Method for preparing anhydrous magnesium chloride from bischofite

A technology of anhydrous magnesium chloride and bischofite, which is applied in the direction of magnesium chloride and magnesium halide, can solve the problems of high construction investment cost, high operating cost, and cannot be completely prevented, and achieve a wide range of process conditions, reduce circulation, and improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

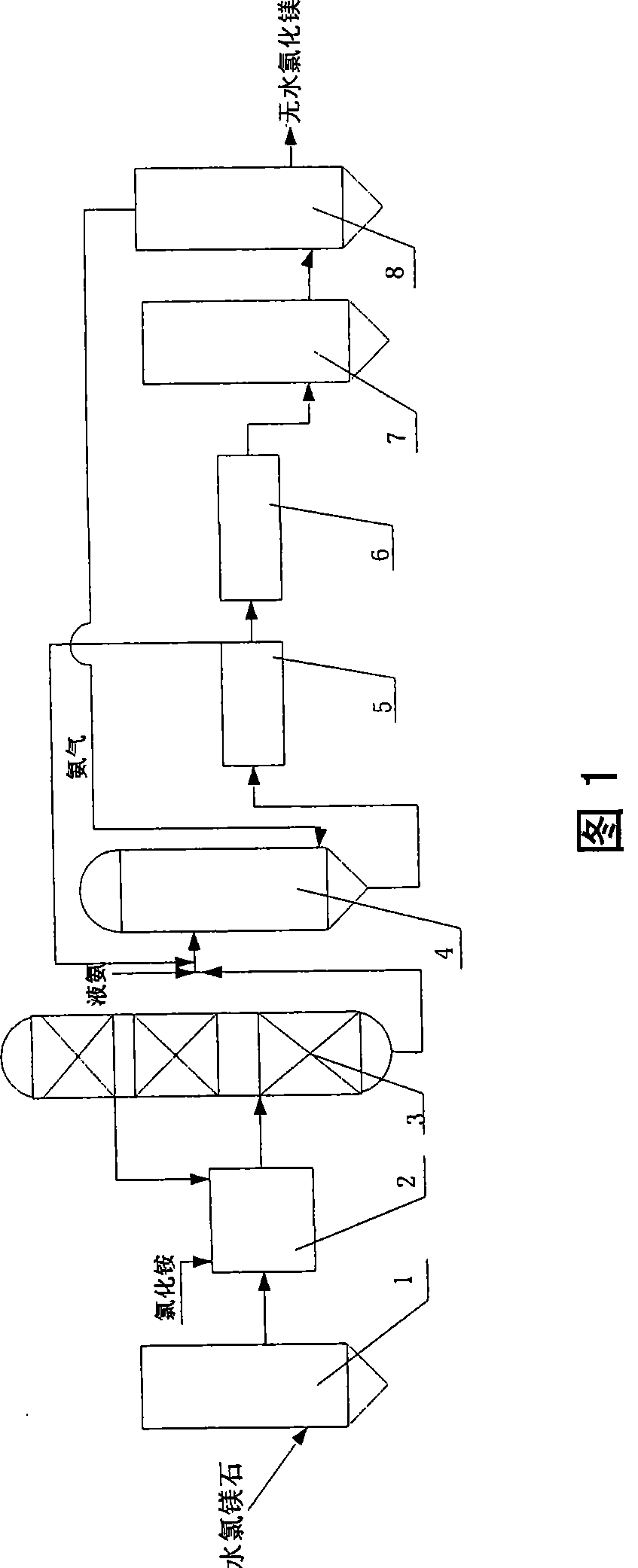

Method used

Image

Examples

example 1

[0048] Get 500g bischofite (MgCl 2 ·6H 2 (0), drying and dehydration at a temperature of 180°C, the weight after drying is 245g, and the weight loss is 255g. Bischofite is dried at 180°C and partially hydrolyzed, and the composition of the dried product is MgCl 2 ·H 2 O and Mg(OH)Cl, where MgCl 2 ·H 2 O accounts for 71.2wt%.

example 2

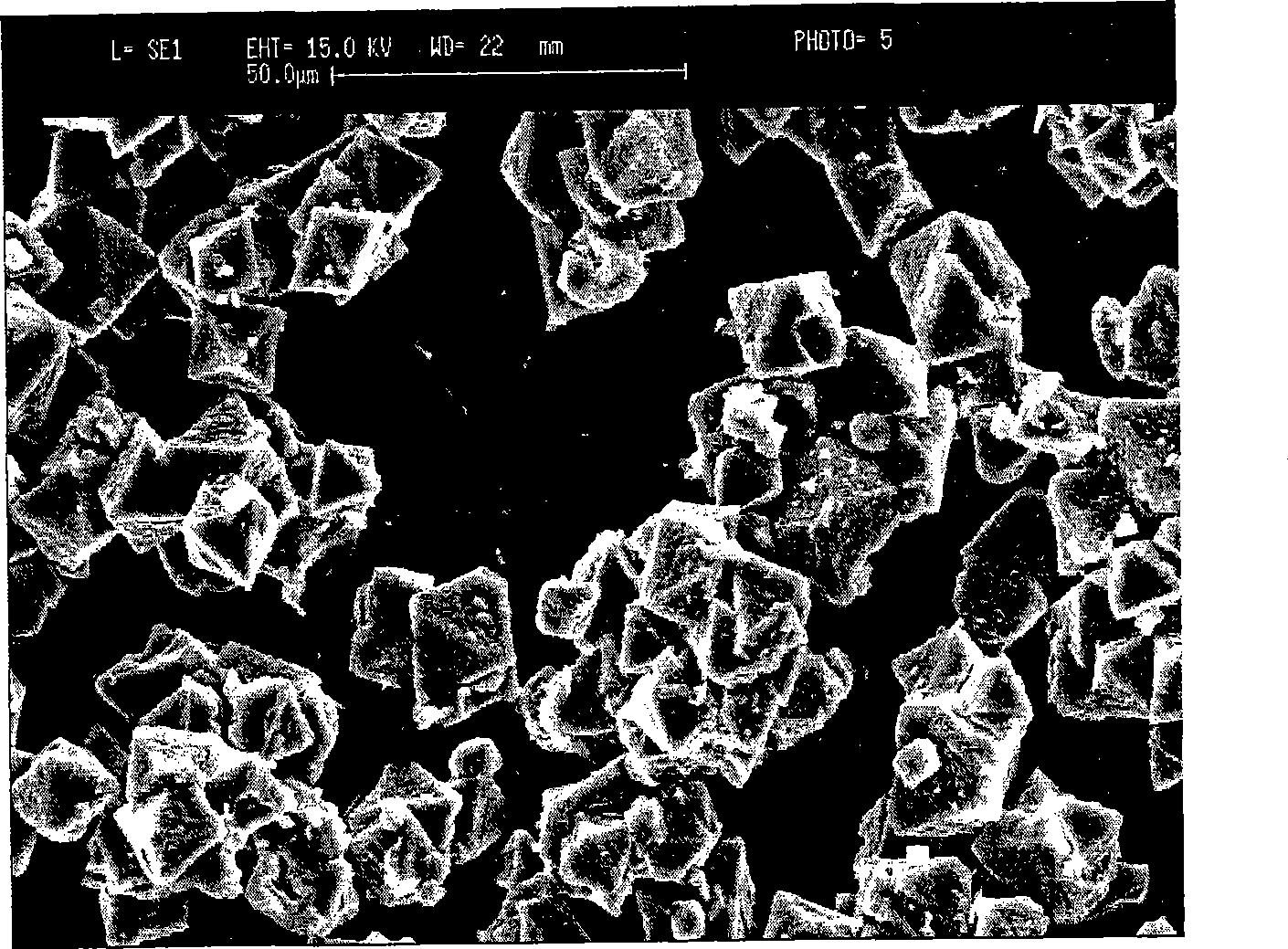

[0050] Dry the bischofite at 180°C and keep it sealed. Take 150g of dried bischofite and dissolve it in 1000ml of ethylene glycol solvent, and add 33g of ammonium chloride at the same time. The water content of the solution was measured by the Karl Fischer method, and the measurement result showed that the water content was 1.60%. Put the prepared solution into a 2000ml three-necked distillation flask, carry out intermittent vacuum distillation and dehydration operation in the distillation tower for 200min. under the conditions of vacuum degree of 660mmHg, temperature 150°C, and reflux ratio of 5:1, and measure the vacuum distillation dehydration. The water content of the solution is 0.20%. Take out the ethylene glycol solution of 800ml magnesium chloride from the tower kettle and cool it down, add 100ml liquid ammonia, then pass through ammonia gas, generate white precipitate of hexaammoniated magnesium chloride in the fluidized bed reaction crystallizer, filter it, and use ...

example 3

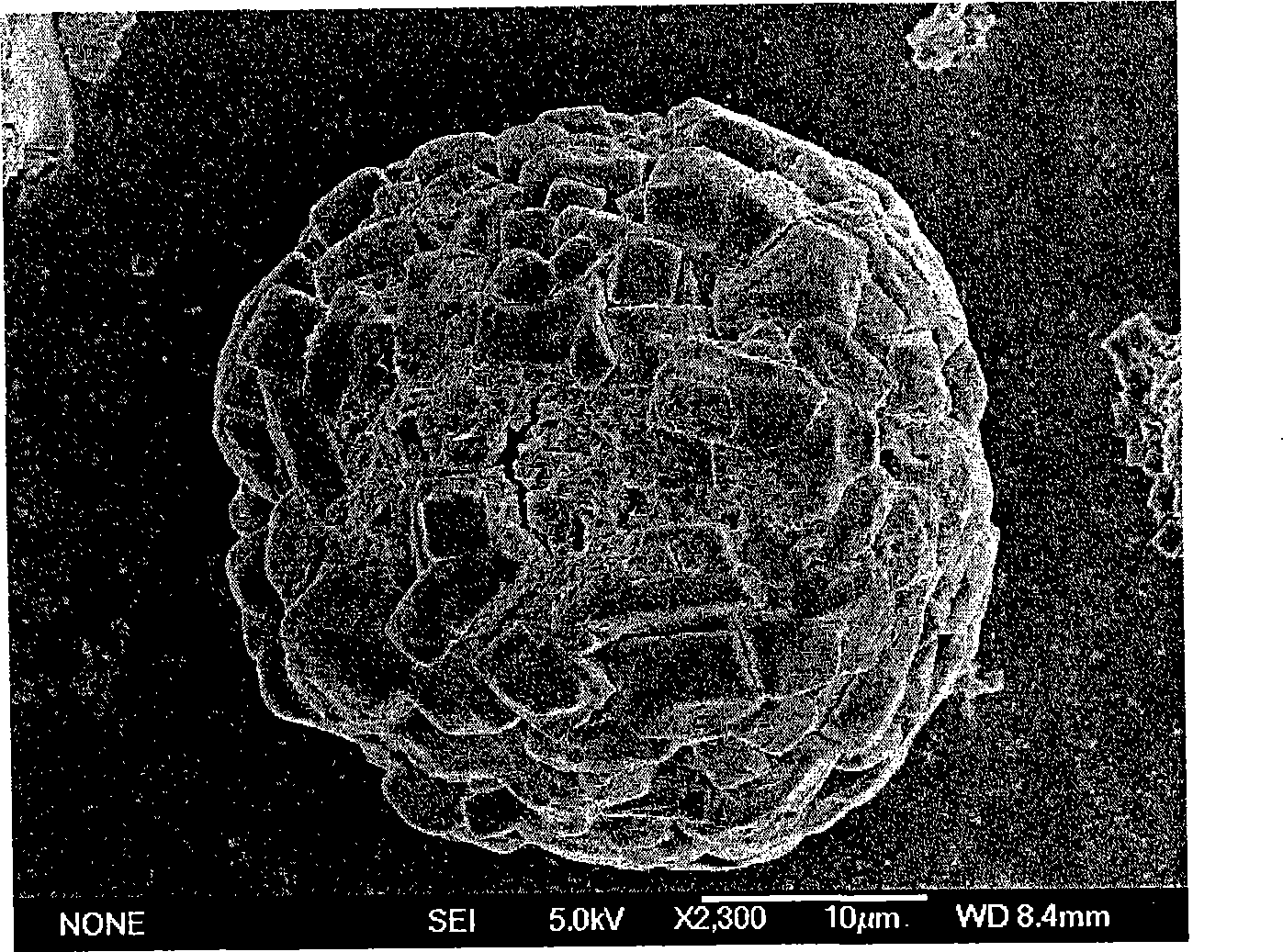

[0052] Get 100g of bischofite, directly dissolve in 1000ml of ethylene glycol for dissolving without drying, adopt the Karl-Fisher method to measure the water content of the solution, and the measurement result shows that the water content is 5.3%. The prepared magnesium chloride hydrate ethylene glycol solution does not go through the step of vacuum distillation and dehydration, and directly carries out the reaction crystallization process. Other steps (reaction crystallization, filtration, washing and drying process) are identical with example 2, and the scanning electron microscope figure of the crystal obtained as a result is as attached image 3 As shown, it can be seen that magnesium chloride hexaammoniate is impure (magnesium chloride hexaammoniate crystal form is an octahedral structure).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com