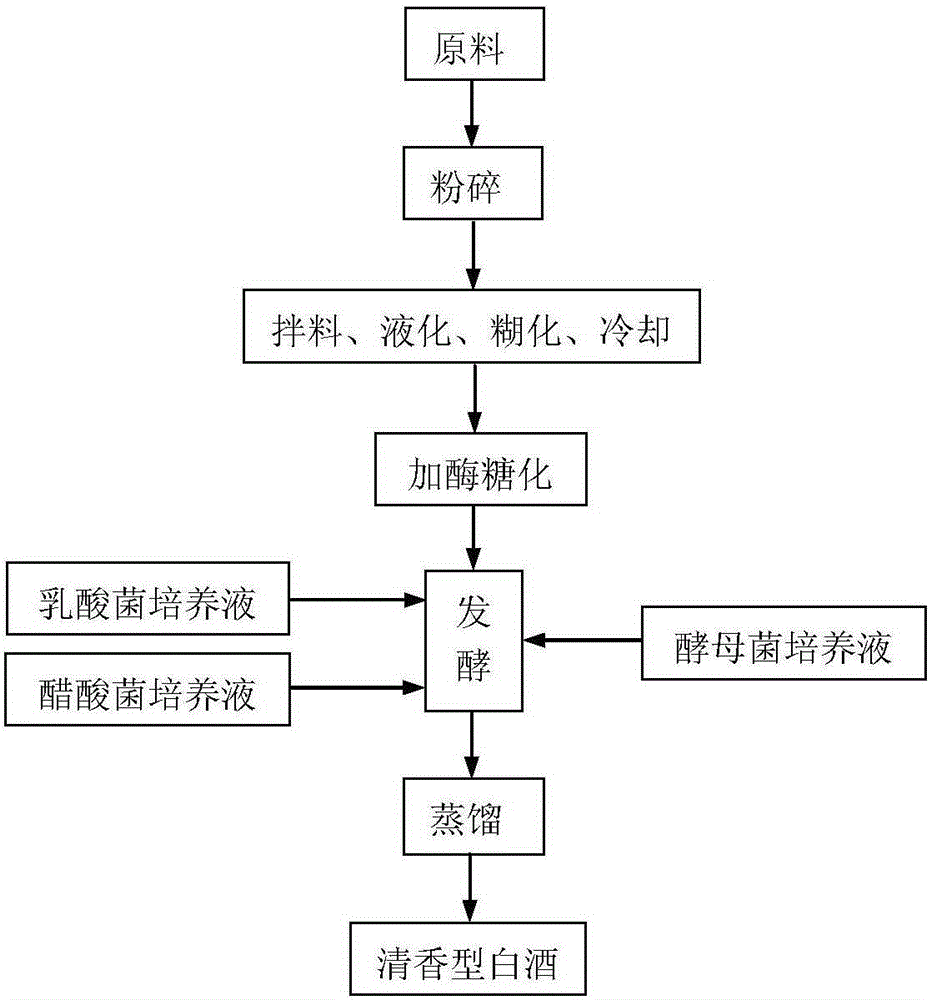

Method for producing fen-flavor liquor through liquid state fermentation

A liquid fermentation technology for Fen-flavor liquor, which is applied in the field of wine making, and can solve problems such as hidden safety hazards, high labor intensity of manual operation, and decline in the quality of finished wine, so as to achieve stable output and quality, shorten fermentation cycle, and soft and harmonious wine body. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

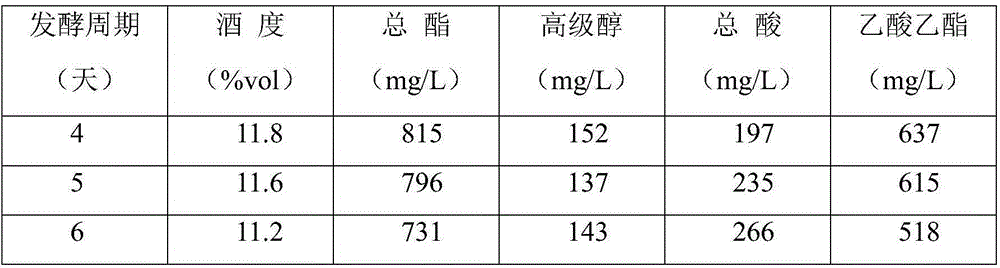

[0032] Example 1: Test results of different fermentation times

[0033] 1. Raw material crushing

[0034] High-quality corn 2.8kg, crushed, of which more than 60% should pass through the 20-mesh sieve.

[0035] 2. Liquefaction and gelatinization

[0036] Add 9L of water to the pulverized raw materials, make a slurry, add 5U of high temperature resistant α-amylase per gram of raw materials, stir well, heat to 90°C under stirring, and maintain at this temperature for 1h. Continue to heat and gelatinize at 0.1 MPa and 121° C. for 60 minutes to obtain a gelatinized liquid.

[0037] 3. Saccharification

[0038] The gelatinization solution was cooled to 60°C, 150U / g of saccharifying enzyme was added, and saccharification was maintained for 20min; cooled to 40°C, 20U / g of acid protease was added, maintained for 15min, and then cooled to 30°C for use.

[0039] 4. Fermentation

[0040] The saccharified mash was cooled to 30°C, followed by yeast CGMCCNo.4350 culture solution 5% (vo...

Embodiment 2

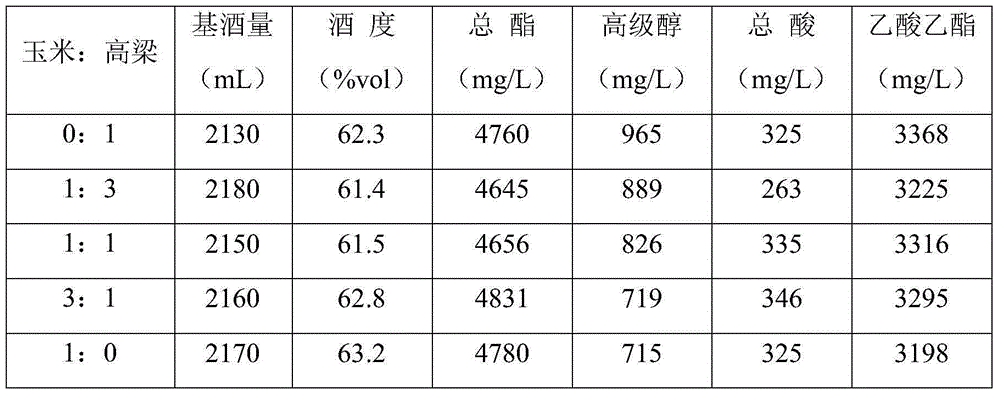

[0044] Example 2: Test results of different raw material ratios

[0045] 1. Raw material crushing

[0046] After crushing, the high-quality corn flour and sorghum flour (those that pass through the 20-mesh sieve should account for more than 60%) total 2.8kg, according to the ratio of 0:1, 1:3, 1:1, 3:1, 1:0. Raw material ratio test.

[0047] 2. Liquefaction and gelatinization

[0048] Add 9L of water to the pulverized raw materials, make a slurry, add 5U of high temperature resistant α-amylase per gram of raw materials, stir well, heat to 90°C under stirring, and maintain at this temperature for 1h. Continue to heat and gelatinize at 0.1 MPa and 121° C. for 60 minutes to obtain a gelatinized liquid.

[0049] 3. Saccharification

[0050] The gelatinization solution was cooled to 60°C, 150U / g of saccharifying enzyme was added, and saccharification was maintained for 20min; cooled to 40°C, 20u / g of acid protease was added, maintained for 15min, and then cooled to 30°C for use. ...

Embodiment 3

[0057] Embodiment 3: a kind of method that novel liquid state fermentation produces fragrance type liquor

[0058] 1. Raw material crushing

[0059] Take 2.8kg of high-quality sorghum, crush to more than 60% and pass through a 20-mesh sieve;

[0060] 2. Liquefaction and gelatinization

[0061] Add 2.8 times of water to the pulverized raw materials, make a slurry, add 4U of high temperature resistant α-amylase per gram of raw materials, stir well, heat to 85°C under stirring, and maintain at this temperature for 1 hour. Continue to heat and gelatinize at 0.1MPa and 121°C for 60min to obtain gelatinized liquid

[0062] 3. Saccharification

[0063] The gelatinization solution was cooled to 55°C, 120U / g of saccharifying enzyme was added, and the saccharification was kept for 15min; cooled to 35°C, 15u / g of acid protease was added, maintained for 10min, and then cooled to 25°C for later use;

[0064] 4. Fermentation

[0065] The saccharified mash cooled to 25°C was added to 4%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com