Fracturing method for deep shale gas through V-shaped pressure curve

A pressure curve and shale gas technology, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc., can solve the problems that are not conducive to improving the complexity of deep shale gas fractures and maximizing the effective stimulation volume, two-way Differences in horizontal stress, increased difficulty in opening and extending horizontal bedding joints or texture joints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

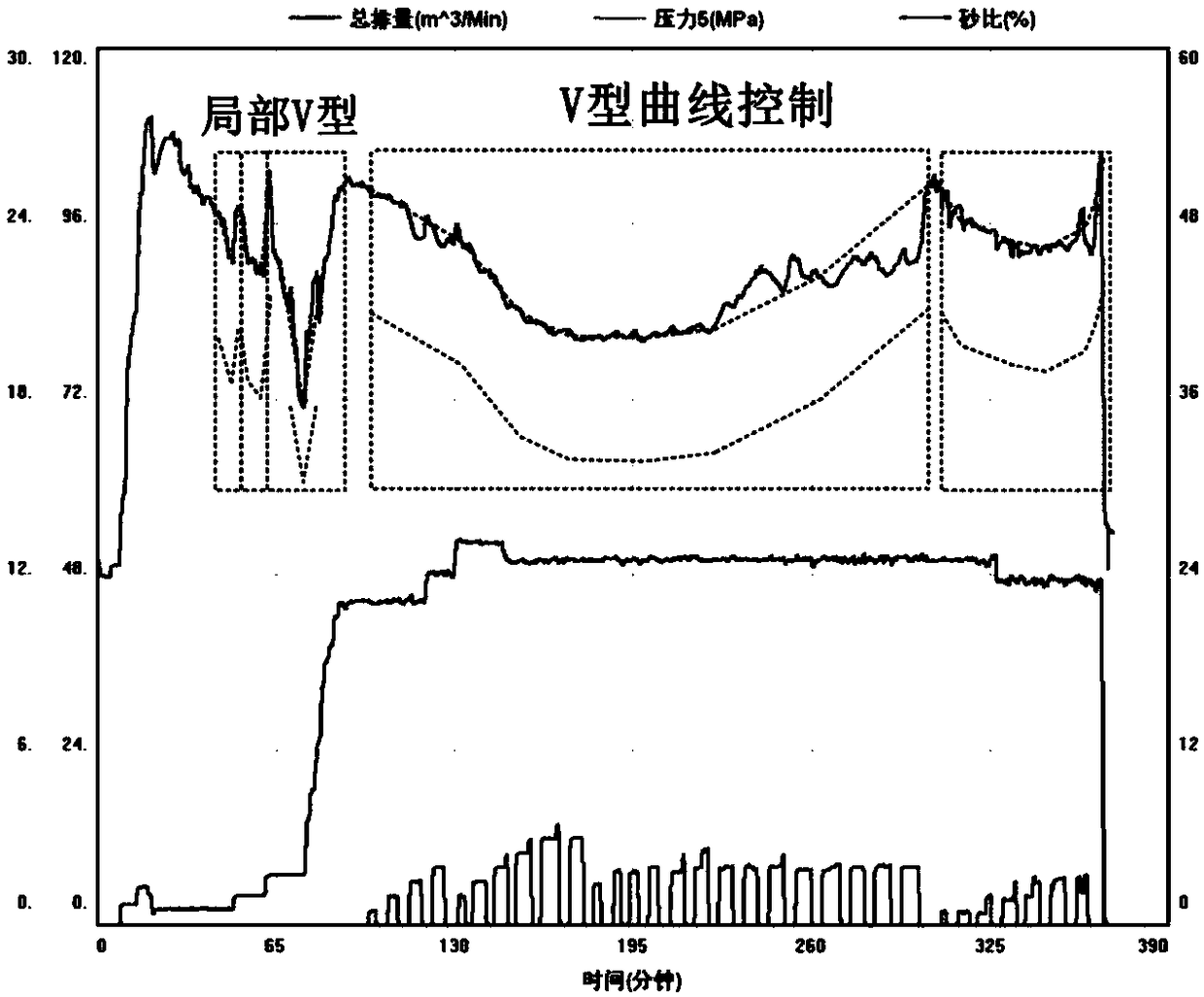

[0070] Well X, a shale gas exploration well, has a maximum vertical depth of 4360 meters and is a typical deep shale gas well:

[0071] (1) Evaluation of key reservoir parameters

[0072] Based on well logging, mud logging and pilot well core experiments, geological parameters such as lithology, physical properties, rock mechanics, three-dimensional stress, and natural fracture development of the target layer are analyzed.

[0073] (2) Optimization of fracture parameters and fracturing construction parameters

[0074] The mature commercial software ECLIPSE is used to optimize the fracture parameters. On this basis, the mature commercial software MEYER is used to optimize and determine the combination of fracturing construction parameters (displacement, liquid volume, sand-liquid ratio and proppant dose, etc.) and the performance parameters of fracturing materials ( viscosity, etc.).

[0075] (3) Perforation position determination and perforation operation

[0076] According...

Embodiment 2

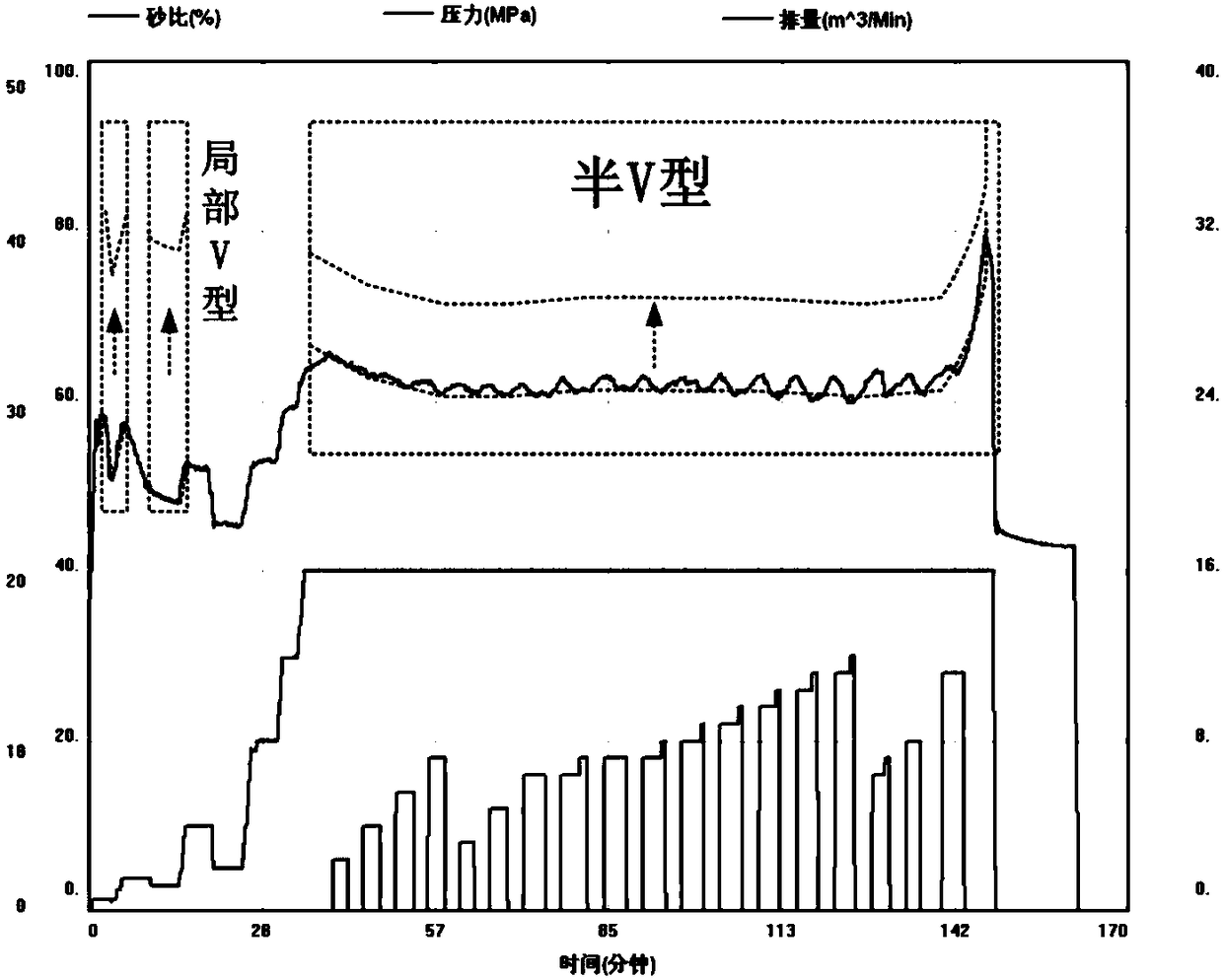

[0096] Well Y, a shale gas well, has a maximum vertical depth of 3810 meters:

[0097] (1) Evaluation of key reservoir parameters

[0098] Based on well logging, mud logging and pilot well core experiments, geological parameters such as lithology, physical properties, rock mechanics, three-dimensional stress, and natural fracture development of the target layer are analyzed.

[0099] (2) Optimization of fracture parameters and fracturing construction parameters

[0100] The mature commercial software ECLIPSE is used to optimize the fracture parameters. On this basis, the mature commercial software MEYER is used to optimize and determine the combination of fracturing construction parameters (displacement, liquid volume, sand-liquid ratio and proppant dose, etc.) and the performance parameters of fracturing materials ( viscosity, etc.).

[0101] (3) Perforation position determination and perforation operation

[0102] According to the evaluation result of (1), the perforation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com