Branch gravity concentration method for recovering accompanying tin from semi-finished product of magnetic concentrated iron of iron-tin ore

A technology of magnetic separation and tin ore, which is applied in the field of iron-tin ore magnetic separation iron intermediate product associated recovery tin branch gravity separation, can solve the problems affecting the quality, tin can not be effectively recovered, etc., to achieve effective recovery, eliminate impact, reduce interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

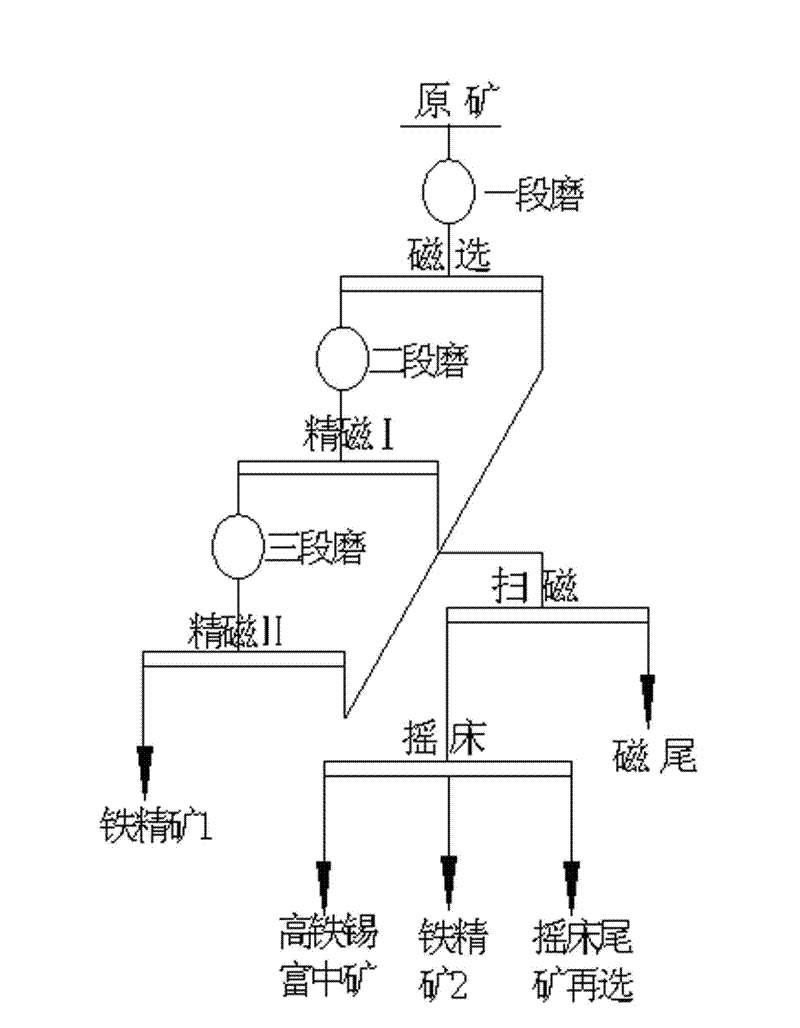

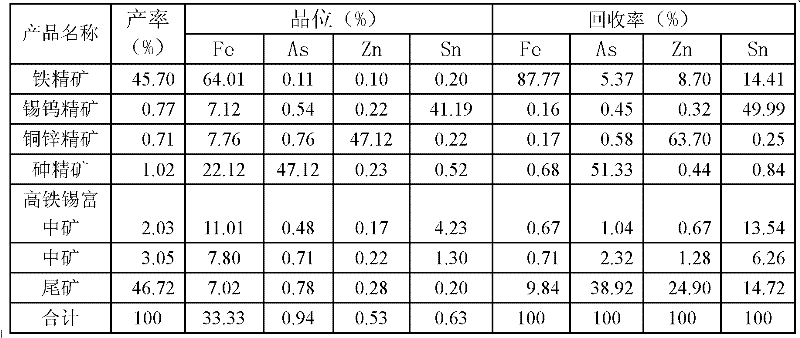

Embodiment 1

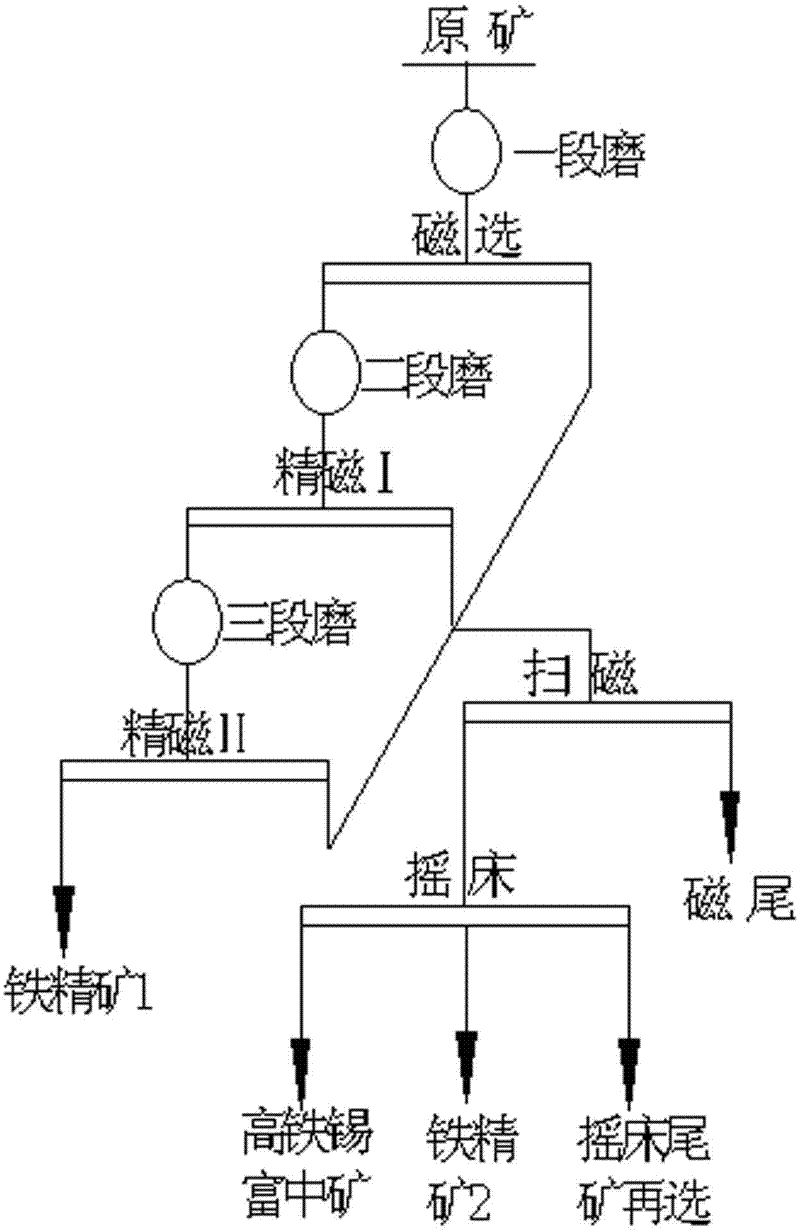

[0009] Example 1: In this example, iron-tin-associated zinc-tungsten-arsenic ore in a dressing plant is used as the production object. The raw ore is ground to 200 mesh, accounting for 45%. Concentrate, the iron coarse concentrate is 65% through the second-stage grinding of 200 mesh, and then through the second magnetic concentration of 1100 Oersted magnetic field strength, the obtained concentrated ore is 95% after the third-stage grinding of 200 mesh , and then through three times of magnetic concentration with a magnetic field strength of 1000 Oersted to produce iron concentrate, the magnetic roughing tailings and magnetic concentration tailings are combined to go through a magnetic (finish) sweep of 1400 Oersted, and the concentrate is swept Shaking table tin separation is carried out again to produce high-iron tin-rich medium ore, and at the same time, some high-quality iron concentrates and some shaking table tin tailings are produced, and the shaking table tin tailings e...

Embodiment 2

[0013] Example 2: In this example, iron-tin-associated zinc-tungsten-arsenic ore in a dressing plant is used as the production object. The raw ore is ground to 200 meshes, accounting for 45%. After grinding, the iron rough concentrate is produced through magnetic separation of 1200 Oersted , 65% of the iron coarse concentrate is 200 mesh through the second-stage grinding, and then through the second selection of 1200 Oersted, and the concentrated ore is 95% after the third-stage grinding of 200 mesh, and then passed through 1200 Oersted Iron concentrate is produced by three times of beneficiation, the rougher tailings and the concentrated tailings are combined to undergo a 1400 Oersted magnetic (finish) scavenging, and the magnetic (fine) scavenging concentrate is then subjected to a shaking table tin selection, While producing high-iron tin-rich medium ore, some high-quality iron concentrates and some shaker tin tailings are also produced. The shaker tin tailings will then ent...

Embodiment 3

[0016] Example 3: In this example, the iron-tin-associated zinc-tungsten-arsenic ore in a dressing plant is used as the production object. The raw ore is ground to 200 meshes, accounting for 45%. After grinding, the iron rough concentrate is produced through magnetic separation at 1300 Oersted , the iron coarse concentrate is 65% after the second-stage grinding to 200 mesh, and then through the second selection of 1200 Oersted, and the iron concentrate is 95% after the third-stage grinding to 200 mesh, and then passed the 1100 Oersted Special three-time selection produces iron concentrate, roughing tailings and concentrated tailings are combined to undergo a 1400 Oersted magnetic (finish) sweep, and the magnetic (fine) sweep concentrate is then subjected to a shaker tin separation , while producing high-iron tin-rich medium ore, some high-quality iron concentrates and some shaker tin tailings are also produced, and the shaker tin tailings enter the second-stage bed grinding of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com