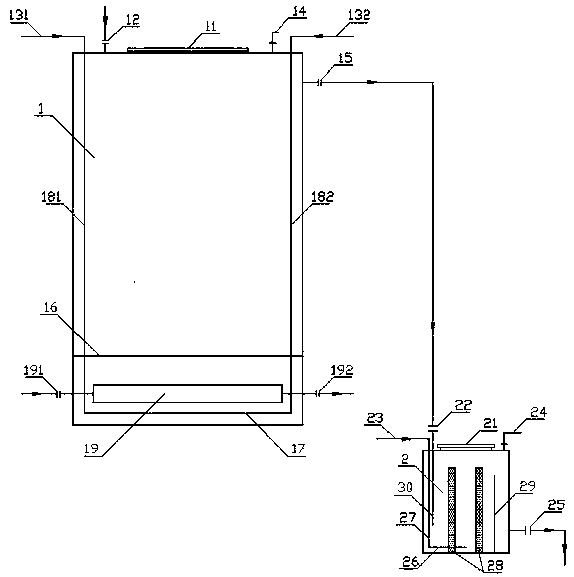

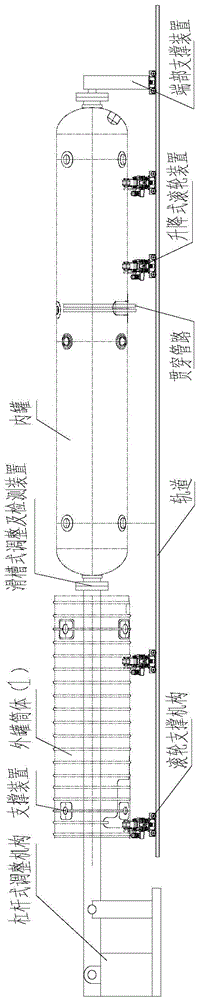

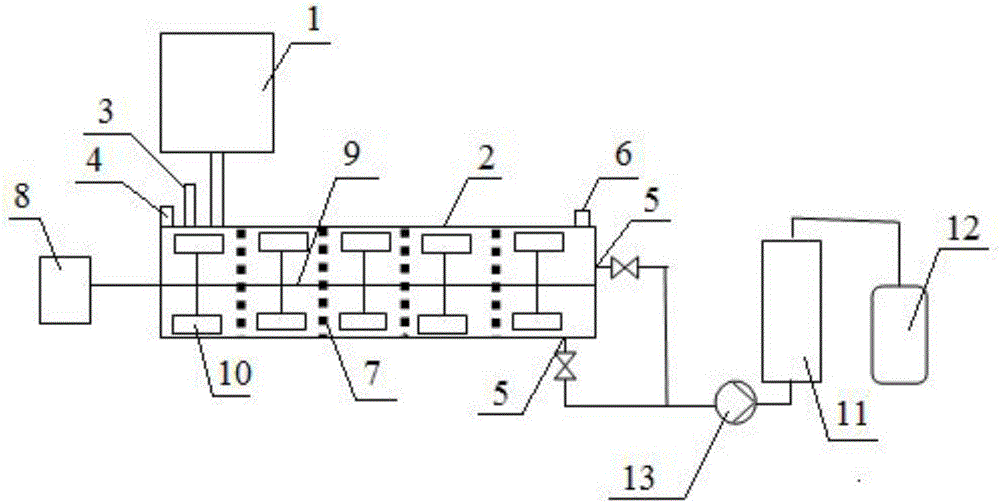

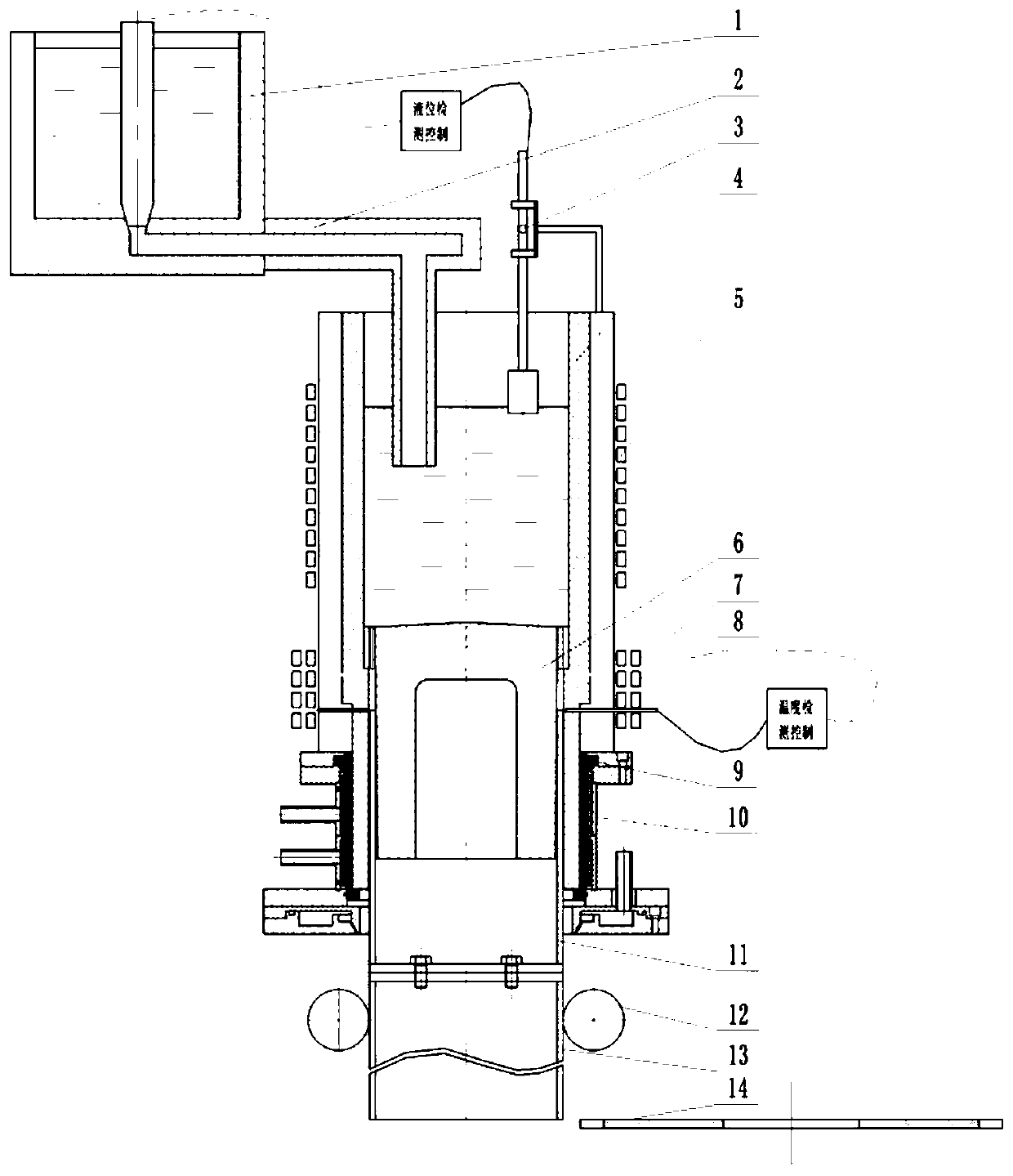

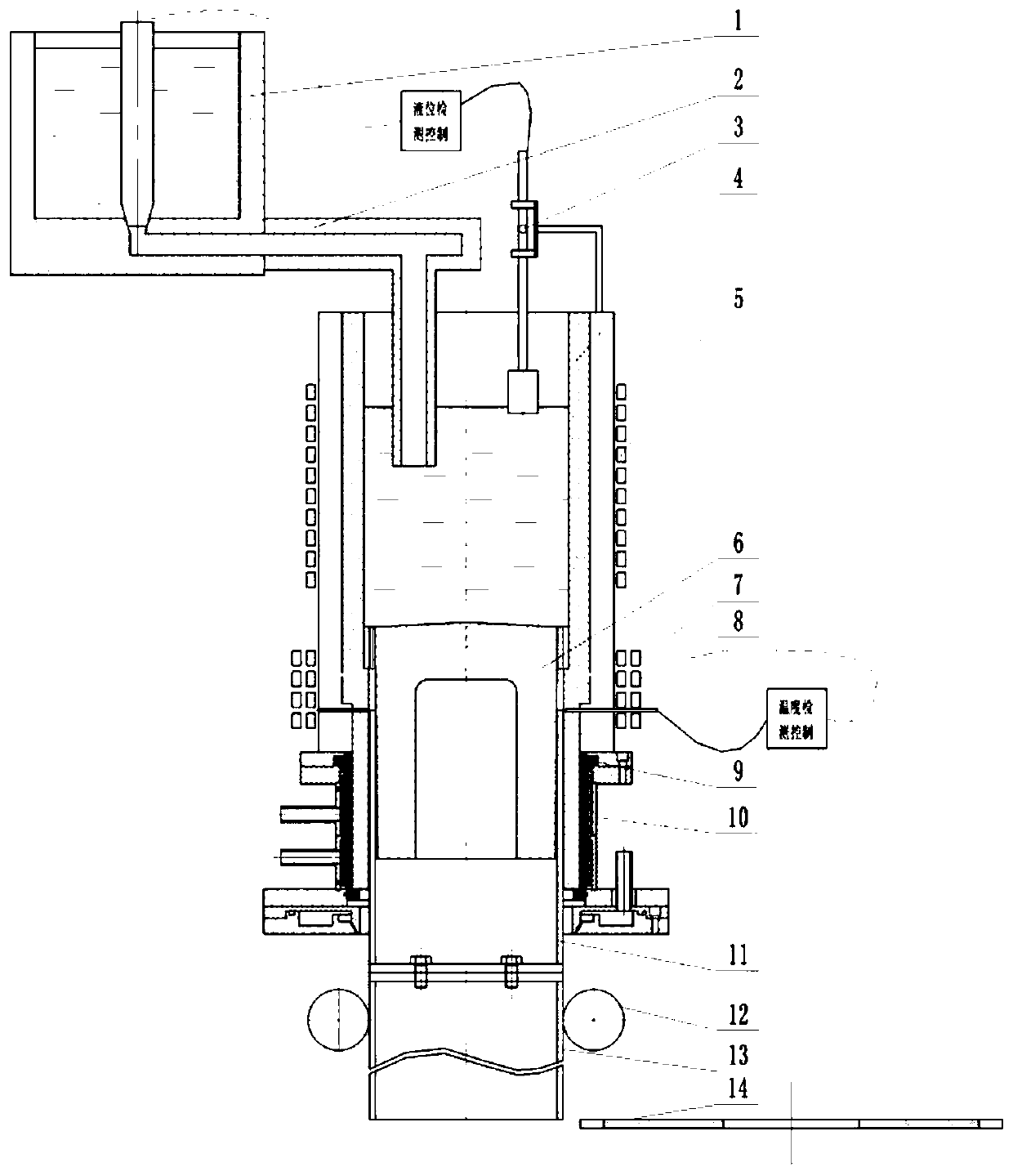

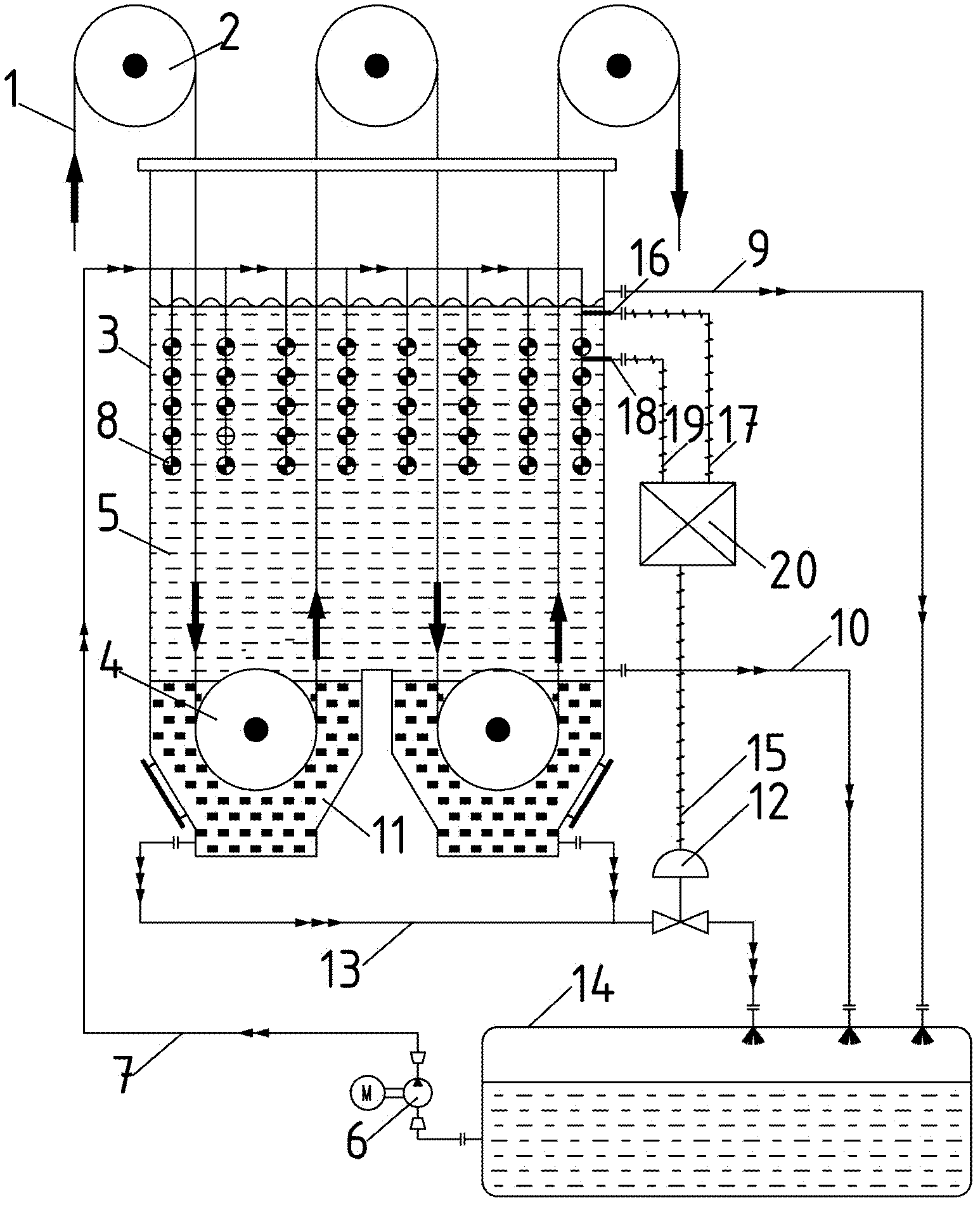

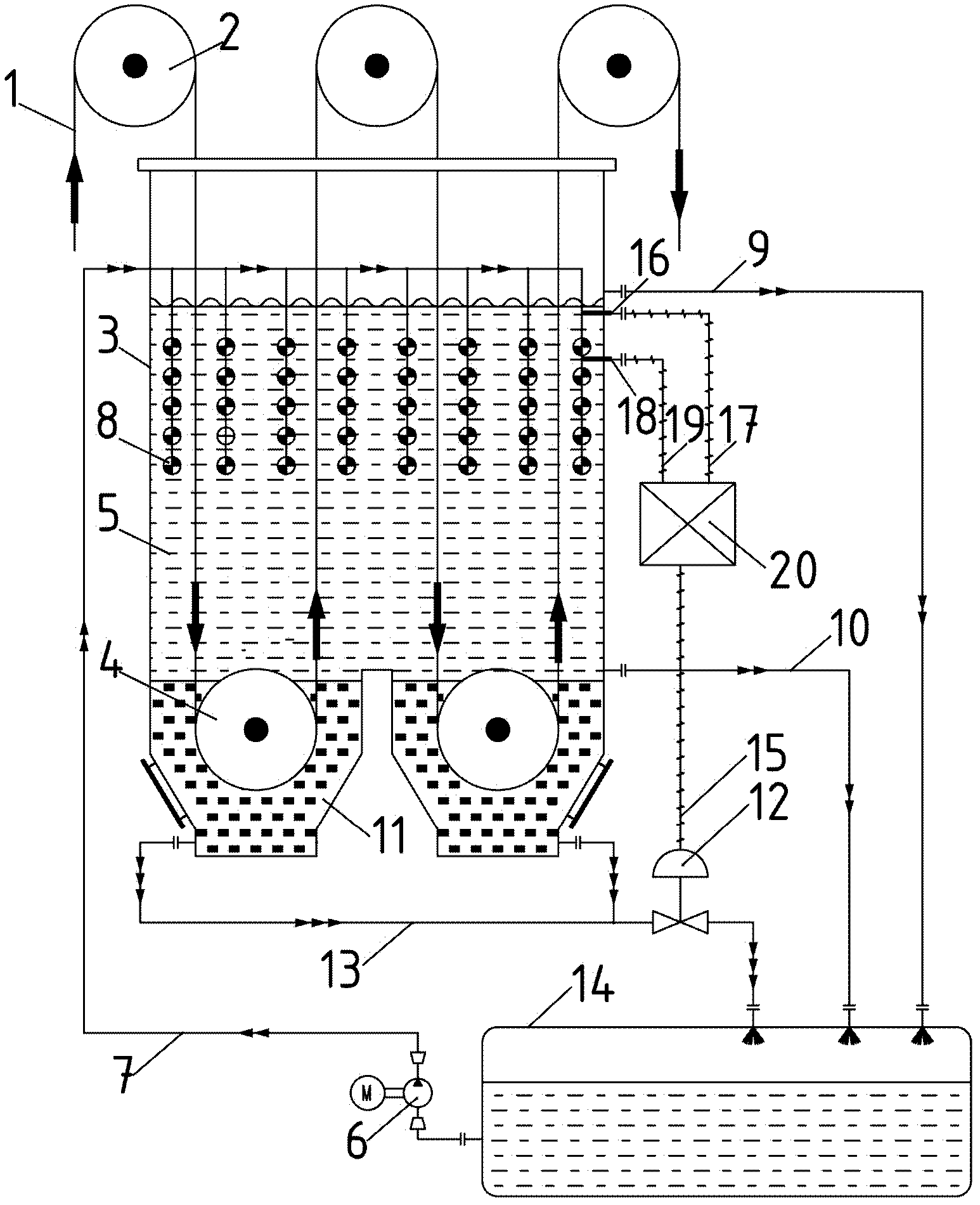

Copper dissolving system and copper dissolving process of electrolytic copper foil

PendingCN110820019AEliminate quality impactReduce volumeCellsElectroforming processesCopper foilCuprous ion

The invention discloses a copper dissolving system of an electrolytic copper foil. The system comprises a primary copper dissolving system and a secondary copper dissolving system which are connectedin series, and is provided with a compressed air assembly which is used for supplying compressed air for the primary copper dissolving system and the secondary copper dissolving system, wherein the primary copper dissolving system comprises a copper dissolving tank; a heat exchange device is arranged on the lower part of the copper dissolving tank; coiled pipes and partition plates are arranged onthe upper part and the lower part of the heat exchange device to introduce the compressed air and prevent copper raw materials; the primary copper dissolving system is connected with the secondary copper dissolving system through an overflowing structure; secondary copper dissolving treatment is conducted in the copper dissolving tank of the secondary copper dissolving system; filtering and overflowing operation is conducted in the copper dissolving treatment process; and the copper dissolving system cooperates a corresponding copper dissolving method to provide and obtain copper ion-containing mixture solutions with different concentration, and the reaction rate is increased through reasonable compressed air supply. The copper dissolving quality can be effectively improved, the cuprous ion content and the organic matter impurity content of a copper sulfate solution are reduced, and the temperature of the solution is reduced.

Owner:湖南龙智新材料科技有限公司

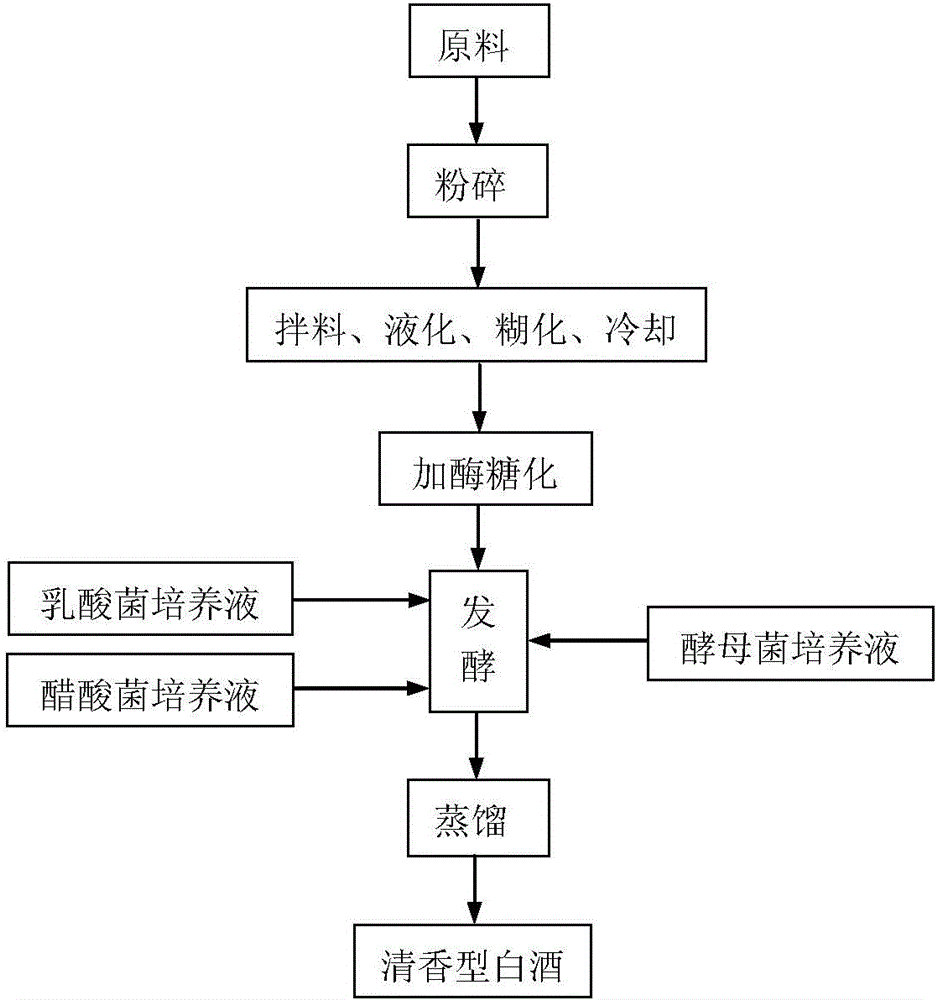

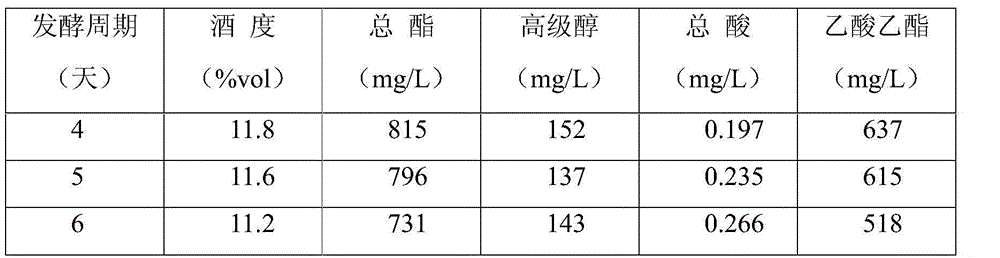

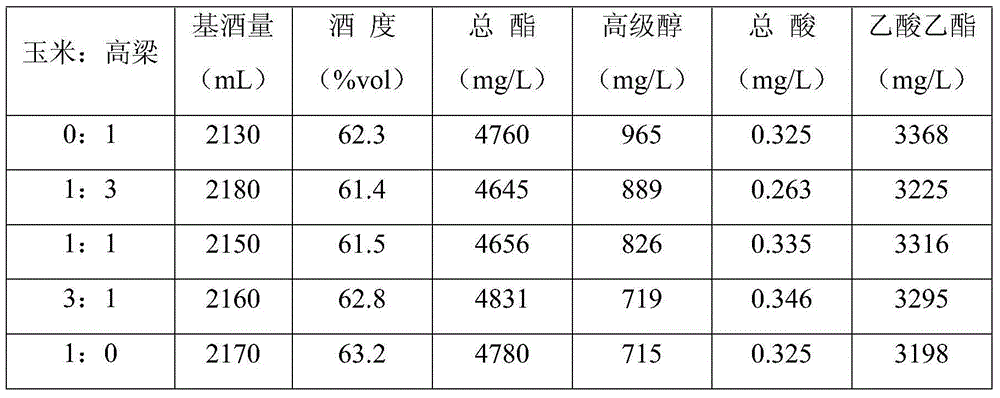

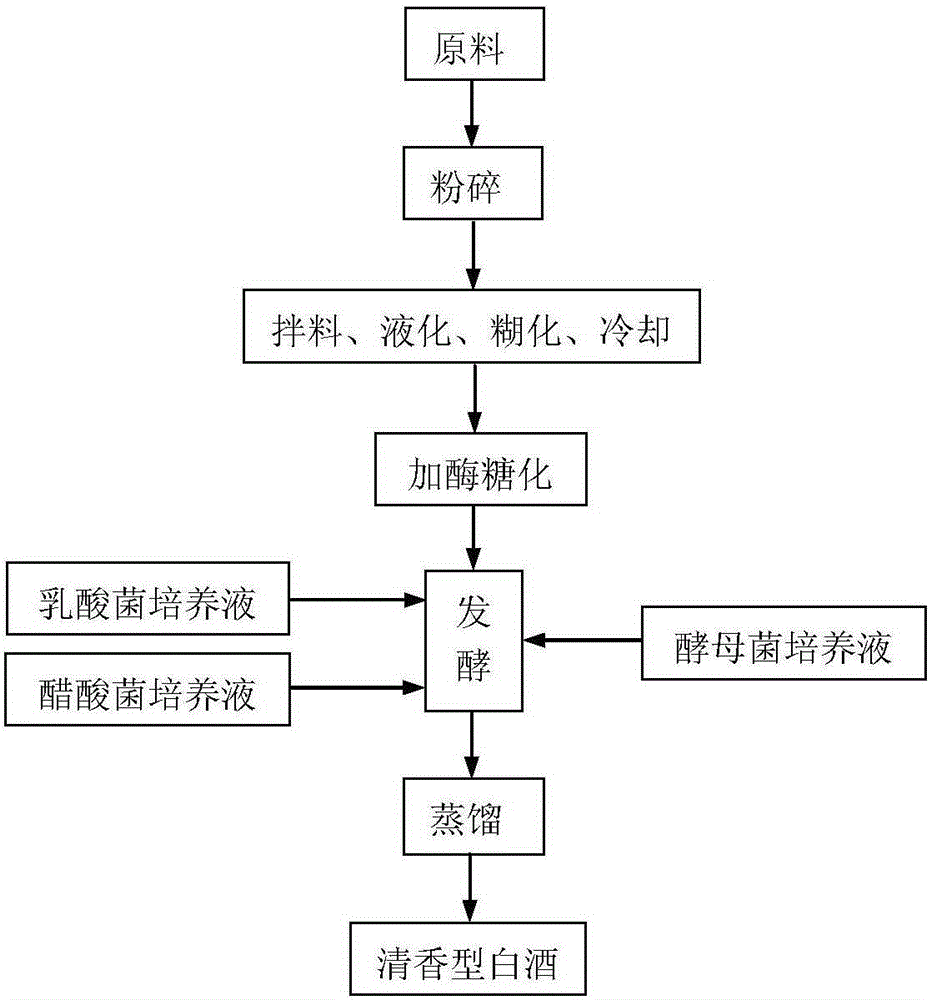

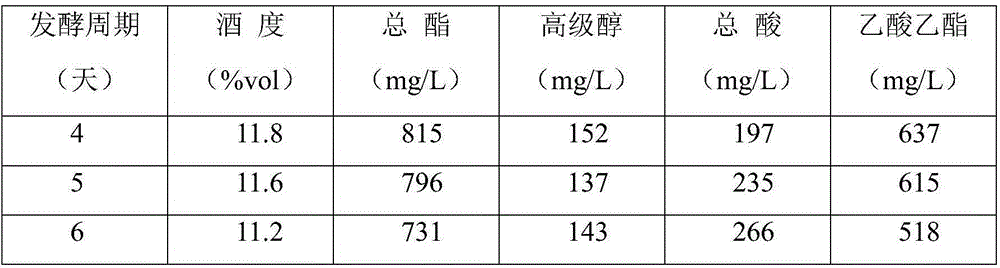

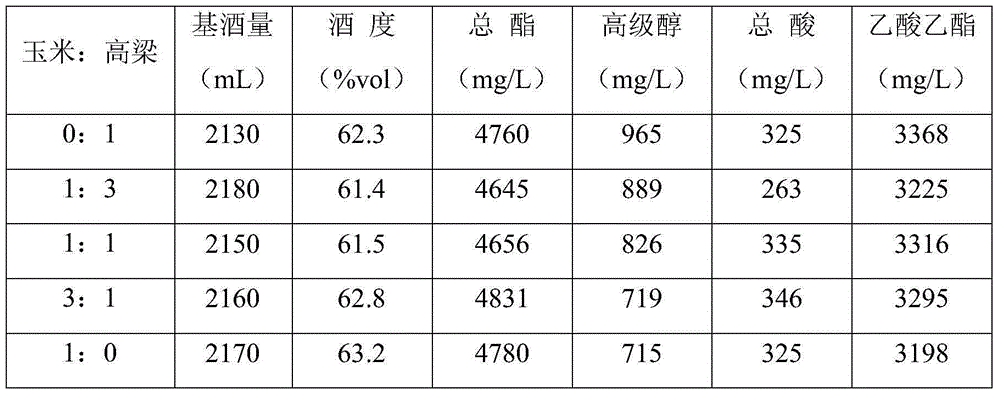

Method for producing fen-flavor liquor by liquid fermentation

InactiveCN104694325AStable outputQuality improvementAlcoholic beverage preparationFood flavorPure culture

The invention discloses a method for producing fen-flavor liquor by liquid fermentation and belongs to the technical field of brewing. The method comprises the following steps: crushing raw materials; liquefying and gelatinizing; saccharifying; fermenting and distilling. The fermenting step comprises the following steps: inoculating a 4-6% saccharomycetes culture solution and a 1-3% a lactic acid bacteria culture solution to cooled converted mash; fermenting for 36-48 hours at 30-35 DEG C; then inoculating a 0.5-1.5% acetic bacteria culture solution; then fermenting for 2-4 days; and then distilling. According to the method, in the brewing process, controlled liquid fermentation is adopted, and parameters of a fermentation technology can be regulated anytime according to the fermentation process, so that the labor intensity is greatly alleviated, the output and quality of liquor are stabilized, and mechanical operation of liquor production is completely realized; moreover, in the brewing process, a mycelium system of pure culture and a commercialized multienzyme system are coordinated with diastatic fermentation, so that the raw material liquor yield is improved by 10-20% and the fermentation period is shortened to 4-6 days and the content of high flavor substances of liquor in a solid state method is maintained, and therefore, grain is saved and consumption is reduced for liquor production.

Owner:TIANJIN UNIV OF SCI & TECH

Method for preparing o-chloroaniline by virtue of solvent-free catalytic hydrogenation

ActiveCN103664641ASolve the problem of hydrogenolysis and dechlorinationReduce corrosionOrganic compound preparationAmino compound preparationPtru catalystSolvent free

The invention belongs to the technical field of fine chemical engineering, and relates to a method for preparing o-chloroaniline by virtue of solvent-free catalytic hydrogenation ortho-nitrochlorobenzene. The method is characterized in that ortho-nitrochlorobenzene is adopted as a raw material to be reacted with hydrogen in the presence of a catalyst at the temperature of 70-120 DEG C and the pressure of 0.5-5.0 MPa so as to obtain o-chloroaniline through the processing after the reaction. By adopting the method, no solvent is added, the defect for adding the solvent can be overcome, the environmental pollution problem and the solvent recycling problem can be avoided, the equipment investment is reduced, the production cost is reduced, the conversion rate of the ortho-nitrochlorobenzene can reach 100 percent, the selectivity of the o-chloroaniline is more than 99.2 percent, and the dechlorinating rate is less than 0.09 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for high-selectivity preparation of 3,4-dichloroaniline

ActiveCN103694124AReduce corrosionSolve the problem of hydrogenolysis and dechlorinationOrganic compound preparationAmino compound preparationPtru catalystNitrobenzene

The invention belongs to the technical field of fine chemical engineering, and relates to a method for preparing 3,4-dichloroaniline from 3,4-dichloronitrobenzene through high-selectivity catalytic hydrogenation. With 3,4-dichloronitrobenzene as raw material and in the presence of a Pt catalyst, 3,4-dichloroaniline is prepared through a catalytic hydrogenation reaction under the pressure of 1.0 MPa-3.0 MPa and at the temperature of 75-120 DEG C. With adoption of the method, the conversion rate of 3,4-dichloronitrobenzene is 100%, the selectivity of 3,4-dichloroaniline is greater than 99.6%, and the dechlorination rate is less than 0.20%. The Pt catalyst is safe to use, and has stable catalytic activity and high selectivity; a dechlorination inhibitor is not required to be added; through introduction of Fe2O3 into the Pt catalyst, a dechlorination phenomenon can be effectively inhibited, and the corrosion of dechlorination to a reaction container during reduction is reduced; and the method is not added with a solvent, overcomes the defect of the addition of the solvent, avoids the problems of pollution of the solvent to the environment and solvent recovery, reduces equipment investment, and reduces production costs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Tank sleeving technological method of railway tank car of double-layer structure

ActiveCN105458609AReduce quality riskAvoid defective productsWelding/cutting auxillary devicesAuxillary welding devicesManufacturing efficiencyProcess control

The invention relates to a tank sleeving technological method of a railway tank car of a double-layer structure. The technological method includes the steps that firstly, one side of an inner tank body and one side of an outer-tank barrel matched with the inner tank body are assembled, wherein one side of the inner tank body and one side of an outer tank body are adjusted by supporting and positioning one side of the outer-tank barrel, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; secondly, the other side of the inner tank body and the other side of the outer-tank barrel matched with the inner tank body are assembled, wherein the other side of the outer-tank barrel and the other side of the inner tank body are adjusted to move relatively, and the sleeved outer-tank barrel and the inner tank body are supported and fixed; thirdly, the two sides of the completely-sleeved outer-tank barrel are overall adjusted, and a circular seam at a combined portion is welded; and finally, end sockets on the two sides are assembled and welded. According to the tank sleeving technological method, quality risks are reduced, all the technical indexes can be more easily guaranteed, and defective products are avoided; the influences of human factors on the quality are eliminated to the maximum degree, and process control is more easily controlled; and the influence of auxiliary time on the production takt is reduced, and the product manufacturing efficiency is improved.

Owner:CRRC YANGTZE CO LTD

Method for producing fen-flavor liquor through liquid state fermentation

ActiveCN105176744AStable outputQuality improvementAlcoholic beverage preparationDistillationFood flavor

The invention discloses a method for producing fen-flavor liquor through liquid state fermentation and belongs to the technical field of liquor making. The method comprises the procedures of raw material pulverization, liquefaction and gelatinization, saccharification, fermentation and distillation, wherein the fermentation procedure comprises the steps of adding cooled saccharification liquor to a 4-6% of saccharomycetes culture solution and a 1-3% of lactic acid bacteria culture solution, conducting fermentation for 36-48 hours at the temperature of 30-35 DEG C, adding the mixture to a 0.5-1.5% of acetic bacteria culture solution, conducting fermentation for another 2-4 days, and subsequently conducting distillation. By means of the method, controllable liquid state fermentation is adopted in the liquor-making process, fermentation process parameters can be regulated and controlled at any moment according to the fermentation process, labor intensity is greatly lowered, the output and quality of the liquor are stabilized, and mechanized operation of liquor production is comprehensively achieved; meanwhile, in the liquor-making process, multiple mycelia obtained through pure culture are adopted to be subjected to synergic saccharification and fermentation together with commercialized multienzyme systems, the content of high flavor substances of liquor obtained through a solid state method is maintained, meanwhile, the liquor output rate of raw materials is raised by 10%-20%, the fermentation cycle is shortened by 4-6 days, and the grain-saving and consumption-reduction purposes of liquor production are achieved.

Owner:TIANJIN UNIV OF SCI & TECH

Continuous ursol dissolving device and method

InactiveCN105688706AEliminate quality impactAchieve stabilityTransportation and packagingRotary stirring mixersAramidPolymer chemistry

The invention belongs to the technical field of synthesis of high polymer and relates to a continuous ursol dissolving device and method, in particular to a continuous dissolving device and method for monomer ursol during continuous polymerization of resin for para-aramid fibers, that is, conventional intermittent dissolving is substituted by PPD continuous dissolving. Therefore, all processes of PPTA polymerization are continuous, and stability in resin molecular weight is ensured, and consistency in resin luster is achieved.

Owner:AFCHINA CORP CO LTD +1

Method for preparing polyester polyol by taking waste polyester bottles as main raw materials

The invention provides a method for preparing polyester polyol by taking waste polyester bottles as main raw materials, comprising the step of introducing the polyols of tri(alpha-hydroxyethyl) isocyanurate, triethanolamine, sorbitol and the like and performing alcoholysis on waste polyester to prepare polyester polyol, wherein a new way for recycling polyester bottle waste materials is developed, and the reaction endpoint of the alcoholysis can be conveniently and effectively controlled by adopting a thin-layer chromatography method. The polyester polyol prepared by the method disclosed by the invention has a hydroxyl value of 150-310 mgKOH / g, a number-average molecular weight of 5000-7000 (which is measured by a gel permeation chromatography method, and with a mobile phase of tetrahydrofuran), and a molecular weight distribution index of 1.7-2.5; and the production cost is 65-80% of the production cost of the existing similar products.

Owner:华大化学(安徽)有限公司

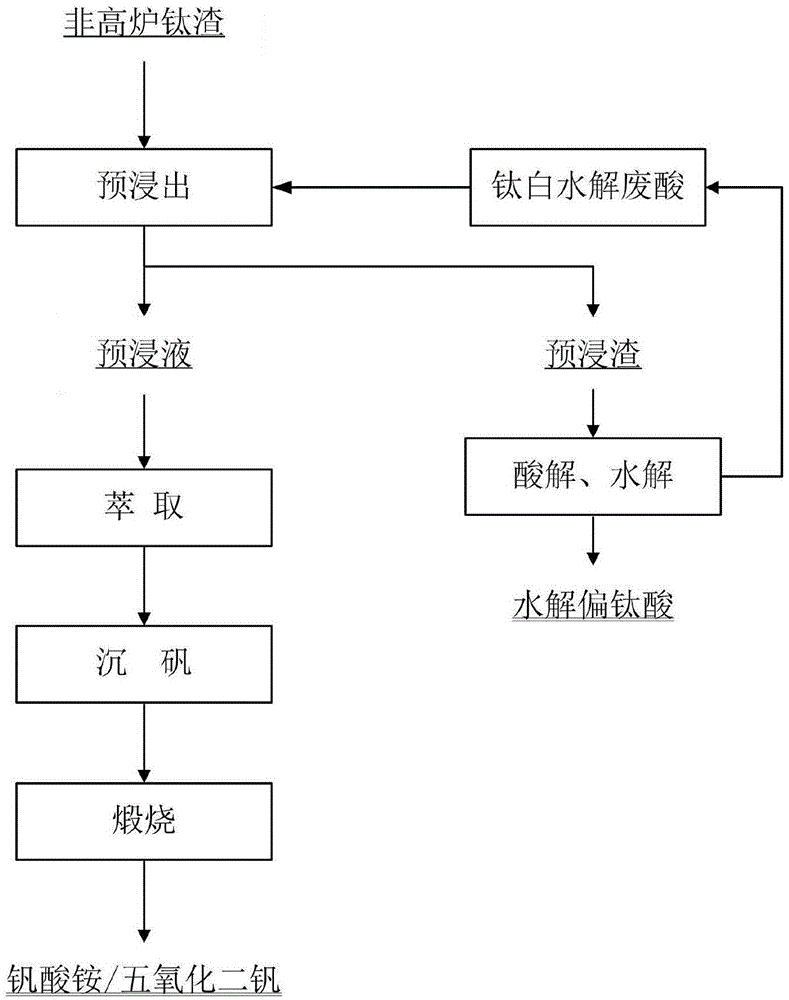

Method of recovering vanadium from non-blast furnace titanium slag

InactiveCN106884089AEfficient recyclingEnsure stabilityTitanium dioxideProcess efficiency improvementAluminum silicateDissolution

The invention discloses a method of recovering vanadium from non-blast furnace titanium slag, and belongs to the technical field of vanadium recovery. According to the method, non-blast furnace titanium slag of vanadium-titanium-iron concentrate is taken as the raw material; the non-blast furnace titanium slag is pre-soaked in waste acids generated during the titanium dioxide production process; during the pre-soaking process, the behavior of vanadium and titanium is effectively controlled; the leaching of vanadium in magnesium aluminum silicate is enhanced; the dissolution of TiO2 in non-blast furnace titanium slag and hydrolysis of TiO2 in titanium dioxide waste acids are inhibited, and the stability of vanadium in waste acids is maintained. Titanium dioxide is prepared from pre-soaked titanium slag through a conventional sulfuric acid method. The pre-soaking solution is reduced and then subjected to an extraction-reverse extraction technology to obtain a vanadium-containing solution so as to prepare a vanadium product. The characteristics of non-blast furnace titanium slag are deeply studied, the titanium dioxide production method (sulfuric acid) is used, the vanadium is comprehensively recovered on the basis that the titanium dioxide waste acids are cyclically utilized, the vanadium (impurity in titanium dioxide production) is recovered and purified, the technology is simple and easy, the vanadium recovery rate is high, high quality titanium dioxide is produced at the same time, and thus the method has a good popularization and application prospect.

Owner:BEIJING GENERAL RES INST OF MINING & METALLURGY

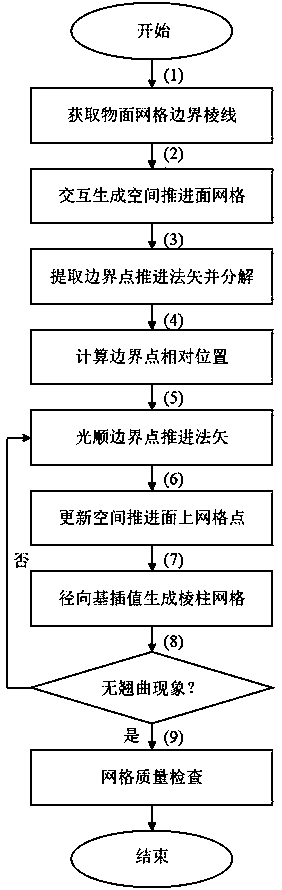

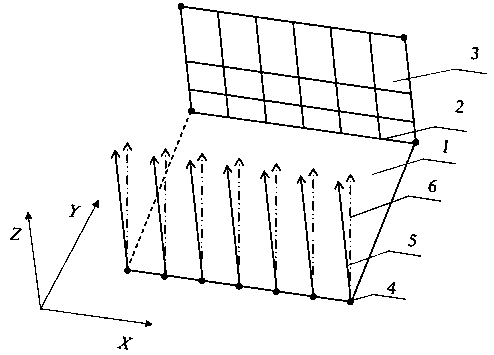

Warping phenomenon elimination method in interactive prism grid generation

ActiveCN111444661AEliminate warpingEliminate quality impactDesign optimisation/simulationComputational simulationClassical mechanics

The invention discloses a method for eliminating a warping phenomenon in interactive prism grid generation. The method comprises the following steps: firstly, artificially interacting to generate a space propulsion grid of product surface grid boundary points; fairing components of propulsion normal vectors of boundary points of the object plane grid in X, Y and Z coordinate directions by using afairing algorithm, interpolating by using a radial basis function method to obtain a space propulsion grid of internal points of the object plane grid, and finally assembling to obtain a boundary layer prism grid for CFD calculation simulation; according to the method, an object plane grid boundary space propelling plane grid generated through manual interaction is optimized, the influence of thewarping phenomenon on the quality of the prism grid is eliminated through the technologies of normal vector fairing, radial basis function interpolation and the like, and the method has obvious technical advantages in the aspect of improving the generation efficiency of the prism grid and the universality of the method.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

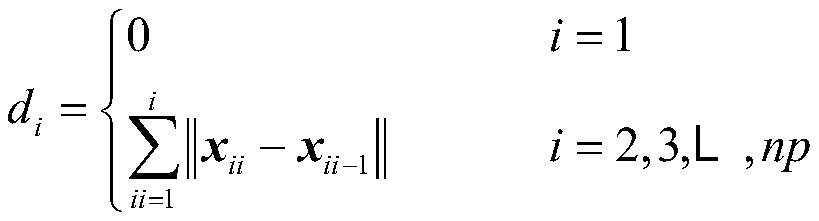

Method for producing whole pumpkin powder through enzymolysis technology

ActiveCN103393026AIncrease productivityIncrease nutritional contentFood shapingFood preparationMicroorganismActive enzyme

The invention relates to a method for producing whole pumpkin powder through using an enzymolysis technology. The method comprises the steps of: cleaning and disinfecting a processed pumpkin; crushing the pumpkin into pumpkin pulp with the particle size being less than or equal to 0.1cm; pre-cooking the pumpkin pulp at 90-95 DEG C for 10-15min; adjusting the pH value of the pre-cooked pumpkin pulp to be 5.3-5.7; adding enzyme into the pumpkin pulp for enzymolysis at 50-55 DEG C; heating the pumpkin pulp to 85-95 DEG C within a period of time of 30min, and keeping for 10-15min for enzyme deactivation; concentrating the pumpkin pulp still the sugar degree is up to 20%-25%; carrying out spray drying to obtain a final powdery whole pumpkin powder material with the moisture content being less than 4.0%. The method has the beneficial effects of improving the production efficiency and the yield of the whole pumpkin powder, improving the nutritional ingredients and taste of the whole pumpkin powder, and simultaneously eliminating the residual active enzyme and the influence of attached microorganisms on the product quality. Moreover, the technological process is reasonably arranged, so that the energy utilization rate is improved, and the energy consumption is reduced.

Owner:宝得瑞(湖北)健康产业有限公司

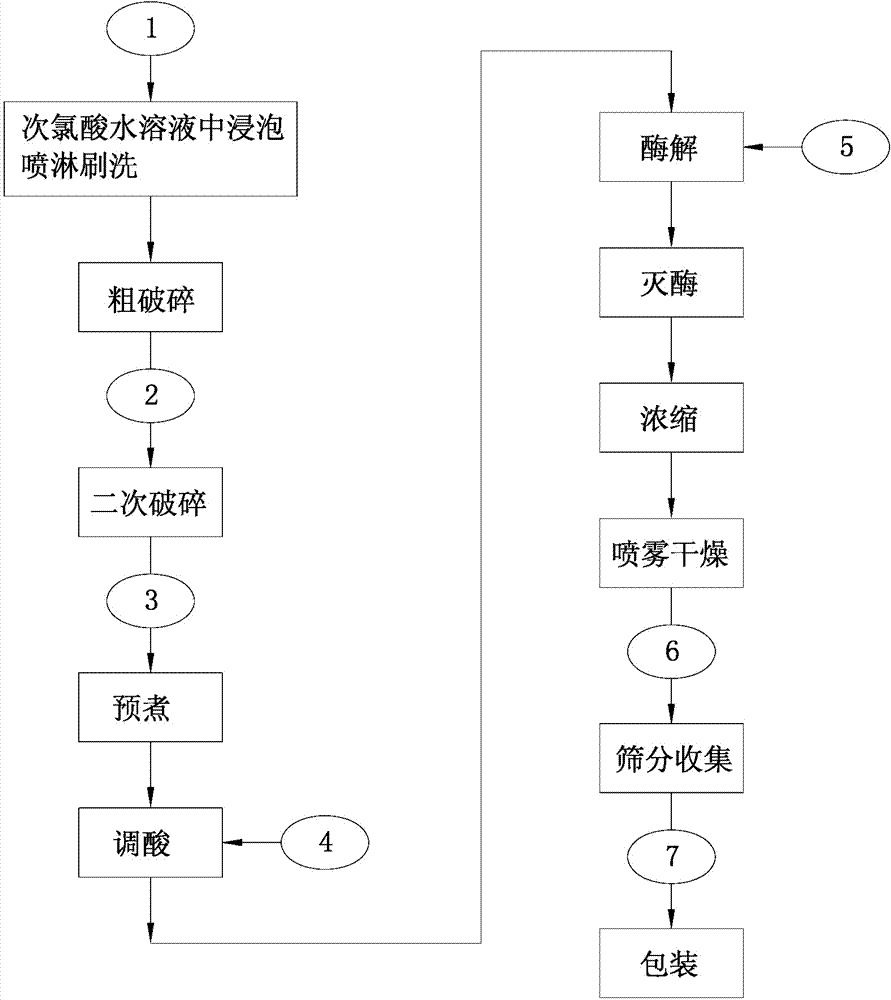

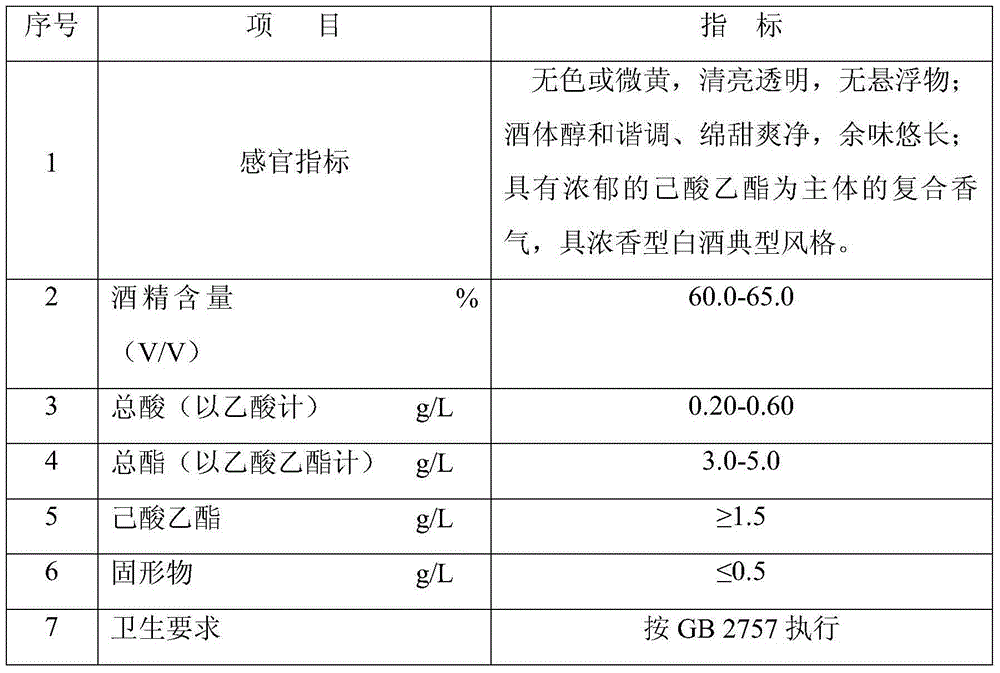

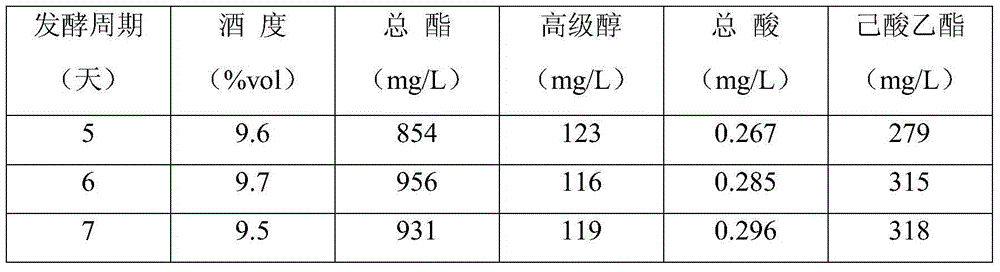

Novel solid fermentation method for producing Luzhou-flavor liquor

InactiveCN104593189AIncrease productivityHigh yieldMicroorganism based processesAlcoholic beverage preparationDistillationFood flavor

The invention discloses a novel solid fermentation method for producing a Luzhou-flavor liquor, and belongs to the technical field of wine brewing. The technology content comprises steps of raw material crushing, liquefaction and gelatinization, starter addition, wort-dividing fermentation, mixed fermentation and distillation, wherein the wort-separating fermentation comprises dividing a wort added with a starter into two portions according to a ratio, and then performing fermentation; concretely, inoculating a high-ester-yield saccharomyces cerevisiae culture solution to a first wort for fermentation, controlling the inoculation amount to be 1-3%, and performing fermentation culturing at 27-33 DEG C for 20-30 h; inoculating a lactic acid bacteria culture solution to a second wort portion, controlling the inoculation amount to be 0.5-2%, and performing fermentation culturing at 33-39 DEG C for 20-30 h; and then performing mixed fermentation. The advantages comprise that influence of environment factors to the fermentation process is eliminated, automatic and mechanized operation during brewing of the Luzhou-flavor liquor is realized, when the content of a high-flavor substance in the Luzhou-flavor liquor is kept, the raw-material liquor yield is substantially improved and the fermentation period is shortened, and thus the production efficiency of the Luzhou-flavor liquor is substantially improved.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

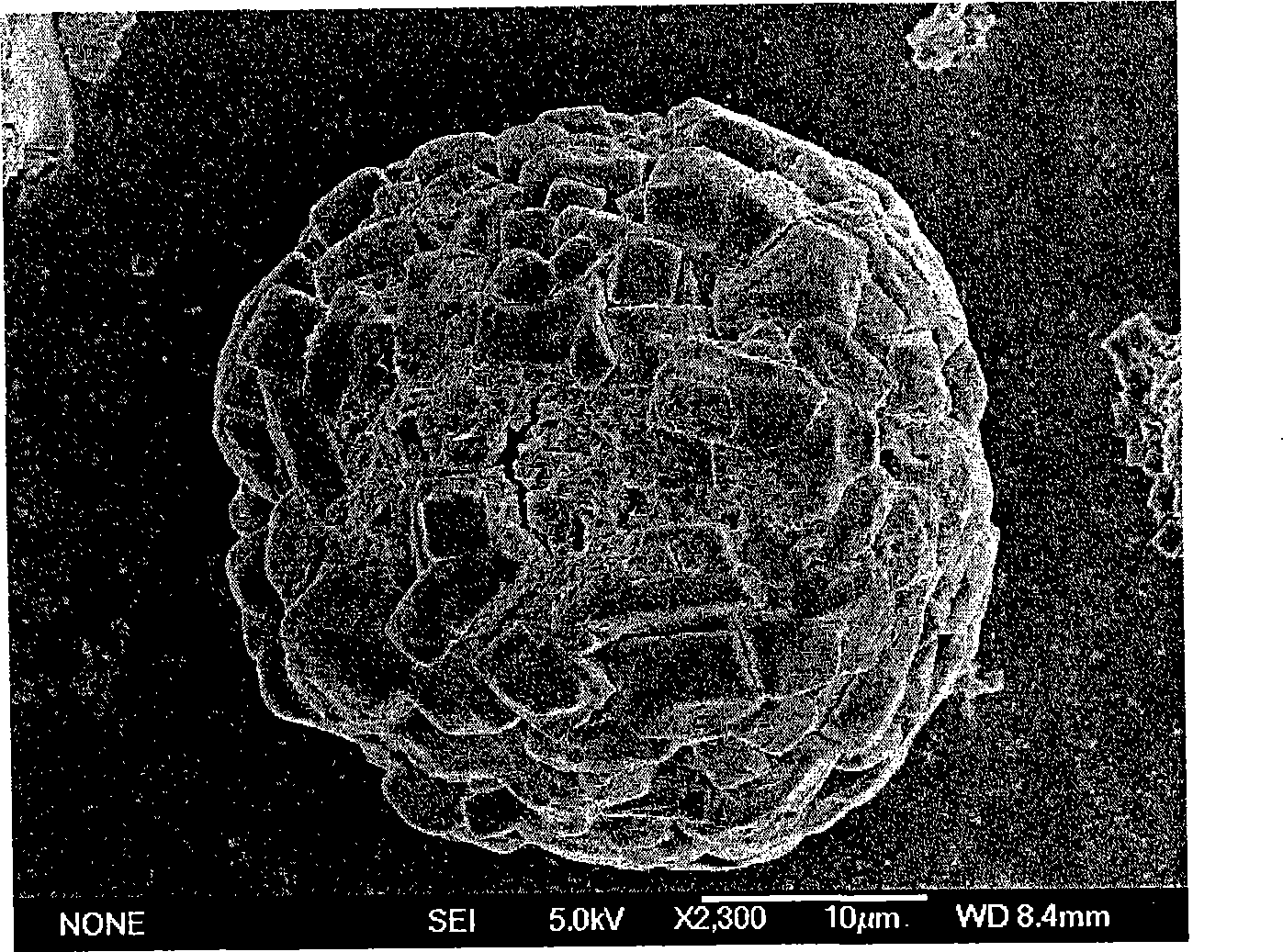

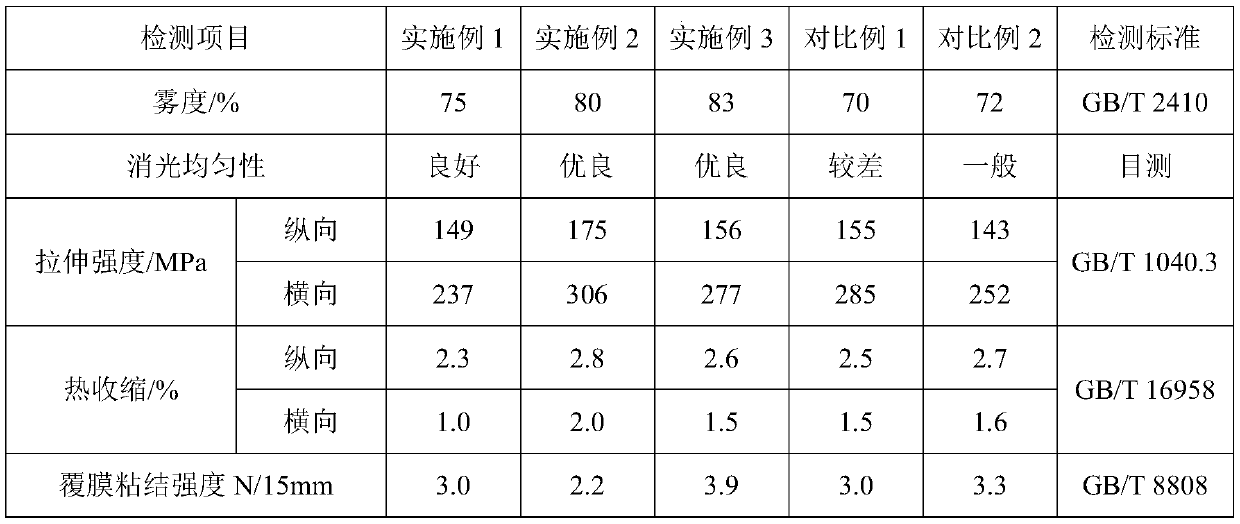

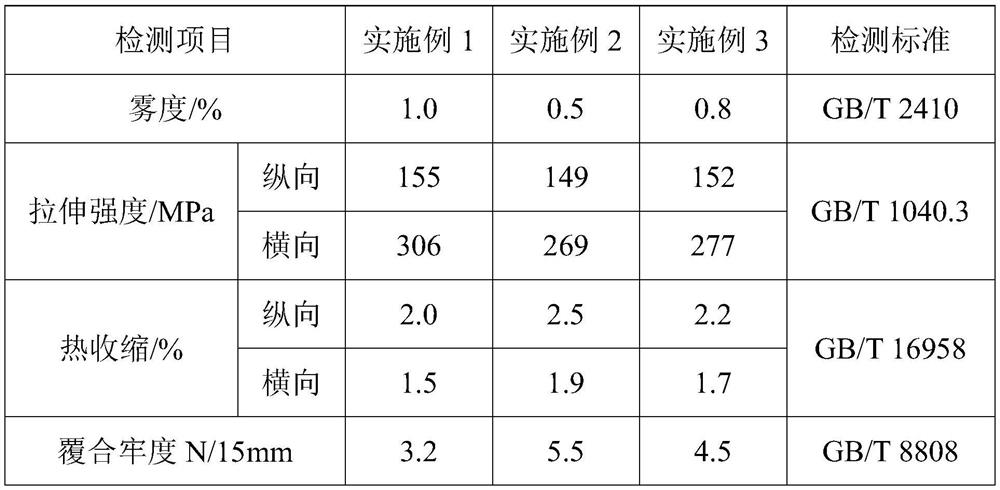

Primer-free BOPP digital matt film with high adhesive strength, and preparation method thereof

InactiveCN110450492AImprove production stabilityGood physical and mechanical propertiesSynthetic resin layered productsLaminationLow-density polyethyleneLinear low-density polyethylene

The invention relates to a primer-free BOPP digital matt film with a high adhesive strength, and a preparation method thereof. The film is sequentially composed of an upper surface layer, a secondarysurface layer, a core layer and a lower surface layer, and each of the upper surface layer and the secondary surface layer is composed of co-polypropylene and high density polyethylene; the core layeris composed of homopolypropylene and an antistatic agent; the lower layer is composed of an organic high-molecular anti-stick master batch and metallocene linear low density polyethylene; and the organic high-molecular anti-stick master batch is composed of spherical acrylate particles and co-polypropylene. The lower surface is directly coated with an EVA melt, and hot pressing compounding is carried out to prepare a pre-coating film, so the pollution of a primer to the environment is avoided; and the organic high-molecular anti-stick master batch added to the lower surface plays a role in anti-sticking, and also can reduce the influences on the optical properties of the film and ensure the light transmittance of the matt film.

Owner:ANHUI GUOFENG PLASTIC

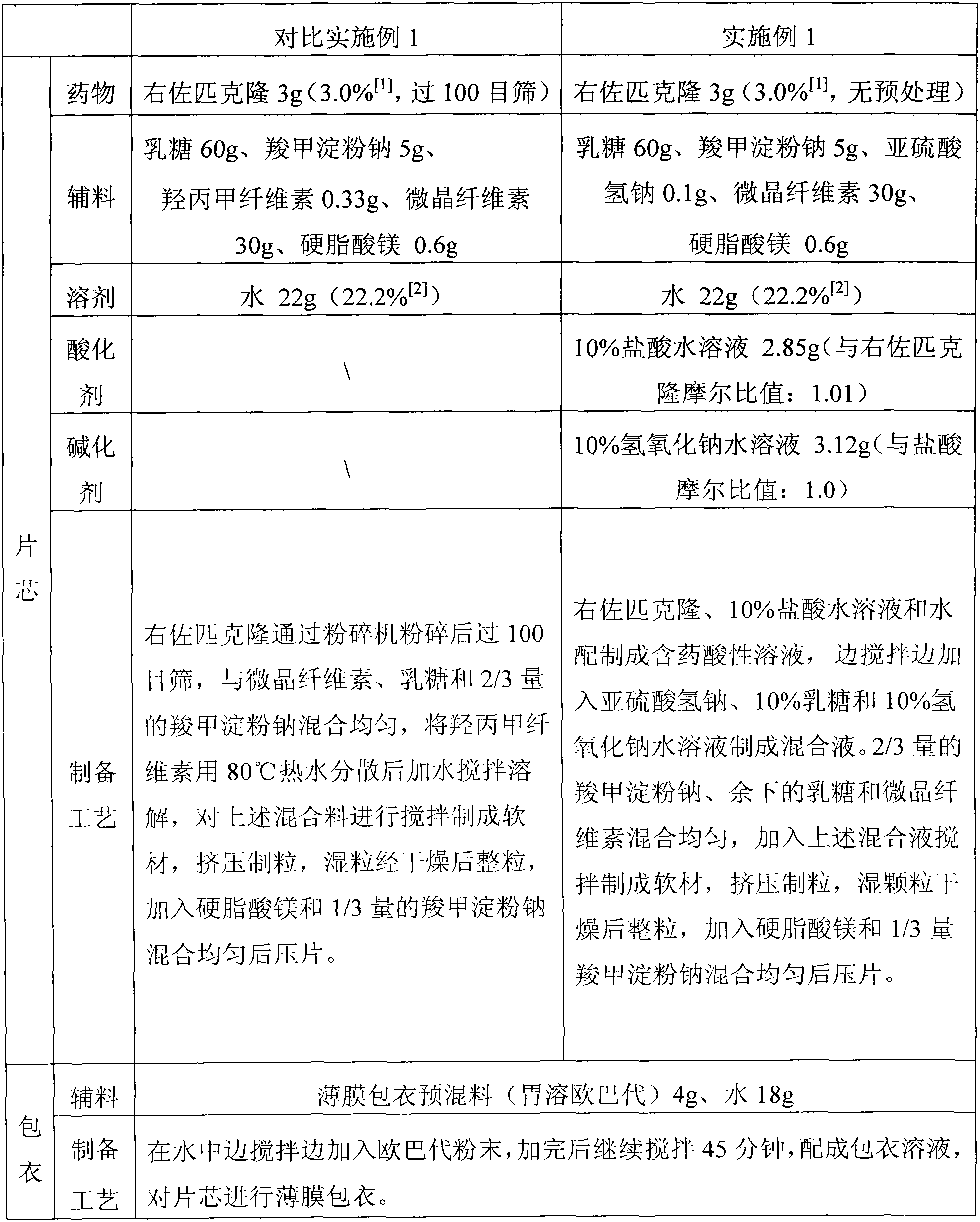

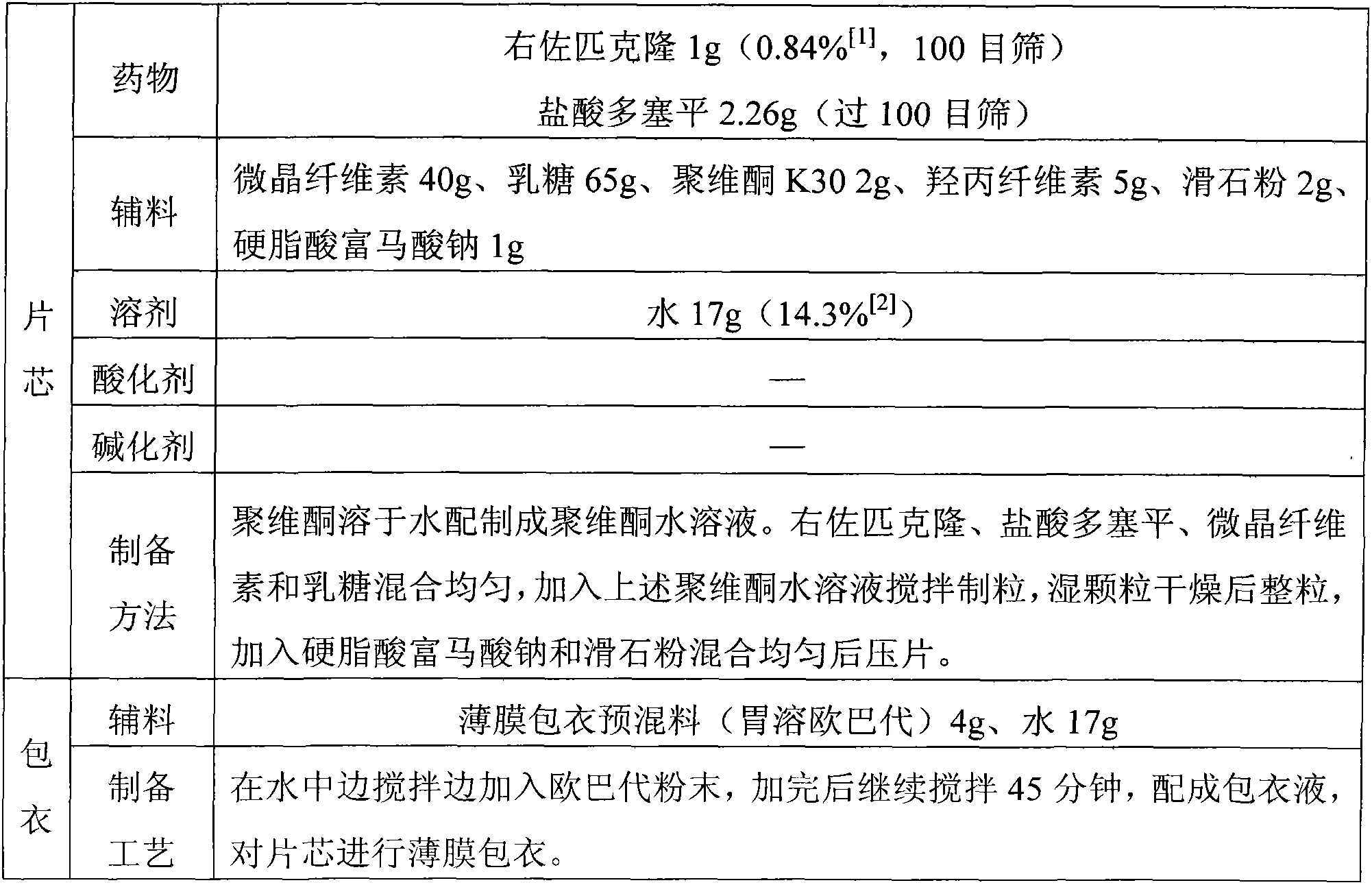

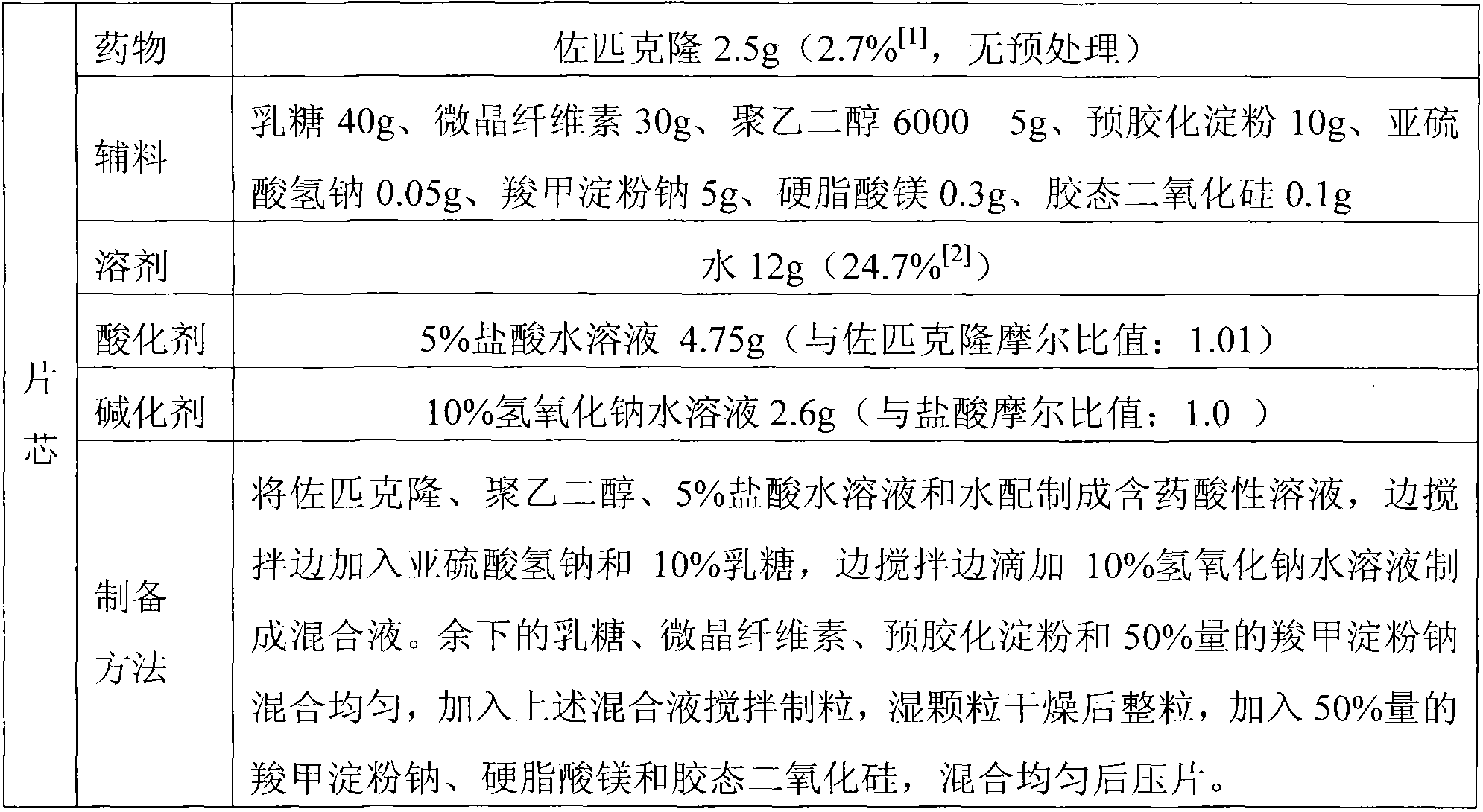

Sedative hypnotic pharmaceutical preparation and its preparation method

ActiveCN102846538AChange surface propertiesImprove wettabilityOrganic active ingredientsNervous disorderOrganic acidSubstance content

The invention discloses a preparation method of a sedative hypnotic pharmaceutical preparation. The preparation method includes the steps of dissolving active ingredient dexzopiclone or zopiclone in acidifier-containing acidic solution to give drug-containing acidic solution, and then performing wet granulation with the obtained drug-containing acidic solution, basifier and adjuvant. The acidifier is hydrochloric acid, and the basifier is sodium hydroxide. One or more of organic weak acid, acid salt and conjugate base of organic weak acid are added before or during the addition of the basifier. The invention also discloses the sedative hypnotic pharmaceutical preparation prepared by the method. The inventive preparation method has no potential safety hazard, simple and convenient operation, low pollution and loss, low cost, and good process controllability. The obtained pharmaceutical preparation has excellent dissolution and stability, and lower related substance content.

Owner:SHANGHAI ZHONGXI PHARMA

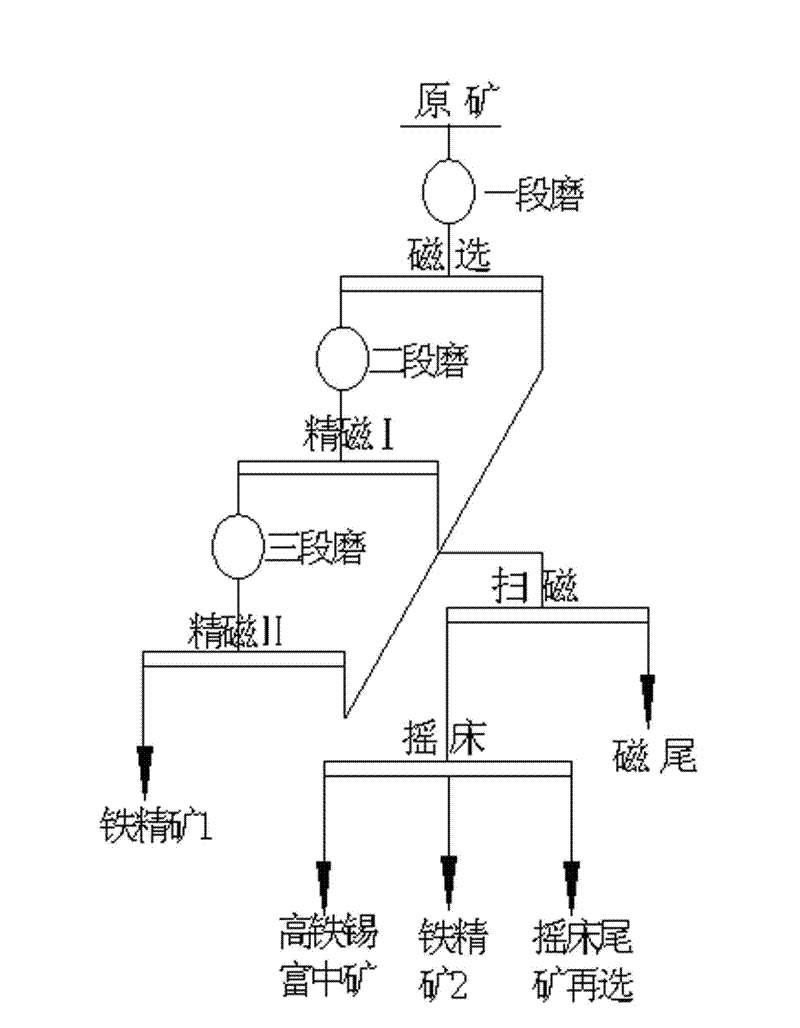

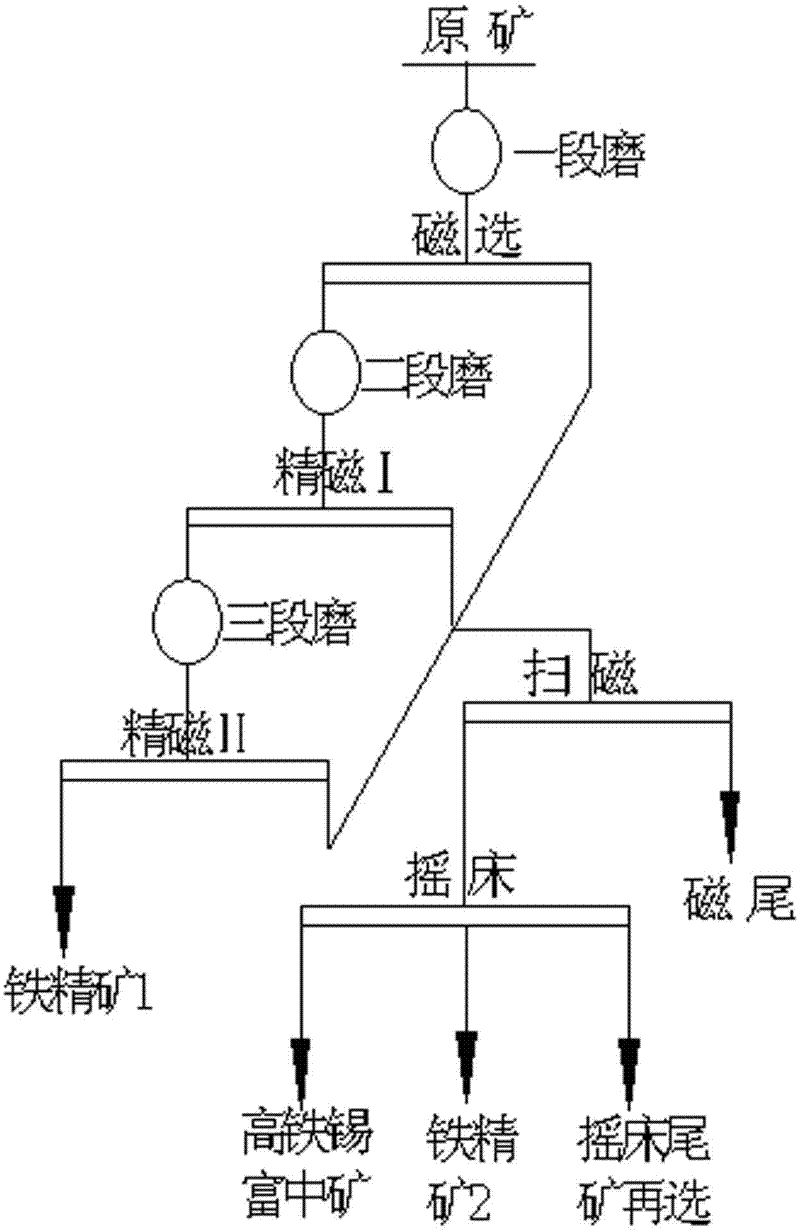

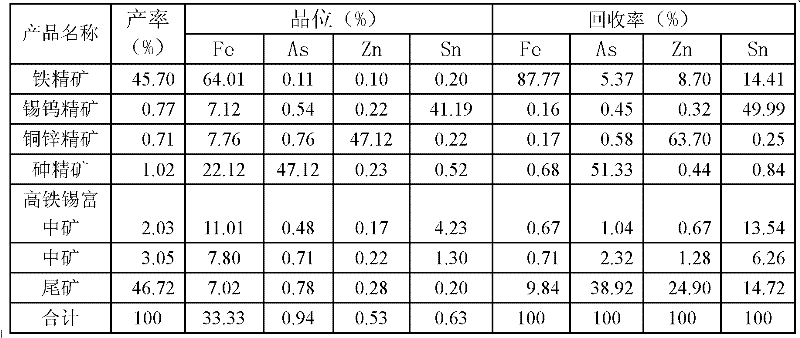

Branch gravity concentration method for recovering accompanying tin from semi-finished product of magnetic concentrated iron of iron-tin ore

InactiveCN102225357AReduce contentHigh recovery rateMagnetic separationNon magneticMaterials science

The invention relates to a branch gravity concentration method for recovering accompanying tin from a semi-finished product of magnetic concentrated iron of iron-tin ore and belongs to the technical field of non-ferrous metal ore beneficiation. The method comprises the following steps: (1) performing magnetic separation after grinding iron-tin accompanying raw ore, grinding the separated magnetic ore and then performing magnetic separation on the separated magnetic ore, and repeating the operations for more than two times, thereby acquiring iron ore concentrate, wherein more than 75% of final grain size of the grinded ore is above 200 meshes and the intensity of a magnetic field for magnetic separation is 900-1300 oersteds; (2) performing a magnetic scavenging process on non-magnetic tailings which are from each stage of magnetic separation, wherein the intensity of the magnetic field is 1200-1400 oersteds; and (3) performing a table gravity concentration process on the ore which is acquired from the magnetic scavenging process, thereby acquiring a middling product rich in iron and tin, iron ore concentrate and table tin tailings. The branch gravity concentration method provided by the invention has the advantages that the method is simple, the operation is easy, the energy source is saved, the process flow is short, the purpose of comprehensively recovering iron and tin is achieved, the recovery rate of iron and tin is high, and the comprehensive cost of beneficiation is low.

Owner:YUNNAN TIN GROUP HLDG

Method for preparing 3, 5-dichloroaniline by means of catalytic hydrogenation

PendingCN109020818AReduce corrosionSolve the problem of hydrogenolysis and dechlorinationOrganic compound preparationChemical recyclingApplication timeDichloroaniline

The invention discloses a method for preparing 3, 5-dichloroaniline by means of catalytic hydrogenation. According to the method, 3, 5-dichloronitrobenzene is used as a raw material, and the 3, 5-dichloroaniline is prepared by taking the 3, 5-dichloronitrobenzene as body and carrying out a catalytic hydrogenation reduction reaction under the conditions of 0.8-1.2MPa and 90-120 DEG C in presence ofa Pt / c catalyst. The method uses the Pt / c catalyst, thus effectively solving the problems of hydrogenolysis and dechlorination in a hydrogenation reduction process of the 3, 5-dichloronitrobenzene; the dechlorination rate does not exceed 0.25%, so that the corrosion, caused by dechlorination, of reaction equipment is reduced, and equipment maintenance and care costs are lowered; the Pt / c catalystis simple in components, low in recovery costs, stable in activity, high in selectivity and long in continuous application time. In addition, the method does not use a dechlorination inhibitor, so that the separation process of the dechlorination inhibitor is omitted, and the influence of the dechlorination inhibitor on the quality of the finished product is fundamentally eliminated.

Owner:JIANGXI HEYI CHEM

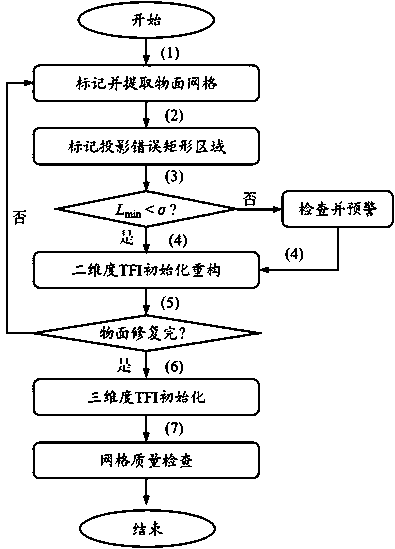

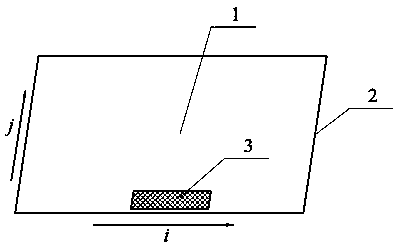

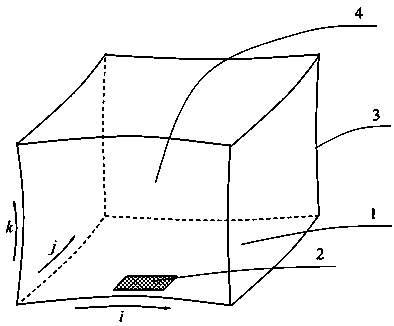

Method for repairing object plane projection error in multi-block structure grid generation

ActiveCN110334450AAvoid Fine Patching IssuesReduce distortionDesign optimisation/simulationSpecial data processing applicationsCommercial softwareBlock structure

The invention discloses a method for repairing projection errors in multi-block structure grid object plane generation. The method comprises the following steps: firstly, screening and marking an object plane grid region with a projection error through surface grid detection, then reconstructing an object plane grid with a projection error by utilizing a two-dimensional extreme interpolation method, then initializing a whole grid block by utilizing a three-dimensional extreme interpolation method, and finally generating a flow field calculation grid meeting a CFD analysis requirement. Different from the technology of repairing a digital model in commercial software to improve the projection precision and avoid generation of grid projection errors, the method provided by the invention is simple; according to the method, a plurality of structural grids with projection errors are repaired, the influence of the projection errors on the quality of the grids is eliminated through technologies such as projection error region detection and initialization reconstruction, and the automation of a repair process can be realized through a program.

Owner:CALCULATION AERODYNAMICS INST CHINA AERODYNAMICS RES & DEV CENT

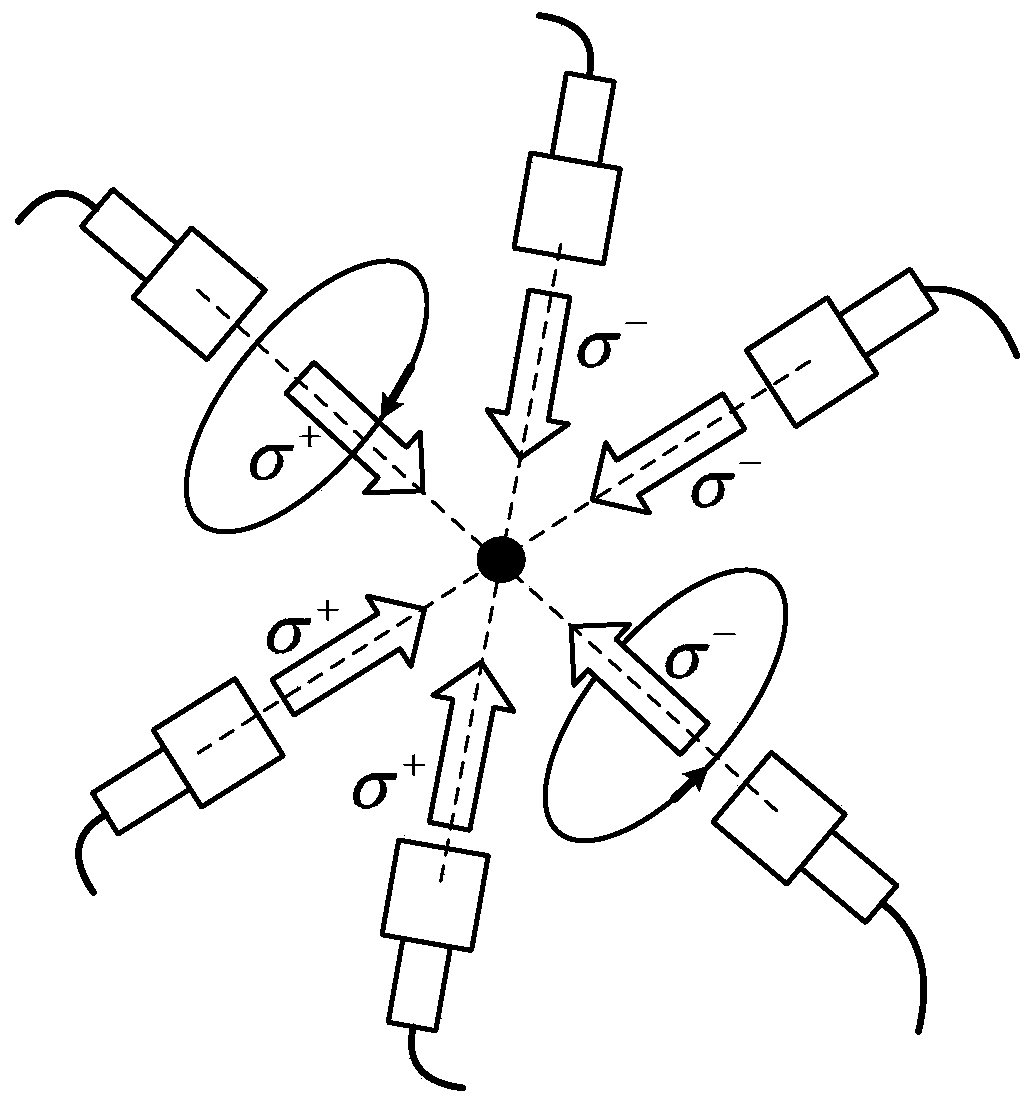

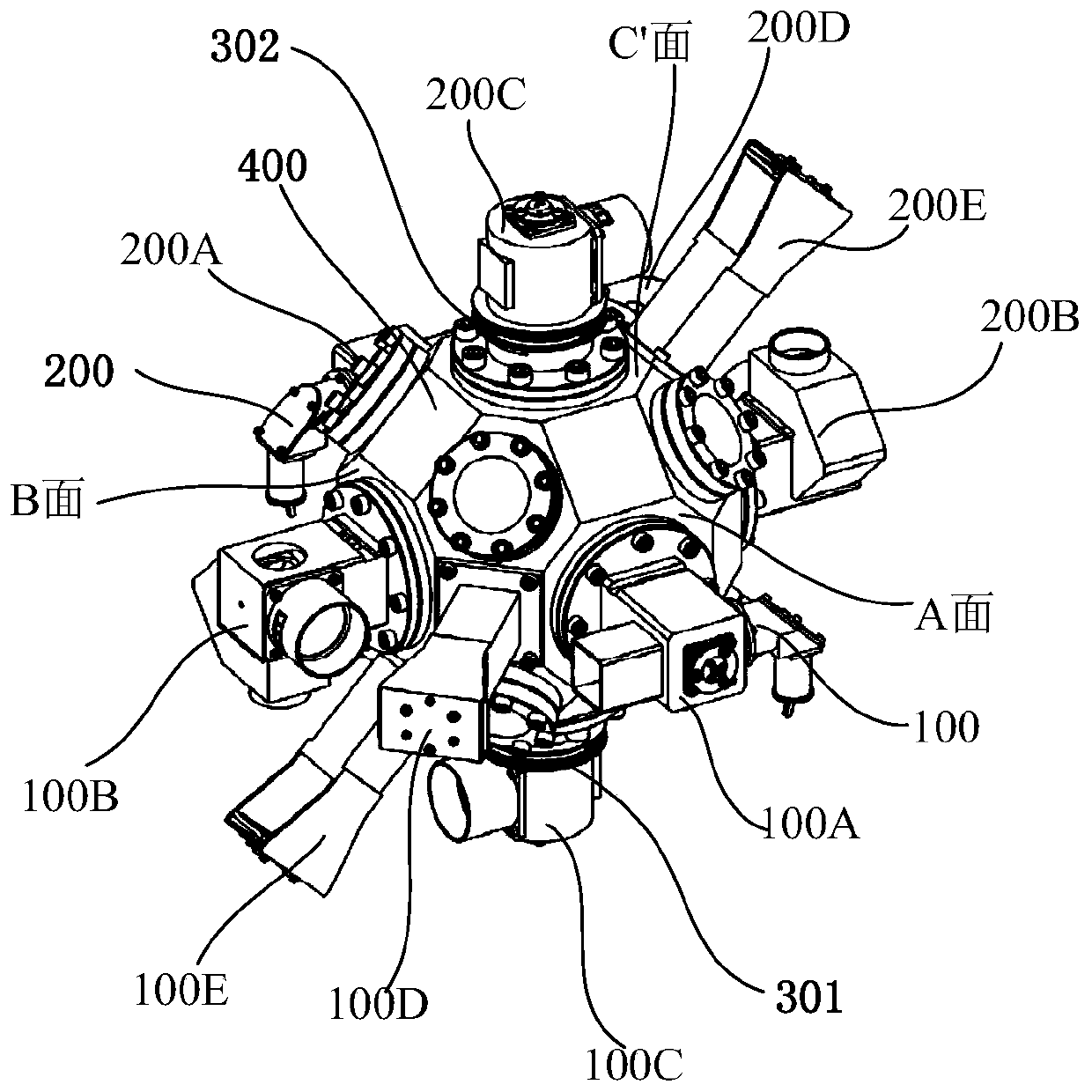

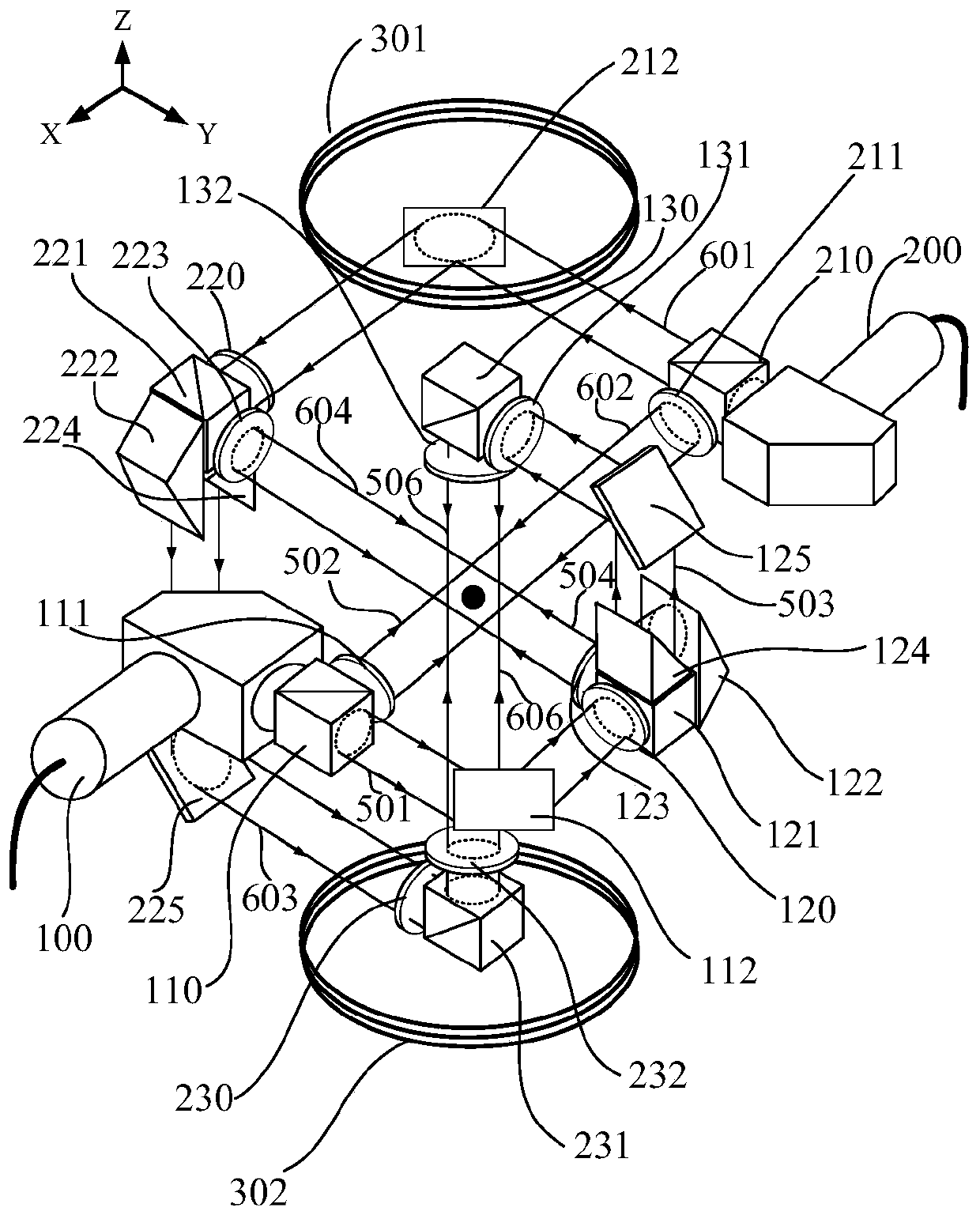

Double-beam input laser cooling atom three-dimensional magneto-optical trap device

ActiveCN111584115AEliminate quality impactImprove performanceNeutron particle radiation pressure manipulationMagneto-optical trapPolarization-maintaining optical fiber

The invention provides a double-beam input laser cooling atom three-dimensional magneto-optical trap device, and aims to overcome the defects that an optical path system of an existing magneto-opticaltrap is easily affected by the external environment, and generated cold atoms have large-amplitude random jitter, and extra errors are introduced although random jittering of cold atom parameters caused by optical fiber factors is reduced. A unique three-dimensional MOT optical path transmission topology is designed, six polarization maintaining optical fibers required originally are reduced to two polarization maintaining optical fibers, and the influence of unstable incident laser polarization degree and light intensity fluctuation on the generated cold atom quality is greatly eliminated; polarization characteristics of laser beams are utilized, multiple times of light beam splitting and reflection are performed, independent adjustment of power and polarization of six beams of laser used for atom cooling is achieved under the condition that only two paths of input light exist, particularly, the power of the six beams of light which are oppositely emitted in pairs at a convergence point can be adjusted to be strictly equal, and the influence caused by inconsistent fluctuation pace of the power of the six beams of light in the working process of the device is greatly reduced.

Owner:XI'AN INST OF OPTICS & FINE MECHANICS - CHINESE ACAD OF SCI

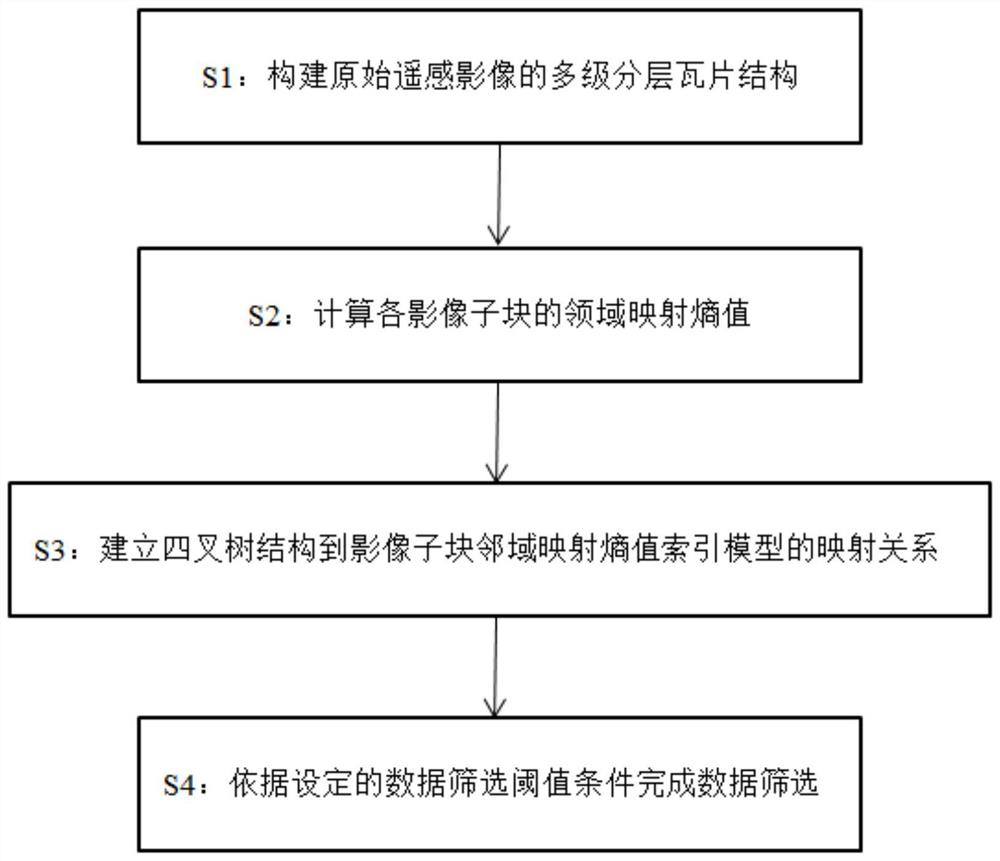

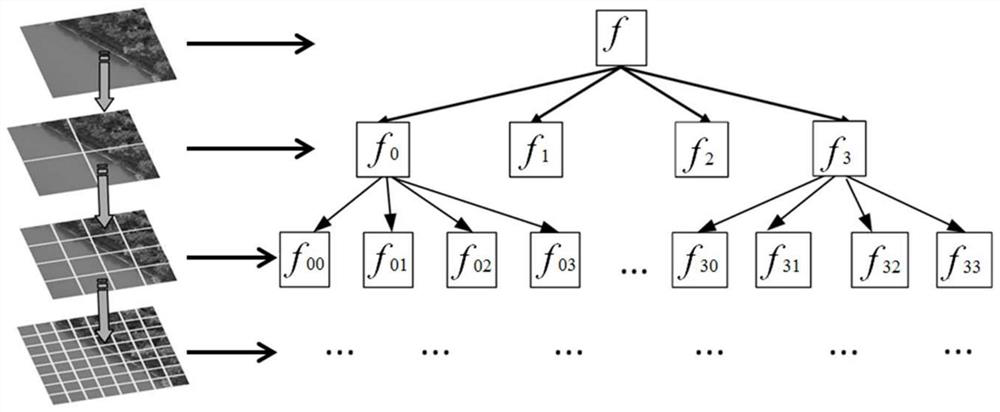

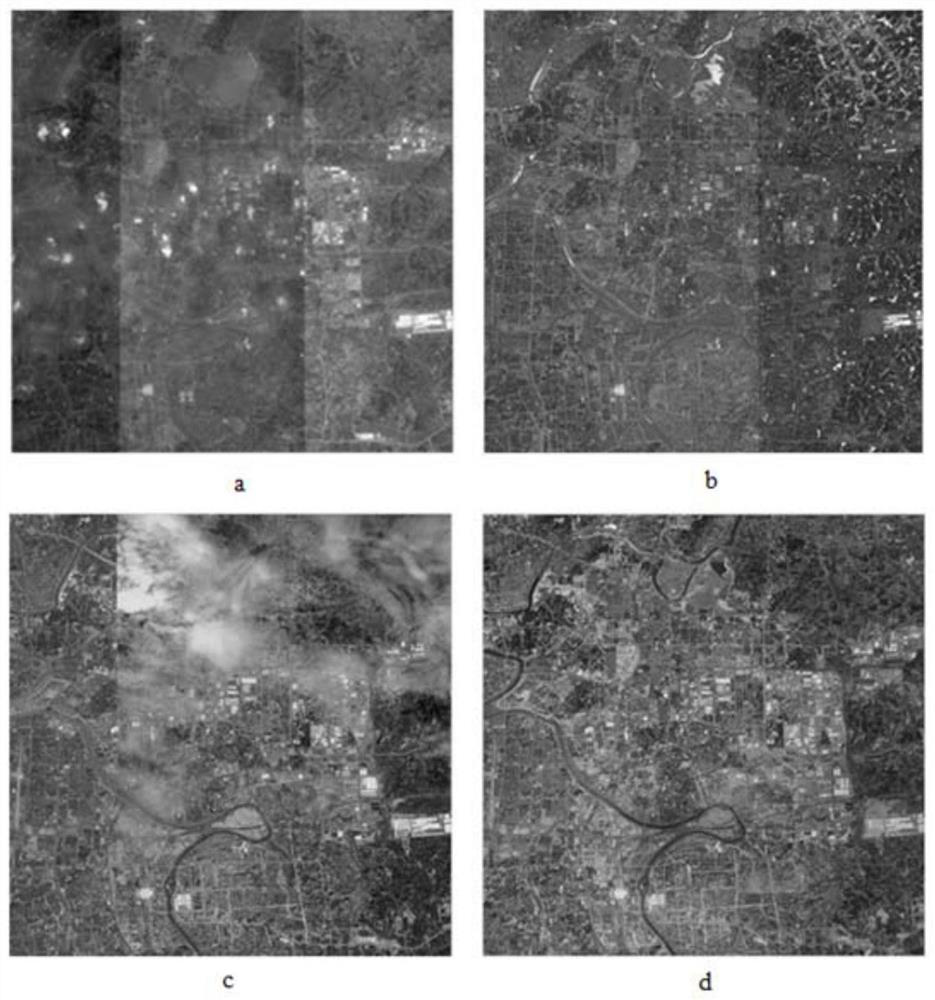

Entropy-based remote sensing image data screening method

ActiveCN112380367AAutomateEfficient and accurate screening processStill image data indexingSpecial data processing applicationsSensing dataEntropy model

The invention belongs to a remote sensing image processing method, and discloses an entropy-based remote sensing image data screening method, which comprises the following steps of: (1) constructing amulti-stage layered tile structure of an original remote sensing image by utilizing a related theory of layering and blocking; (2) calculating a neighborhood mapping entropy value of each image sub-block in each level of tile structure according to a neighborhood mapping entropy model of the remote sensing image information; (3) constructing an index of the neighborhood mapping entropy of each image sub-block in combination with the quadtree structure, and establishing a mapping relationship from the quadtree structure to a neighborhood mapping entropy index model of each image sub-block according to the hierarchical characteristics of the multi-level hierarchical tile structure; and (4) completing data screening according to a set data screening threshold condition so as to acquire required remote sensing image data. Automatic screening of original remote sensing image data is realized by utilizing the information entropy, and the data quality of the remote sensing image is improvedwhile the redundancy of the remote sensing data is reduced.

Owner:CENT SOUTH UNIV

Hickory nut shell brown pigment and its preparation method

InactiveCN103319912AKeep aliveGuaranteed stabilityNatural dyesBulk chemical productionSupersonic wavesDigestion

An extraction method of a high-performance and high-stability Northeast hickory nut shell brown pigment relates to a natural pigment processing technology. According to the invention, compound enzyme-supersonic wave-supercritical are creatively and effectively combined in synergism. Thus, residues require no secondary digestion or extraction but only require extraction once so as to effectively avoid the influence of secondary extraction on pigment activity. With the cooperation of compound enzyme, extraction rate is greatly raised, and the influence of fat on the pigment is avoided. The whole course is carried out at a low and mild temperature, thus guaranteeing the pigment activity and activity stability and achieving an unexpected technical effect. The preparation method provided by the invention has advantages of simple technology, short period and no complex equipment, is easy to operate, is adopted to obviously raise product performance, and is suitable for industrial production.

Owner:HEILONGJIANG VOCATIONAL INST OF ECOLOGICAL ENG

Machining process of high-precision thin-walled pure aluminum or aluminum alloy pipes

The invention provides a machining process of high-precision thin-walled pure aluminum or aluminum alloy pipes, and the machining process aims to solve the problems that in a traditional extrusion production process of high-precision aluminum or aluminum alloy pipes, the size precision and the yield are low, and in horizontal continuous casting, the wall thickness uniformity is poor and mold sticking is prone to happening. The method adopts a vertical continuous casting technology to prepare the high-precision thin-walled pure aluminum or aluminum alloy pipe blanks, the solid-liquid interfaceposition is located at the transition area of a heat section and a cold section by controlling the continuous casting and molding, the formed pipe blanks have columnar crystal structures with high inner and outer surface quality and high orientation degree in the continuous casting direction, axial extending deformation of subsequent cold machining like rolling and drawing is facilitated, the continuous cast pipe blanks can be directly subjected to large-deformation cold machining and molding without face milling, short-process production of the high-precision thin-walled pure aluminum or aluminum alloy pipes is achieved, and the problems that in a traditional process of the high-precision thin-walled pure aluminum or aluminum alloy pipes, the investment is large, the process is long, theyield is low and the cost is high are solved.

Owner:CHINALCO MATERIALS APPL RES INST CO LTD

Three-dimensional cultivation technology of high-quality pollution-free blueberry

InactiveCN108293543AImprove qualityImprove the soil environmentCultivating equipmentsPlant protectionBlueberry PlantsSeedling

The invention relates to a three-dimensional cultivation technology of high-quality pollution-free blueberry. A scientific and reasonable seedling and nursery stock selection and breeding technology is adopted, and a field planting mode and a whole process management mode in a production period are standardized, so that the resistance of blueberry plants is improved, healthy growth of blueberry fruits is promoted, the overall yield and fruit grade of the blueberry fruits are improved, and healthy and orderly development of the blueberry industry is ensured.

Owner:成都老农王农业开发有限公司

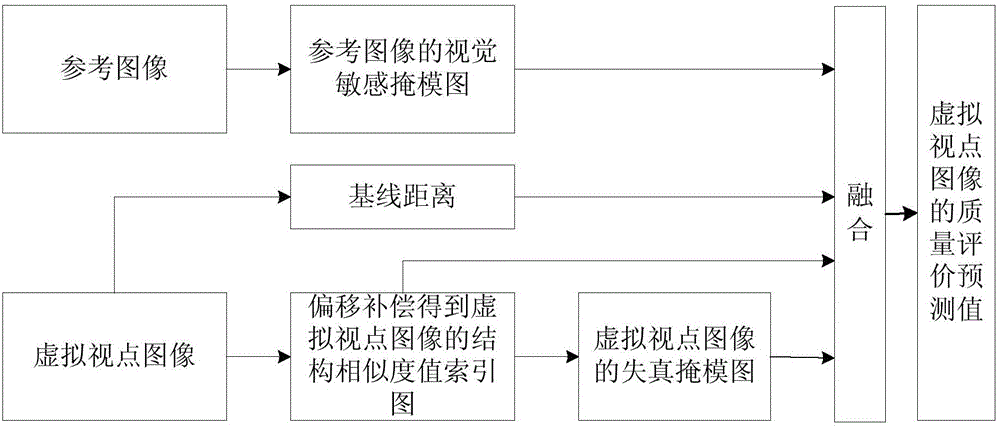

Virtual viewpoint quality evaluation method based on visual masking effect

ActiveCN105828061AEliminate quality impactSubjective and objective quality results are consistentImage enhancementImage analysisViewpointsObjective quality

The invention discloses a virtual viewpoint quality evaluation method based on a visual masking effect. According to the method, the types of virtual viewpoint rendering distortions are fully considered, offset compensation is performed on a virtual viewpoint image, the offset compensation process aims at special distortions such as a pixel point offset in the rendering of a virtual viewpoint, the affect of the pixel point position offset on the quality of the virtual viewpoint image is well eliminated, and thus subjective and objective quality results of the virtual viewpoint image are more accordant; the human visual characteristics are fully considered, a visual sensitive mask pattern of a reference image is extracted, the affect of distortion of a visual insensitive area in the virtual viewpoint image on the objective quality evaluation result is eliminated, and thus the objective quality evaluation result is more accordant with human visual characteristics; a distortion amplitude masking effect and a distortion distribution masking effect are fully considered, the distortion masking pattern of the virtual viewpoint image is computed for extracting areas with large distortion amplitudes and concentrated distortion distributions, and the affects of the distortions with different amplitudes and different distributions on the human visual subjective quality are effectively distinguished.

Owner:深圳威尔视觉科技有限公司

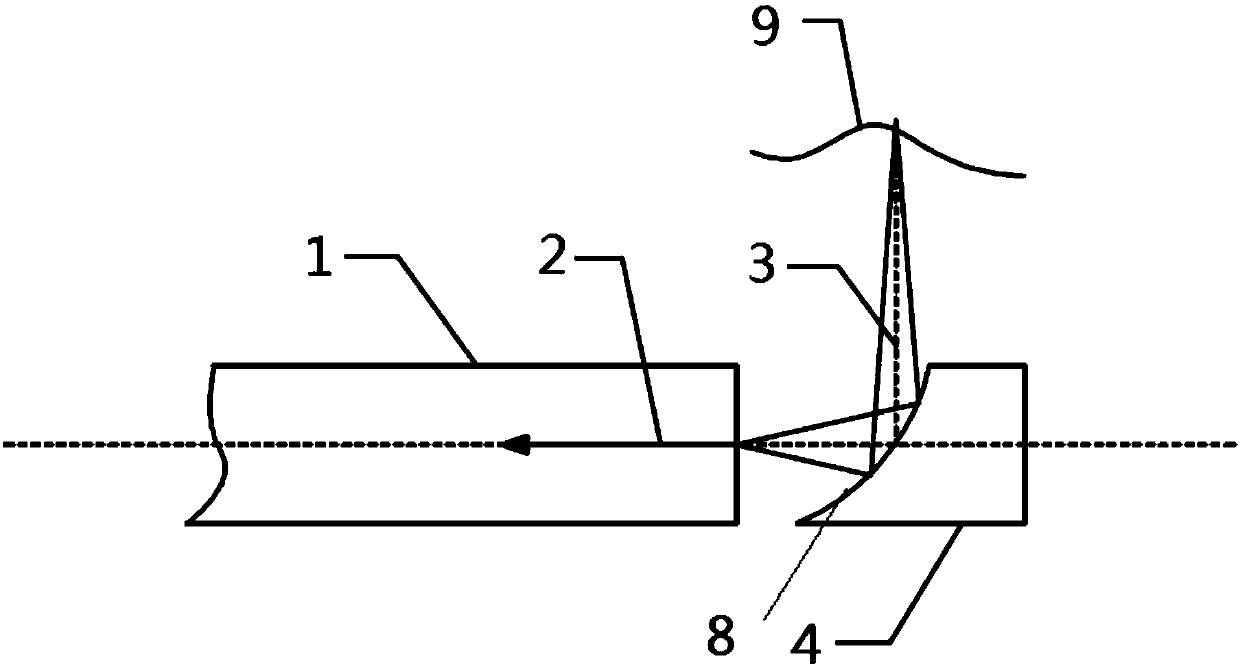

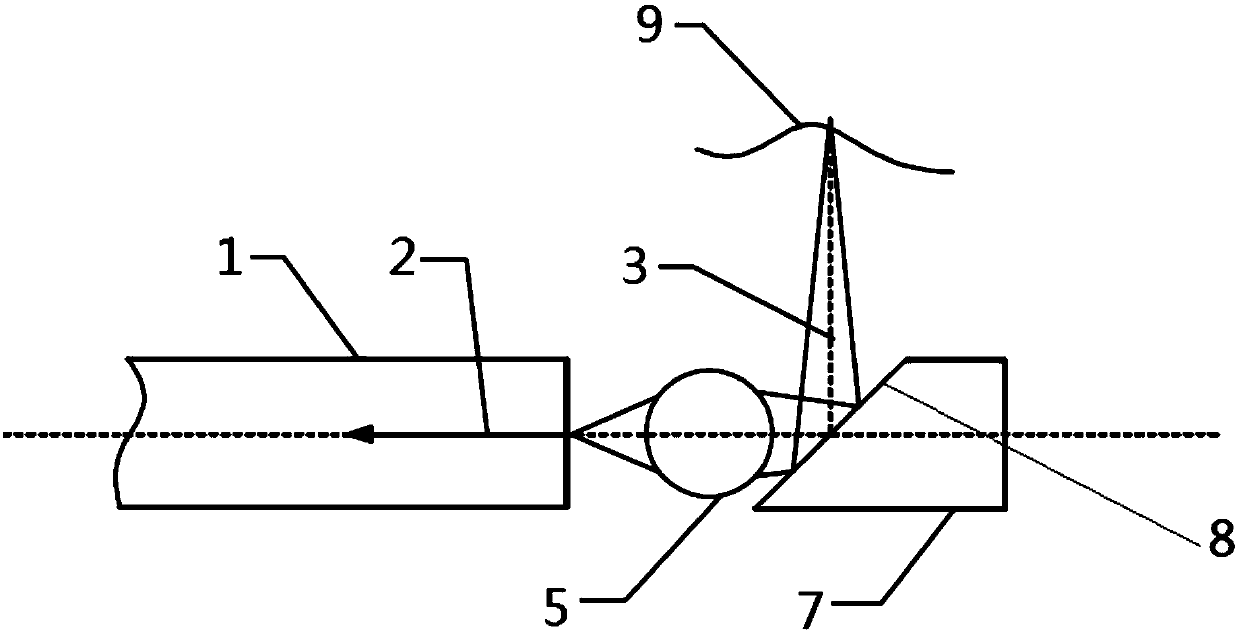

Endoscopic optical coherence tomographic imaging probe and imaging system thereof

PendingCN107692969AAvoid problems with hard-to-match consistencyEliminate quality impactSurgeryEndoscopesOphthalmologyRadiology

The present invention provides an endoscopic optical coherence tomographic imaging probe and an imaging system thereof. The endoscopic optical coherence tomographic imaging probe comprises a single mode optical fiber and a beam turning member. A reflective surface is arranged between the end of the single mode optical fiber and the beam turning member. The beam turning component comprises a beam turning surface, and the included angle of the beam turning surface or its cut surface and the axial line of the singlemode optical fiber is an acute angle.A small part of the light of the light beam emitted by the singlemode optical fiberis reflected bythe reflective surface and returns to the original path to form a reference light, most of the light of the light beam emitted by the singlemode optical fiberis reflected by the beam turning surface and cast onasample structure to be measured, and the signal light returned from the sample structure passes through the beam turning member, is coupled into the single mode optical fiber of the probe, and then merges with the reference light to form an interference light signal. With the above technical scheme, a reference arm shares the light path with a sample arm, and the entire light path system is simpler, more compact, and more reliable; and the quality and stability of images are improved.

Owner:INNERMEDICAL CO LTD

Sequential deslagging control device for soaking tanks and automatic deslagging soaking tank

The invention discloses a sequential deslagging control device for soaking tanks and an automatic deslagging soaking tank. The sequential deslagging control device for soaking tanks can quickly carry out sequential discharge on slurry deposited in a soaking tank at a cleaning section of a continuous annealing and galvanization unit according to the actual production, and through the sequential opening and closing of an automatic deslagging valve, a situation that slurry is accumulated at the bottom of a sinking roller of the soaking tank is effectively prevented, thereby avoiding the influences of the slurry on the surface qualities of strip steel and the sinking roller; through a liquid level difference between two liquid level switches, the replacement ratio of new and old chemical solvents in the soaking tank is accelerated, and the quantity of a fresh chemical solvent in the soaking tank is ensured as large as possible, thereby facilitating a situation that the chemical solvent carries out better chemical and physical reactions with the strip steel, and improving the surface cleaning effect of the strip steel; and the timely discharge of the slurry ensures the cleanliness of the chemical solvents in the soaking tank, and the slurry does not reversely pollute the chemical solvents in the soaking tank, thereby enhancing the cleanliness of the chemical solvents, and improving the cleaning effect of the chemical solvents.

Owner:攀钢集团西昌钢钒有限公司

BOPP film capable of being directly used for paper-plastic compounding and preparation method thereof

PendingCN112123902AQuality assuranceAvoid pollutionSynthetic resin layered productsLow-density polyethylenePolymer science

The invention discloses a BOPP film capable of being directly used for paper-plastic compounding and a preparation method thereof, and relates to the technical field of films. The BOPP film comprisesan upper surface layer, a core layer and a lower surface layer. The upper surface layer is made of homo-polypropylene and anti-sticking master batch, and the anti-sticking master batch is composed ofhollow ceramic microbeads and homo-polypropylene; the core layer is made of homo-polypropylene; and the lower surface layer is made of an ethylene-ethyl acrylate copolymer and low-density polyethylene. The BOPP film prepared by the method is good in brightness, and can be directly compounded with paper under a hot pressing condition, so that a procedure and a tool for applying a hot melt adhesiveare omitted, and the pollution of a primer to the environment is avoided; and besides, in the preparation process, the core layer melt is distributed into a plurality of die heads, and a multi-layer co-extrusion structure is adopted, so that the requirements of production equipment for different film thicknesses can be flexibly met, and the burden of the equipment is reduced.

Owner:ANHUI GUOFENG PLASTIC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com