Method for producing whole pumpkin powder through enzymolysis technology

A technology of pumpkin whole powder and enzymolysis, which is applied in the field of food processing, can solve the problems of lack of mature technology of pumpkin whole powder, affecting the quality of stable products, low enzymolysis efficiency, etc., so as to be beneficial to human body absorption and improve energy utilization rate. , the effect of arranging the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

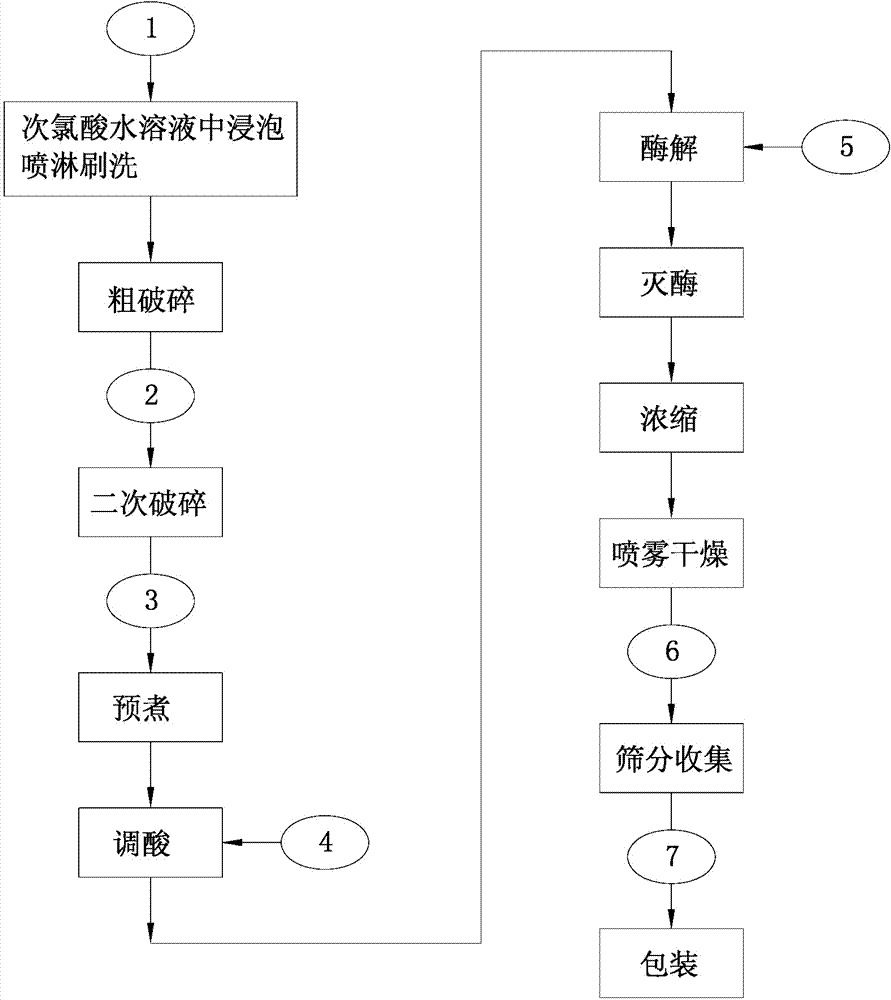

[0027] A method for producing whole pumpkin powder by enzymatic hydrolysis process. The stems of the mature pumpkin with golden skin are cut off and processed into whole pumpkin powder. The flow chart is as follows figure 1 The method for producing pumpkin powder by the enzymolysis process is carried out according to the following steps:

[0028] (1) Clean the raw materials, clean and disinfect the processed pumpkin 1; soak the processed pumpkin in 40ppm hypochlorous acid aqueous solution for 20 minutes, then spray and scrub the soaked pumpkin with two 3m long roller brushes, until there is no disinfectant residue on the epidermis.

[0029] (2) Coarse crushing, coarsely crushing the washed pumpkin with a pulverizer to obtain pumpkin pulp 2 with a particle size diameter less than or equal to 0.5 cm;

[0030] (3) secondary crushing, the pumpkin pulp after coarse crushing is further crushed with a colloid mill to obtain pumpkin pulp 3 with a particle size of less than or equal t...

Embodiment 2

[0040] This embodiment is a preferred solution of Embodiment 1.

[0041] The steps of producing whole pumpkin powder by the enzymolysis process are:

[0042] (1) Clean raw materials, clean and disinfect processed pumpkins; soak processed pumpkins in 40ppm hypochlorous acid aqueous solution for 20 minutes, then spray and scrub the soaked pumpkins with two 3m-long roller brushes until No disinfectant remains on the skin.

[0043] (2) Coarsely crushing, coarsely crushing the washed pumpkin with a pulverizer to obtain pumpkin pulp with a particle size diameter less than or equal to 0.5cm;

[0044] (3) secondary crushing, the pumpkin pulp after coarse crushing is further crushed with a colloid mill to obtain pumpkin pulp with a particle size less than or equal to 0.1 cm.

[0045](4) Precooking, the pumpkin pulp after the secondary crushing enters the precooking pipeline, the precooking temperature is 90°C, and the precooking time is 15 minutes.

[0046] (5) To adjust the acidity...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com