Machining process of high-precision thin-walled pure aluminum or aluminum alloy pipes

A processing technology, aluminum alloy technology, applied in the field of metal materials, can solve the problems of uneven wall thickness, low yield, large shrinkage, etc., and achieve the effects of high quality, shortened production process, and reduced intermediate annealing times

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

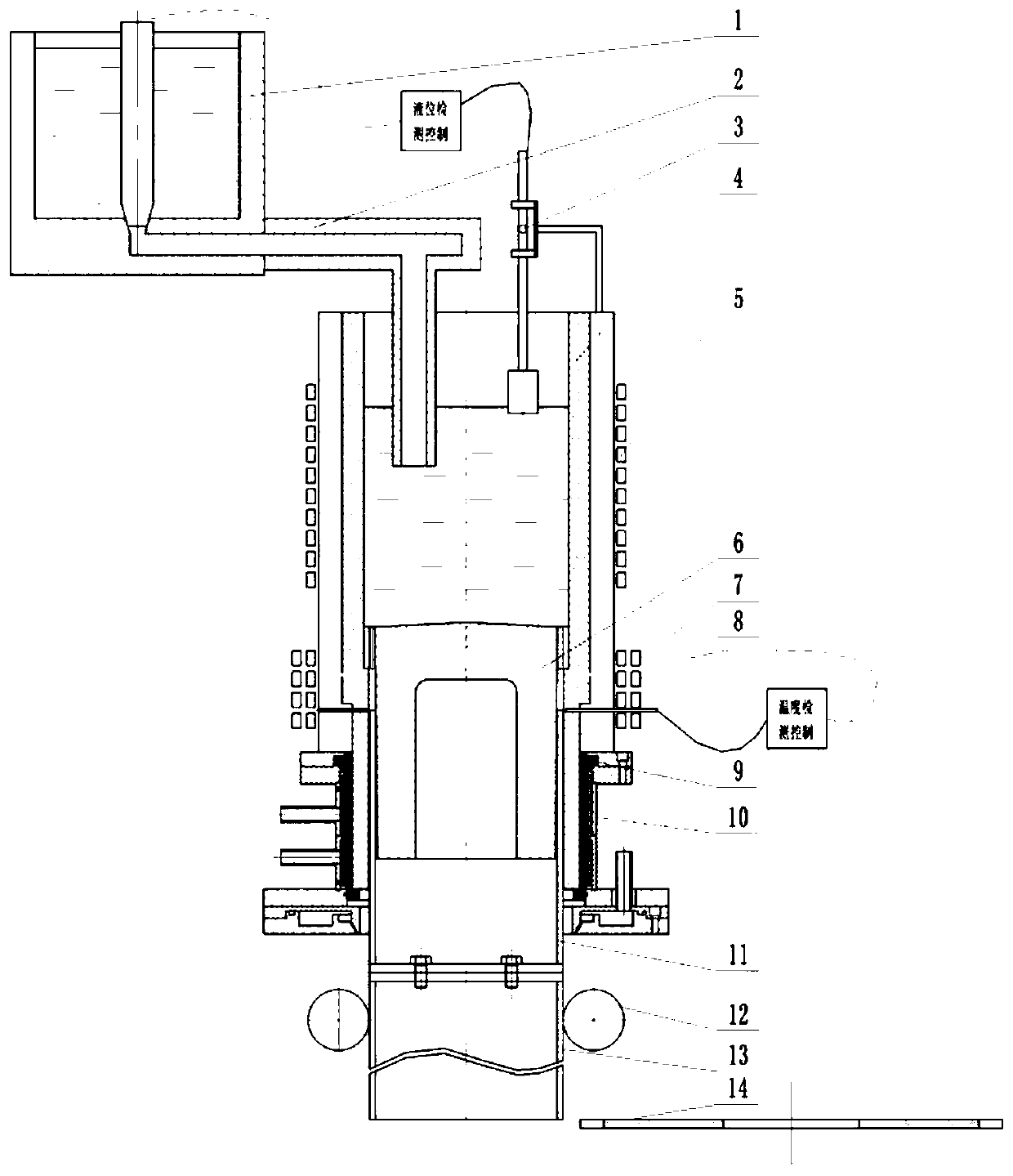

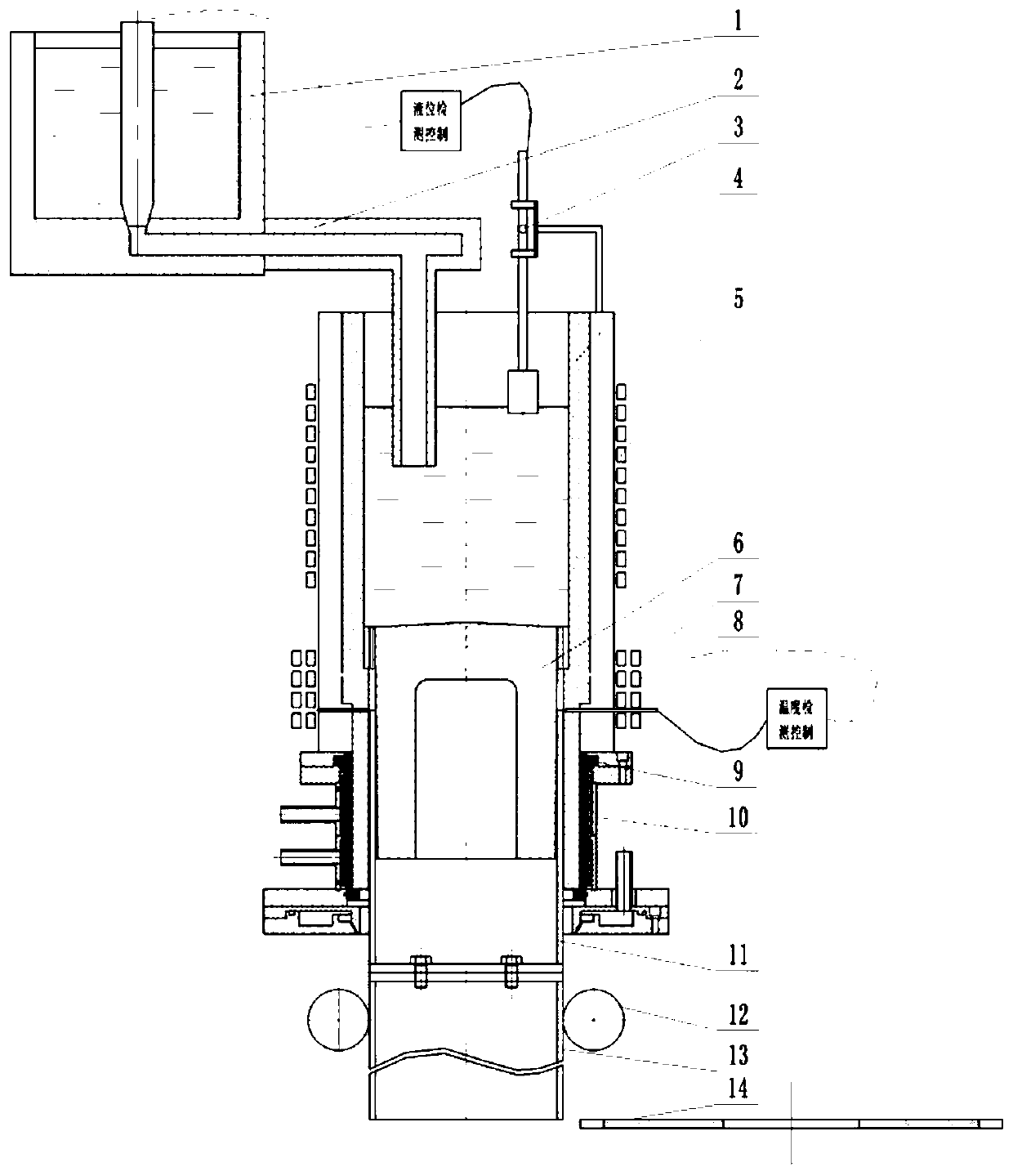

Image

Examples

Embodiment 1

[0076] Embodiment 1: The production method of the aluminum tube whose size is Ф50×1mm

[0077] Step 1: Use vertical continuous casting to prepare a tube blank with a diameter of Ф70×5mm. The melting temperature of molten aluminum is 810°C, the holding temperature is 770°C, the temperature of the hot mold (mold heating) is 720°C, and the flow rate of cooling water (water-cooled copper sleeve) for the cold mold is 800L / h, traction speed 120mm / min.

[0078] Step 2: Carry out 3 passes of three-roller periodic cold rolling on the tube blank prepared in step 1, the specification of the rolled tube is φ62×1.6mm, the average pass deformation is 28.3%, and the cumulative pass deformation is 53.6%. The pass deformation decreases gradually with the increase of the cumulative deformation.

[0079] Step 3: The annealed pipe is stretched for 4 passes, and the average elongation coefficient of each pass is 1.25.

[0080] Step 4: The stretched pipe is annealed, the annealing temperature is...

Embodiment 2

[0081] Embodiment 2: The production method of the aluminum tube whose size is Ф70×1.5mm

[0082] Step 1: Prepare a tube blank with a diameter of Ф100×7mm by vertical continuous casting, the melting temperature of molten aluminum is 780°C, the holding temperature is 750°C, the temperature of the hot mold (mold heating) is 720°C, and the flow rate of cooling water (water-cooled copper sleeve) for the cold mold is 900L / h, traction speed 100mm / min.

[0083] Step 2: Carry out 3 passes of three-roller periodic cold rolling to the tube blank prepared in step 1, the rolled tube specification is φ90×2.8mm, the average pass deformation is 27.9%, and the cumulative pass deformation is 62.5%. The pass deformation decreases gradually with the increase of the cumulative deformation.

[0084] Step 3: Perform intermediate low-temperature annealing on the rolled pipe, the annealing temperature is 200°C, and the annealing time is 1h. The annealed pipe was stretched for 3 passes, and the aver...

Embodiment 3

[0086] Embodiment 3: The production method of the aluminum pipe whose size is Ф100×2mm

[0087] Step 1: Prepare a tube billet with a diameter of Ф150×8mm by vertical continuous casting, the melting temperature of molten aluminum is 750°C, the holding temperature is 750°C, the temperature of the hot mold (mold heating) is 700°C, and the flow rate of cooling water (water-cooled copper sleeve) for the cold mold is 1000L / h, traction speed 80mm / min.

[0088] Step 2: Carry out 4 passes of three-roller periodic cold rolling to the tube blank prepared in step 1. The average pass deformation is 35.5%, and the cumulative pass deformation is 82.7%. increase gradually decreases.

[0089] Step 3: Carry out bright annealing on the rolled pipe, the annealing temperature is 300℃, and the annealing time is 60min. The purpose is to change the pipe structure to meet the product use requirements.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com