Patents

Literature

44 results about "Terephthaloyl dichloride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

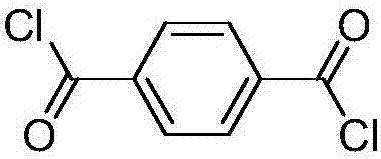

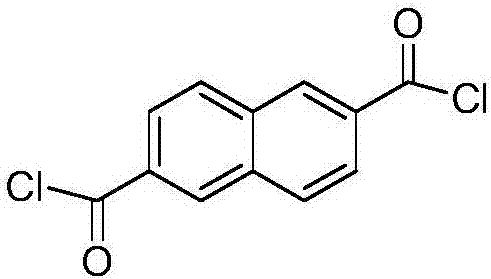

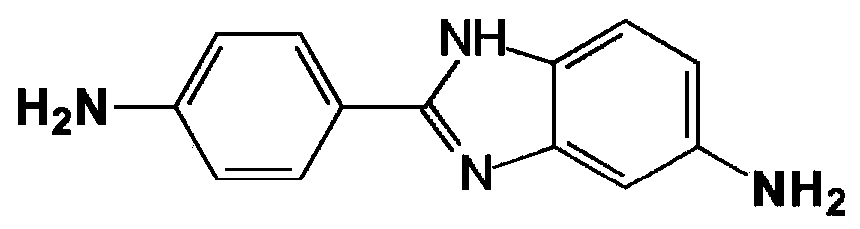

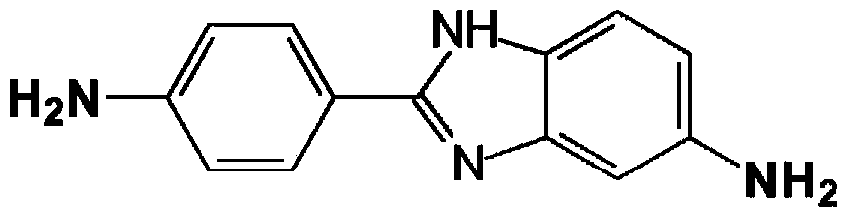

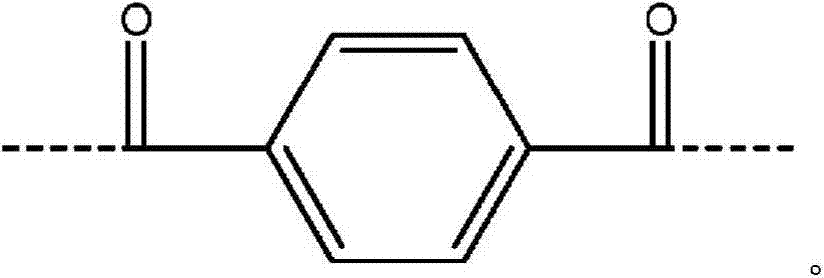

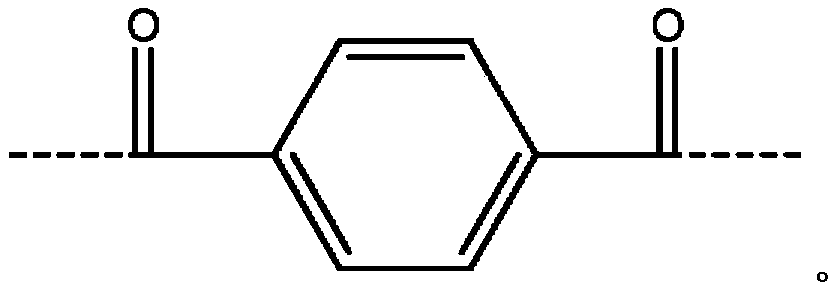

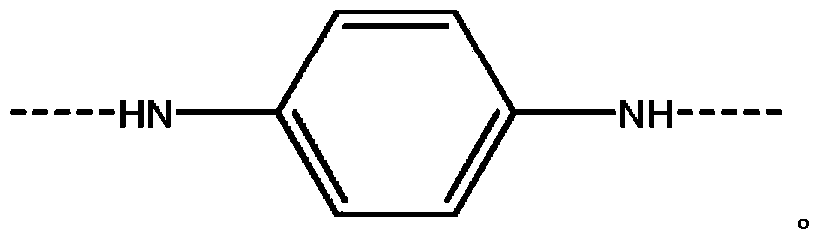

Terephthaloyl dichloride p-Phthalyl chloride TCL. Identifiers CAS Number. ... Terephthaloyl chloride (TCL, 1,4-benzenedicarbonyl chloride) is the acid chloride of terephthalic acid and is one of two monomers used to make Kevlar(R), the other being p-phenylenediamine.

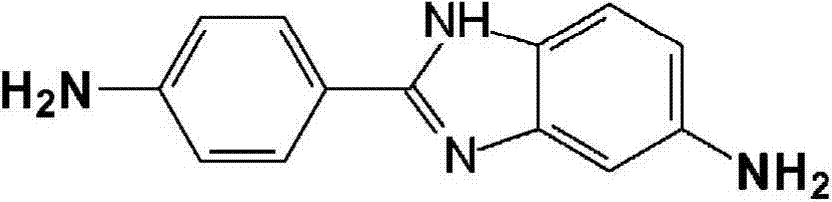

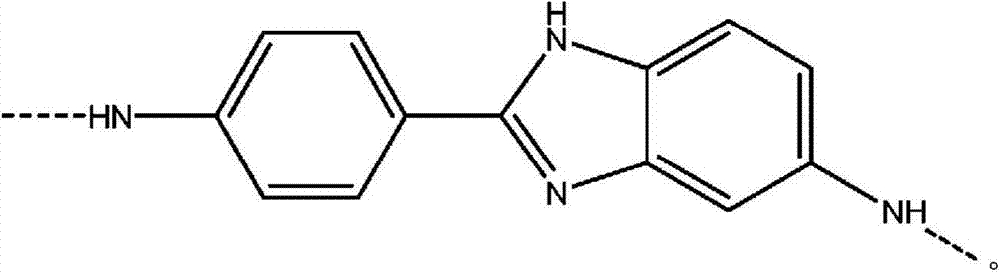

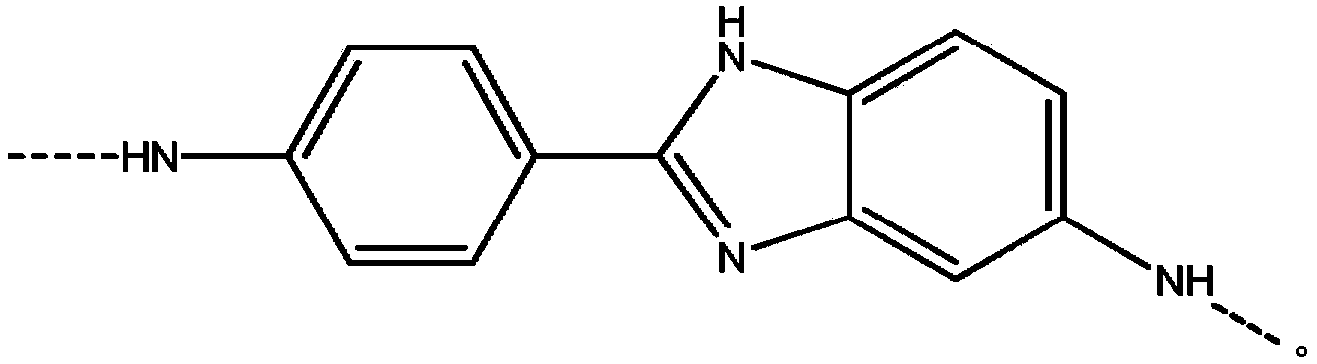

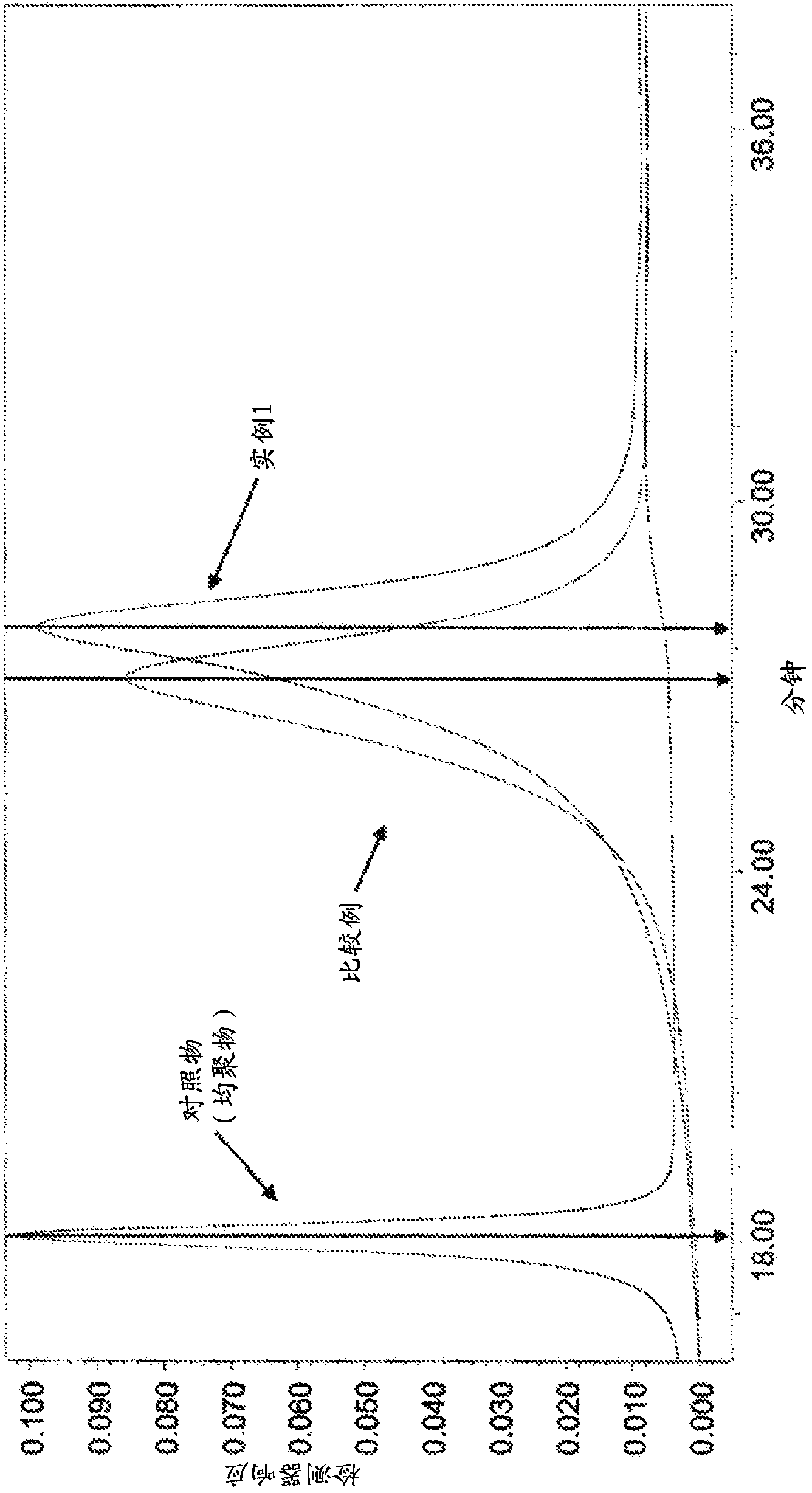

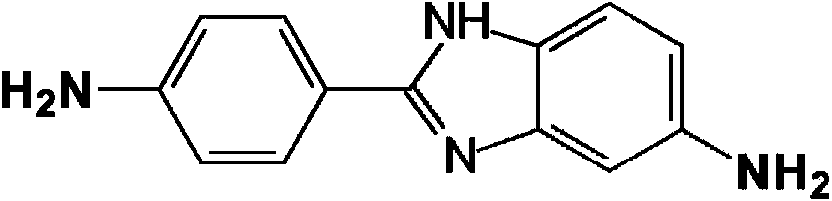

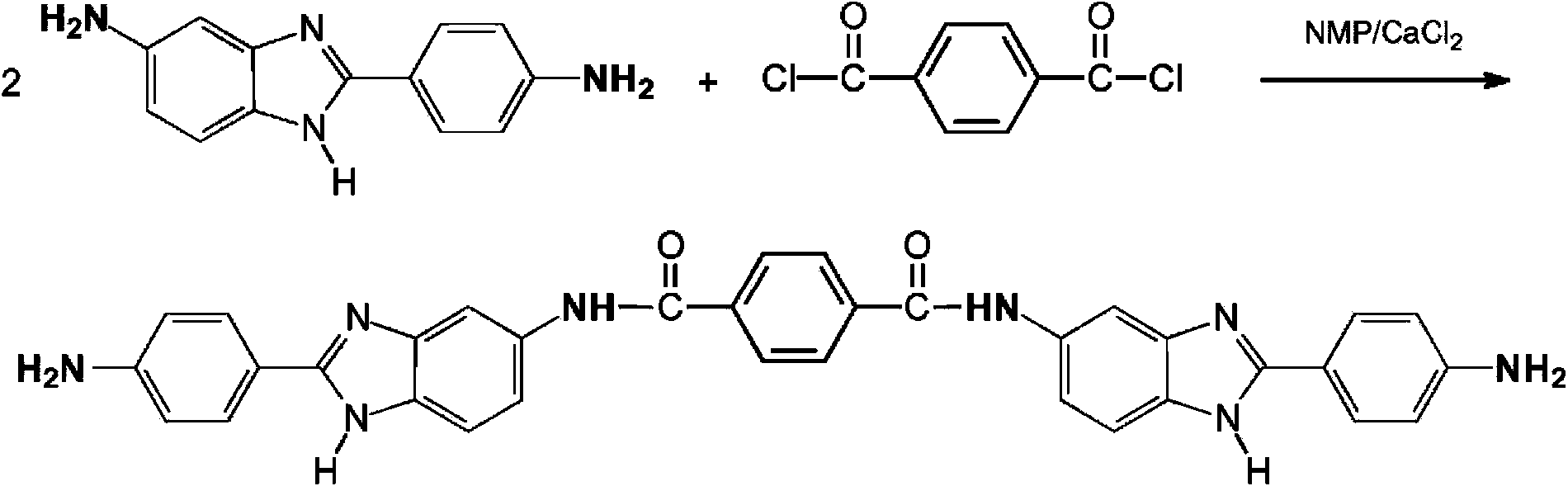

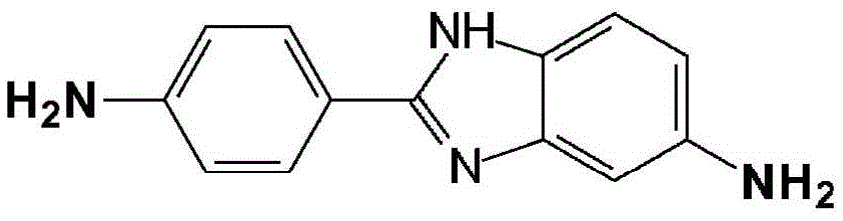

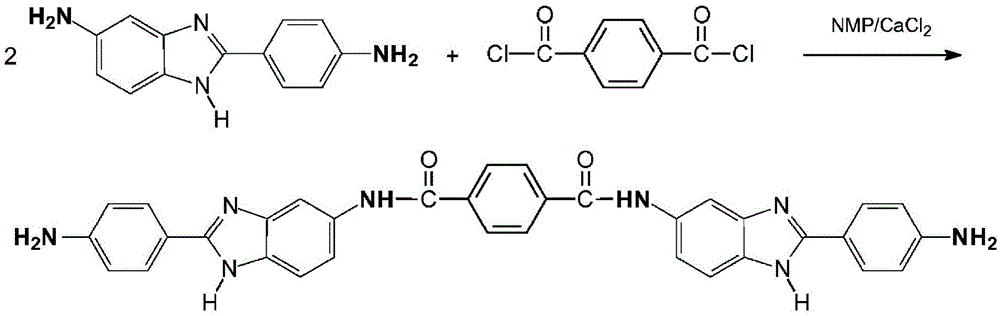

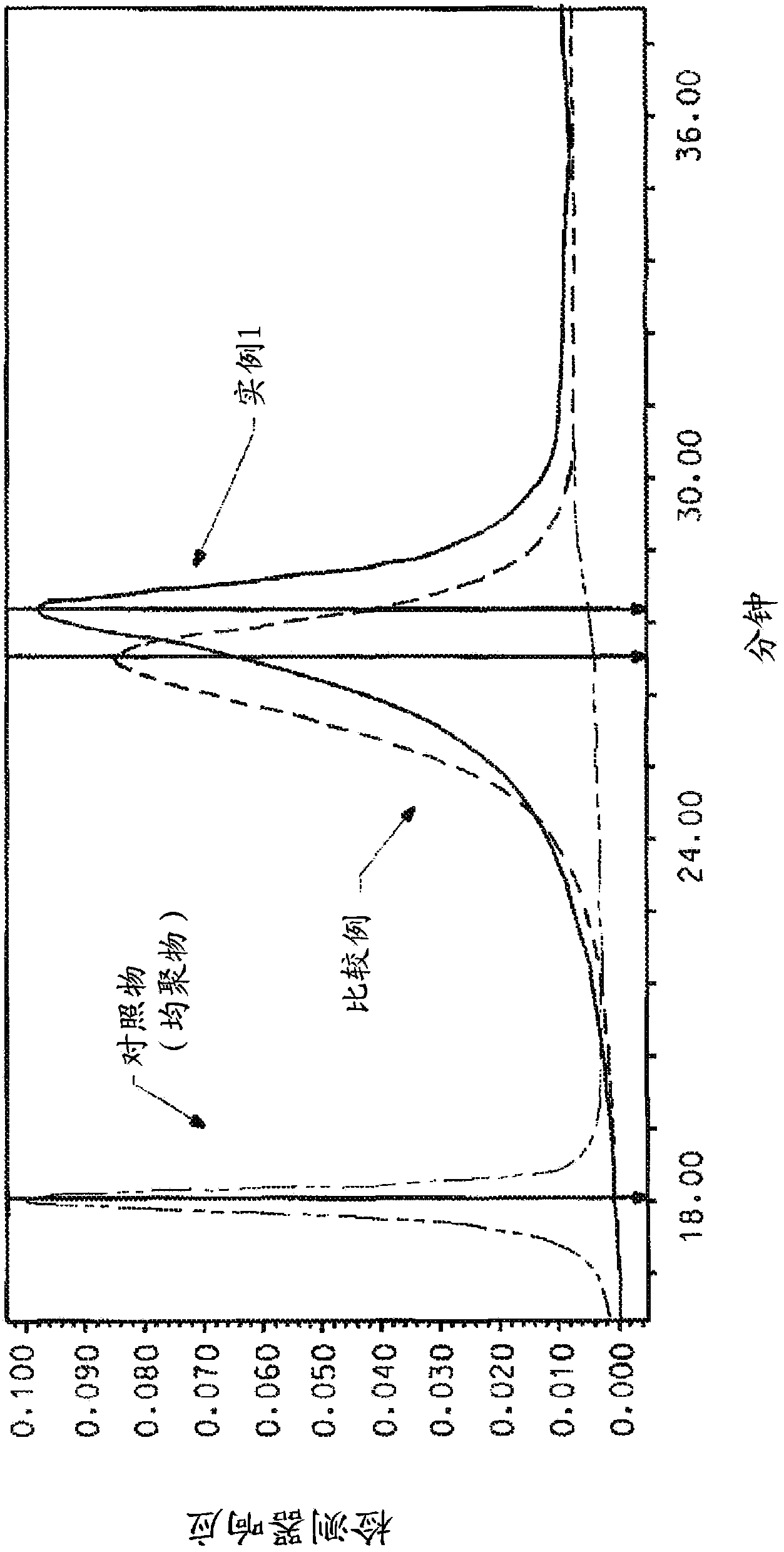

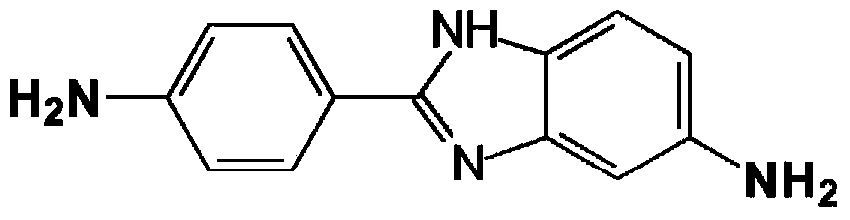

Large scale process for polymerization of dapbi-containing polyaramid

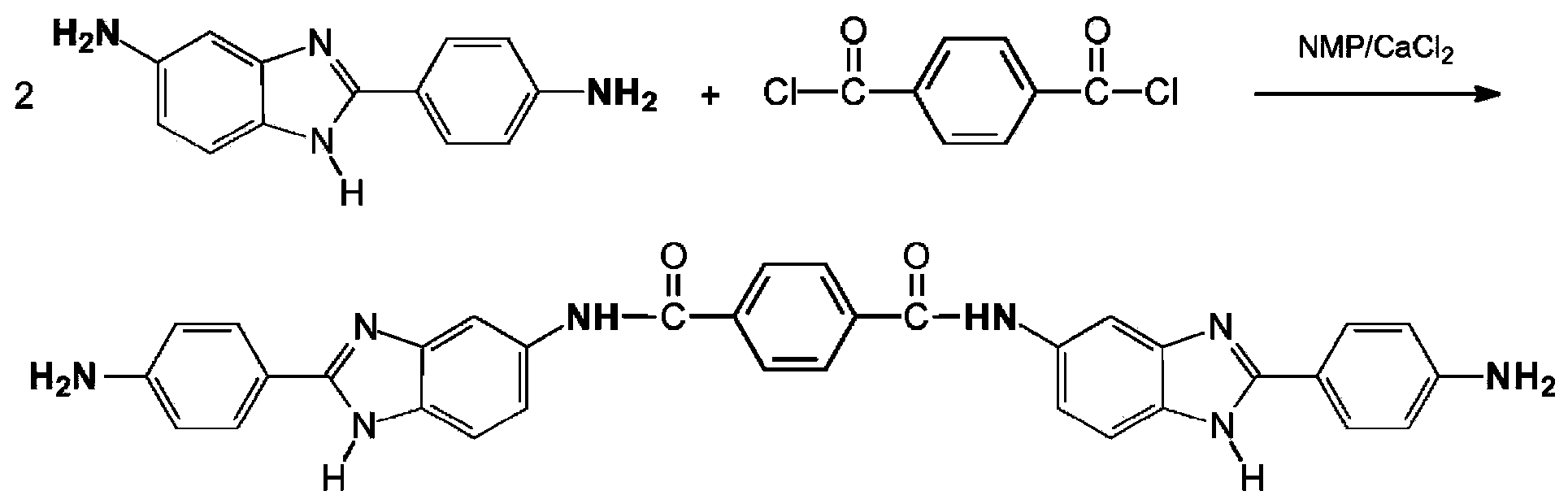

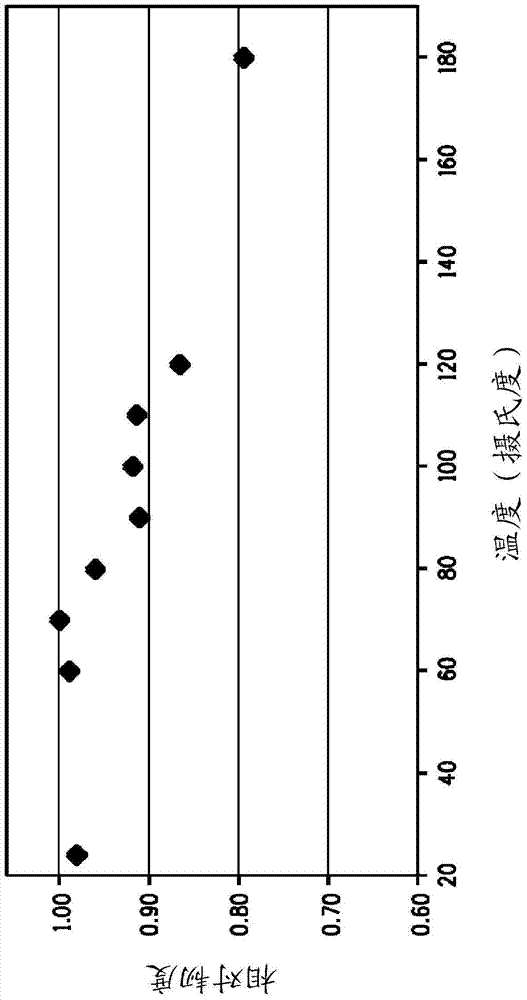

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

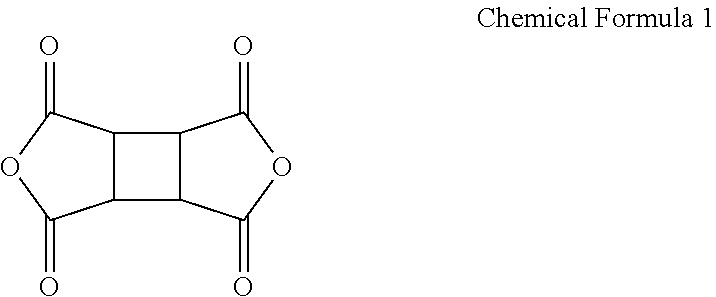

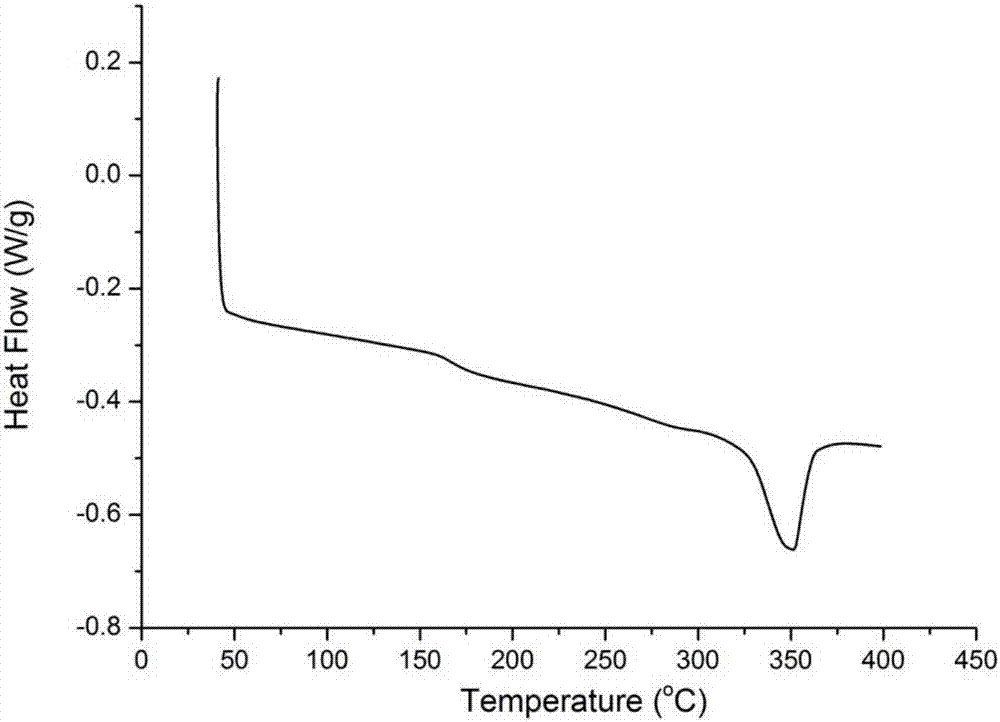

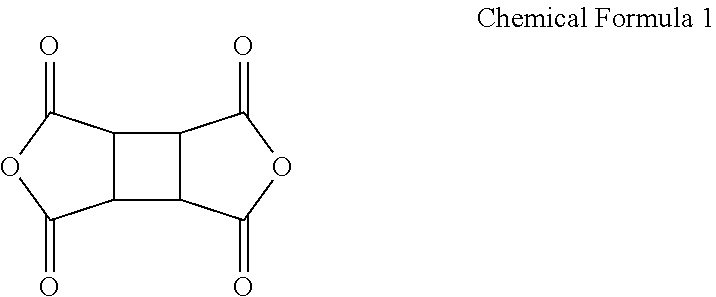

Poly(amide-imide) copolymer film, window for display device, and display device

ActiveUS20170342224A1Improve mechanical propertiesExcellent optical propertiesSiccativesDigital data processing detailsImidePolyamide-imide

A poly(amide-imide) copolymer film having a tensile modulus of greater than or equal to 5.4 GPa, and a yellowness index of less than or equal to 3.6, wherein the poly(amide-imide) copolymer film is a reaction product of an aromatic dianhydride including biphenyl tetracarboxylic dianhydride and 4,4′-hexafluoroisopropylidene diphthalic dianhydride, an aliphatic dianhydride including 1,2,3,4-cyclobutane tetracarboxylic dianhydride, an aromatic diamine including 2,2-bis(trifluoromethyl) benzidine, and an aromatic dicarbonyl compound including terephthaloyl dichloride.

Owner:SAMSUNG ELECTRONICS CO LTD +1

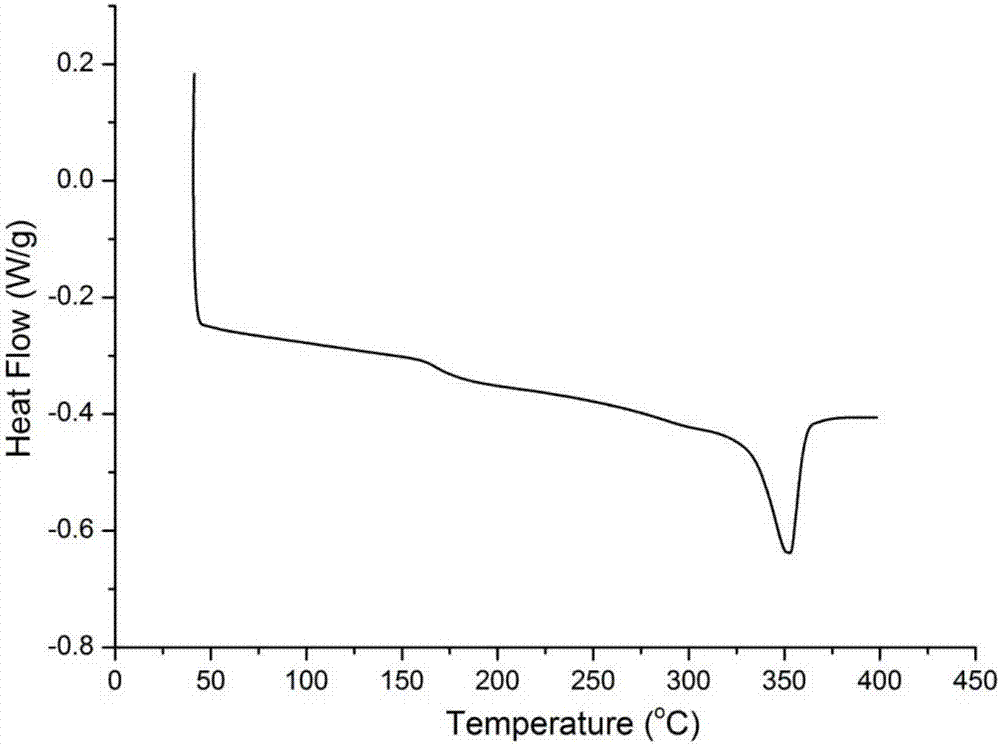

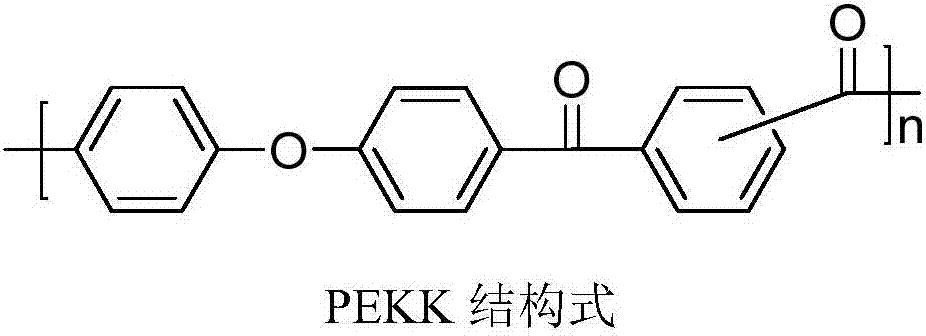

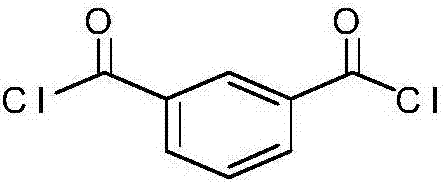

Preparation method of block polyether ketone ketone

The invention belongs to the technical field of polymer synthesis and particularly relates to a preparation method of block polyether ketone ketone. The preparation method comprises the following steps of adding a solvent, lewis acid and lewis base in two prepolymerization reaction bottles respectively; and then respectively adding diphenyl ether and isophthaloyl / terephthaloyl dichloride with an equal molar ratio for reaction to produce a prepolymer A and a prepolymer B with better mobility, then adding the produced prepolymer A and prepolymer B in a polymerization reaction bottle for reaction, and performing mashing, washing and drying to prepare the block polyether ketone ketone. The preparation method is simple in technology and low in cost; and the prepared polyether ketone ketone hashigher degree of crystallinity and rapider crystallization rate.

Owner:SHANDONG KAISHENG NEW MATERIALS

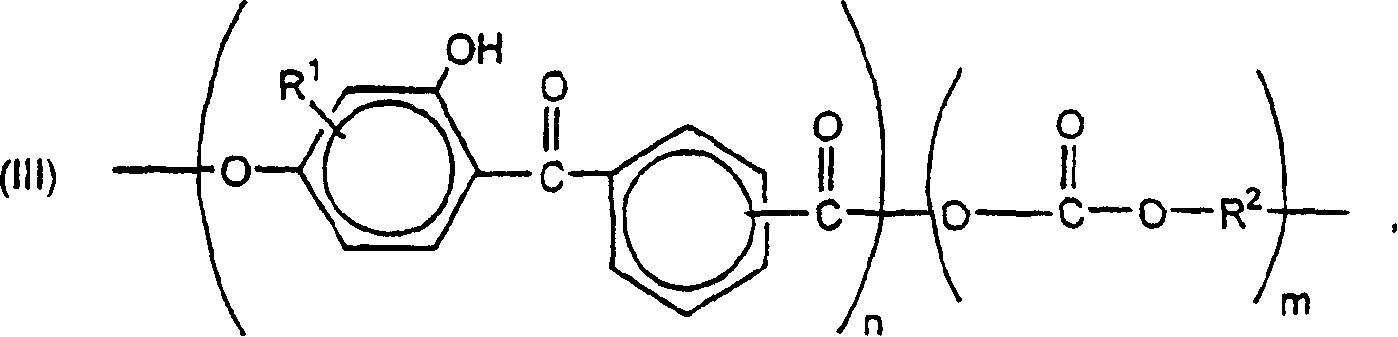

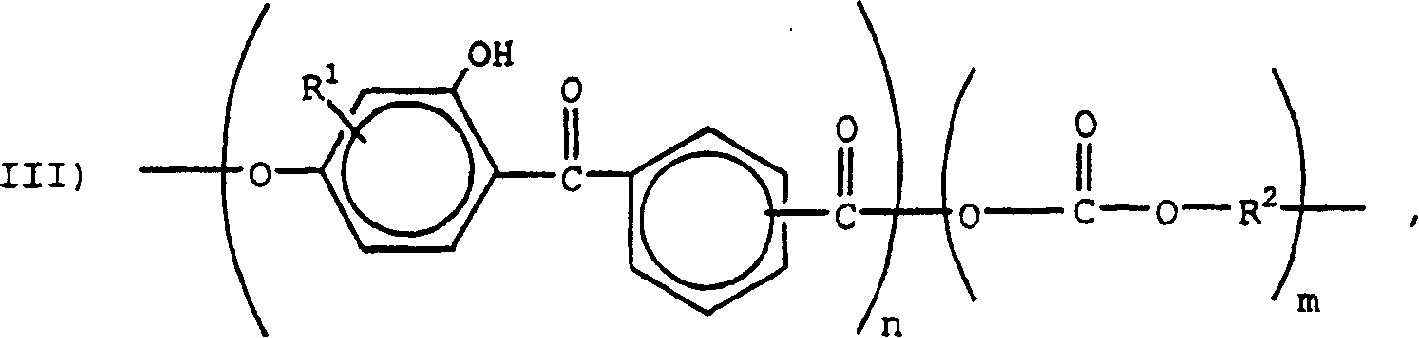

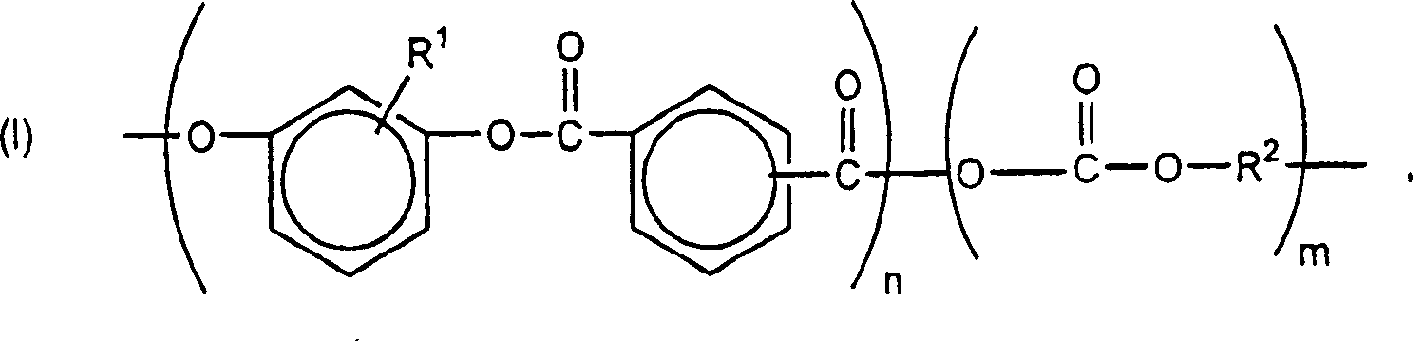

Weatherable block copolyestercarbonates and blends containing them

A process for preparation of block copolyestercarbonates which is implemented as follow: first conducting a reaction between at least one of resorcinol or an alkyl- or haloresorcinol and at least one aromatic dicarboxylic acid dichloride, preferably isophthaloyl dichloride, terephthaloyl dichloride or a mixture thereof, to produce a hydroxy-terminated polyester intermediate, and then conducting a reaction of the intermediate with a carbonate precursor, preferably in the presence of a dihydroxy compound such as bisphenol A. The products have excellent physical properties, including a high degree of weatherability. They may be blended with other polymers such as polycarbonates, poly(alkylene carboxylates), polyarylates, polyetherimides, and addition polymers to improve the weatherability thereof.

Owner:SABIC GLOBAL TECH BV

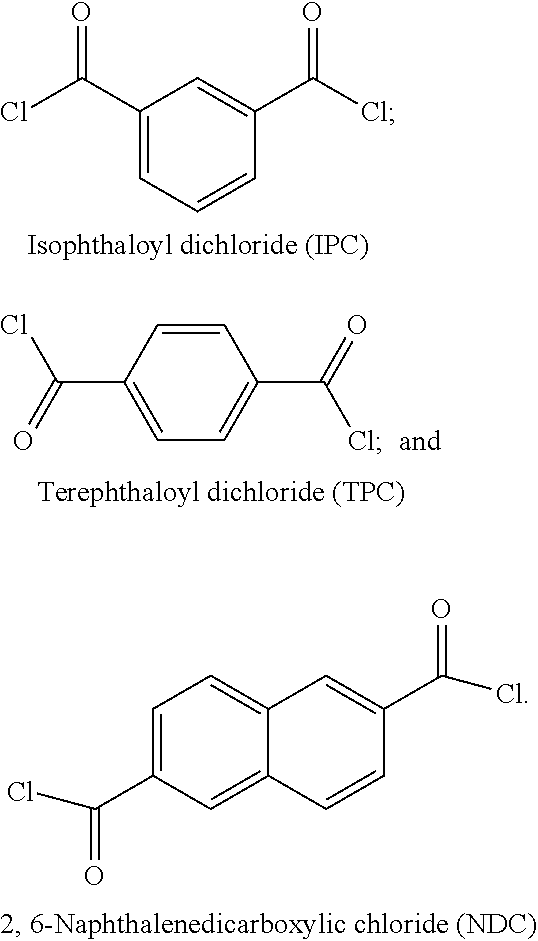

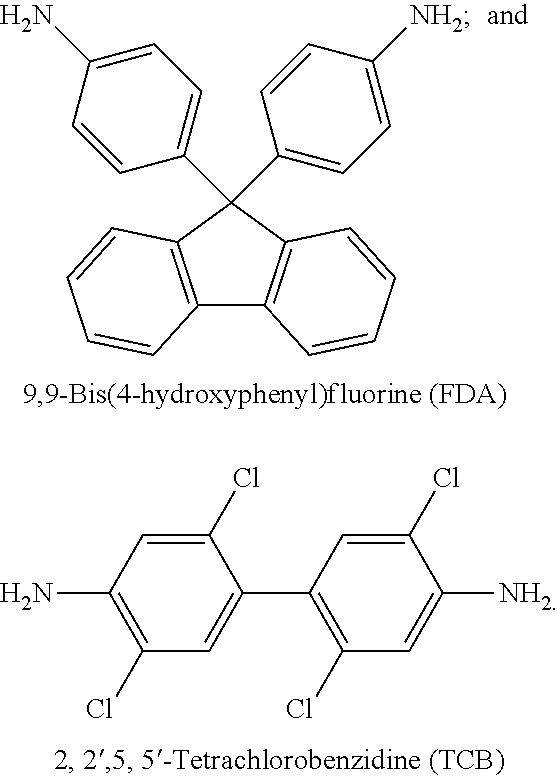

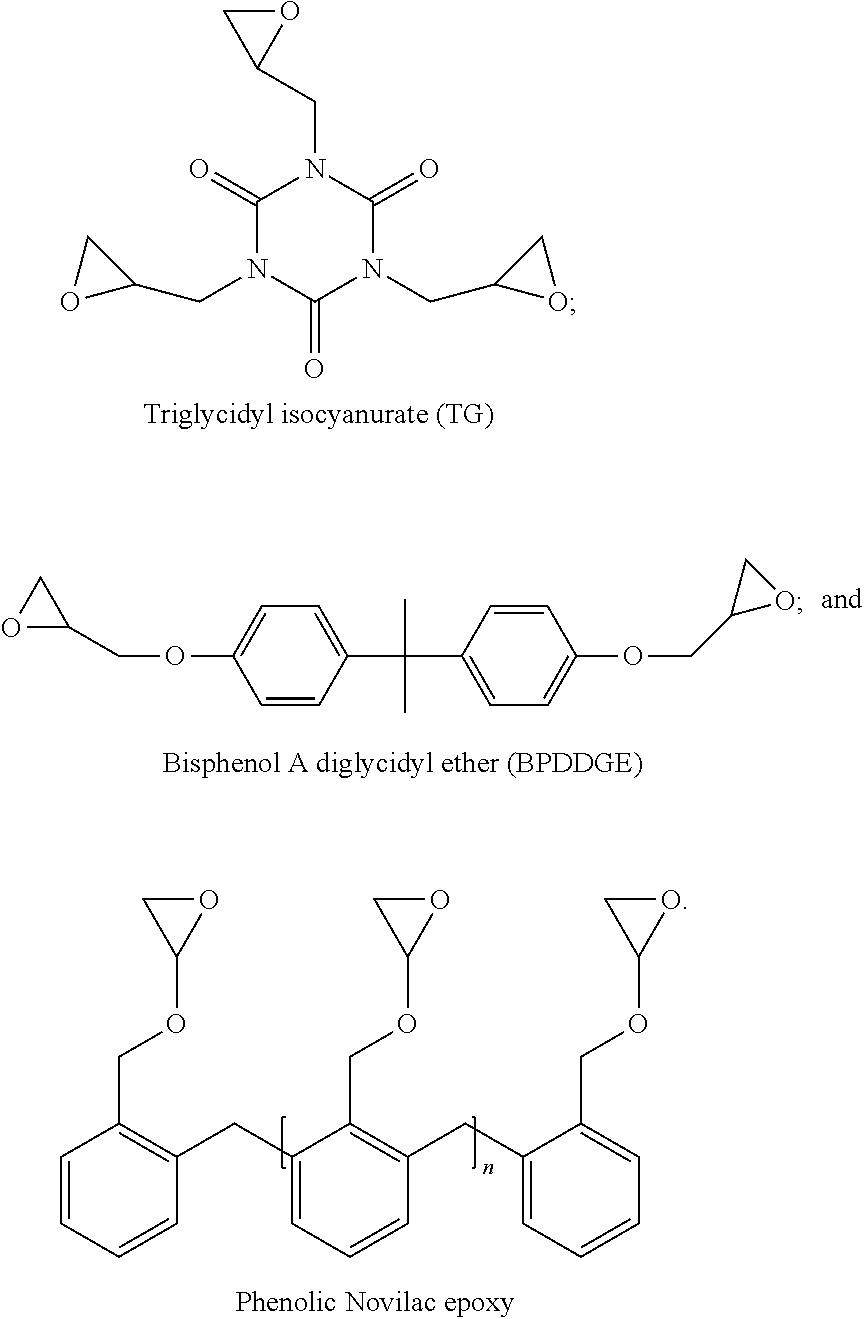

Solvent resistant, transparent aromatic polyamide films with high refractive indices

A solvent resistant, transparent aromatic polyamide film with a high refractive index may be made by reacting at least one aromatic diacid chloride, a first aromatic diamine, and at least one crosslinking agent or a second aromatic diamine in an organic solvent to form an aromatic polyamide polymer in solution. In one embodiment, the at least one aromatic diacid chloride is selected from the group consisting of isophthaloyl dichloride, terephthaloyl dichloride, 2, 6- naphthalene-dicarboxylic chloride, or combinations thereof and the first aromatic diamine is selected from the group consisting of 9, 9-Bis(4-hydroxyphenyl)fluorine, 2, 2 ',5,5'- Tetrachlorobenzidine, or combinations thereof. The organic solvent is then evaporated from the aromatic polyamide polymer in solution to form a transparent aromatic polyamide precursor film. The precursor film is then heated at a temperature close to the glass transition temperature of the transparent aromatic polyamide precursor film to form the solvent resistant, transparent aromatic polyamide film.

Owner:AKRON POLYMER SYST +4

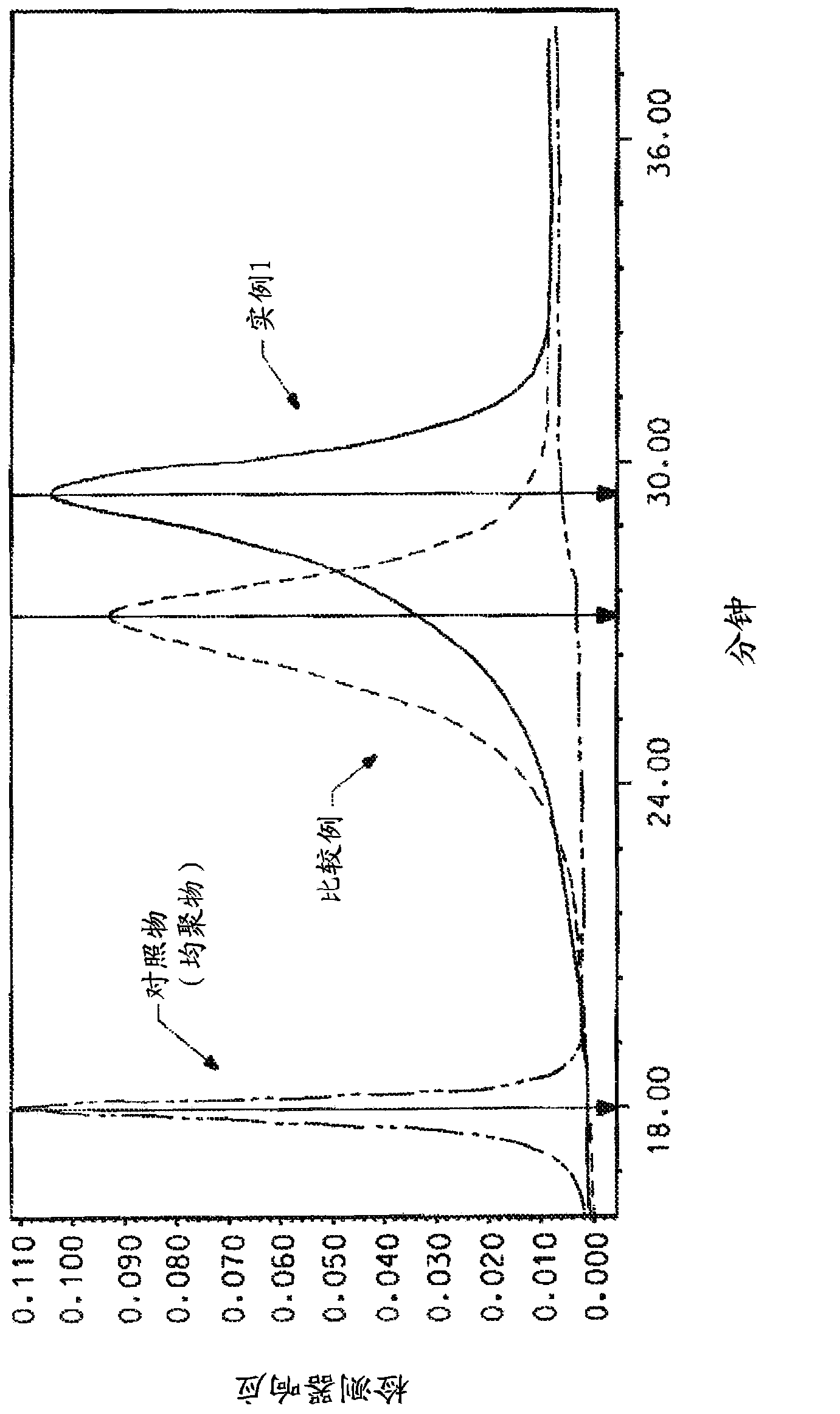

High-strength copolymerized aramid fiber and preparing method therefor

InactiveUS20170241048A1Improve solubilityHigh intrinsic viscosityFilament/thread formingMonocomponent copolyamides artificial filamentOrganic solventAramides

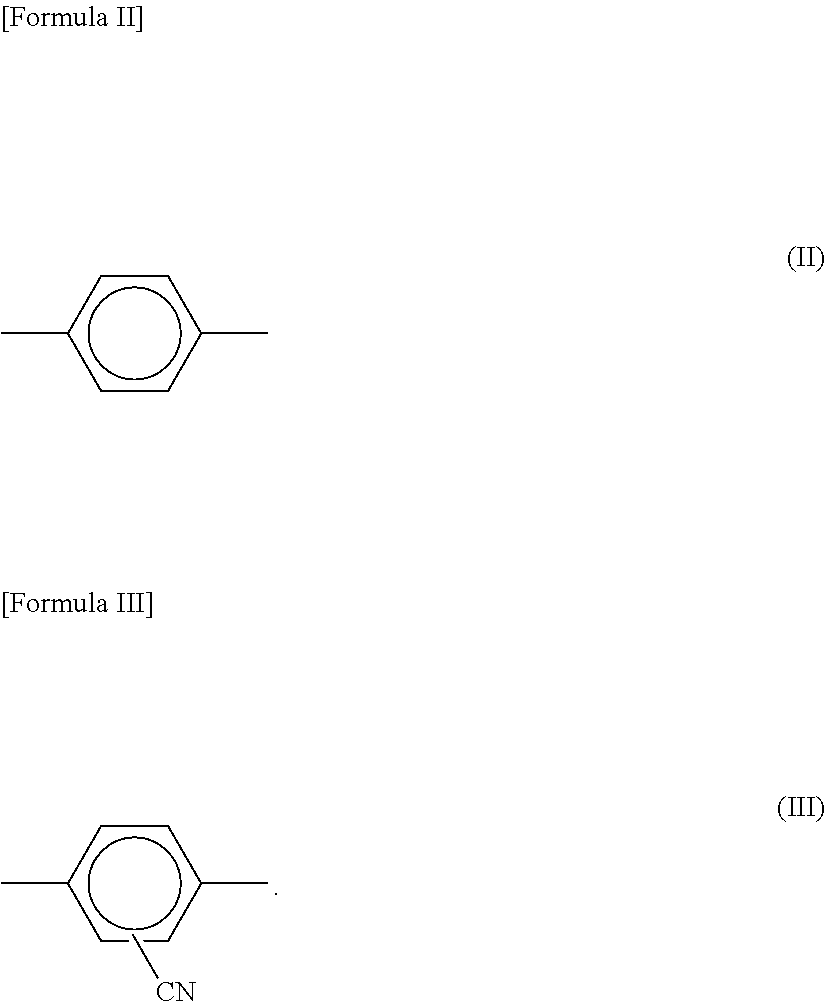

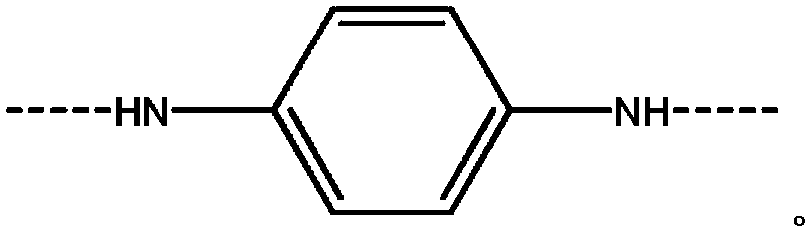

Disclosed is a high-strength copolymerized aramid fiber which includes aramid copolymers containing an aromatic group substituted with a cyano group (—CN), so as to have an intrinsic viscosity (IV) of 6.0 to 8.5, a polydispersity index (PDI) of 1.5 to 2.0, a strength of 23 to 32 g / d, and an elastic modulus of 1,100 to 1,300 g / d. The high-strength copolymerized aramid fiber may be prepared by a method which includes, when para-phenylenediamine, cyano-para-phenylenediamine, and terephthaloyl dichloride are sequentially added to an organic solvent and reacted together to prepare a copolymerized aramid fiber, adding and dispersing a neutralizing agent in the organic solvent before the reaction of the para-phenylenediamine, cyano-para-phenylenediamine and terephthaloyl dichloride, which were dissolved in the organic solvent.

Owner:KOLON IND INC

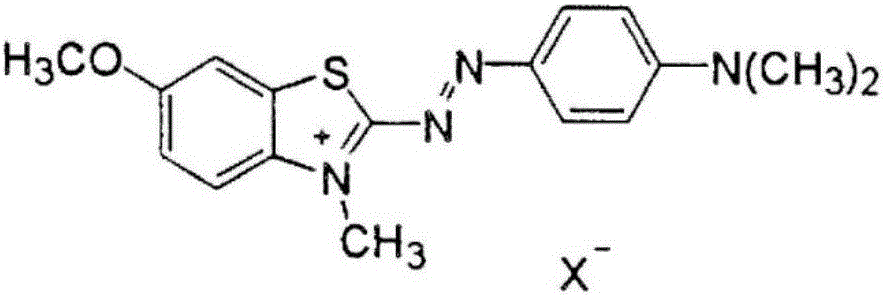

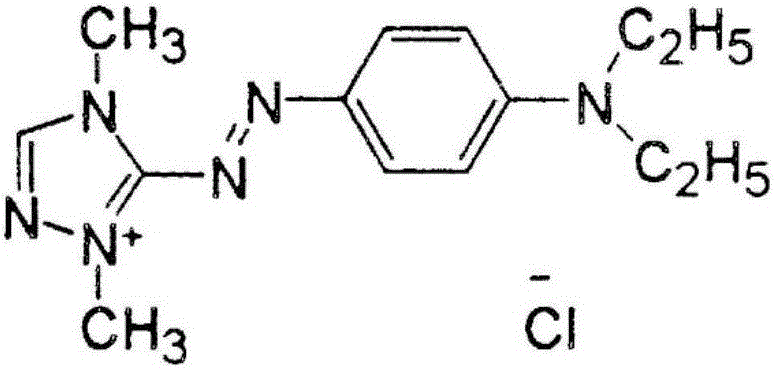

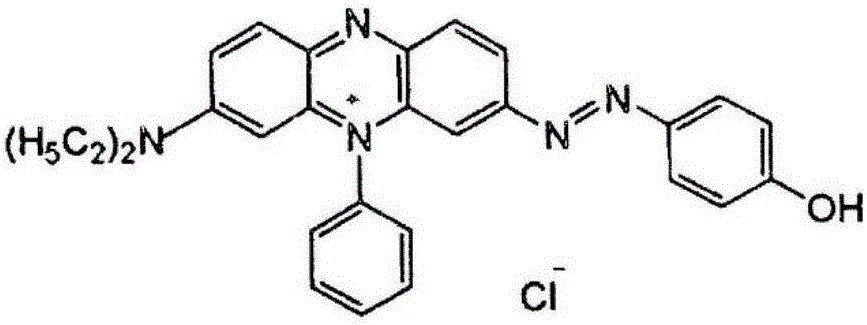

Copolymerized aramid dope-dyed yarn and method for preparing same

ActiveCN105899717AReduce solubilityReduce the degree of polymerizationMonocomponent copolyamides artificial filamentPigment addition to spinning solutionYarnOrganic solvent

Owner:KOLON IND INC

Solvent Resistant, Transparent Aromatic Polyamide Films with High Refractive Indices

A solvent resistant, transparent aromatic polyamide film with a high refractive index may be made by reacting at least one aromatic diacid chloride, a first aromatic diamine, and at least one crosslinking agent or a second aromatic diamine in an organic solvent to form an aromatic polyamide polymer in solution. In one embodiment, the at least one aromatic diacid chloride is selected from the group consisting of isophthaloyl dichloride, terephthaloyl dichloride, 2,6-naphthalene-dicarboxylic chloride, or combinations thereof and the first aromatic diamine is selected from the group consisting of 9,9-Bis(4-hydroxyphenyl)fluorine, 2,2′,5,5′-Tetrachlorobenzidine, or combinations thereof. The organic solvent is then evaporated from the aromatic polyamide polymer in solution to form a transparent aromatic polyamide precursor film. The precursor film is then heated at a temperature close to the glass transition temperature of the transparent aromatic polyamide precursor film to form the solvent resistant, transparent aromatic polyamide film.

Owner:AKRON POLYMER SYST

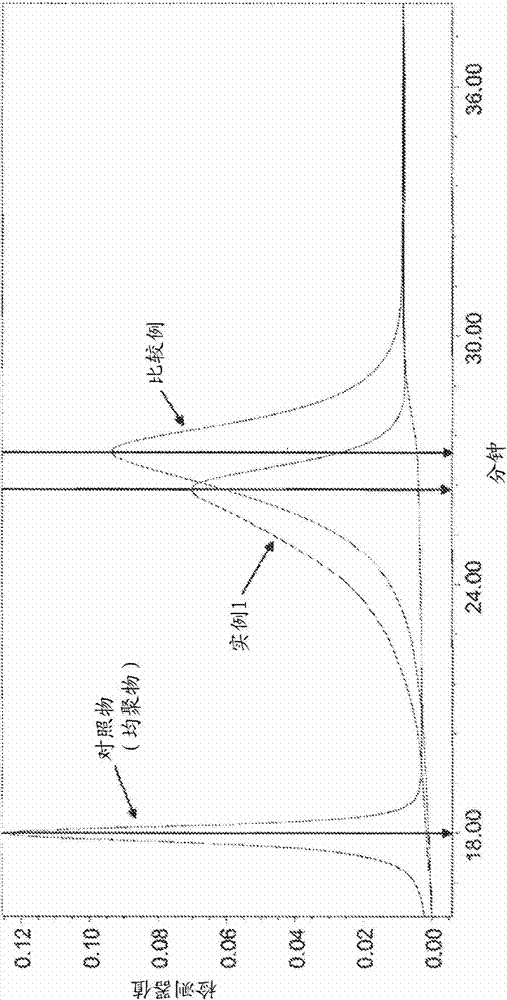

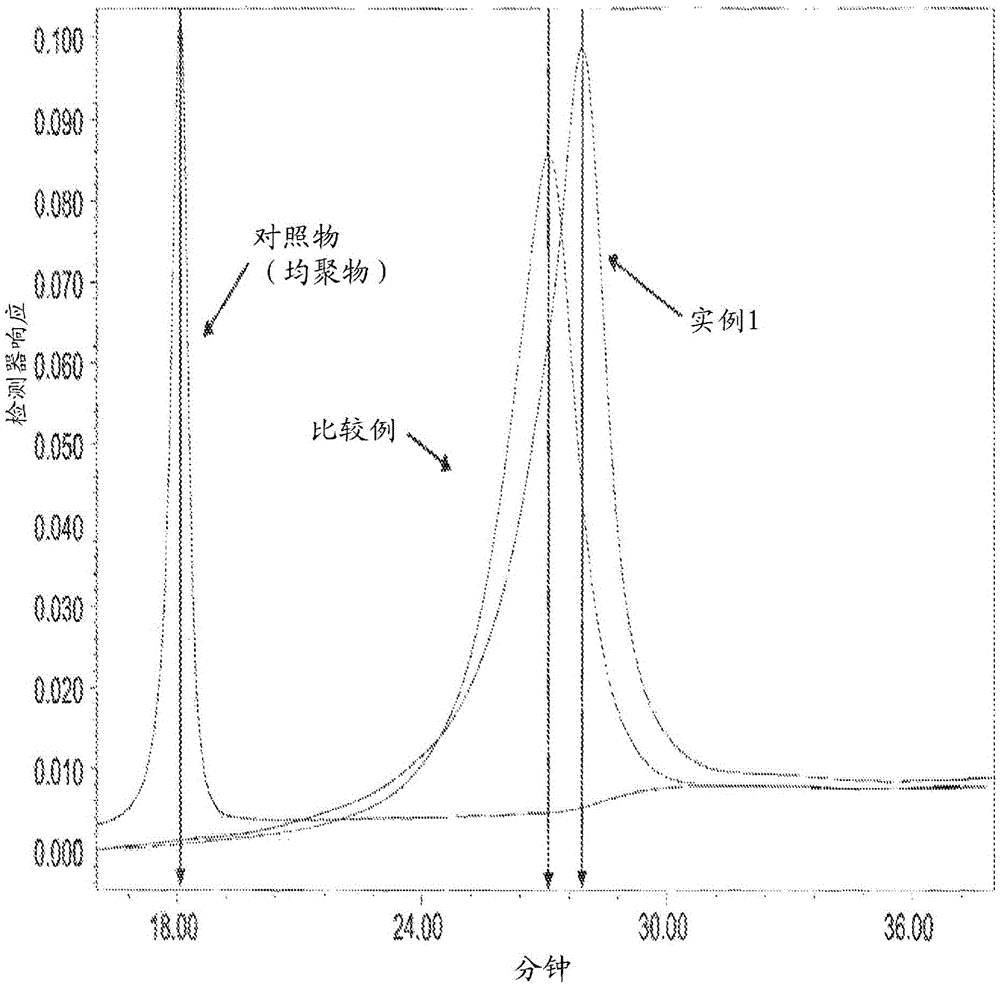

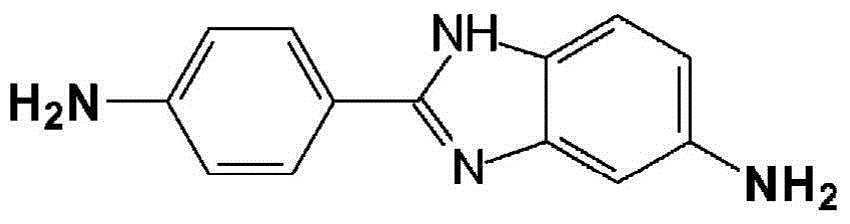

Aramid copolymer

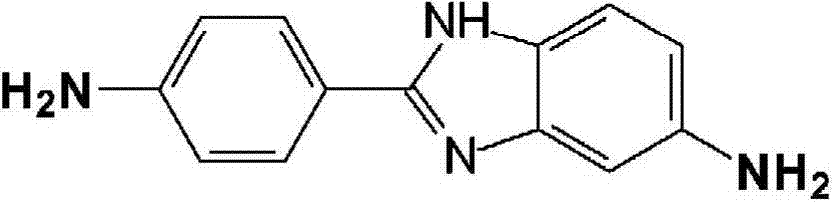

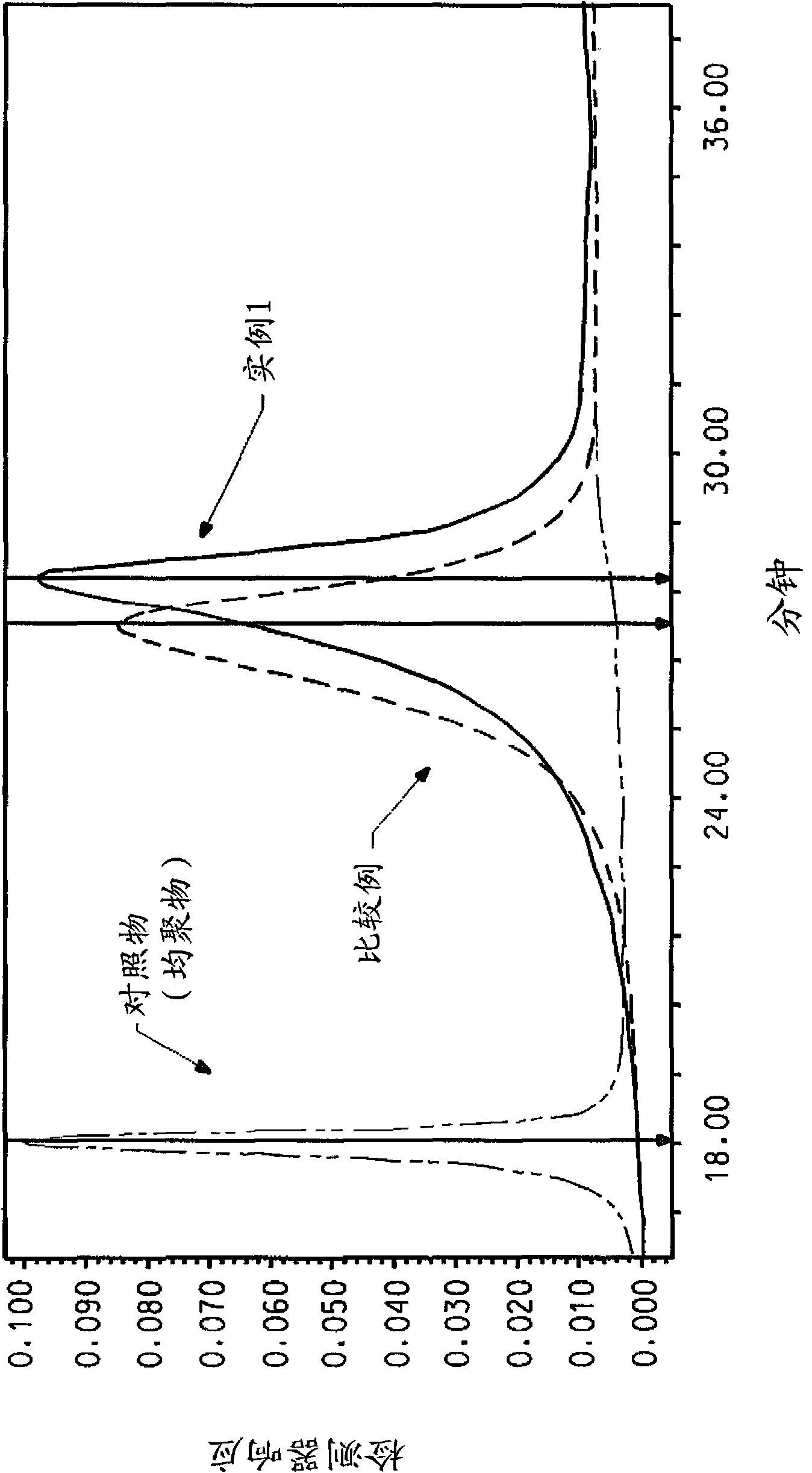

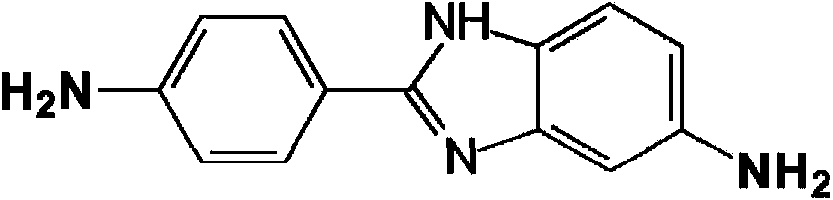

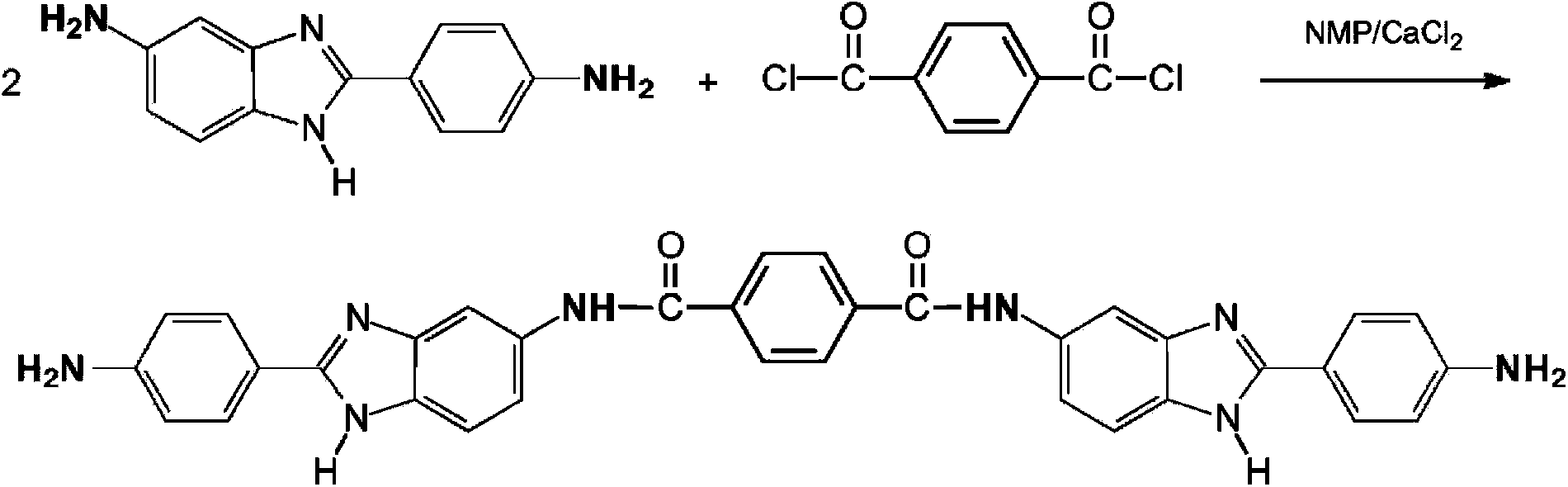

The invention concerns polymer comprising residues of 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine, and terephthaloyl dichloride, the polymer having a IPC peak block ratio of 1.45 to 1.47 and an inherent viscosity of greater than 2 dl / g.

Owner:DUPONT SAFETY & CONSTR INC

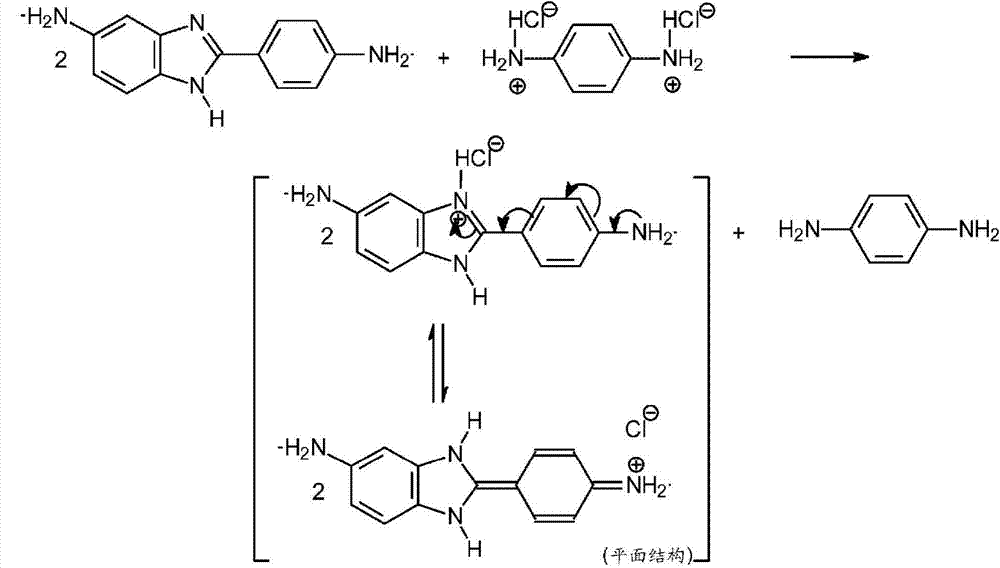

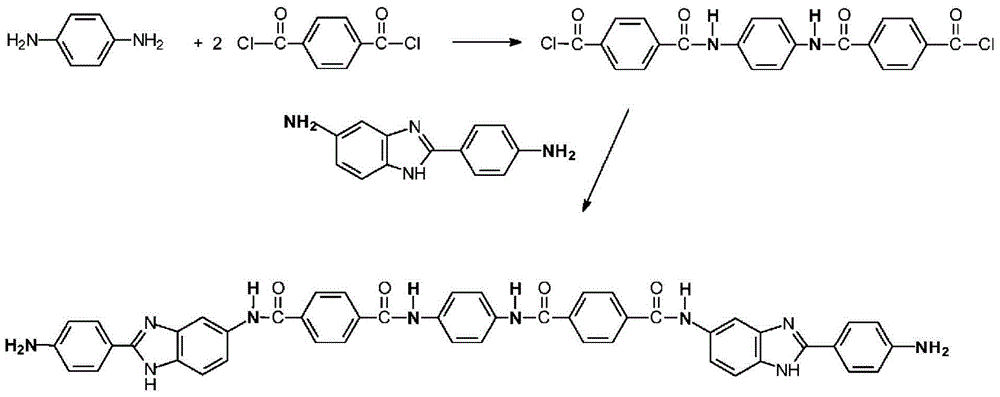

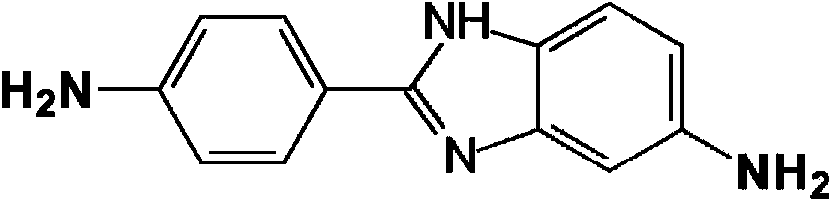

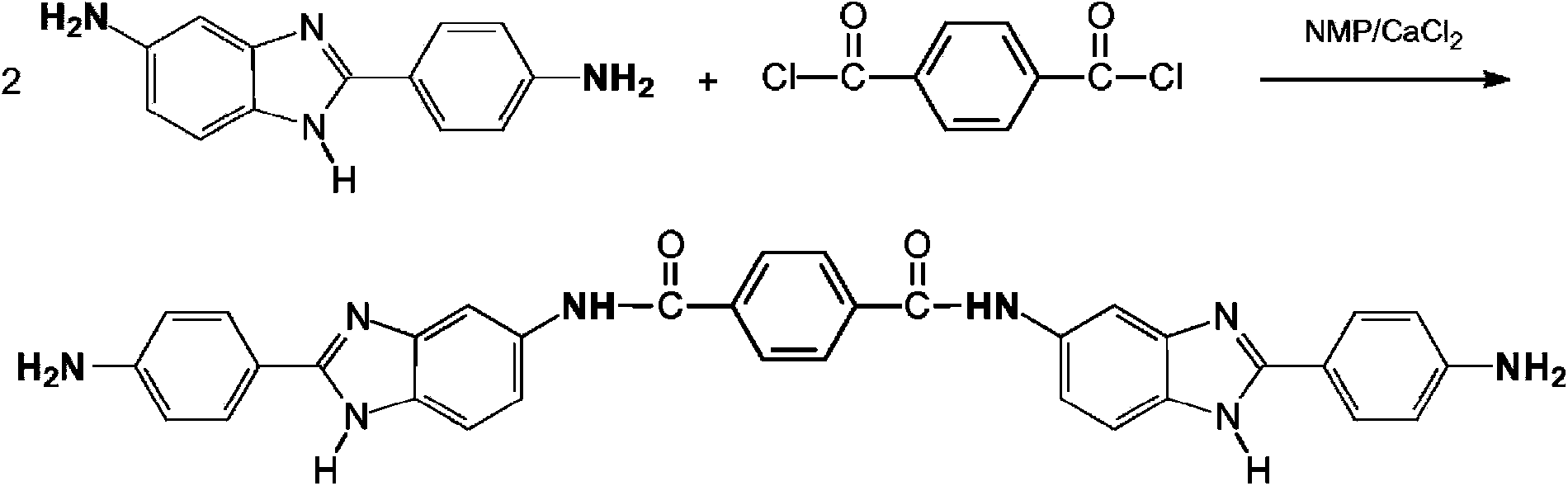

Process for forming an aramid copolymer

The invention concerns processes for forming a polymer comprising residues of 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine (PPD), and terephthaloyl dichloride, comprising the steps of: (a) forming a solution of oligomers having amine end groups from two moles of DAPBI and one mole of terephthaloyl dichloride in a solvent system comprising an organic solvent and an inorganic salt; (b) adding PPD to the solution of oligomers; and (c) adding additional terephthaloyl dichloride to form a polymer.

Owner:DUPONT SAFETY & CONSTR INC

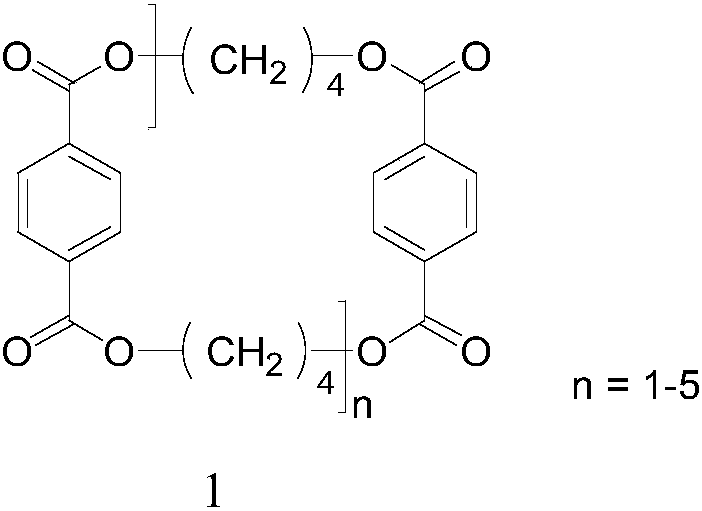

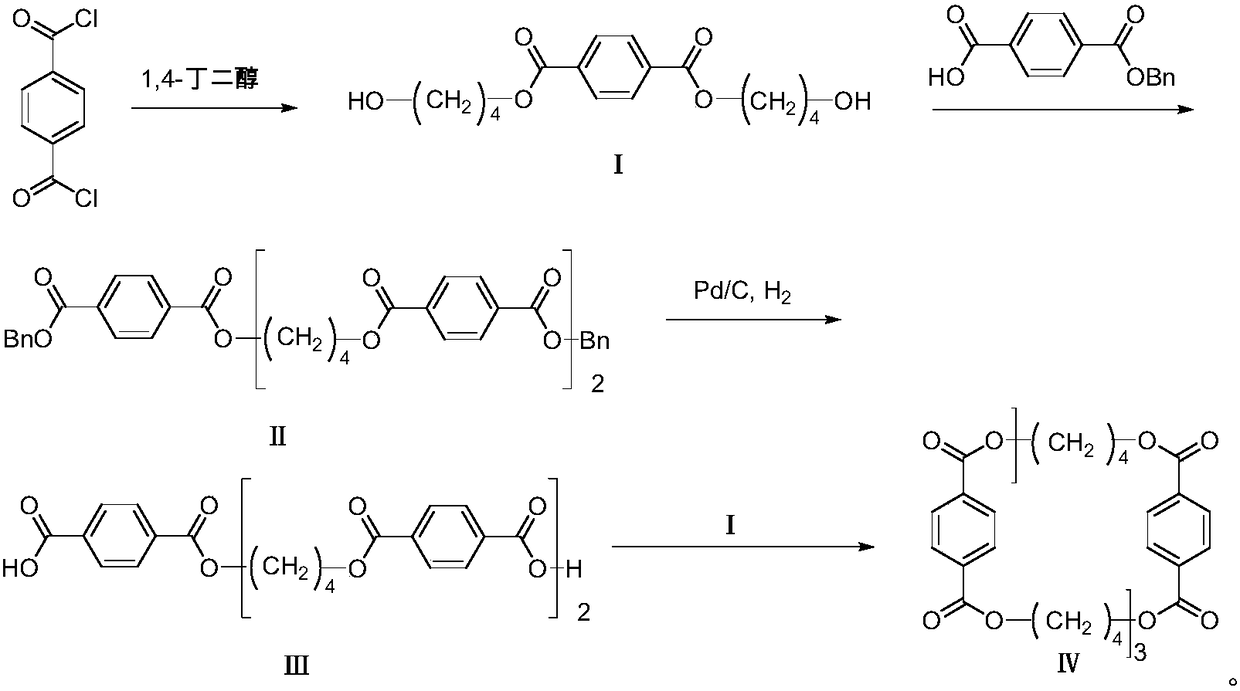

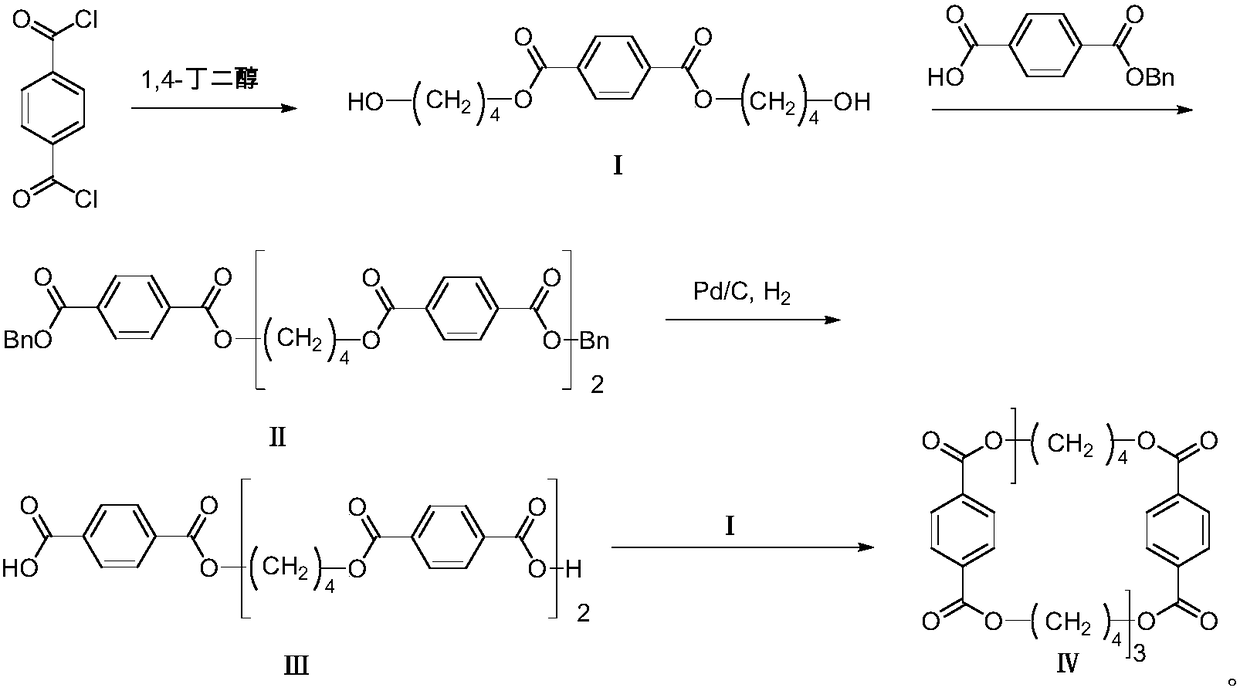

Preparation method of cyclic tetrapolybutylene terephthalate

InactiveCN108440492AShort synthetic routeHigh yieldOrganic chemistryPolytetramethylene terephthalateHydrogen

The invention discloses a preparation method of cyclic tetrapolybutylene terephthalate. The method comprises the steps as follows: a) an initial material, namely, terephthaloyl dichloride, reacts with1,4-butanediol under the action of an alkaline reagent, and terephthalic bis(4-hydroxyl-butyl)ester, namely, a compound I, is obtained; b) the compound I reacts with monobenzyl terephthalate under the action of a condensing agent, and bis(4-(4-benzyloxy terephthaloyl)butyl)terephthalate, namely, a compound II, is obtained; c) the compound II is dissolved in a proper solvent, a catalyst is added to reduce debenzylation under the action of palladium-carbon and hydrogen, and 4,4'-[terephthaloyl bis(oxytetramethylene oxycarbonyl)]dibenzoic acid, namely a compound III, is obtained; d) the compoundIII reacts with the compound I under the action of a condensing agent, and the target product, namely, cyclic tetrapolybutylene terephthalate, is obtained. The method is low in cost, short in synthesis route, convenient to operate, high in product quality and good in industrial application value.

Owner:EAST CHINA NORMAL UNIV +2

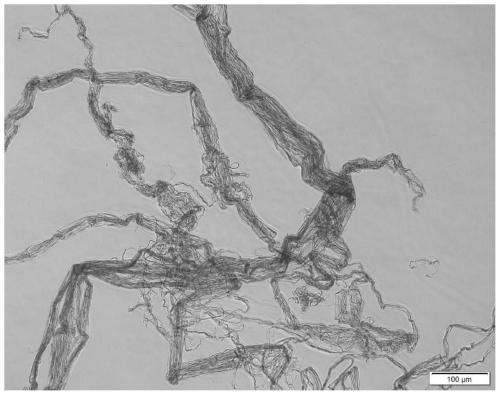

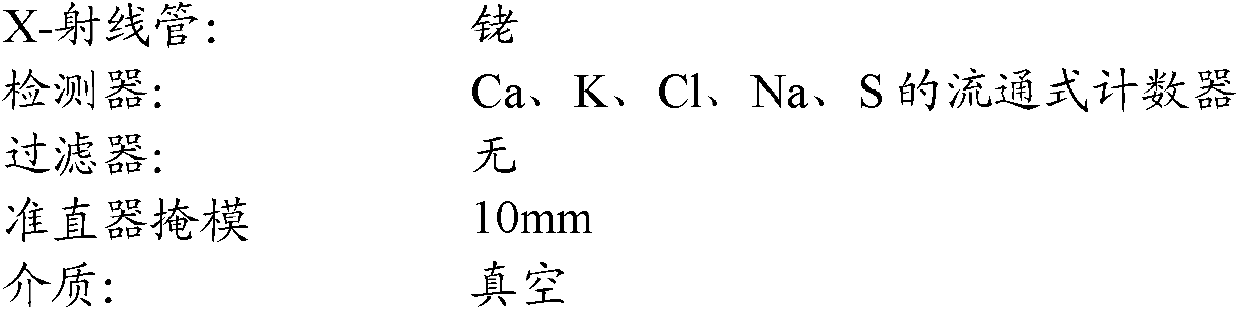

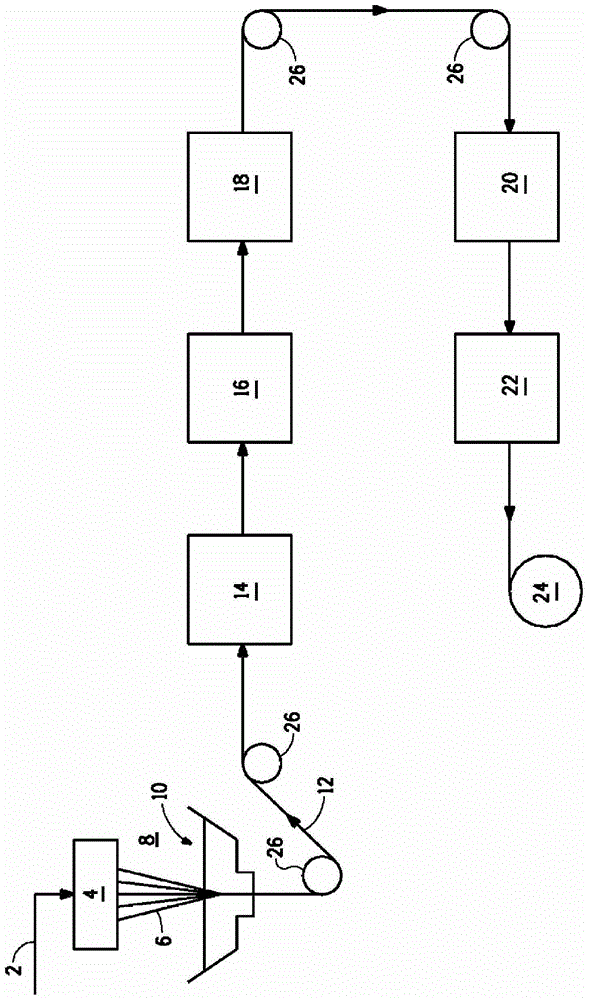

Para-aramid precipitation fiber and continuous production method thereof

ActiveCN110129912ASimple methodControllable structureMonocomponent polyamides artificial filamentMicrometerDiameter ratio

The invention provides a continuous production method of para-aramid precipitation fiber. A p-phenylenediamine solution and a terephthaloyl dichloride melt are polymerized in a double-screw reactor, aproduct is mixed with a pre-coagulation agent, and pre-precipitation is performed; an obtained aramid product and a coagulating bath are precipitated in a mixing pump to form fiber, and the para-aramid precipitation fiber is obtained, wherein the pre-coagulation agent comprises a first solvent, a second solvent and an aid; the length-diameter ratio of the twin-screw reactor is (30:1)-(60:1), therotating speed is 60-500 rpm, and a discharging port at the tail end of the screws is kept at 70 DEG C or below; a first adding port and a second adding port are formed in the twin-screw reactor; thefirst adding port is located in the initial position of screws; the p-phenylenediamine solution and the terephthaloyl dichloride melt are added via the first adding port; the second adding port is located in the 1 / 2-6 / 7 position of the screws in the discharging direction; the pre-coagulation agent is added via the second adding port. The method comprises a simple technological process, equipment selection is reasonable, the method is accurate and controllable, and the product structure is easy to adjust. The fiber is on the micrometer-millimeter scale.

Owner:CHAMBROAD CHEM IND RES INST CO LTD +1

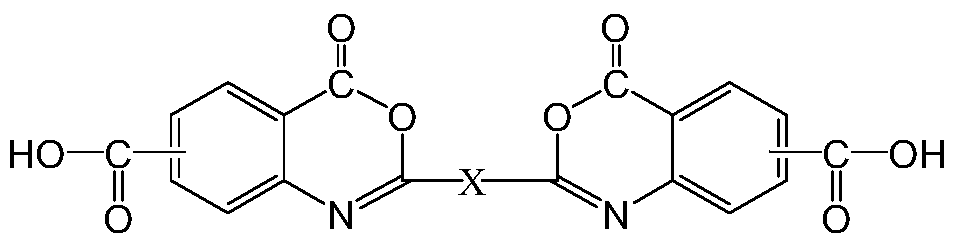

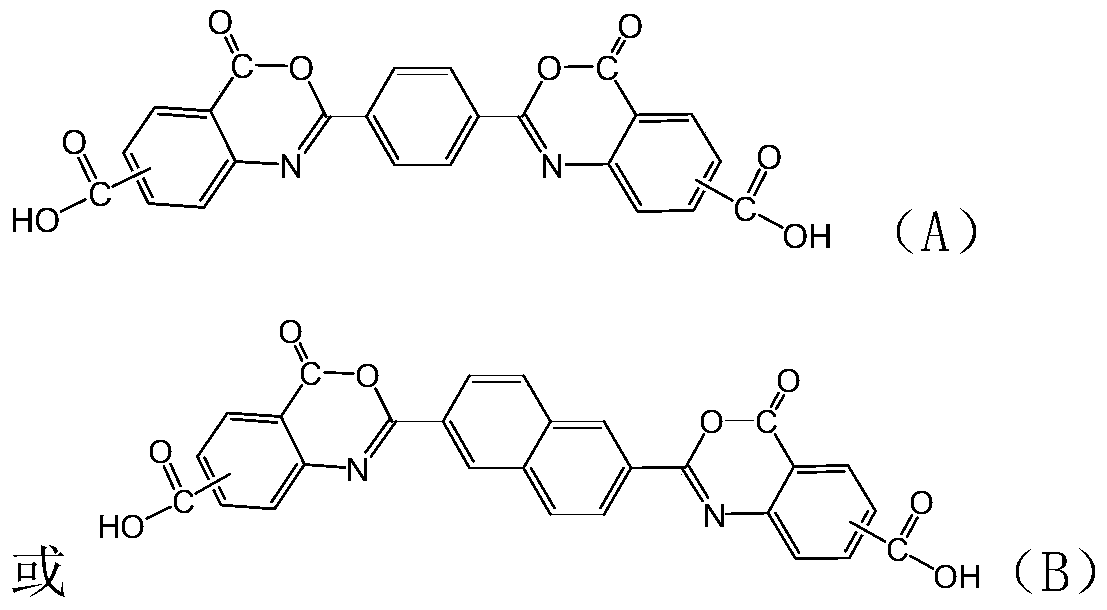

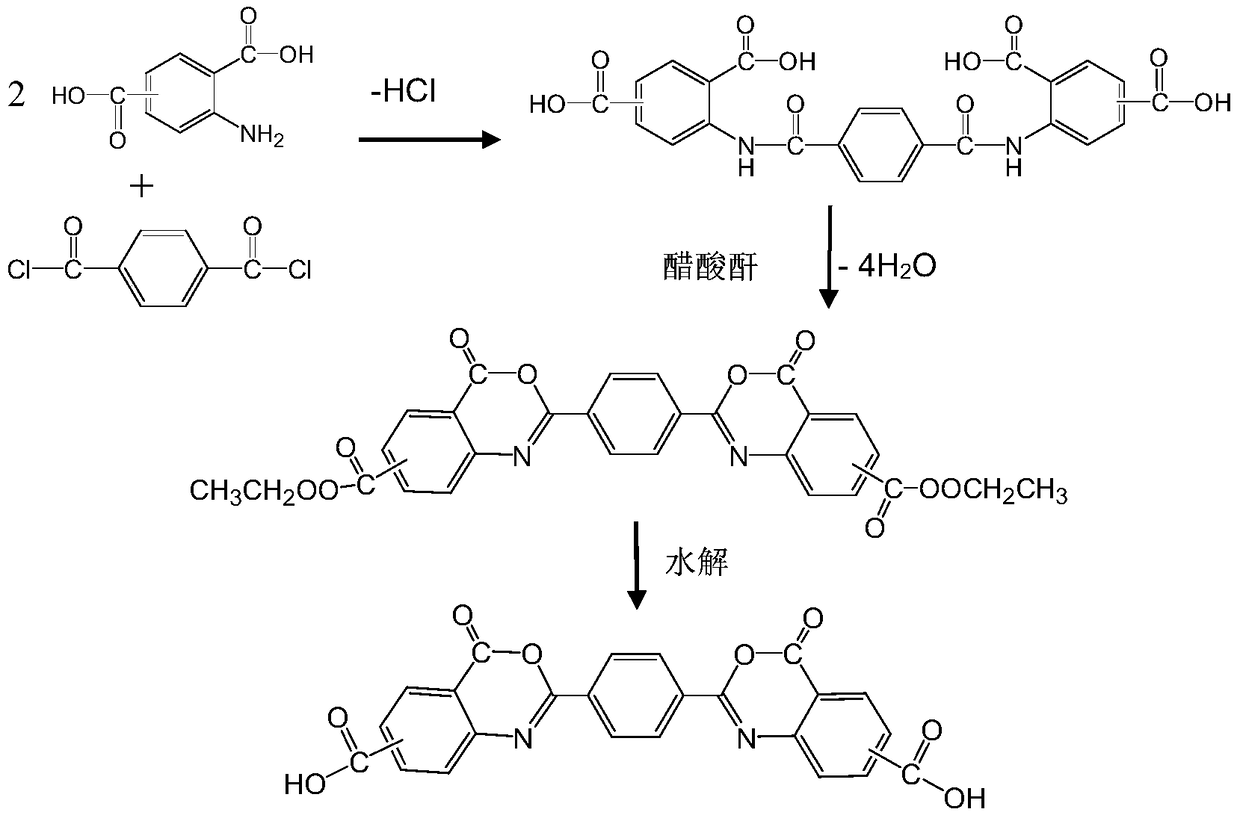

A kind of dibasic acid monomer containing benzoxazinone group and its polyester copolymer

ActiveCN105061349BImprove mechanical propertiesImproves UV resistanceOrganic chemistryDimethyl terephthalateEthylene glycol

The invention relates to a biacid monomer containing benzoxazinone radical groups and a polyester copolymer thereof. The biacid monomer containing the benzoxazinone radical groups is obtained by means of reaction of 2-aminaterephthalic acid and terephthaloyl dichloride or teranaphthyl dichloride; the polyester copolymer is formed by polycondensating terephthalic acid or dimethyl terephthalate, ethylene glycol and biacid monomer containing benzoxazinone radical groups, and the molar ratio of the three monomers is 100:(10 to 90):(1 to 99). The biacid monomer has the advantages that the biacid monomer containing the benzoxazinone radical groups is connected to a polyester main chain by virtue of a copolymerization method, so that the polyester is good in ultraviolet stability and excellent in mechanical performance, and the weakness of the polyester in the prior art that after a large content of ultraviolet absorbent (the weight percent is more than 5 percent) is added, the mechanical performance is decreased can be overcome.

Owner:JIANGSU YUXING FILM TECH

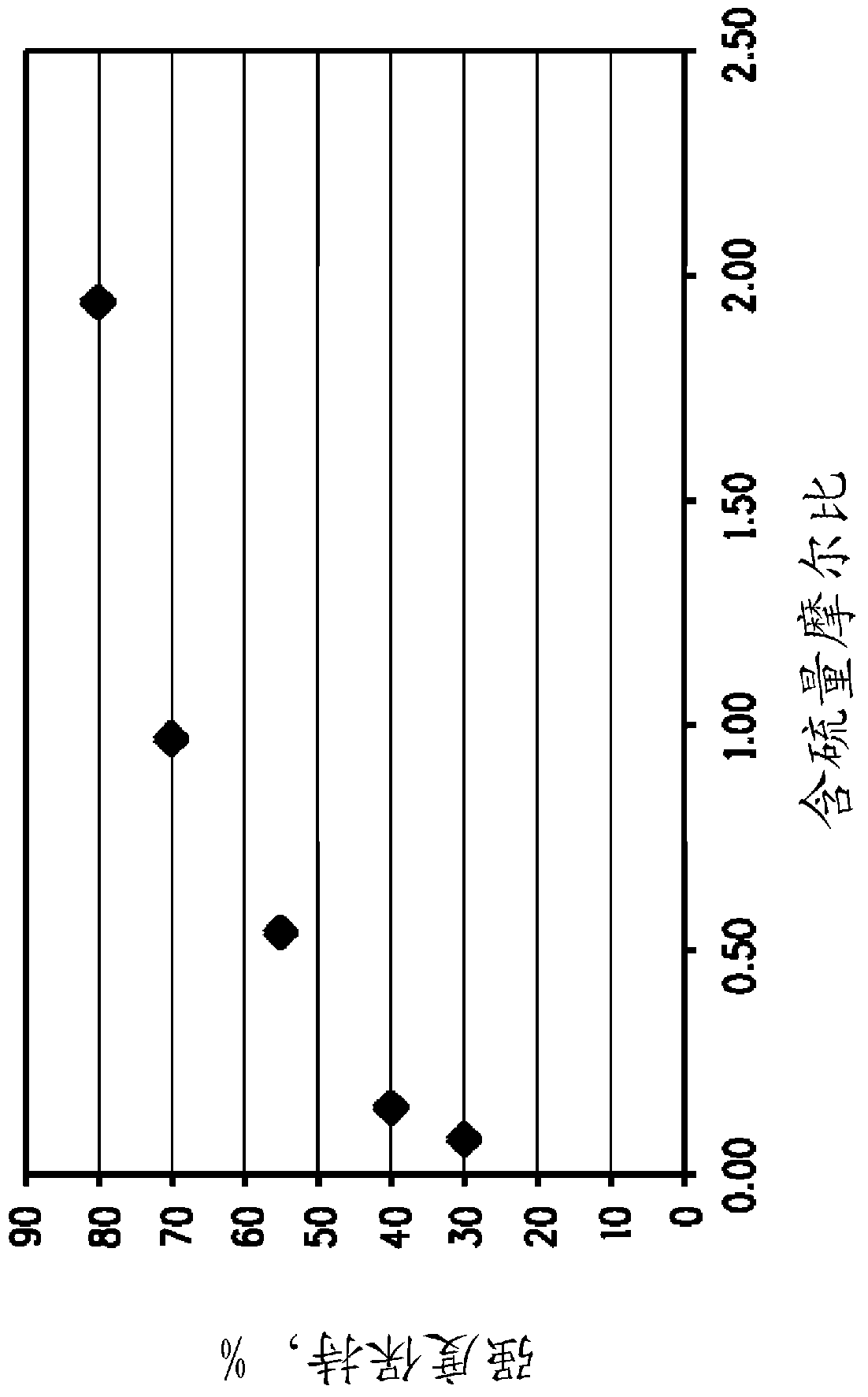

Copolymer fibers and processes for making same

ActiveCN103328699AArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentYarnFiber

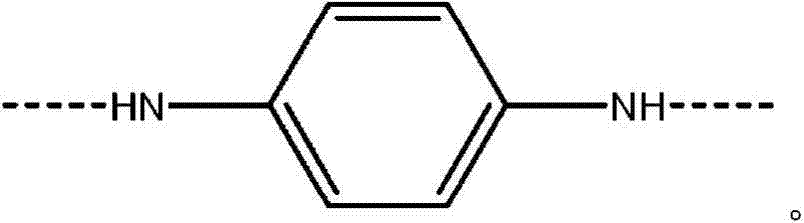

The present invention concerns yarns comprising copolymer derived from the copolymerization of para-phenylenediamine, 5(6)-amino-2-(p-aminophenyl) benzimidazole; and terephthaloyl dichloride wherein the ratio of moles of 5(6)-amino-2-(p-aminophenyl) benzimidazole to the moles of para-phenylenediamine is 30 / 70 to 85 / 15; the yarn having a sulfur content greater than 0.1%; and the hydrolytic strength retention of the yarn is greater than 60%. The invention also concerns processes for making such yarns.

Owner:DUPONT SAFETY & CONSTR INC

Poly(amide-imide) copolymer film, window for display device, and display device

ActiveUS10738173B2Maintain good propertiesSiccativesDigital data processing detailsPolymer scienceMeth-

A poly(amide-imide) copolymer film having a tensile modulus of greater than or equal to 5.4 GPa, and a yellowness index of less than or equal to 3.6, wherein the poly(amide-imide) copolymer film is a reaction product of an aromatic dianhydride including biphenyl tetracarboxylic dianhydride and 4,4′-hexafluoroisopropylidene diphthalic dianhydride, an aliphatic dianhydride including 1,2,3,4-cyclobutane tetracarboxylic dianhydride, an aromatic diamine including 2,2-bis(trifluoromethyl) benzidine, and an aromatic dicarbonyl compound including terephthaloyl dichloride.

Owner:SAMSUNG ELECTRONICS CO LTD +1

Process for forming an aramid copolymer

The invention concerns processes for forming a polymer comprising residues of 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine, and terephthaloyl dichloride, the process comprising: (a) forming a solution of oligomers having chloride end groups from one mole of paraphenylene diamine and 1.3 to 5 moles of terephthaloyl dichloride a solvent system comprising an organic solvent and an inorganic salt; and (b) adding DAPBI and terephthaloyl dichloride to the solution of oligomers to form a polymer.

Owner:DUPONT SAFETY & CONSTR INC

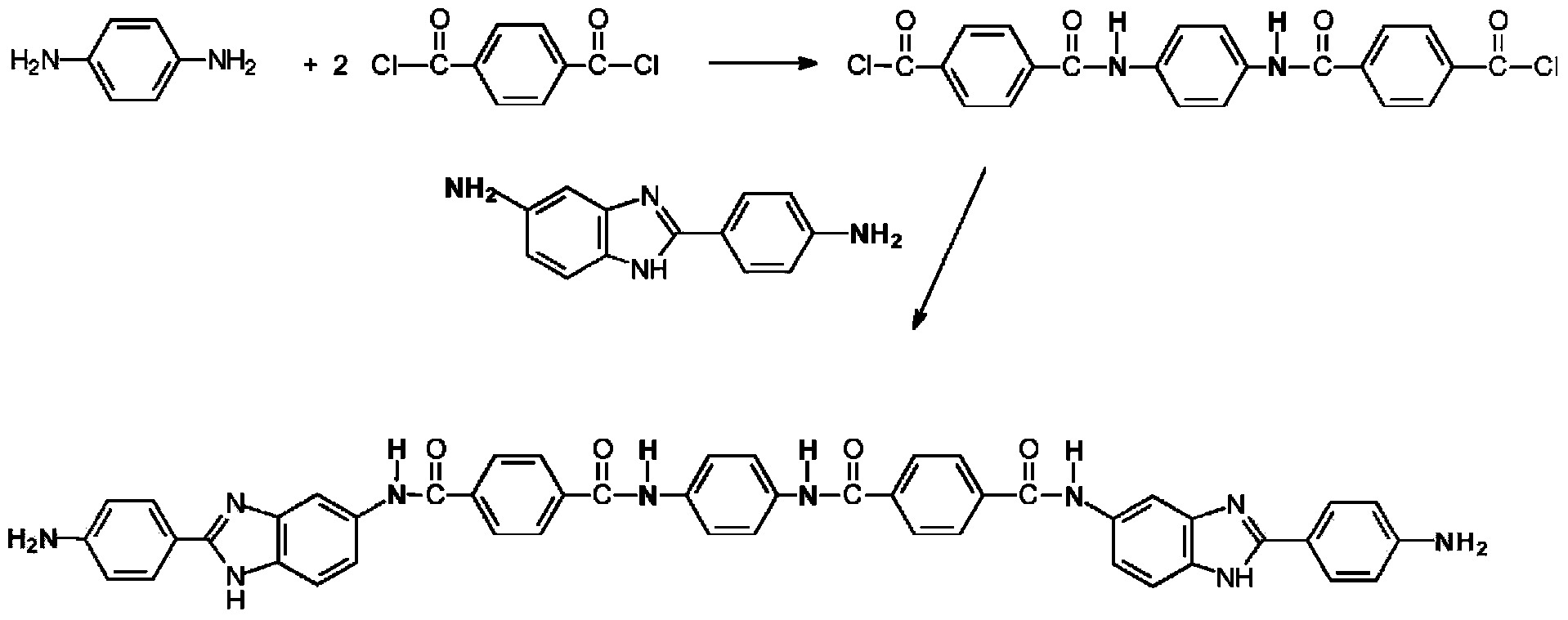

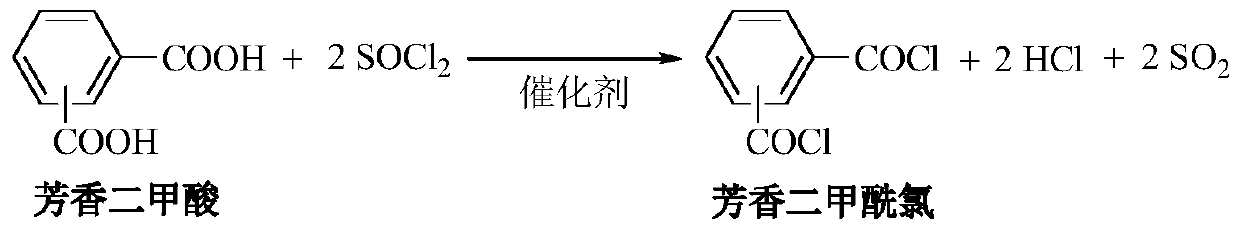

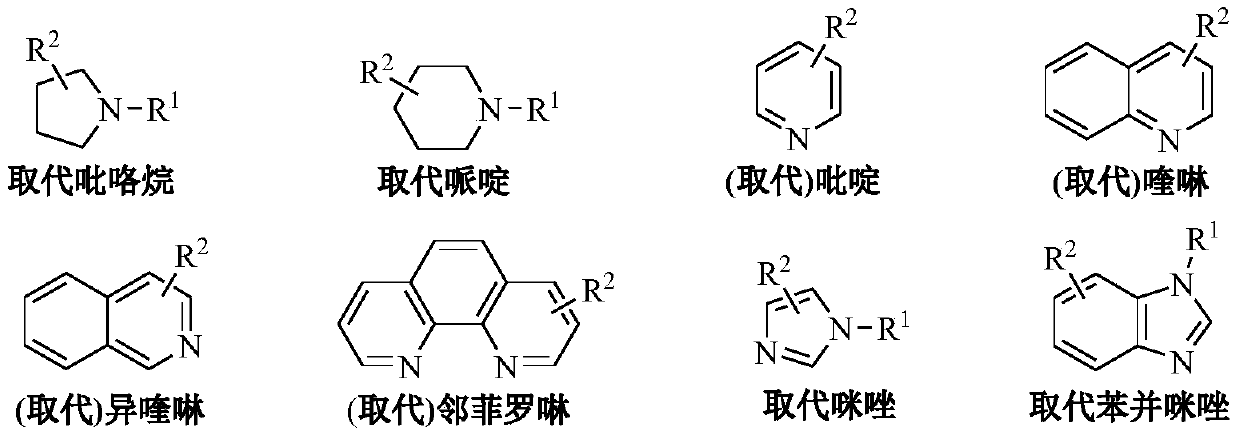

A kind of method for preparing aromatic diacid chloride

ActiveCN105646191BHigh yieldShort reaction timeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsPhenanthrolineQuinoline

The invention relates to a method for preparing aromatic diacid chloride, specifically, in a pressure reactor, using thionyl chloride, phthalic acid, isophthalic acid, terephthalic acid and other aromatic diacids as raw materials, pyrrole Alkanes, piperidines, pyridines, quinolines, isoquinolines, o-phenanthrolines, imidazoles, benzimidazoles and other nitrogen-containing organic bases or their derivatives are used as catalysts, reacted at 90-135°C for 1-3 hours, and the pressure of the reaction system is controlled Between 0.2 and 4Mpa, distill or vacuum distillation to recover thionyl chloride and catalyst, and the molar yield of phthaloyl dichloride, isophthaloyl dichloride, terephthaloyl dichloride and other aromatic diacid chlorides is up to 99%. , with a purity of over 99%. The invention has the advantages of short reaction time, high product yield, simple and convenient reaction operation and the like.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

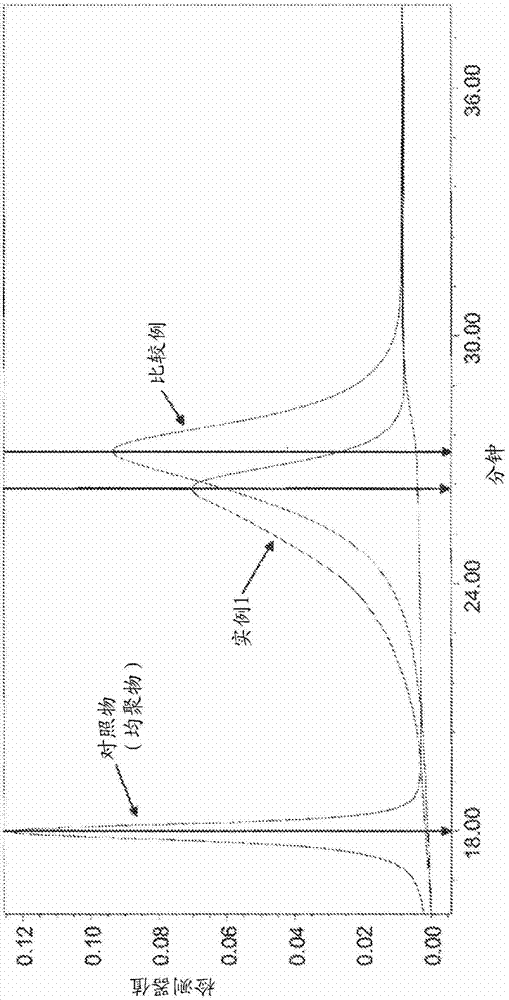

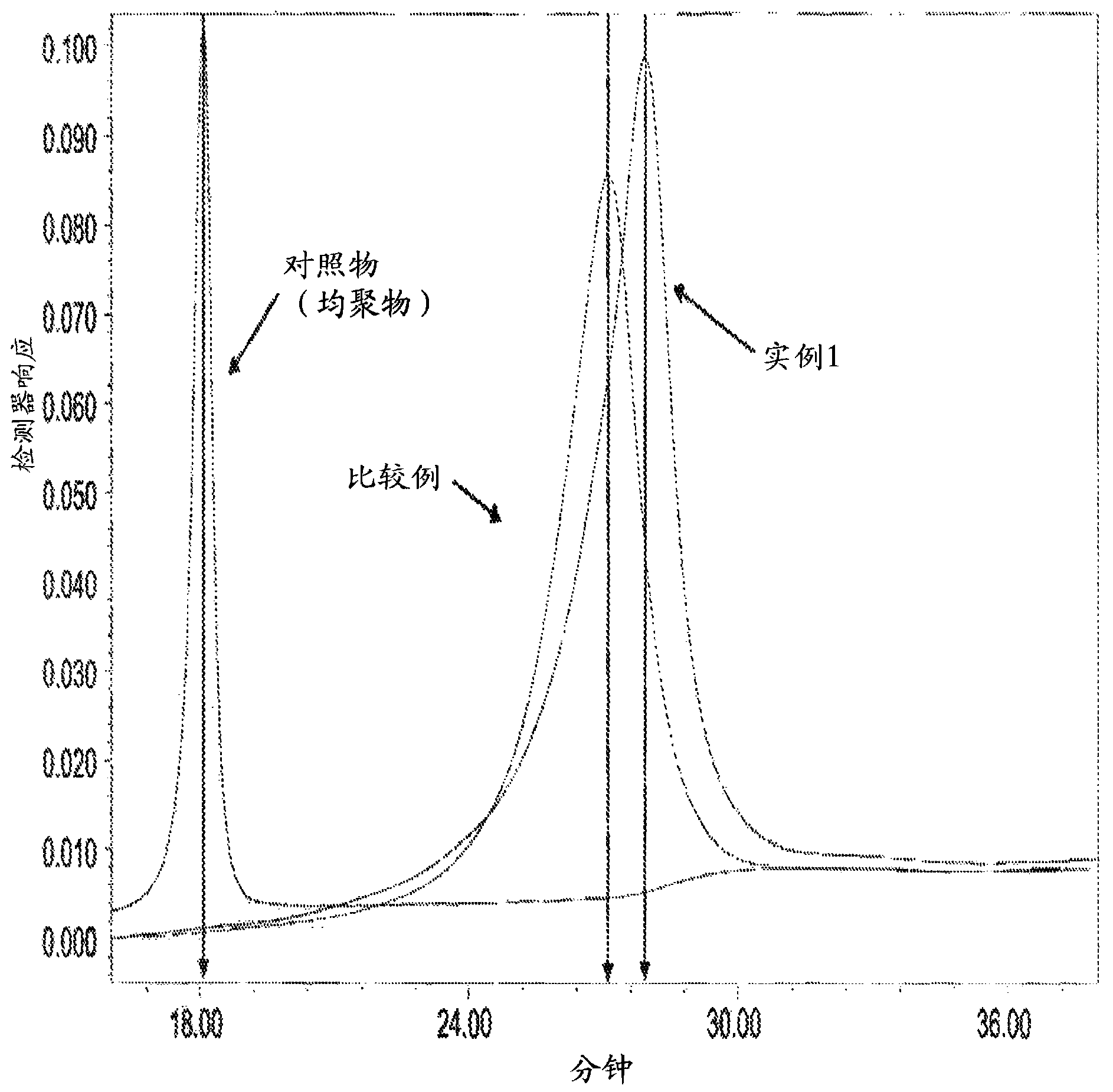

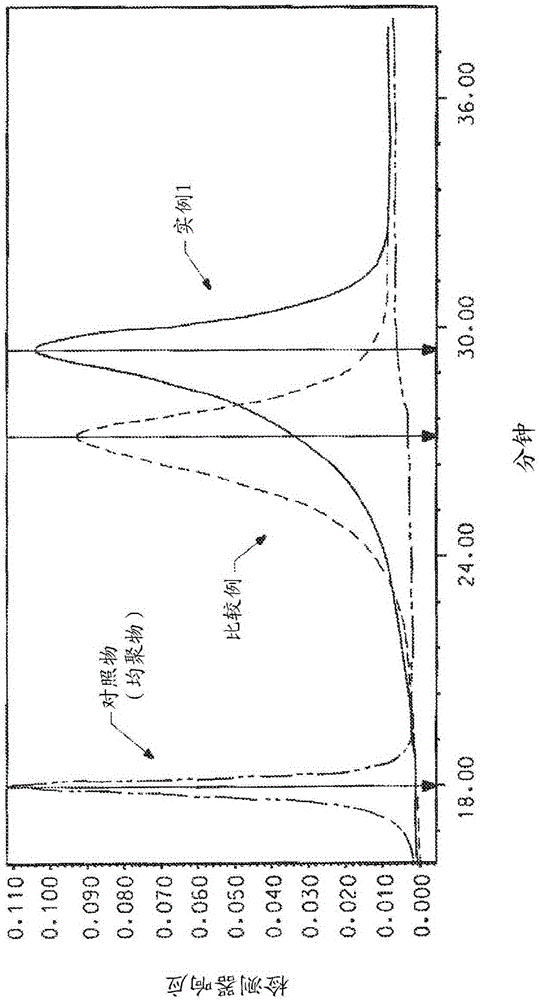

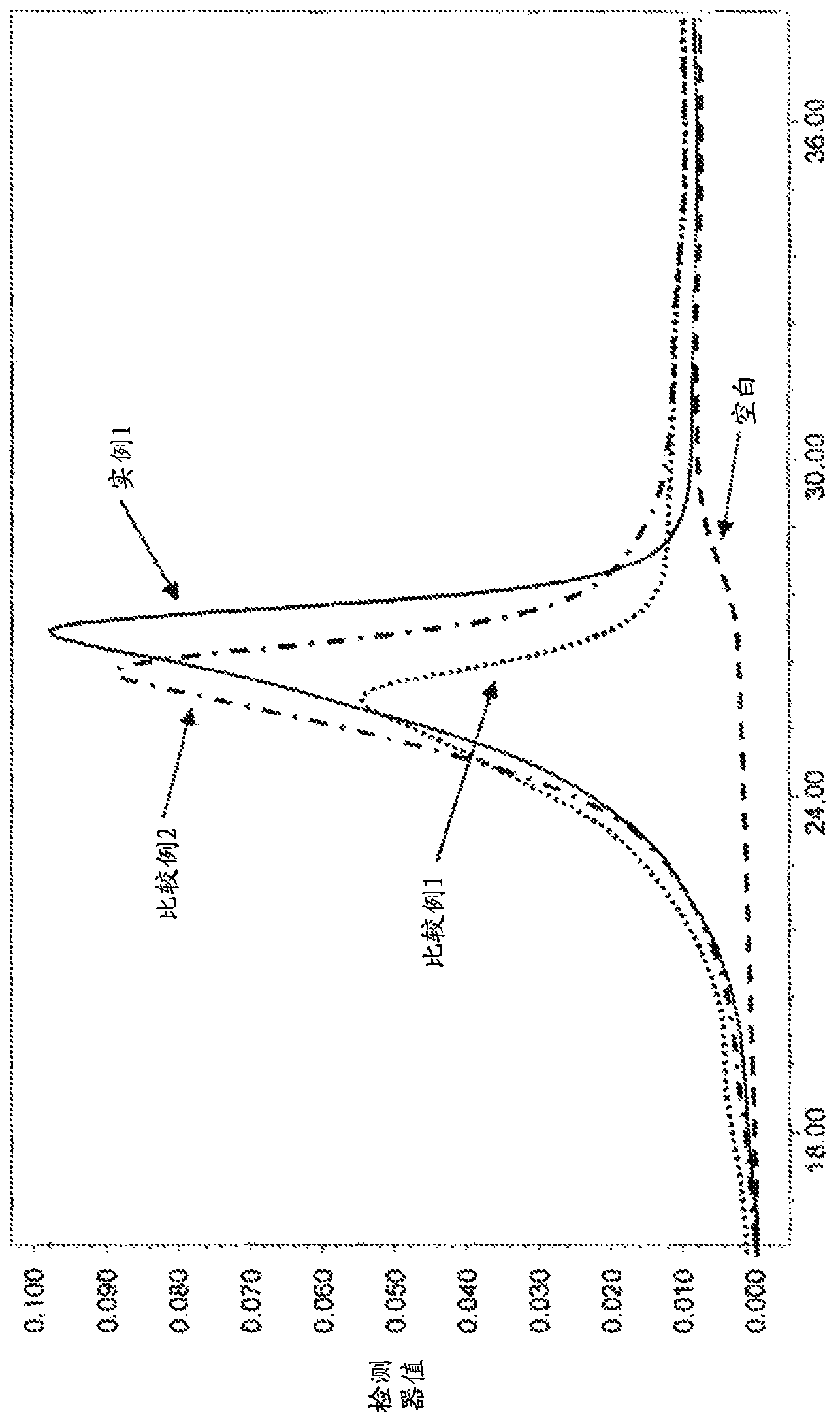

Process for forming aramid copolymers

ActiveCN104684965BIncreased inherent viscosityReduce manufacturing costInorganic saltsPolymer science

The present invention relates to a method of forming polymer crumbs comprising 2-(4-aminophenyl)-5(6)-aminophenylbenzimidazole (DAPBI), p-phenylenediamine (PPD) and the residue of terephthaloyl dichloride (TCl), the method comprising the steps of: i) forming a slurry of b mole % DAPBI in a solvent system comprising an organic solvent and c weight % of an inorganic salt , wherein the inorganic salt is present in an amount of at least 5% by weight of the organic solvent; ii) contacting the slurry with a substoichiometric amount of terephthaloyl chloride to form a prepolymer solution; and iii) making The prepolymer solution is contacted with y mole % of PPD and additional TCL to form a polymer solution; wherein the total amount of TCL added in steps ii) and iii) is equal to the amount of DAPBI added in steps i) and iii) and A stoichiometric amount based on the total amount of PPD; the DAPBI and PPD are added in an amount sufficient to provide a polymer-based polymer solution having a weight percent solids of 12% or greater; and wherein the sum of y+b is 100 , and the product of b×c is 225 or greater.

Owner:DUPONT SAFETY & CONSTR INC

Preparation and drying of copolymer fibers

ActiveCN103328703BArtificial filament washing/dryingMonocomponent copolyamides artificial filamentFiberPolymer science

The present invention concerns processes for reducing water in never-dried fiber comprising copolymer derived from the copolymerization of para-phenylenediamine, 5(6) -amino-2-(p-aminophenyl)benzimidazole; and terephthaloyl dichloride, the process comprising the steps of: (a) heating the never-dried fiber to a temperature of at least 20° C. but less than 100 ° C. until the moisture content of the fiber is 20 weight percent or less of the fiber; and (b) further heating the fiber to a temperature of at least 350° C.

Owner:DUPONT SAFETY & CONSTR INC

Aramid copolymer

The invention concerns polymer comprising 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), PPD, and terephthaloyl dichloride, the polymer having an IPC peak block ratio of 1.52 to 1.56 and an inherent viscosity of greater than 2 dl / g.

Owner:DUPONT SAFETY & CONSTR INC

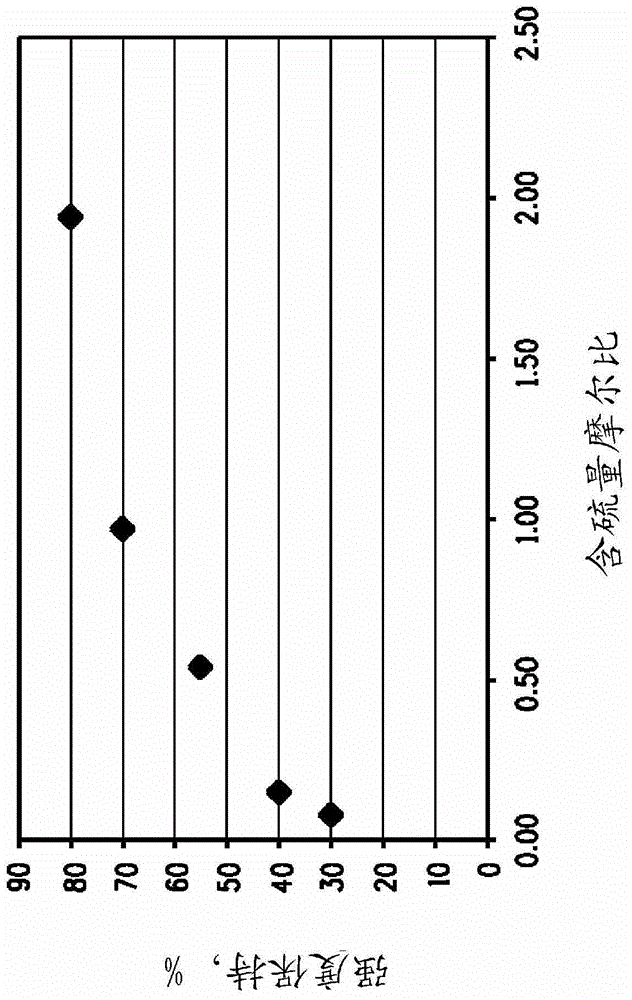

Copolymer fiber and method of making same

ActiveCN103314141BArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentFiberYarn

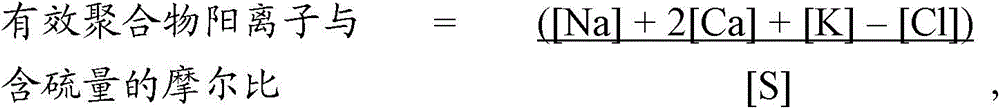

The present invention relates to yarns comprising copolymers derived from the copolymerization of p-phenylenediamine, 5(6)-amino-2-(p-aminophenyl)benzimidazole and terephthaloyl dichloride, wherein The ratio of moles of 5(6)-amino-2-(p-aminophenyl)benzimidazole to moles of p-phenylenediamine is from 30 / 70 to 85 / 15. The yarn has a sulfur content of greater than 0.1%; and has an effective polymer cation to sulfur content molar ratio of at least 0.3. Additional aspects of the invention relate to methods of making such yarns.

Owner:DUPONT SAFETY & CONSTR INC

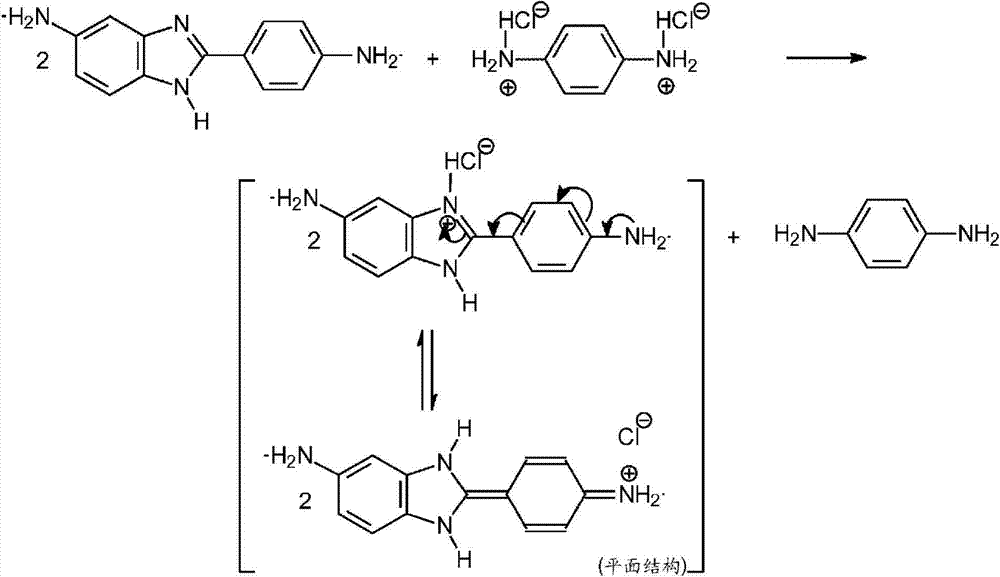

Process for forming an aramid copolymer

The invention concerns processes for forming a polymer comprising residues of 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine, and terephthaloyl dichloride, comprising the steps of: a) forming a solution of DAPBI and paraphenylene diamine dihydrochloride in a solvent system comprising an organic solvent and an inorganic salt; b) cooling the solution to a temperature of 30 DEG C or less; c) adding a stoichiometric amount of terephthaloyl dichloride, relative to the total amount of the DAPBI and the paraphenylene diamine dihydrochloride, to the solution; and d) agitating the solution of step c) to form a polymer.

Owner:DUPONT SAFETY & CONSTR INC

Process for forming an aramid copolymer

The invention concerns polymer comprising residues of 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine (PPD), and terephthaloyl dichloride, made by a process comprising the steps of: (a) forming a slurry of b mole percent DAPBI and y mole percent PPD in a solvent system comprising organic solvent and c weight percent of an inorganic salt, wherein the inorganic salt is present in an amount of at least 5 weight percent of the organic solvent, DAPBI and PPD being present in an amount sufficient for providing a polymer solution having a weight percent solids of 12 percent or greater on a polymer basis; and (b) contacting the slurry of step a) with a stoichiometric amount of terephthaloyl dichloride to form a product comprising the polymer; wherein the sum of y + b is 100 and the product of b x c is 225 or greater.

Owner:DUPONT SAFETY & CONSTR INC

Process for forming an aramid copolymer

The invention concerns processes for forming polymer crumb comprising residues of 2-(4-amino phenyl)-5(6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine (PPD), and terephthaloyl dichloride, comprising the steps of: (a) forming a slurry of b mole percent DAPBI and y mole percent PPD in a solvent system comprising organic solvent and c weight percent of an inorganic salt, wherein the inorganic salt is present in an amount of at least 5 weight percent of the organic solvent, DAPBI and PPD being present in an amount sufficient for providing a polymer solution having a weight percent solids of 12 percent or greater on a polymer basis; and (b) contacting the slurry of step a) with a stoichiometric amount of terephthaloyl dichloride to form a product comprising the polymer; wherein the sum of y+b is 100, and the product of b*c is 225 or greater.

Owner:DUPONT SAFETY & CONSTR INC

Process of forming aramid copolymer

The invention concerns processes for forming a polymer comprising residues of 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine (PPD), and terephthaloyl dichloride, comprising the steps of: (a) forming a slurry of DAPBI in a solvent system comprising an organic solvent and an inorganic salt; (b) adding less than a stoichiometric amount, relative to the amount of DAPBI, of terephthaloyl dichloride to the slurry; (c) agitating the slurry to react the DAPBI and terephthaloyl dichloride to form an oligomeric solution; (d) adding PPD to the oligomeric solution and agitating until essentially all of the PPD is dissolved, followed by the addition of terephthaloyl dichloride to form a prepolymer solution; and (e) allowing the prepolymer solution to form a polymer.

Owner:DUPONT SAFETY & CONSTR INC

Weatherable block copolyestercarbonates and blends containing them

Owner:SABIC GLOBAL TECH BV

Method of forming an aromatic polyamide copolymer

Owner:DUPONT SAFETY & CONSTR INC

Method of forming an aromatic polyamide copolymer

Owner:DUPONT SAFETY & CONSTR INC

Aramid copolymer

The invention concerns polymer powder comprising 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine, and terephthaloyl dichloride, capable of being dissolved in a solvent system comprising (i) N-methyl-2-pyrrolidone (NMP) or dimethylacetamide (DMAC) and (ii) an inorganic salt; wherein said polymer is capable of being redissolved in said solvent system after said polymer has been removed from said solvent system.

Owner:DUPONT SAFETY & CONSTR INC

Process for preparing aramid copolymer

The invention concerns processes for forming a polymer comprising residues of 2-(4-amino phenyl)-5 (6) amino phenyl benzimidazole (DAPBI), paraphenylene diamine, and terephthaloyl dichloride, comprising the steps of: (a) forming a slurry of DAPBI and paraphenylene diamine in a solvent system comprising an organic solvent and an inorganic salt; and (b) adding a stoichiometric amount of terephthaloyl dichloride to the slurry in a single addition and allowing the formation of the polymer.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com