Primer-free BOPP digital matt film with high adhesive strength, and preparation method thereof

A technology of high adhesion and primer, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of increasing the energy consumption of the pre-coating film process, difficult control of the processing process, and affecting the brightness of the pre-coating film. , to achieve beautiful appearance effect, beautiful high-tech anti-counterfeiting function, and improve the effect of anti-scratch performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

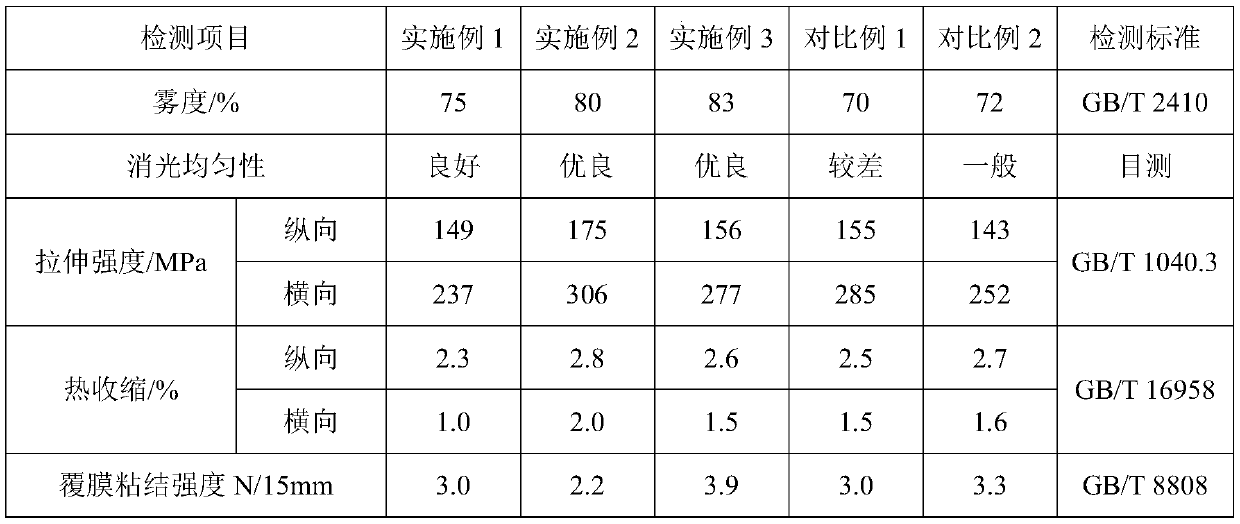

Examples

Embodiment 1

[0030] A primer-free high-bond strength BOPP digital matting film in this embodiment, from top to bottom is an upper surface layer, a subsurface layer, a core layer and a lower surface layer, wherein the upper surface layer and the subsurface layer are matting layers, Composed of 55 wt% copolymerized polypropylene and 45 wt% high density polyethylene.

[0031] The core layer consists of 0.5 wt% antistatic agent and 99.5 wt% homopolypropylene.

[0032] The lower surface layer is made of 90wt% metallocene linear low density polyethylene and 10wt% organic polymer anti-adhesive masterbatch.

[0033] Wherein the organic polymer anti-adhesive masterbatch in the lower surface layer is composed of spherical acrylate particles with a particle size of 2 μm and copolymerized polypropylene.

[0034] Based on the total thickness of the BOPP digital matting film, in this embodiment, the thickness of the upper surface layer and the subsurface layer accounts for 30%, the thickness of the low...

Embodiment 2

[0041] A primer-free high-bond strength BOPP digital matting film in this embodiment, from top to bottom is an upper surface layer, a subsurface layer, a core layer and a lower surface layer, wherein the upper surface layer and the subsurface layer are matting layers, Composed of 50 wt% copolymerized polypropylene and 50 wt% high density polyethylene.

[0042] The core layer consisted of 1.5 wt% antistatic agent and 98.5 wt% homopolypropylene.

[0043] The lower surface layer is composed of 97wt% metallocene linear low density polyethylene and 3wt% organic polymer anti-adhesive masterbatch.

[0044] Wherein the organic polymer anti-adhesive masterbatch in the lower surface layer is composed of spherical acrylate particles with a particle size of 1 μm and copolymerized polypropylene.

[0045] Based on the total thickness of the BOPP digital matting film, in this embodiment, the thickness of the upper surface layer and the subsurface layer accounts for 12%, the thickness of the...

Embodiment 3

[0052] A primer-free high-bond strength BOPP digital matting film in this embodiment, from top to bottom is an upper surface layer, a subsurface layer, a core layer and a lower surface layer, wherein the upper surface layer and the subsurface layer are matting layers, Composed of 45 wt% copolymerized polypropylene and 55 wt% high density polyethylene.

[0053] The core layer consisted of 2.5 wt% antistatic agent and 97.5 wt% homopolypropylene.

[0054] The lower surface layer is composed of 95wt% metallocene linear low density polyethylene and 5wt% organic polymer anti-adhesive masterbatch.

[0055] Wherein the organic polymer anti-adhesive masterbatch in the lower surface layer is composed of spherical acrylate particles with a particle size of 3 μm and copolymerized polypropylene.

[0056] Based on the total thickness of the BOPP digital matting film, in this embodiment, the thickness of the upper surface layer and the subsurface layer accounts for 20%, the thickness of the l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com