Patents

Literature

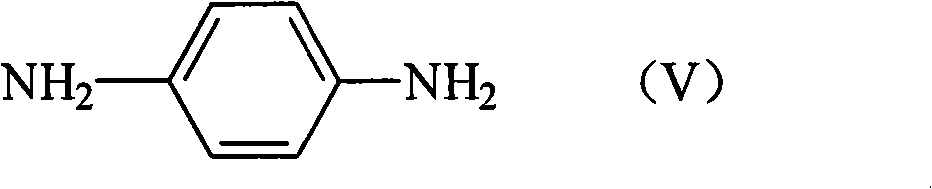

38 results about "Para phenylenediamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Large scale process for polymerization of dapbi-containing polyaramid

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

Lubricant compositions stabilized with multiple antioxidants

InactiveUS20060128574A1Prevent oxidationPromote oxidationLiquid carbonaceous fuelsAdditivesAntioxidantOxidation stability

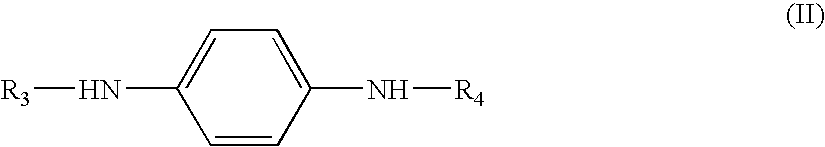

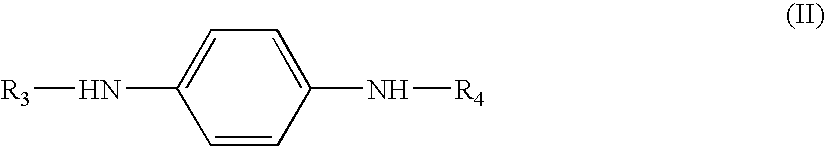

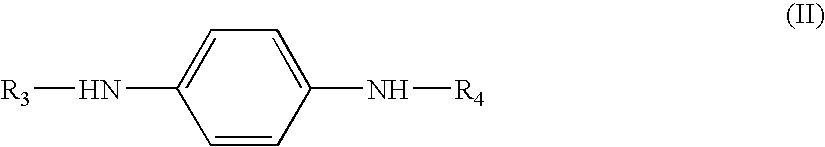

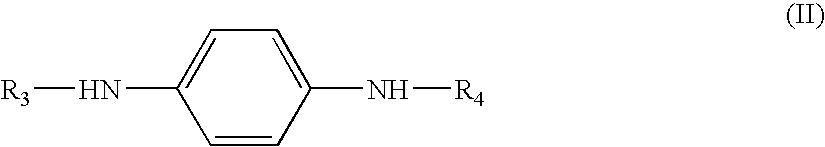

A lubricant composition is disclosed that comprises lubricating oil and a mixture of at least two antioxidants, the first antioxidant being a secondary diarylamine and the second antioxidant being a substituted para-phenylenediamine. Also disclosed is a method of increasing the oxidation stability of a lubricating oil comprising adding thereto at least two antioxidants, the first antioxidant being a secondary diarylamine and the second antioxidant being a substituted para-phenylenediamine.

Owner:LANXESS SOLUTIONS US INC

Lubricant compositions stabilized with multiple antioxidants

InactiveUS7704931B2Prevent oxidationPromote oxidationLiquid carbonaceous fuelsAdditivesAntioxidantOxidation stability

A lubricant composition is disclosed that comprises lubricating oil and a mixture of at least two antioxidants, the first antioxidant being a secondary diarylamine and the second antioxidant being a substituted para-phenylenediamine. Also disclosed is a method of increasing the oxidation stability of a lubricating oil comprising adding thereto at least two antioxidants, the first antioxidant being a secondary diarylamine and the second antioxidant being a substituted para-phenylenediamine.

Owner:LANXESS SOLUTIONS US INC

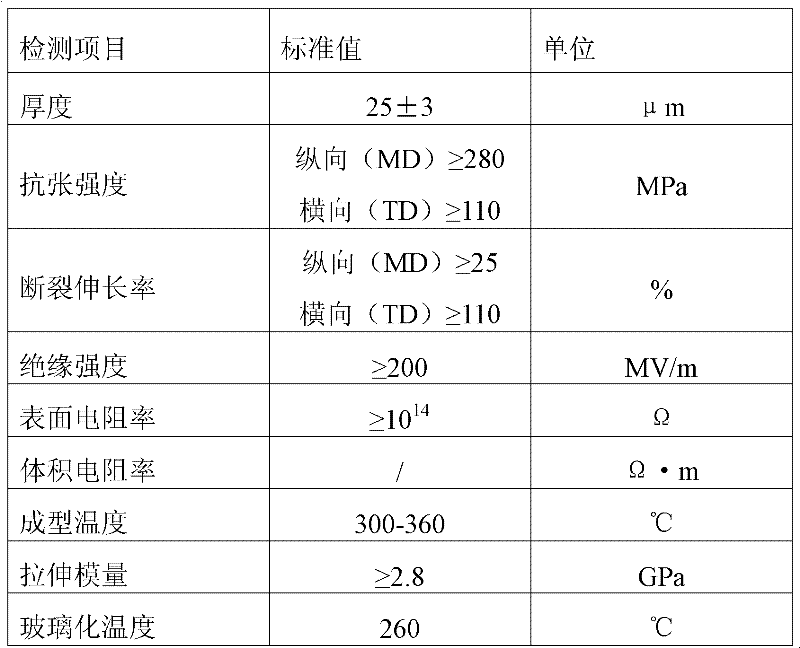

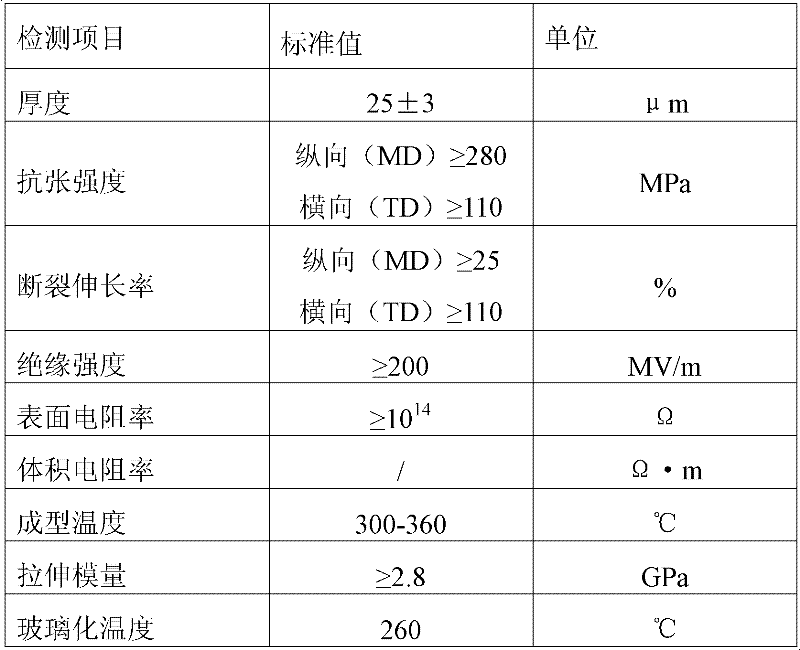

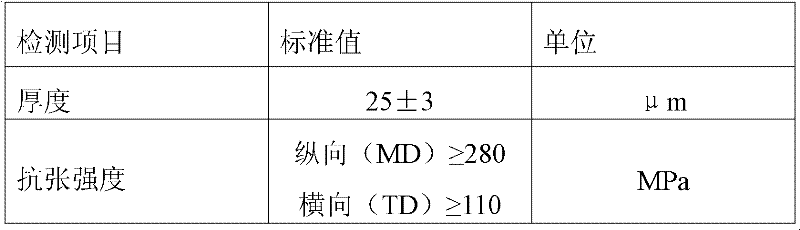

Production method for formable polyimide film

The present invention discloses a production method for a formable polyimide film. The method comprises resin synthesizing, defoaming, slobbering and film forming, and winding and splitting. The resin synthesizing treatment comprises: pressing 4,4'-dimethyl acetamide into an amine dissolving kettle; adding a calculated mixture comprising 4,4'-diaminodiphenyl ether, para-phenylenediamine and 4,4'-diamino-diphenyl-methane to the amine dissolving kettle, stirring for 1 hour until the mixture is completely dissolved in the 4,4'-dimethyl acetamide; pressing the resulting mixing solution into a reaction kettle; adding a calculated mixture comprising 4,4'-oxydiphthalic anhydride, 3,3',4,4'-biphenyl tetracarboxylic diandhydride and pyromellitic dianhydride to the reaction kettle, carrying out a reaction for 4 hours to form a sol type polyamide acid resin, wherein the viscosity of the resin is adjusted by adjusting the amount of the residual anhydride. The prepared formable polyimide film by the method of the present invention can not be deformed after forming, and good physical properties, good electrical properties and good mechanical properties of the film can be maintained.

Owner:宁波今山电子材料有限公司

Method for producing polyimide laminate, and polyimide laminate

ActiveCN103732404AImprove heat resistanceGood chemical resistanceLayered product treatmentSynthetic resin layered productsCarboxylic acidPolyamic acid

The present invention relates to a polyimide laminate obtained by: casting, onto a substrate, a polyamic acid solution composition including a phosphorus compound, and a polyamic acid that is obtained from a tetracarboxylic acid component including 3,3',4,4'-biphenyltetracarboxylic acid dianhydride as a principal component, and a diamine component including para-phenylenediamine as a principal component; and heating the above to form a polyimide layer having a thickness of less than 50 [mu]m on the substrate.

Owner:UBE IND LTD

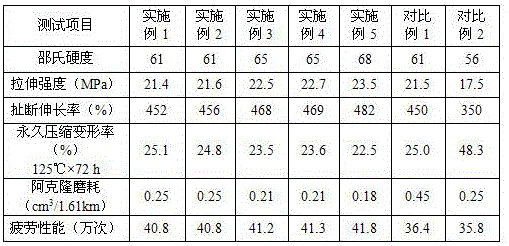

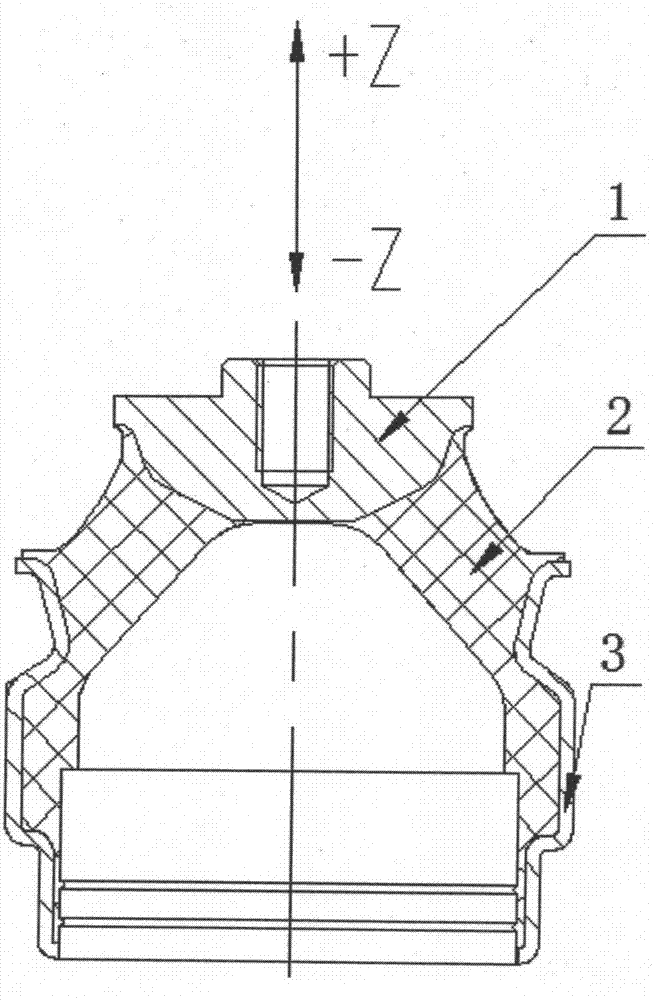

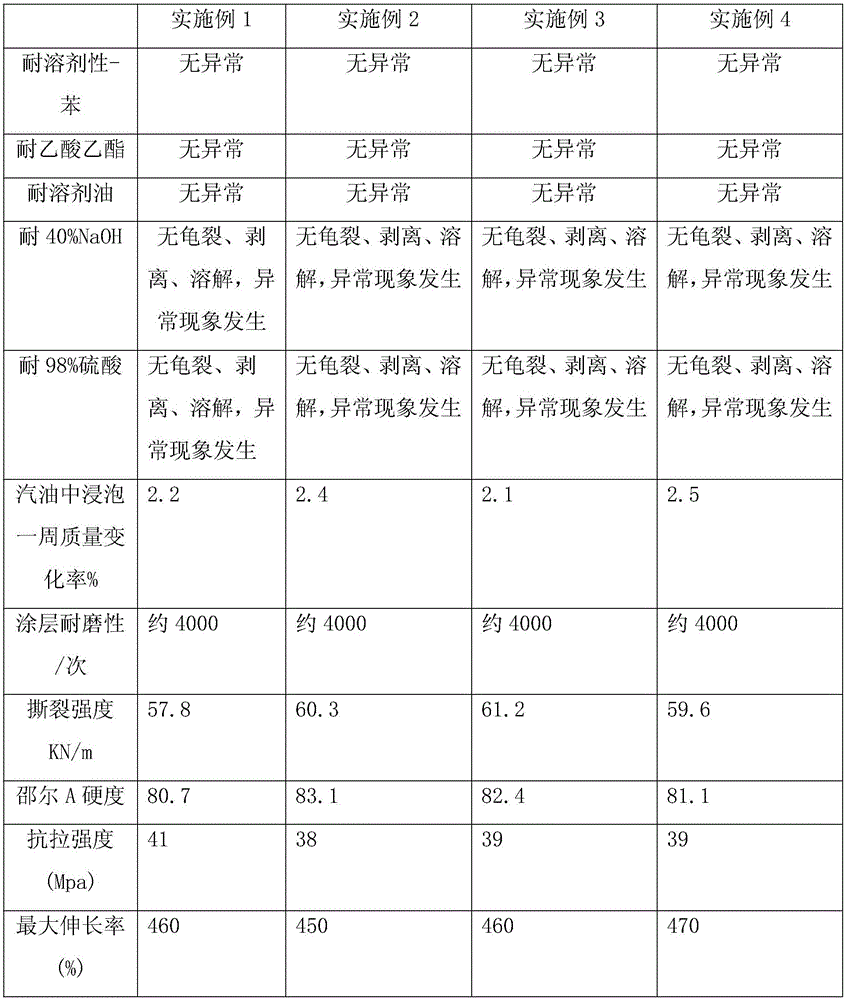

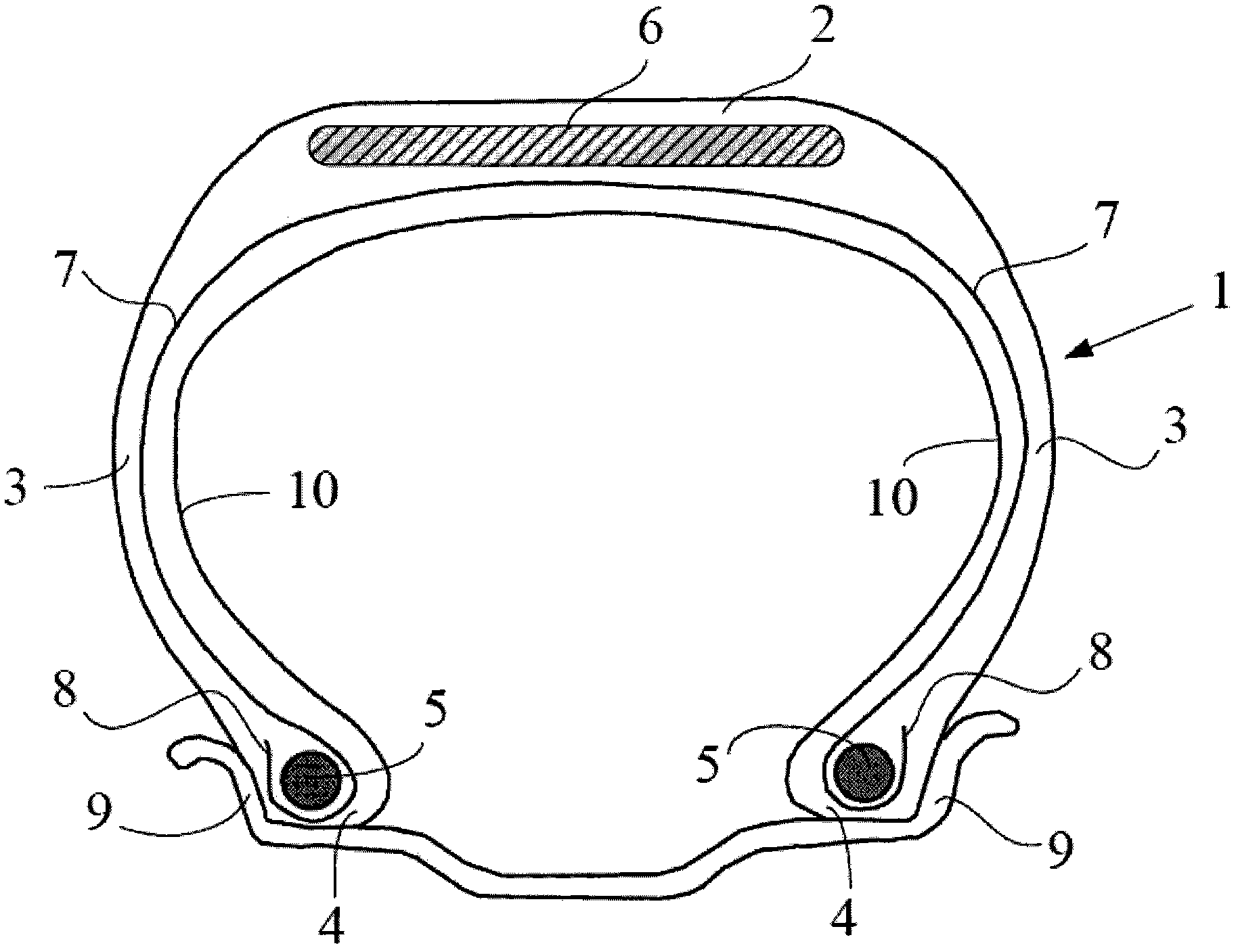

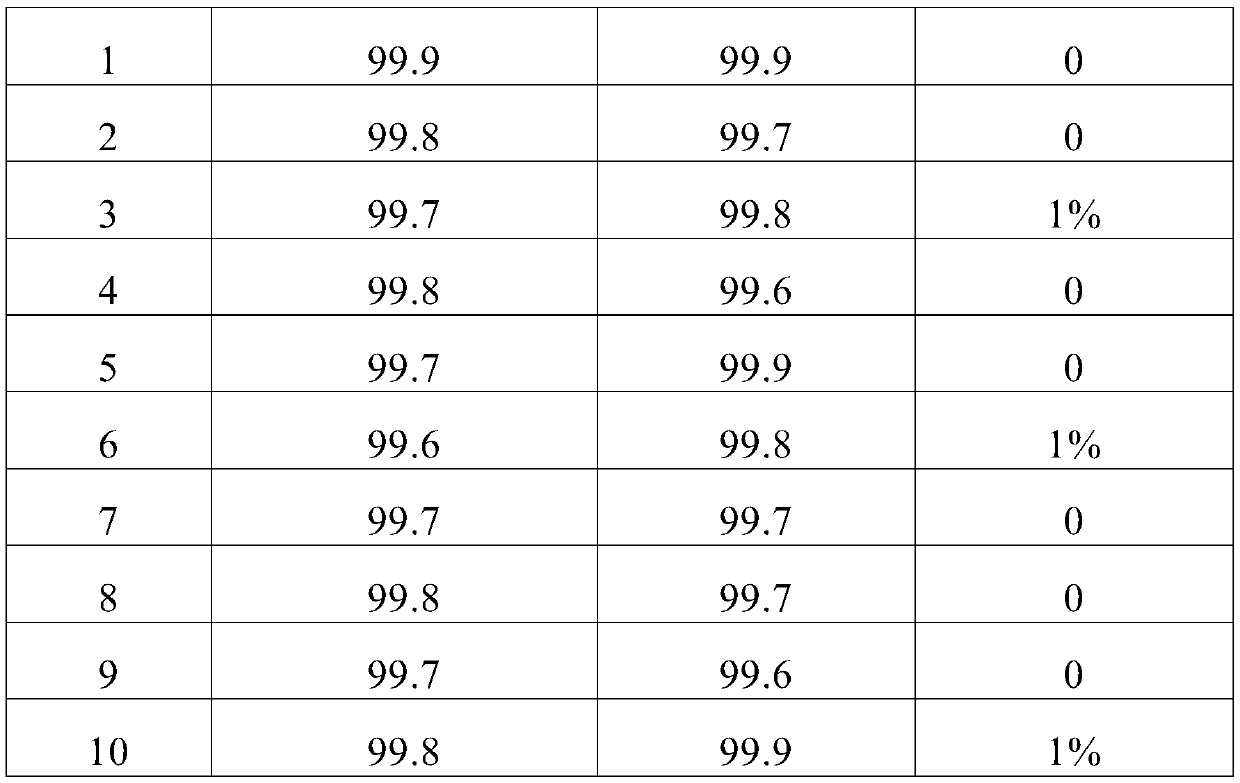

Automotive abrasion-resistant damping rubber and preparation method thereof

The invention provides automotive abrasion-resistant damping rubber and preparation method thereof. The preparation method comprises the following steps that 1, natural rubber and polybutadience rubber are added to a mixer for mixing; 2, the rubber material obtained in the step 1, high-abrasion-resistance carbon black N330, zinc oxide, stearic acid, N-isopropyl-N'-phenyl para-phenylenediamine, styrenated phenol, dibenzothiazyl disulfide, tetramethyl thiuram disulfide, polyether urethane modified epoxy resin, polyacrylate toughened and modified epoxy resin, nano silicon carbide, calcium sulfate whiskers and magnesium borate whiskers are added to the mixer for mixing; (3) sulfur is added to the rubber material in the step 2 for mixing again; 4, the rubber material obtained in the step 3 is vulcanized in a vacuumizing and vulcanizing machine. The automotive abrasion-resistant damping rubber has good elasticity, mechanical properties and abrasion-resistant properties.

Owner:ZHEJIANG BAILANGSHI RUBBER & PLASTIC TECH CO LTD

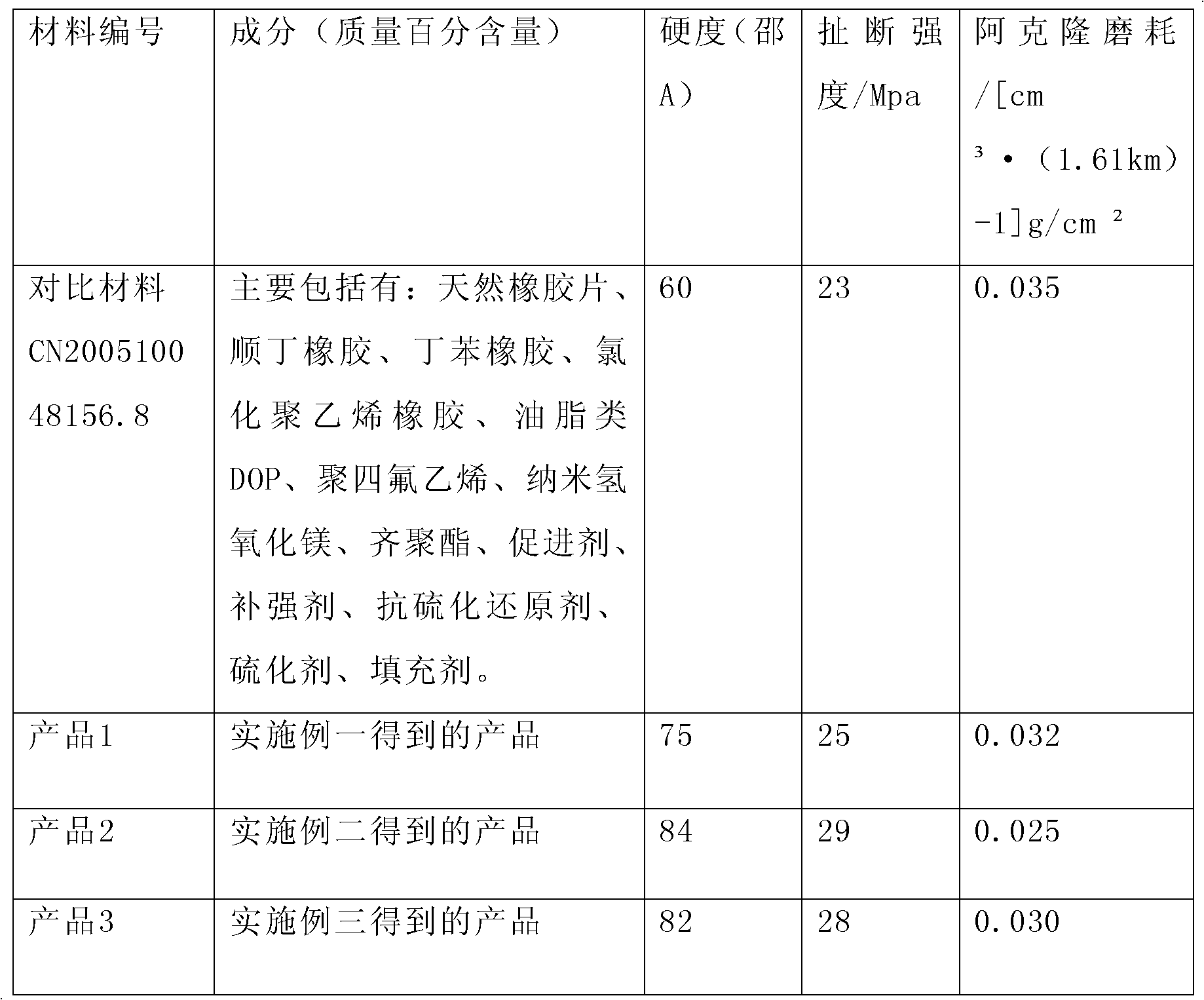

Fluorine-containing rubber valve composite material and preparation method thereof

InactiveCN102321321AGood high and low temperature resistanceImprove wear resistanceWear resistantTemperature resistance

The present invention provides a low-cost and good-performance rubber composite material and a preparation method thereof. The method provided by the present invention has characteristics of simple process and low cost, and is applicable for the industrial production. The composite material is prepared from the following raw materials, wherein the raw materials comprise, by weight, 60-70 parts of fluororubber, 10-15 parts of nitrile butadiene rubber, 1-2 parts of calcium hydroxide, 3-5 parts of magnesium hydroxide, 1-2 parts of micro crystalline wax, 1-2 parts of sulfur, 2-3 parts of dihydroxyhenzene, 1-2 parts of an accelerating agent N-cyclohexyl-2-benzothiazole sulfenamide C13H16N2S2 and 1-2 parts of an anti-aging agent N-phenyl-N'-yl-para-phenylenediamine. According to the present invention, the wear resistant rubber composite material has excellent wear resistance, the weight of the rubber composite material is lighter than the weight of the metal, such that the high-performance and wear-resistant rubber provided by the present invention can be widely applicable for the workplaces with requirements of wear resistance, high temperature resistance and low temperature resistance so as to substantially improve the service lives of the work-piece, the device and the like.

Owner:TONGLING WANTONG VALVE

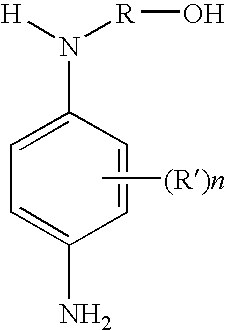

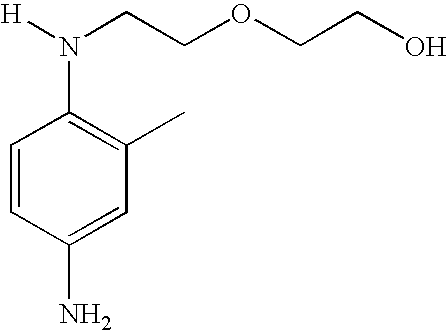

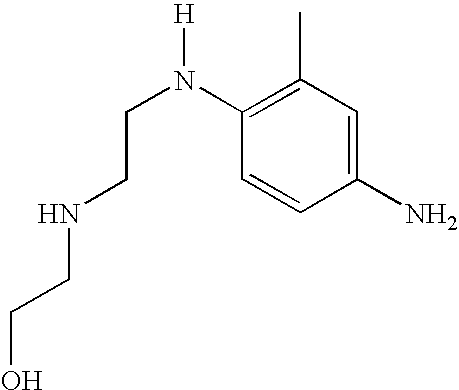

Ortho-and/or meta-substituted N-alkylhydroxylated secondary para-phenylenediamine compounds, compositions for dyeing keratin fibers comprising such compounds, and processes of dyeing therewith

InactiveUS7445645B2Improve the immunityImproved profileCosmetic preparationsHair cosmeticsFiberKeratin

The present disclosure relates to novel N-alkylhydroxylated secondary para-phenylenediamine compounds, to a composition for dyeing keratin fibers, for instance human keratin fibers such as the hair, comprising, in a medium that is suitable for dyeing, at least one ortho- and / or meta-substituted N-alkylhydroxylated secondary para-phenylenediamine, to a process for dyeing keratin fibers comprising applying this composition, and also a dyeing “kit.”

Owner:LOREAL SA

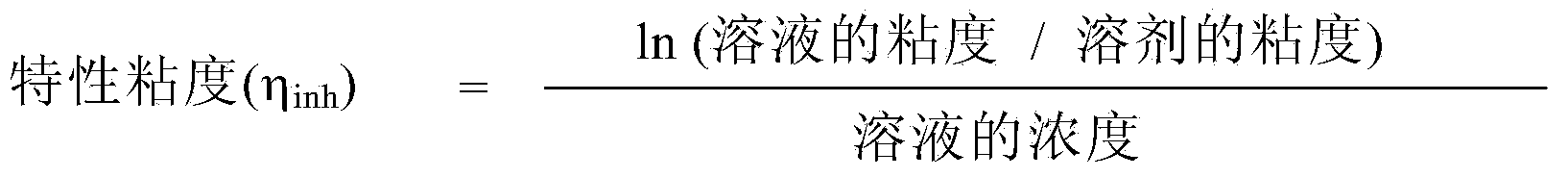

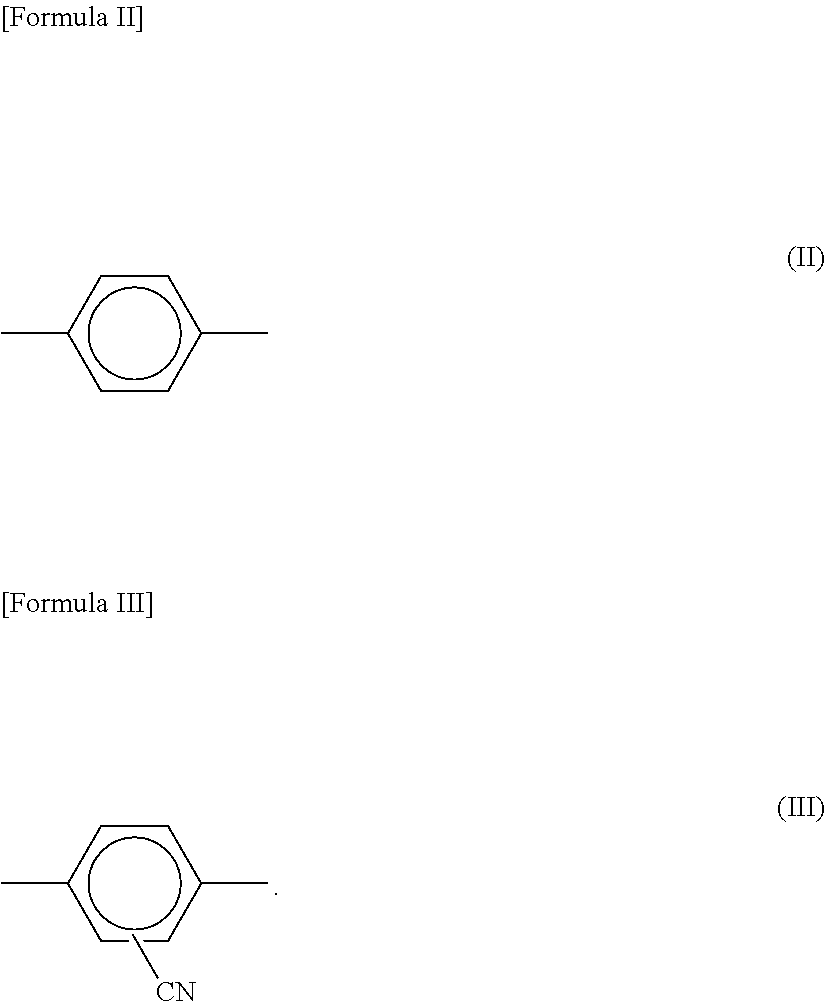

High-strength copolymerized aramid fiber and preparing method therefor

InactiveUS20170241048A1Improve solubilityHigh intrinsic viscosityFilament/thread formingMonocomponent copolyamides artificial filamentOrganic solventAramides

Disclosed is a high-strength copolymerized aramid fiber which includes aramid copolymers containing an aromatic group substituted with a cyano group (—CN), so as to have an intrinsic viscosity (IV) of 6.0 to 8.5, a polydispersity index (PDI) of 1.5 to 2.0, a strength of 23 to 32 g / d, and an elastic modulus of 1,100 to 1,300 g / d. The high-strength copolymerized aramid fiber may be prepared by a method which includes, when para-phenylenediamine, cyano-para-phenylenediamine, and terephthaloyl dichloride are sequentially added to an organic solvent and reacted together to prepare a copolymerized aramid fiber, adding and dispersing a neutralizing agent in the organic solvent before the reaction of the para-phenylenediamine, cyano-para-phenylenediamine and terephthaloyl dichloride, which were dissolved in the organic solvent.

Owner:KOLON IND INC

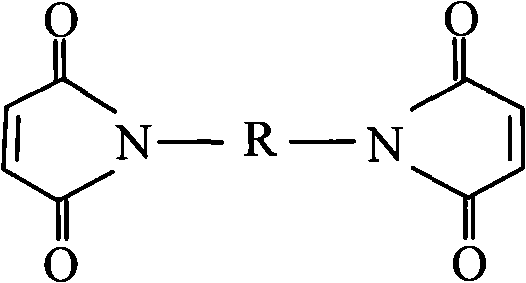

Rubber Composition for Tires Comprising an Acetylacetonate Compound

Rubber composition which can be used in particular for the manufacture of tires, comprising at least a diene elastomer, a reinforcing filler, a crosslinking system, between 0.2 and 10 phr of an antioxidant, such as a substituted para-phenylenediamine, and between 0.2 and 10 phr of an acetylacetonate of an alkali metal or alkaline earth metal, chosen in particular from the group consisting of Li, Na, K, Mg, Ca and the mixtures of such metals. This acetylacetonate compound makes it possible to advantageously reduce the consumption of antioxidant during the thermo-oxidizing ageing of the composition. Metal / rubber composite comprising such a composition and at least a metal reinforcement. Tire comprising a such composition or such a composite.

Owner:MICHELIN RECH & TECH SA +1

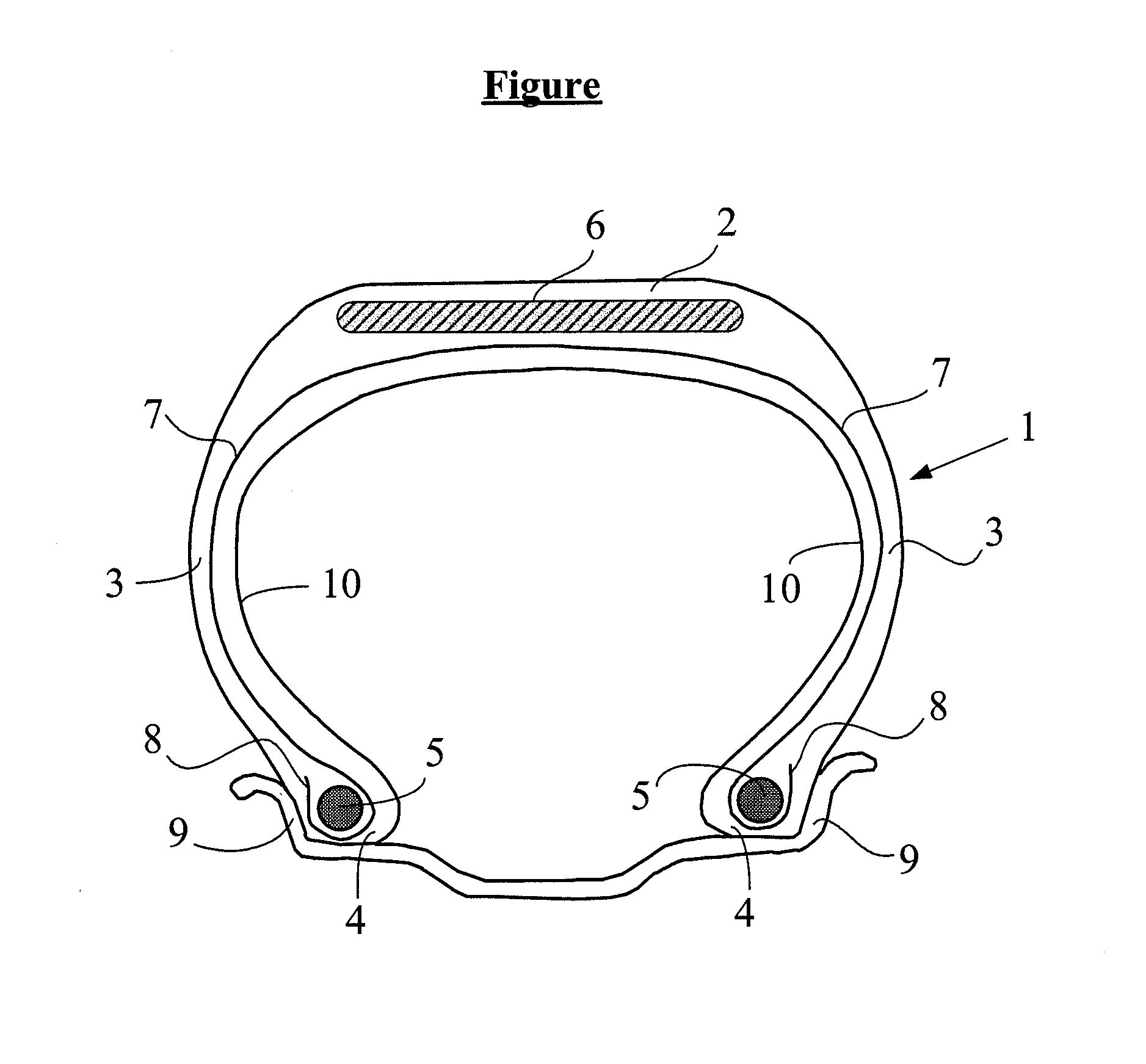

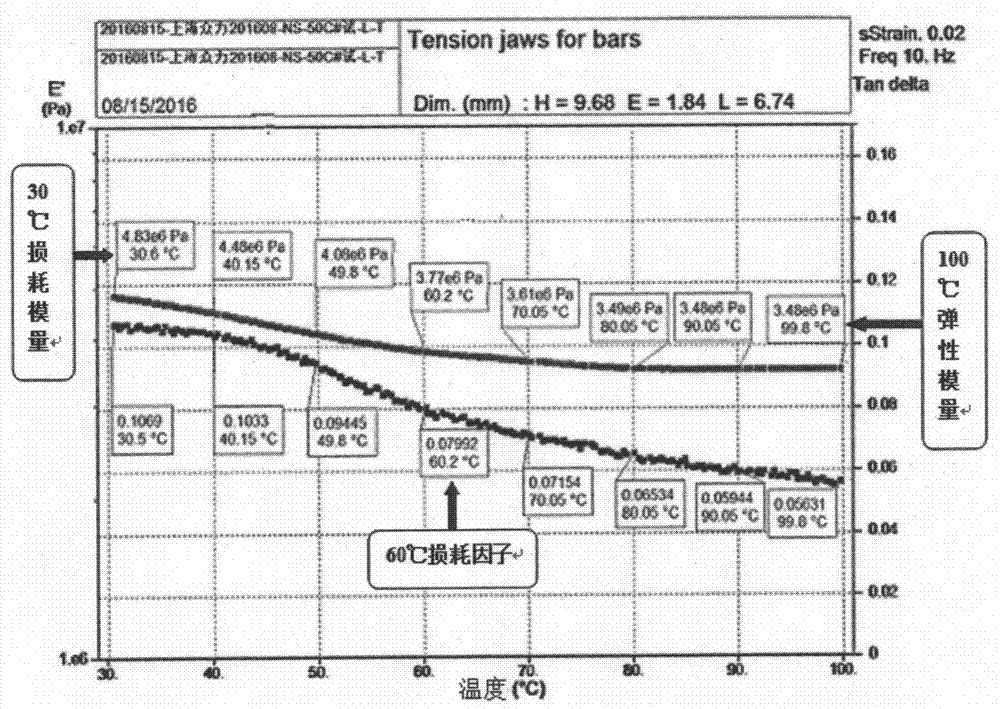

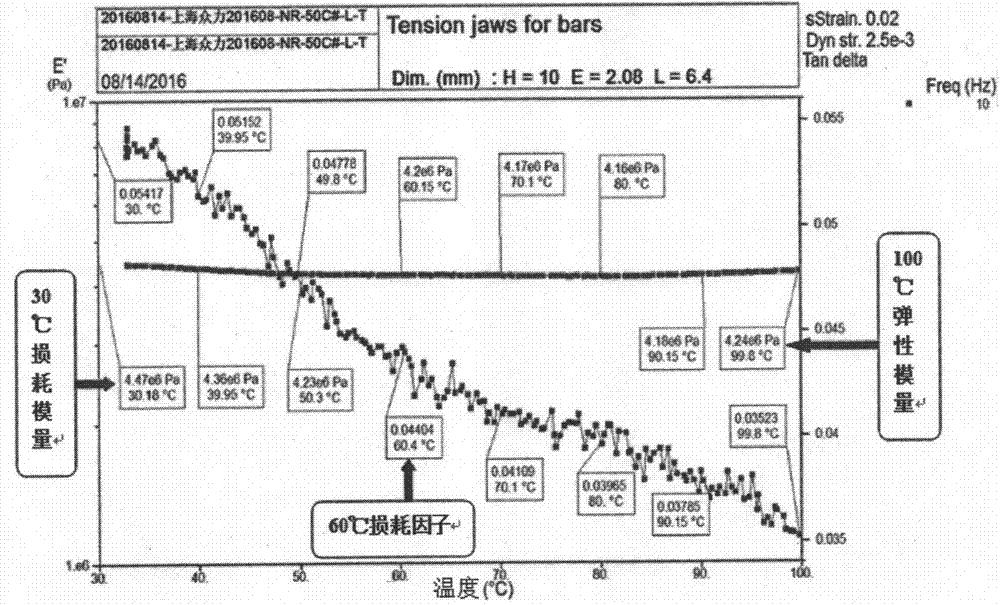

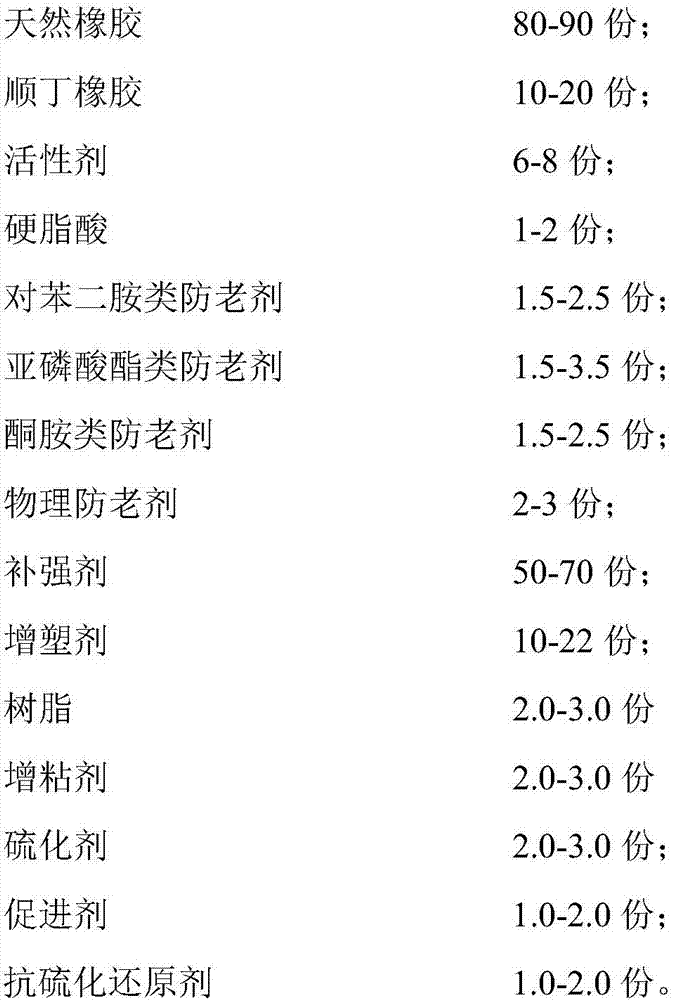

Rubber composition of automobile motor suspension

The invention discloses a rubber composition of automobile motor suspension. The composition is prepared from, by weight, 2.5-3.5 parts of physical antiager, 7-10 parts of activating agent, 5-8 partsof plasticizer, 0.6-1 part of vulcanizing agent, 100 parts of white carbon black wet natural rubber, 1.5-2.5 parts of diaryl secondary amine antiager, 2-3 parts of para-phenylenediamine derivative antiager, 18-25 parts of reinforcing agent, 1.5-2 parts of assistant crosslinker and 1.5-1.8 parts of accelerator. The rubber composition of the automobile motor suspension has the advantages that the high temperature resistance and heat resistance performance is good, and dynamic modulus loss is low; physical property change of a rubber material is little after aging, the strength retaining rate ishigh, and permanent deformation through high-temperature compression is good; the produced motor suspension has low stiffness and good NVH effect, high-temperature creep and high-temperature fatigue performance, and the motor suspension is at the top of the industry and recognized by clients at home and abroad.

Owner:SHANGHAI ZHONGLI INVESTMENT

Tire Rubber Composition Comprising an Acetylacetonate Compound

Rubber composition which can be used in particular for the manufacture of s, comprising at least a diene elastomer, a reinforcing filler, a crosslinking system, between 0.2 and 10 phr of an antioxidant, such as a substituted para-phenylenediamine, and between 0.2 and 10 phr of chromium (III) acetylacetonate. This acetylacetonate compound makes it possible to advantageously reduce the consumption of antioxidant during the thermo-oxidizing ageing of the composition. Metal / rubber composite comprising such a composition and at least a metal reinforcing member. comprising such a composition or such a composite.

Owner:MICHELIN RECH & TECH SA +1

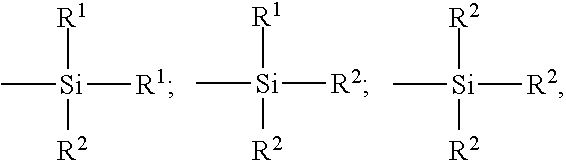

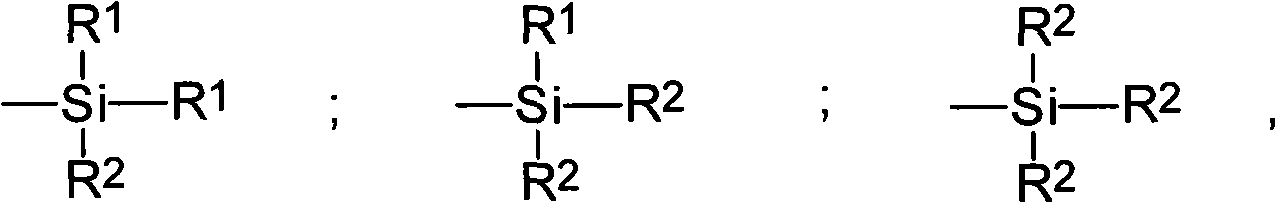

High-performance silicone/fluoroether composite rubber glove and preparation method thereof

InactiveCN106702755AImprove high temperature resistanceImprove corrosion resistanceFireproof paintsGlovesPolymer science(Hydroxyethyl)methacrylate

The invention provides a high-performance silicone / fluoroether composite rubber glove. The silicone / fluoroether composite rubber is prepared from the following components in parts by weight: 80 to 120 parts of fluoroether rubber, 40 to 60 parts of methyl vinyl silicone rubber, 1 to 3 parts of a peroxidation vulcanizing agent, 5 to 8 parts of zinc oxide, 15 to 30 parts of phenolic resin, 0.5 to 1.5 parts of an accelerant, 0.1 to 0.5 part of an antioxidant, 15 to 30 parts of hydroxyethyl methylacrylate modified graphene, 3 to 6 parts of dioctyl phthalate, 0.8 to 1.6 parts of B-naphthyl para-phenylenediamine and 50 to 100 parts of tetrahydrofuran. The fluoroether rubber and the silicone rubber are blended and the advantages of the fluoroether rubber and the silicone rubber are completely combined, so the prepared material has excellent high-temperature resistance, corrosion resistance, oil resistance and extremely excellent mechanical property, can be applied to the industrial extreme environment, and creates conditions for application of the future industry.

Owner:顺泰精密橡胶(深圳)有限公司

Rubber composition for tires comprising an acetylacetonate compound

Rubber composition which can be used in particular for the manufacture of tires, comprising at least a diene elastomer, a reinforcing filler, a crosslinking system, between 0.2 and 10 phr of an antioxidant, such as a substituted para-phenylenediamine, and between 0.2 and 10 phr of an acetylacetonate of an alkali metal or alkaline earth metal, chosen in particular from the group consisting of Li, Na, K, Mg, Ca and the mixtures of such metals. This acetylacetonate compound makes it possible to advantageously reduce the consumption of antioxidant during the thermo-oxidizing ageing of the composition. Metal / rubber composite comprising such a composition and at least a metal reinforcement. Tire comprising a such composition or such a composite.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

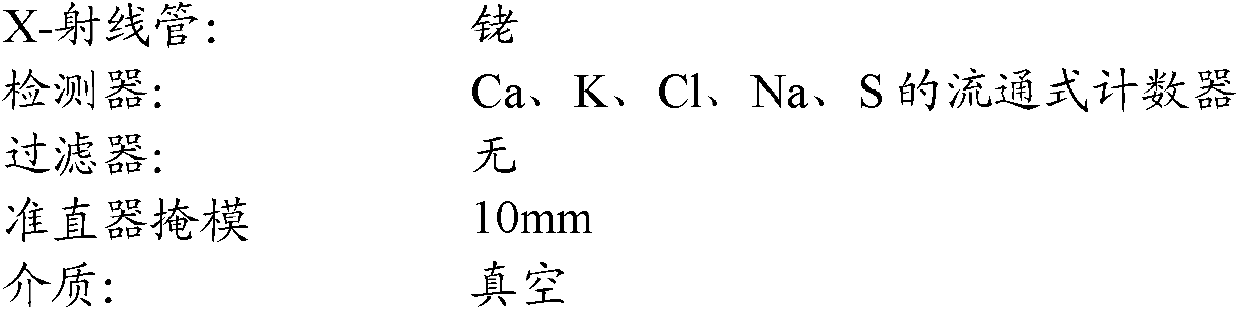

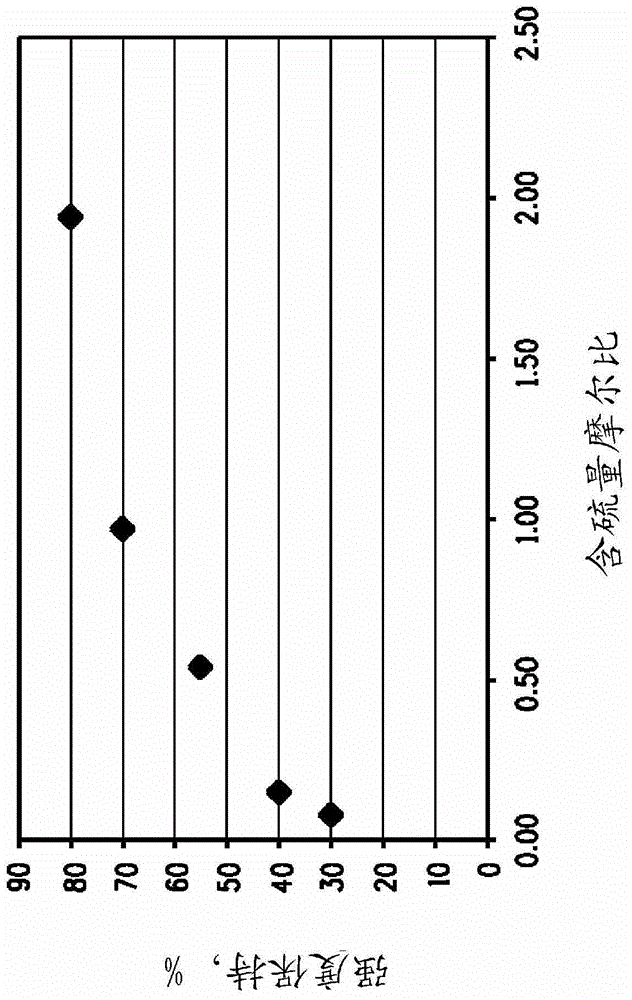

Copolymer fibers and processes for making same

ActiveCN103328699AArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentYarnFiber

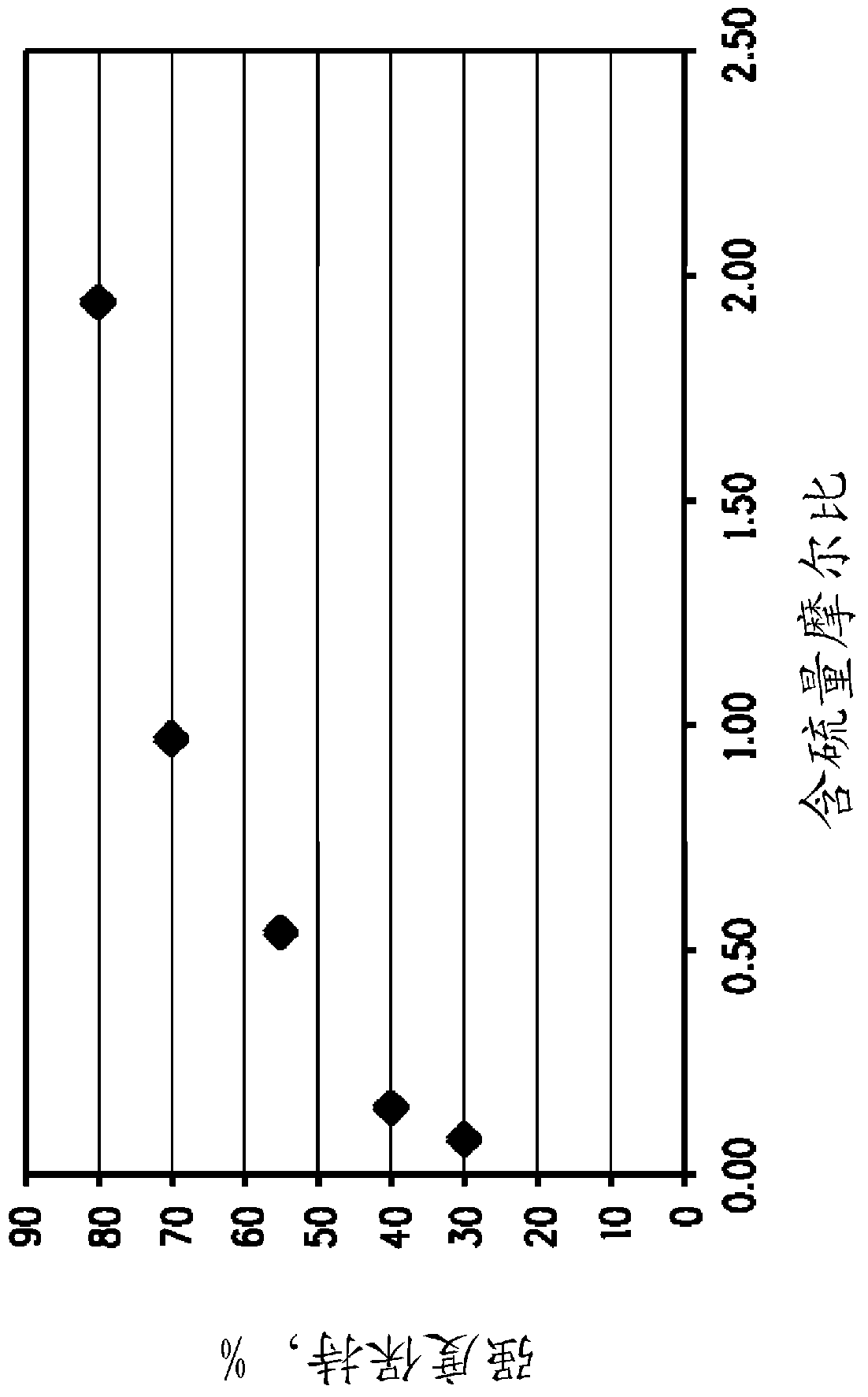

The present invention concerns yarns comprising copolymer derived from the copolymerization of para-phenylenediamine, 5(6)-amino-2-(p-aminophenyl) benzimidazole; and terephthaloyl dichloride wherein the ratio of moles of 5(6)-amino-2-(p-aminophenyl) benzimidazole to the moles of para-phenylenediamine is 30 / 70 to 85 / 15; the yarn having a sulfur content greater than 0.1%; and the hydrolytic strength retention of the yarn is greater than 60%. The invention also concerns processes for making such yarns.

Owner:DUPONT SAFETY & CONSTR INC

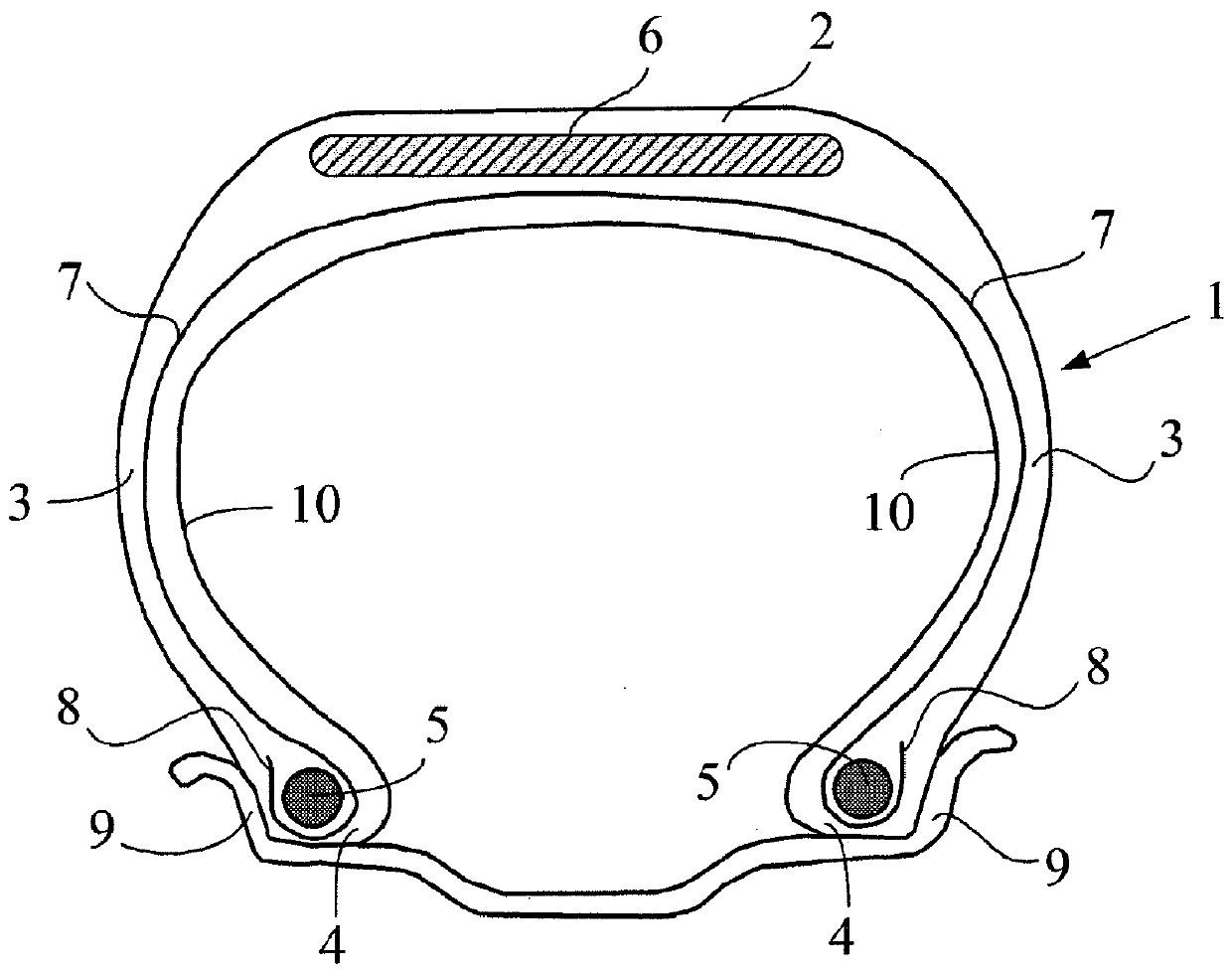

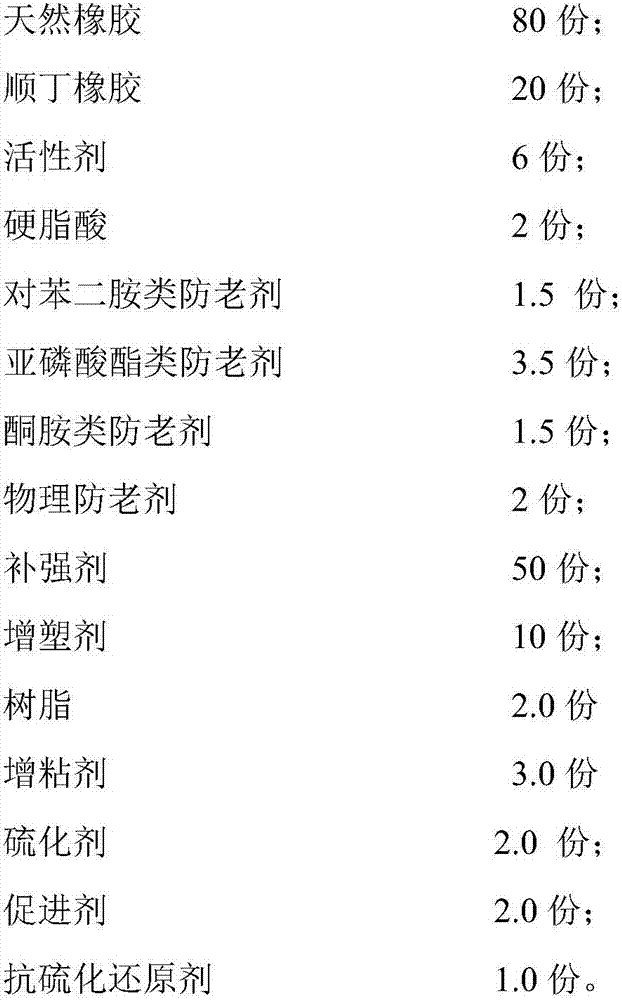

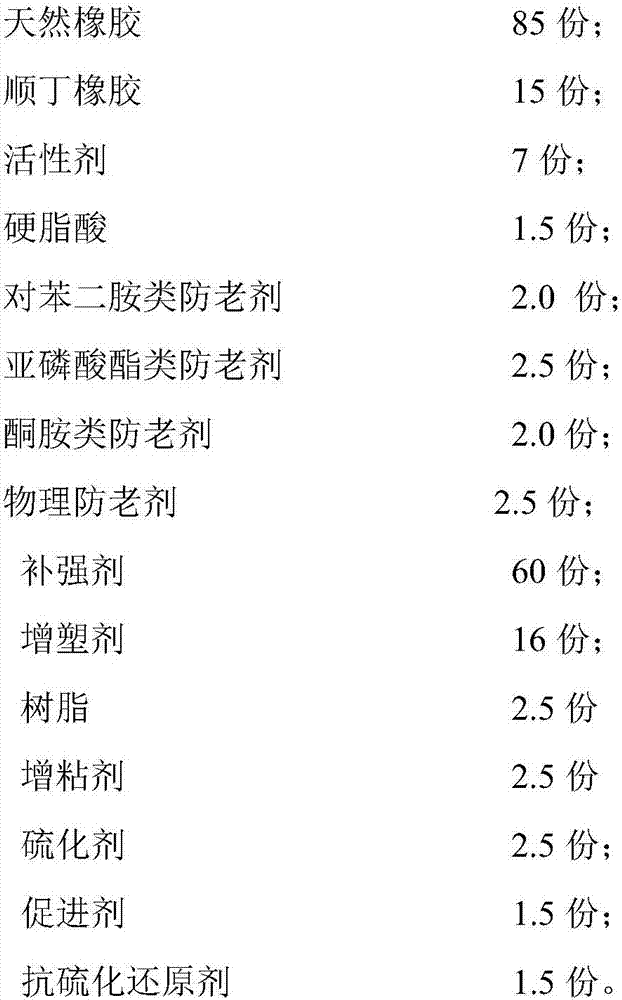

Rubber composition used for automobile suspension bushing

The invention provides a rubber composition used for an automobile suspension bushing. The composition comprises 80-90 parts of natural rubber, 10-20 parts of butadiene rubber, 6-8 parts of activatingagent, 1-2 parts of stearic acid, 1.5-2.5 parts of para-phenylenediamine antiager, 1.5-3.5 parts of phosphite ester antiager, 1.5-2.5 parts of keto-amine antiager, 2-3 parts of physical antiager, 50-70 parts of reinforcing agent, 10-22 parts of plasticizer, 2.0-3.0 parts of resin, 2.0-3.0 parts of tackifier, 2.0-3.0 parts of vulcanizing agent, 1.0-2.0 parts of accelerator and 1.0-2.0 parts of anti-sulphuration reducing agent. The invention further provides the preparation method of the rubber composition. The rubber composition has good mechanical performance and fatigue resistance performance, and not only is the adhesive performance effectively improved, but good heat resistance performance is provided; the rubber composition is used for the automobile suspension bushing and maintains good adhesive performance and low stiffness loss after being used for a long time.

Owner:SHANGHAI ZHONGLI AUTO PARTS

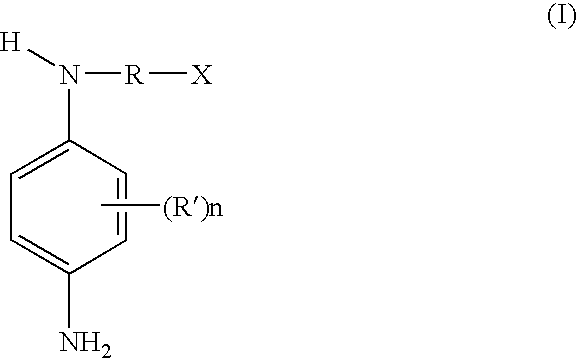

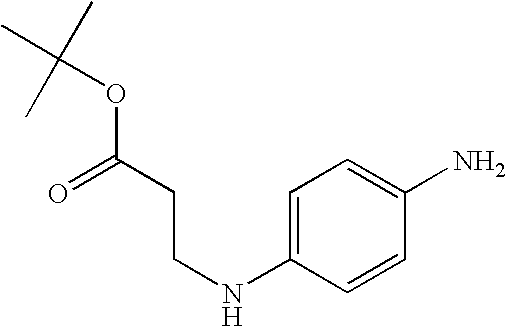

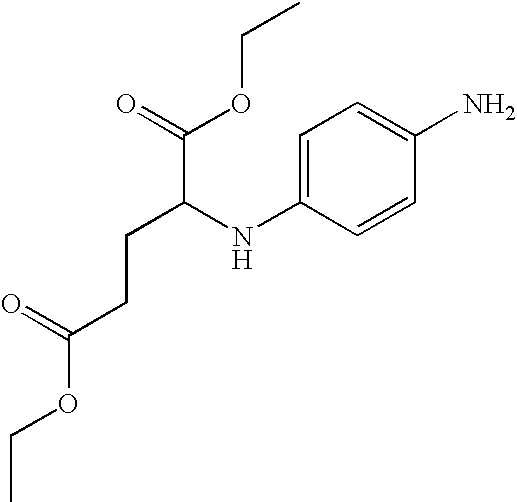

Secondary para-phenylenediamines having a carboxyl group, dye compositions comprising the same, and dyeing processes using the compositions

InactiveUS7384432B2Prevent degradationImproved profileCosmetic preparationsHair cosmeticsFiberPara phenylenediamine

The present disclosure relates to novel secondary para-phenylenediamines having a carboxyl group. The present disclosure further relates to a dye composition comprising at least one secondary para-phenylenediamine for dyeing keratin fibers, such as human hair, a process for preparing the composition, and a process and kit for dyeing keratin fibers using the composition.

Owner:LOREAL SA

Tire rubber composition comprising an acetylacetonate compound

Rubber composition which can be used in particular for the manufacture of s, comprising at least a diene elastomer, a reinforcing filler, a crosslinking system, between 0.2 and 10 phr of an antioxidant, such as a substituted para-phenylenediamine, and between 0.2 and 10 phr of chromium (III) acetylacetonate. This acetylacetonate compound makes it possible to advantageously reduce the consumption of antioxidant during the thermo-oxidizing ageing of the composition. Metal / rubber composite comprising such a composition and at least a metal reinforcing member. comprising such a composition or such a composite.

Owner:OCIETE DE TECH MICHELIN +1

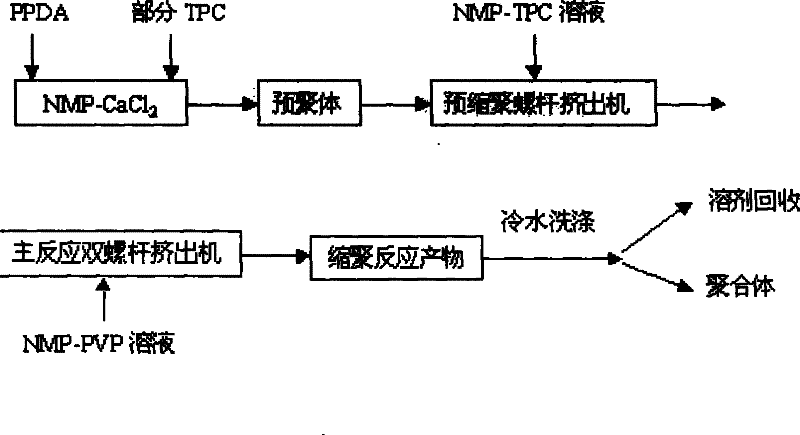

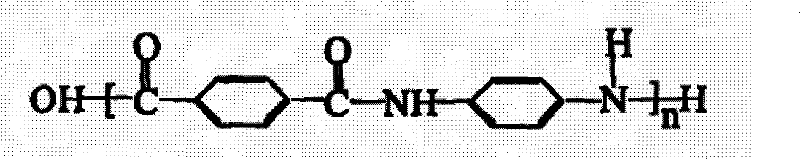

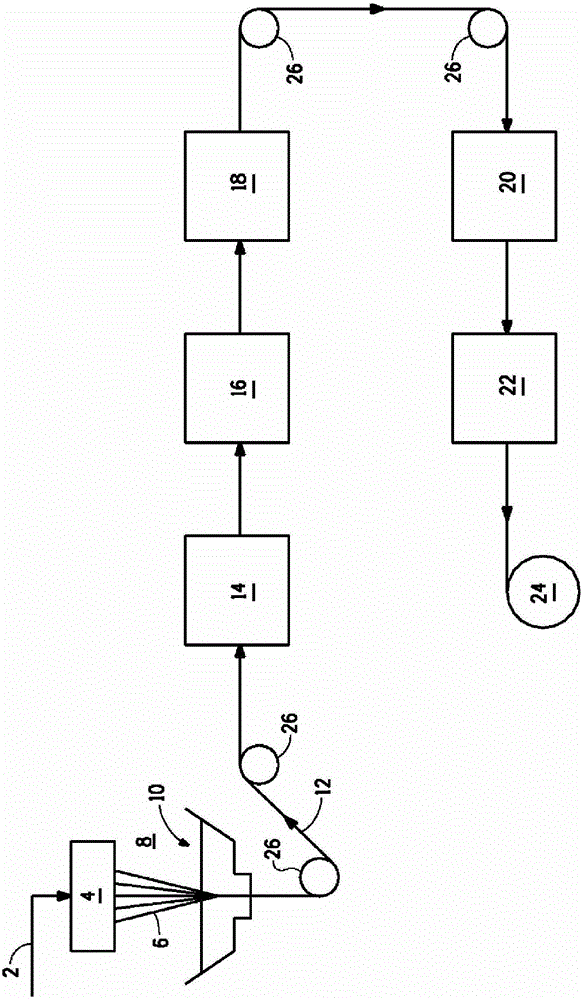

Novel preparation technique for poly (p-phenylene terephthalamide)

The invention discloses a new technique used for manufacturing poly(p-phenytene terephthalamide) resin, which comprises steps that: (1) para-phenylenediamine and 50-95 percent of terephthaloyl chloride are treated with pre-polycondensation in a solution system at low temperature; (2) the left 5-50 percent of the terephthaloyl chloride is made into a solution with 30-70 percent of content in N-methyl pyrrolidone, and the solution is pumped into a pre-polycondensation screw extruder together with prepolymer; (3) the reaction mixture is intruded into a main reaction screw extruder and a macromolecule addictive, polyvinyl pyrrolidone-N-methyl pyrrolidone solution is dripped in; (4) the extruded polymer is washed with ice water and neutralized by the cleaning solution of calcium carbonate andpotassium hydroxide and the solvent is recycled; (5) the washed polymer is dehydrated and dried, then light yellow polymer powder of the poly(p-phenytene terephthalamide) with logarithmic viscosity number of 4-7.5dl / g is obtained. The poly (p-phenytene terephthalamide) resin which is manufactured by adopting the technique of the invention has simple technology, being convenient for uninterrupted production, and the prepared polymer powder has fresh color and luster and stable capacities, and the resin has good spinnability, the spun fiber has good color and luster, high strength and high modulus.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD

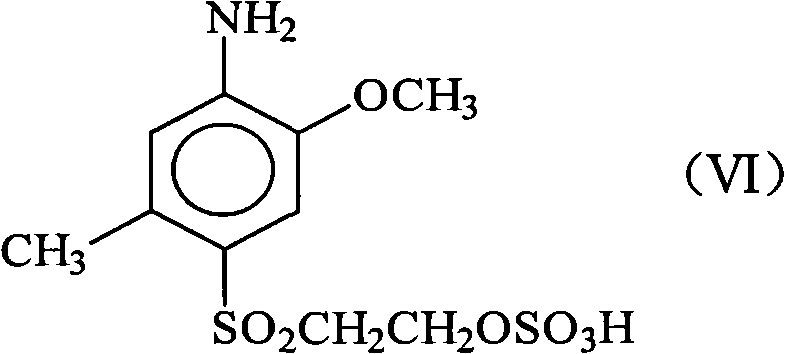

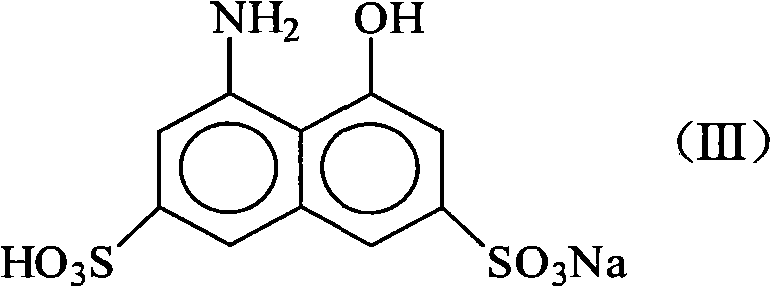

Reactive navy blue dyestuff for nylon dyeing

ActiveCN101817996AImprove sharpnessHigh color fixing rateOrganic chemistryReactive dyesSulfateVinyl sulfone

The invention relates to a reactive navy blue dyestuff for nylon dyeing, which has a structural formula (I) and is prepared by a method comprising the following steps of: (a) adding hydrochloric acid solution and solution of sodium nitrite into para(meta)-nitroaniline; (b) adding H acid into the solution of the step (a); (c) dissolving cresidine para-ester in water; (d) adding the solution obtained in the step (c) into aqueous solution of cyanuric chloride, and adding para-phenylenediamine into the mixture after reaction; (e) adding the hydrochloric acid solution into the solution of the step(d), and then adding the solution of the sodium nitrite into the mixture; (f) dropping the solution of the step (e) into the solution of the step (b); and (g) converting beta-sulfate ethyl sulfone ofan alkaline coupling fluid obtained in the step (f) into vinyl sulfone groups under an alkaline condition so as to prepare the compound of the structural formula (I).

Owner:TIANJIN DEK CHEM

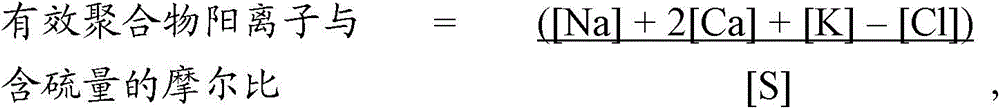

Copolymer fiber and method of making same

ActiveCN103314141BArtificial filament washing/dryingMonocomponent synthetic polymer artificial filamentFiberYarn

The present invention relates to yarns comprising copolymers derived from the copolymerization of p-phenylenediamine, 5(6)-amino-2-(p-aminophenyl)benzimidazole and terephthaloyl dichloride, wherein The ratio of moles of 5(6)-amino-2-(p-aminophenyl)benzimidazole to moles of p-phenylenediamine is from 30 / 70 to 85 / 15. The yarn has a sulfur content of greater than 0.1%; and has an effective polymer cation to sulfur content molar ratio of at least 0.3. Additional aspects of the invention relate to methods of making such yarns.

Owner:DUPONT SAFETY & CONSTR INC

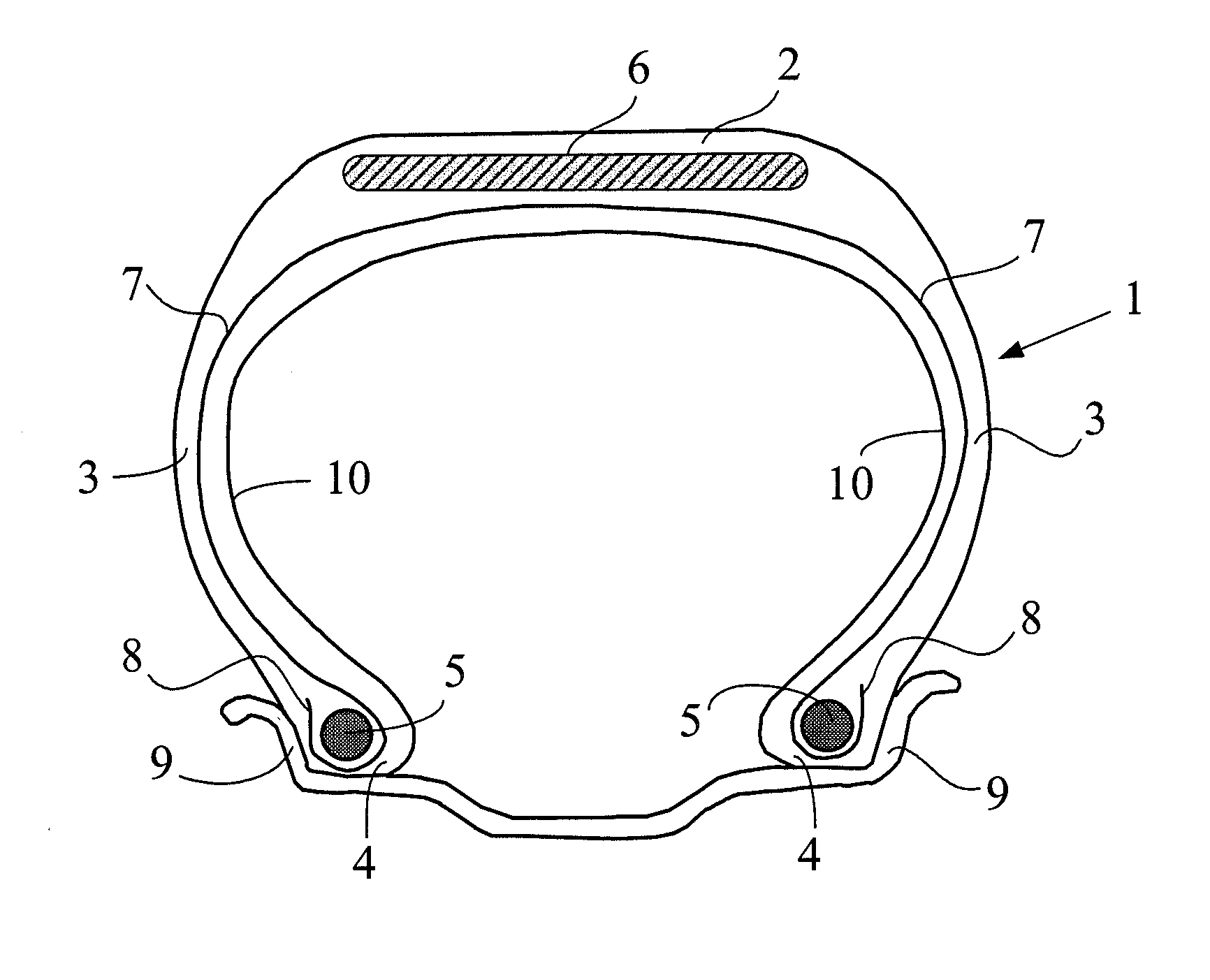

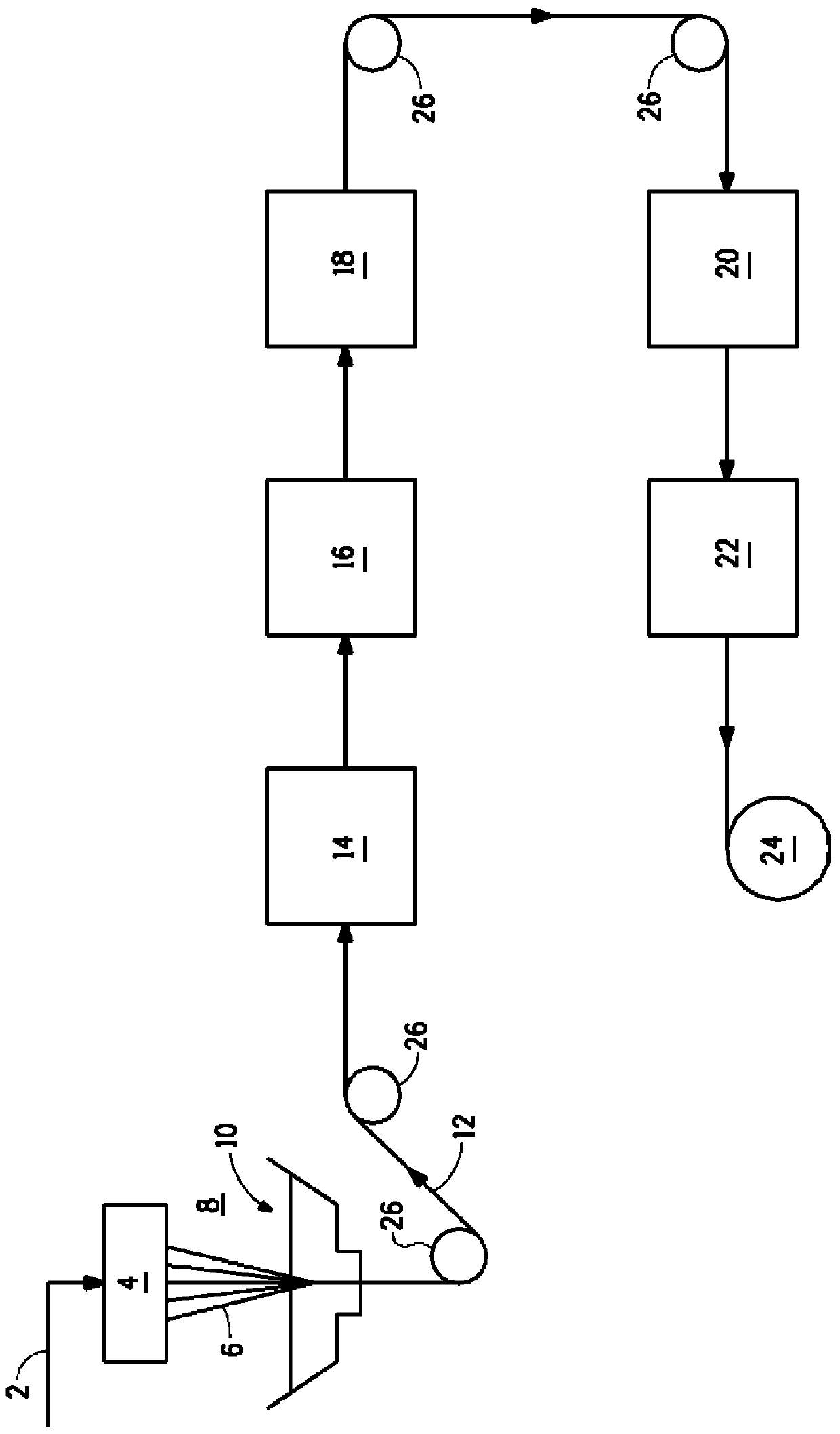

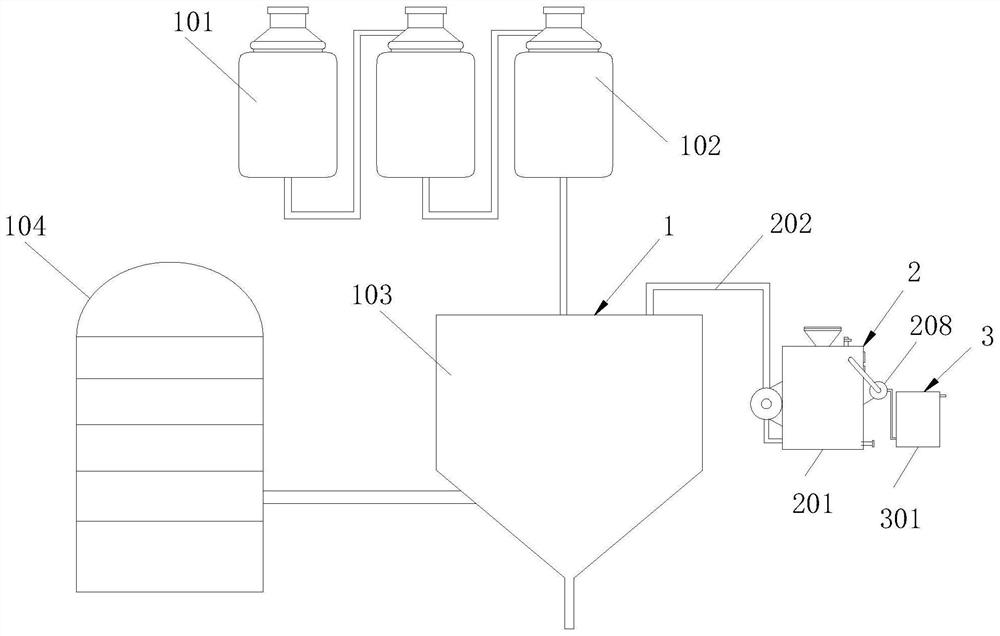

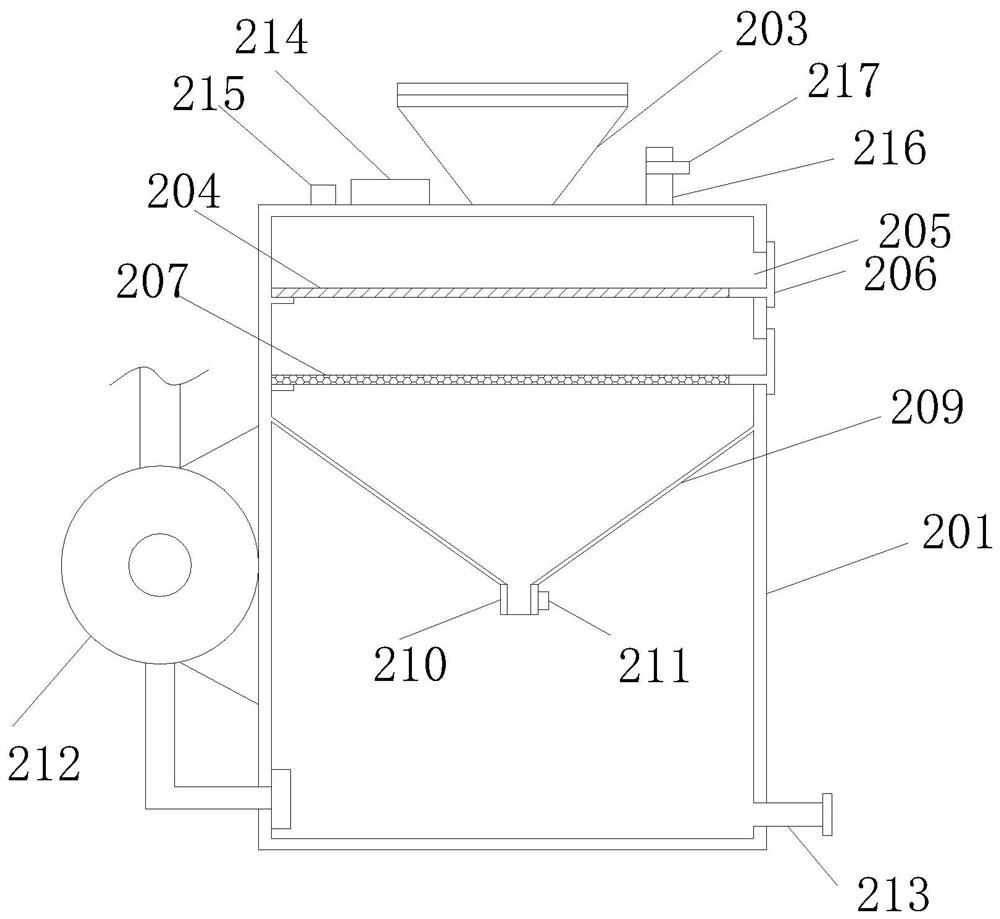

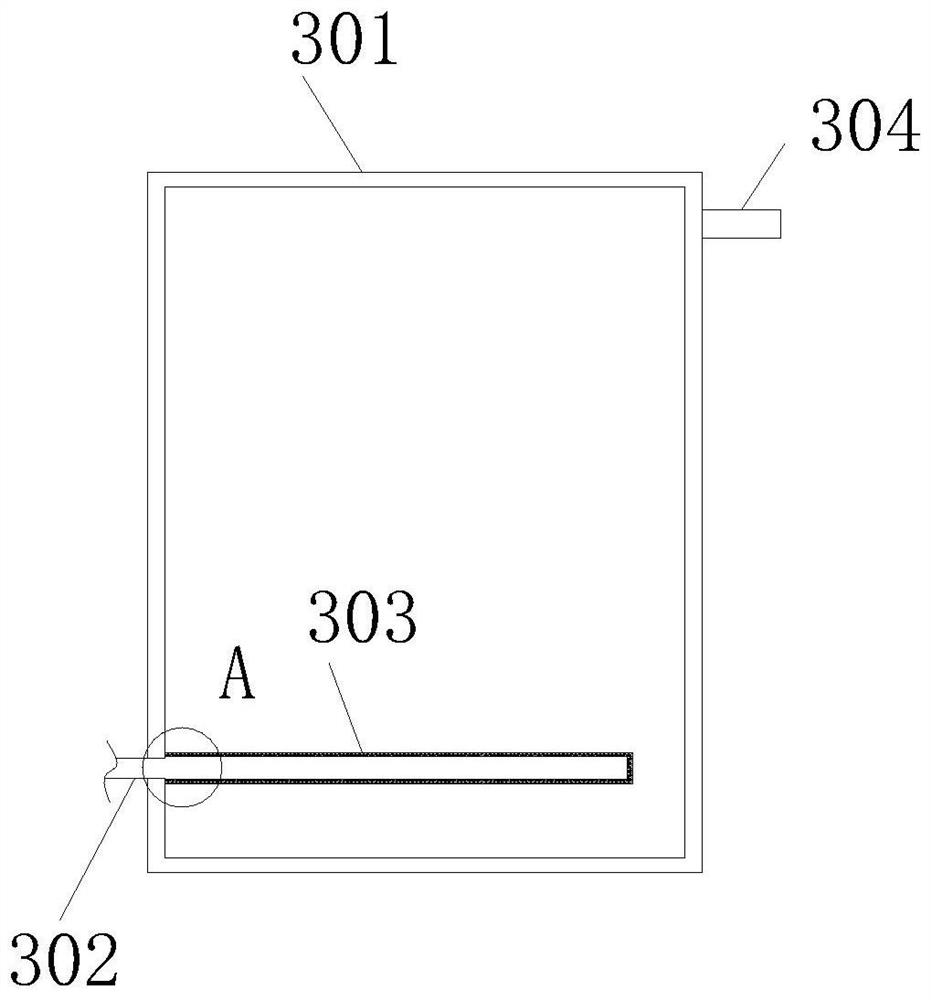

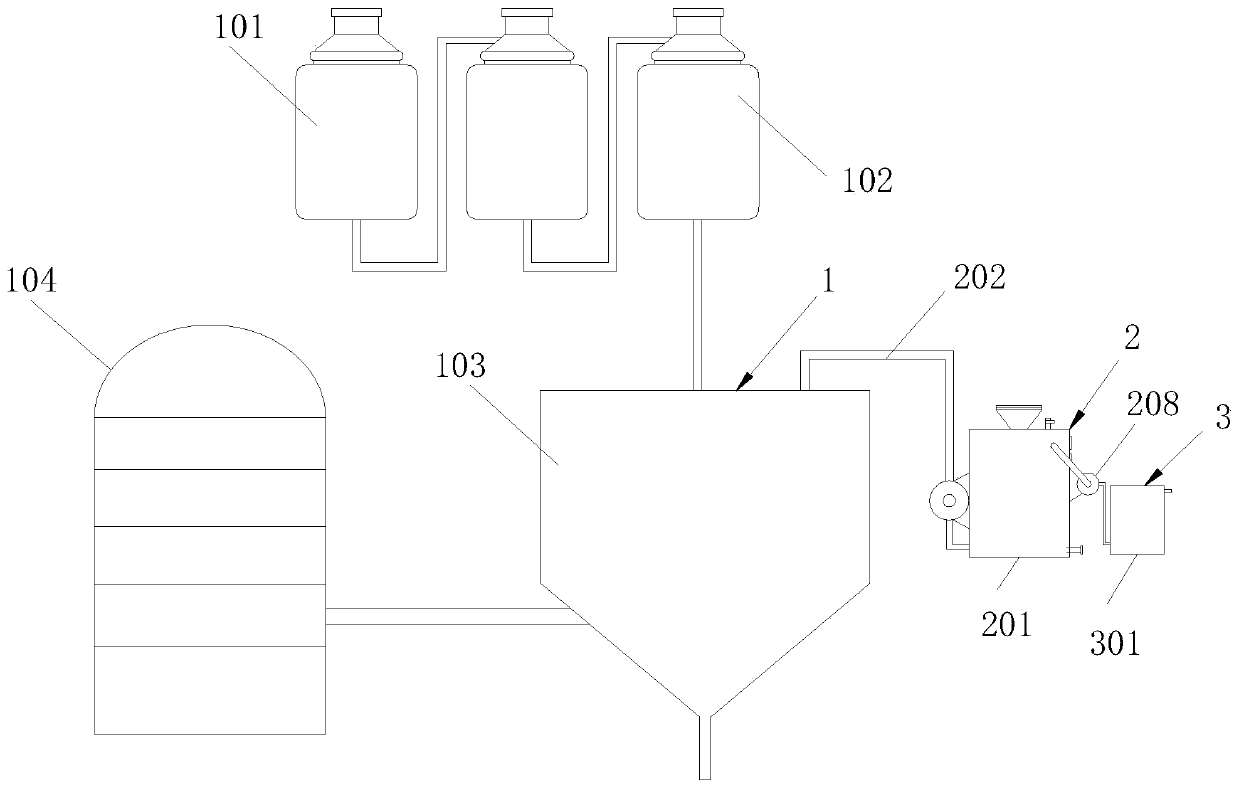

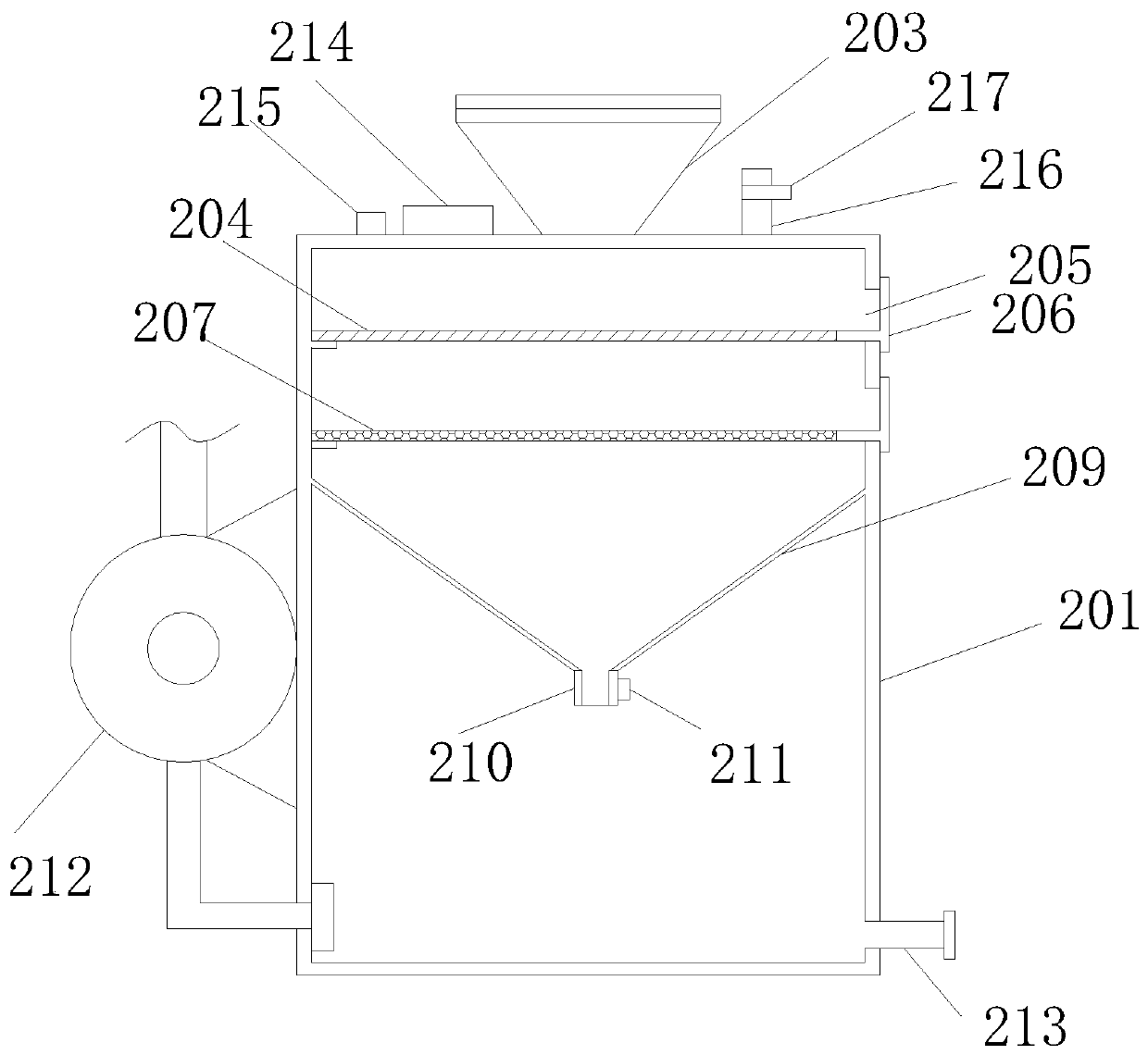

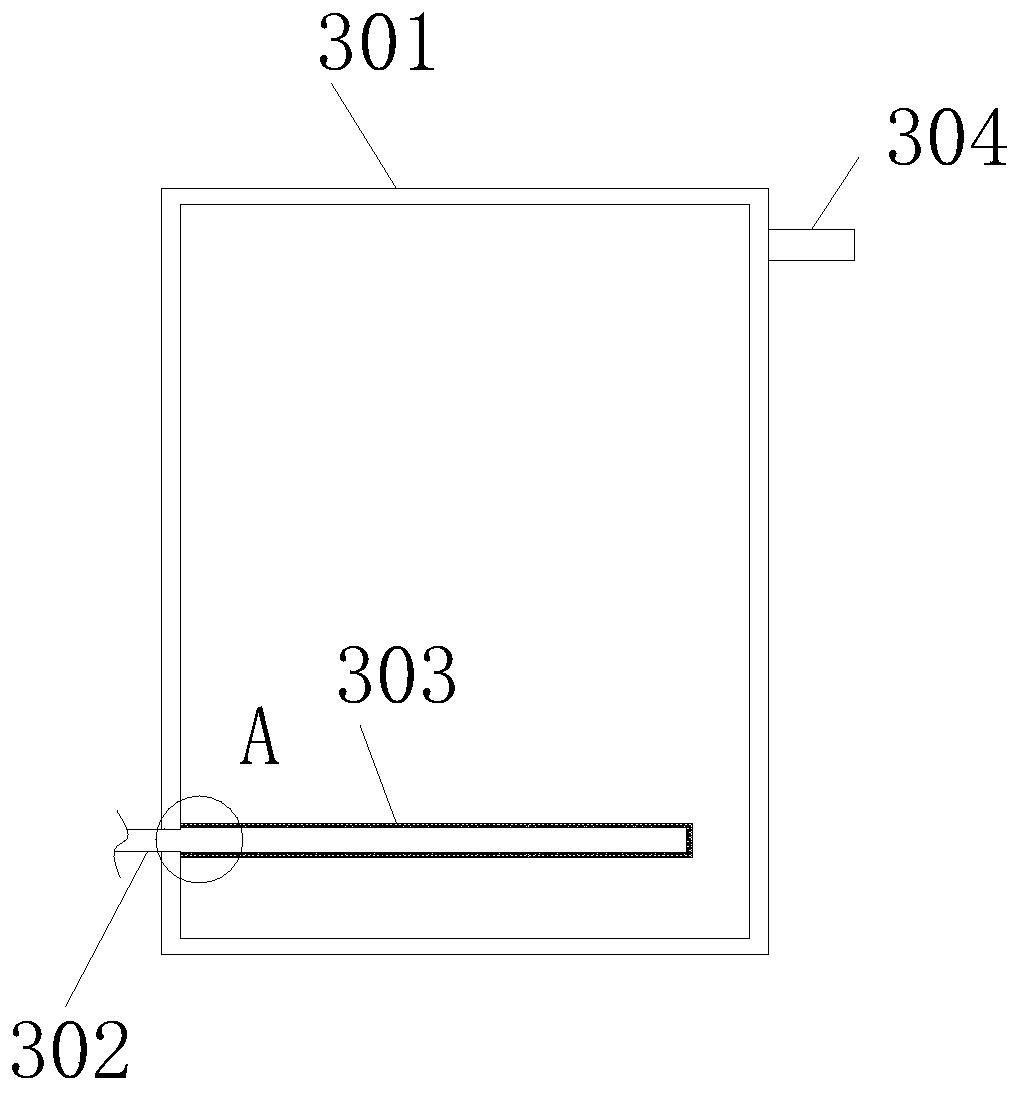

A kind of preparation method of dinitrobenzene continuous catalytic hydrogenation for the preparation of phenylenediamine

ActiveCN110437075BReduce lossEfficient collectionAmino compound purification/separationOrganic compound preparationPtru catalystHydrogenation reaction

The present invention is applicable to the technical field of phenylenediamine preparation, and provides a preparation method for continuous catalytic hydrogenation of dinitrobenzene for the preparation of phenylenediamine, which uses a phenylenediamine preparation device to realize the preparation of phenylenediamine. The phenylenediamine preparation device includes a preparation assembly, a recovery assembly and a purification assembly, the preparation assembly includes a hydrogenation reactor, a maturation tank, a multistage settling tank and a rectification tower, and the recovery assembly includes a recovery box, a reflux pipe, a feed Bucket, first filter screen, second filter screen, air pump, leaking liquid funnel, liquid outlet valve, return pump, controller, timer, inlet pipe and air valve, the purification assembly includes purification box, communication pipe, shunt pipe , exhaust pipe, air hole, by setting the recovery box for recovering the catalyst, also being provided with an air pump for drying the catalyst and a purification box for purifying the gas extracted by the air pump, the present invention has the advantages of high catalyst recovery efficiency and environmental protection The characteristics of little pollution.

Owner:上海鸿源鑫创材料科技有限公司

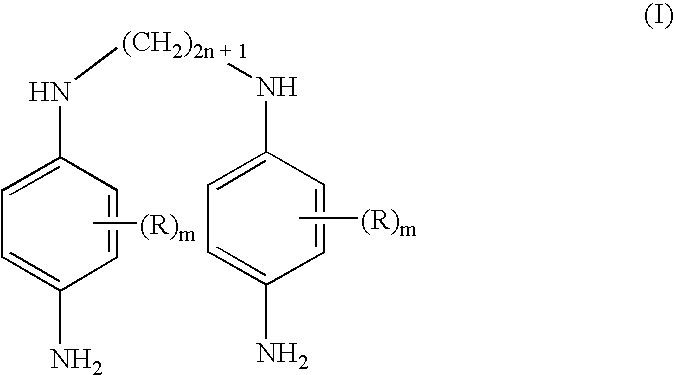

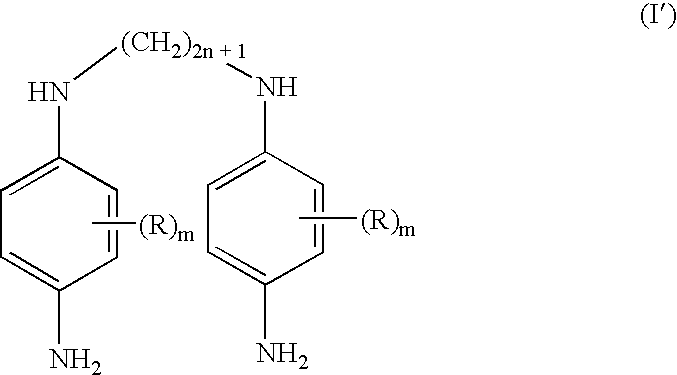

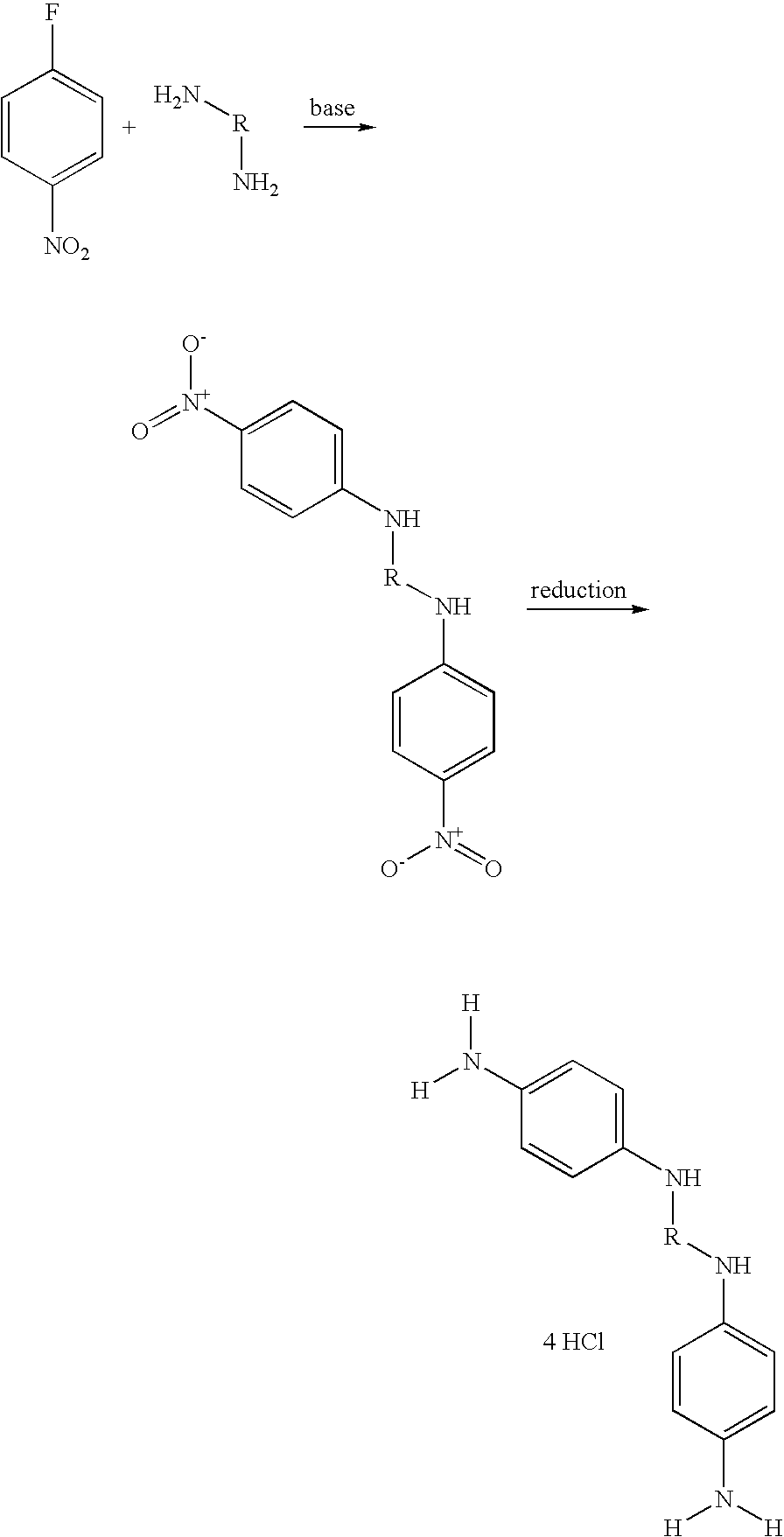

Double secondary para-phenylenediamine compounds, dye compositions comprising same, and dyeing process using the compositions

The present disclosure relates to double secondary para-phenylenediamine dye compounds. The present disclosure further relates to a dye composition comprising at least one double secondary para-phenylenediamine compound, a process for dyeing keratin fibers using the composition, and a kit for dyeing keratin fibers comprising a separate composition comprising an oxidizing agent.

Owner:1192062 ALBERTA +1

A kind of high-performance silicon/fluorine ether compound rubber glove and preparation method thereof

InactiveCN106702755BImprove high temperature resistanceImprove corrosion resistanceFireproof paintsGlovesPolymer science(Hydroxyethyl)methacrylate

Owner:顺泰精密橡胶(深圳)有限公司

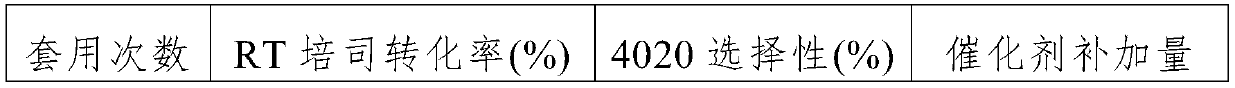

Preparation method of catalyst used for synthesizing phenylenediamine rubber anti-aging agent

ActiveCN110124745AImprove adsorption capacityAvoid unstable performanceOrganic-compounds/hydrides/coordination-complexes catalystsPreparation by reductive alkylationHydrazine compoundInstability

The invention discloses a preparation method of a catalyst used for synthesizing a phenylenediamine rubber anti-aging agent. The catalyst comprises an activated carbon carrier, and platinum, iron andnickel supported on the activated carbon carrier. The preparation method of the catalyst comprises the following steps: step 1, preparing the activated carbon carrier; step 2, preparing a solution containing iron and nickel; step 3, preparing slurry containing nano iron and nickel; step 4, preparing a platinum-containing solution; and step 5, adding hydrazine hydrate into the slurry containing thenano iron and nickel, adding the platinum-containing solution dropwise, performing heat-preservation impregnation, performing cooling, performing filtration, and washing the filter cake to obtain thecatalyst. According to the method provided by the invention, the auxiliary metal nano nickel and iron are preferentially adsorbed by the activated carbon to modify platinum carbon, the nano iron andnickel and the activated carbon carrier are more firmly adsorbed, so that instability of performance of the catalyst caused by loss of the auxiliary metals is avoided, the activity of the catalyst isimproved, and the selectivity and stability of the catalyst are enhanced; and the prepared catalyst can be used for a synthetic reaction of the phenylenediamine rubber anti-aging agent, and the catalyst has high reaction activity, high selectivity and good stability.

Owner:XIAN CATALYST NEW MATERIALS CO LTD

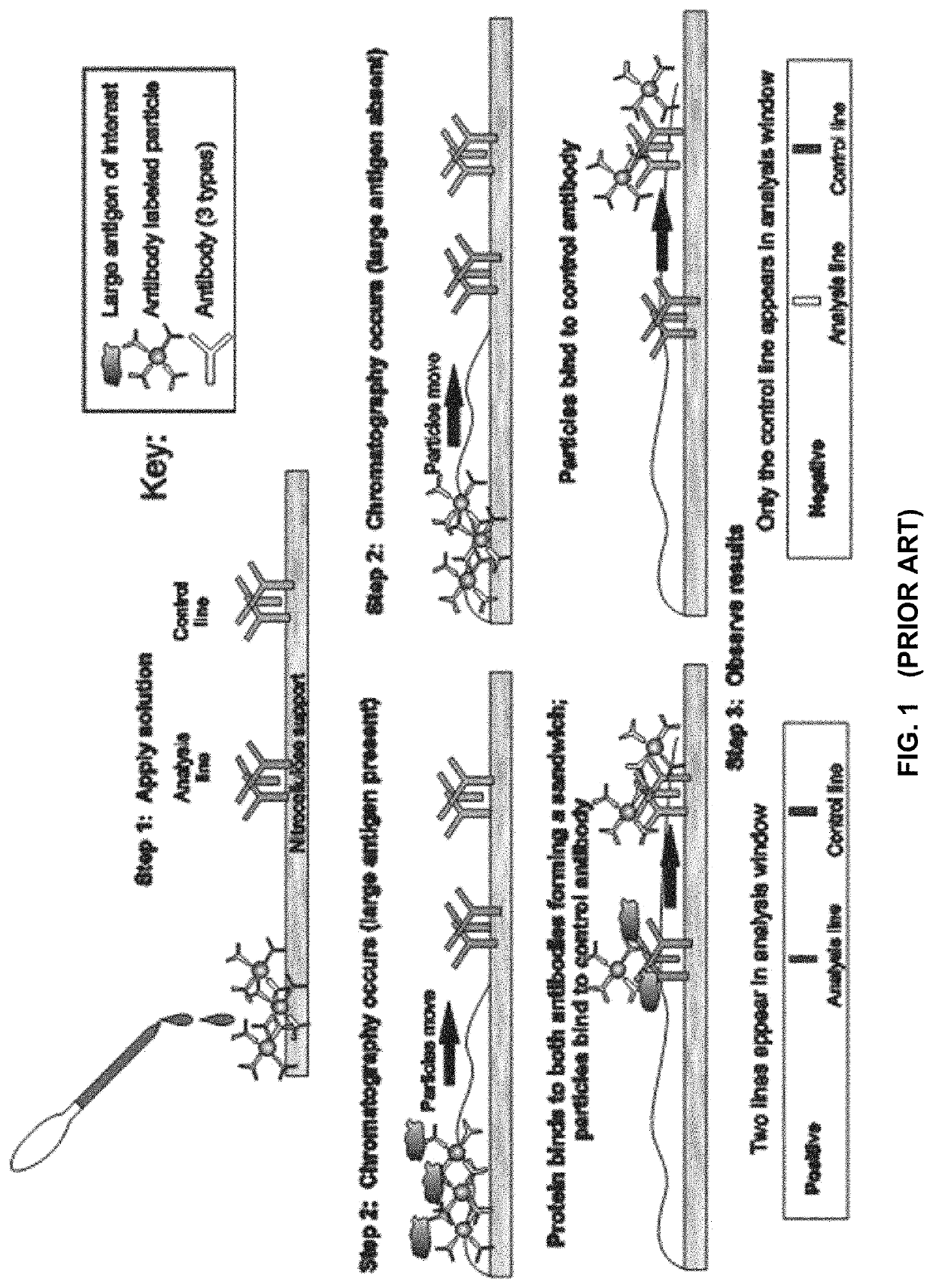

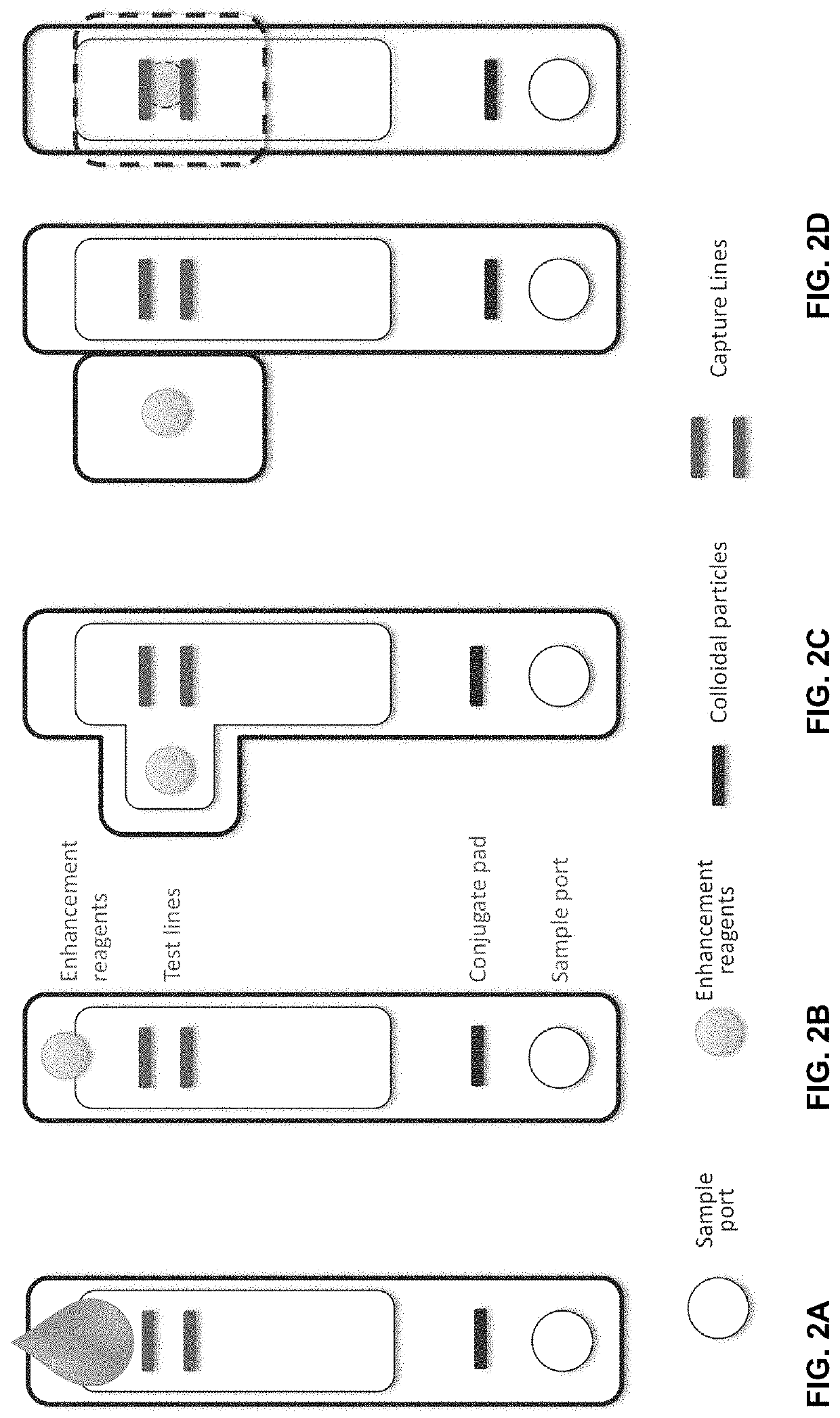

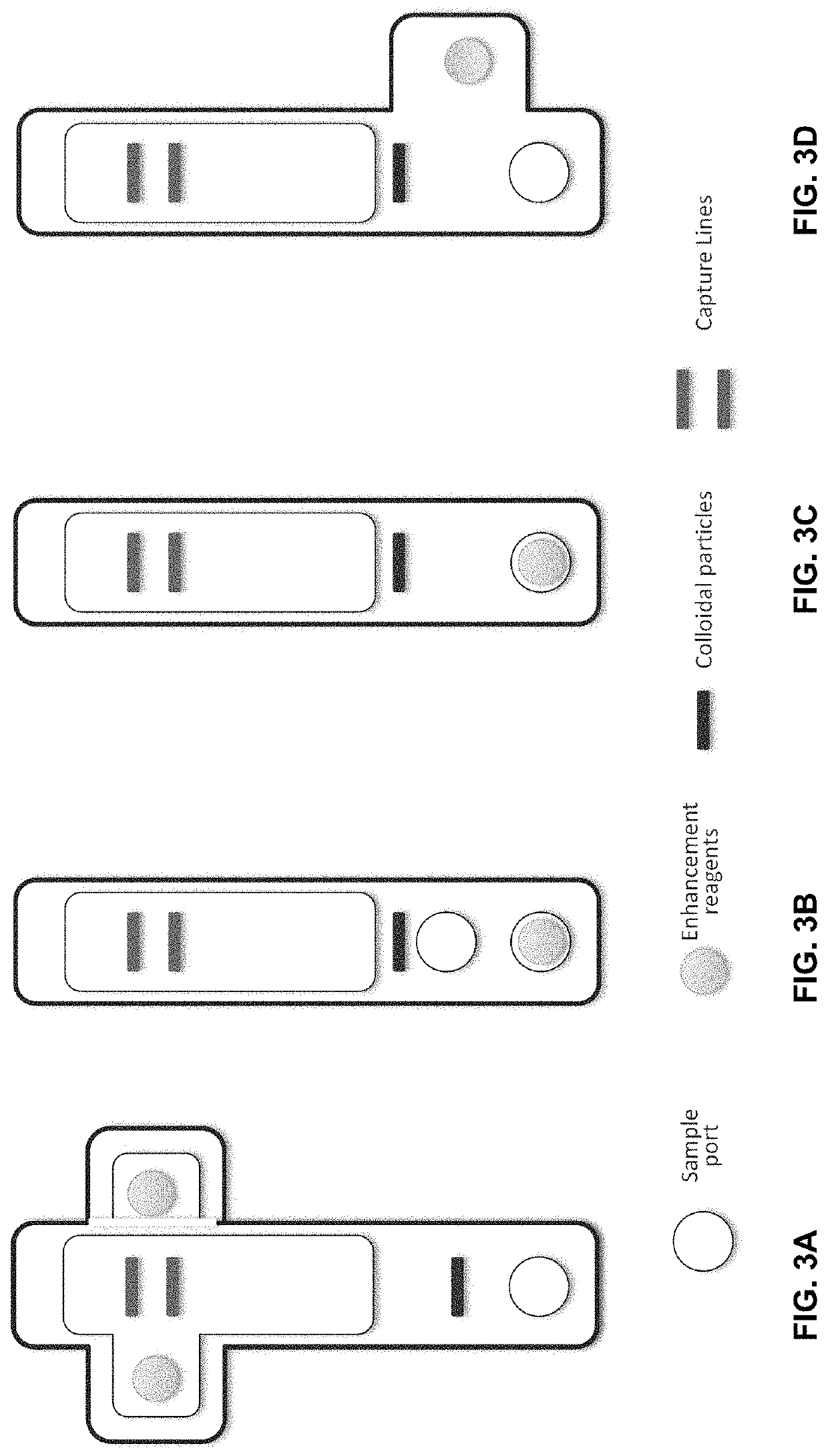

Catalytic signal enhancement for lateral flow immunoassays

ActiveUS20190391138A1High sensitivityExtension of timeMaterial analysis by observing effect on chemical indicatorNanotechnologyReducing agentPalladium nanoparticles

Owner:UNITED STATES OF AMERICA

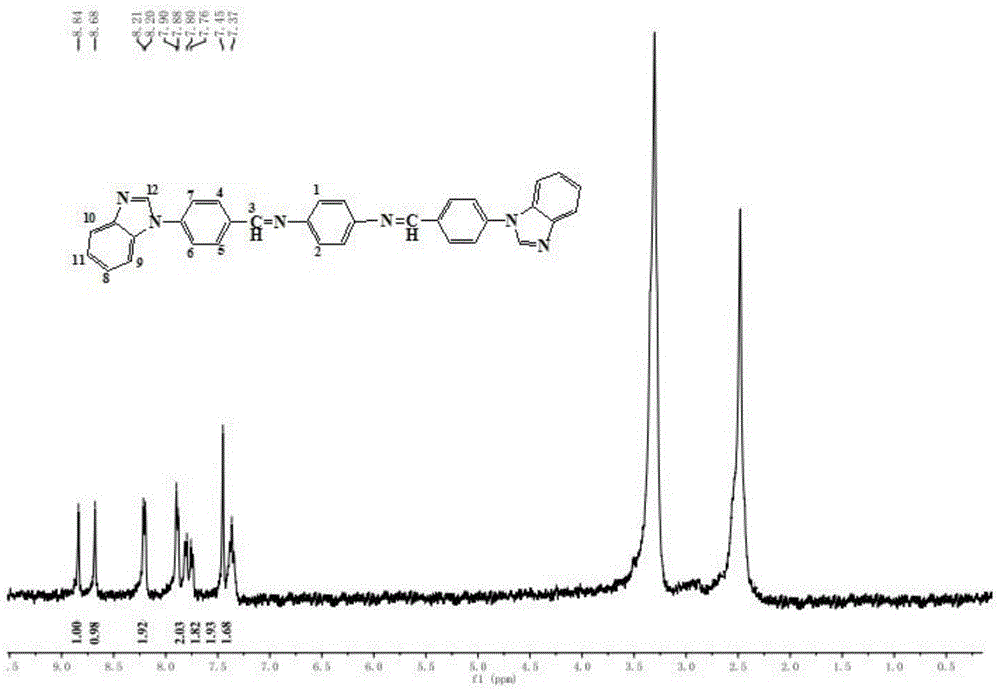

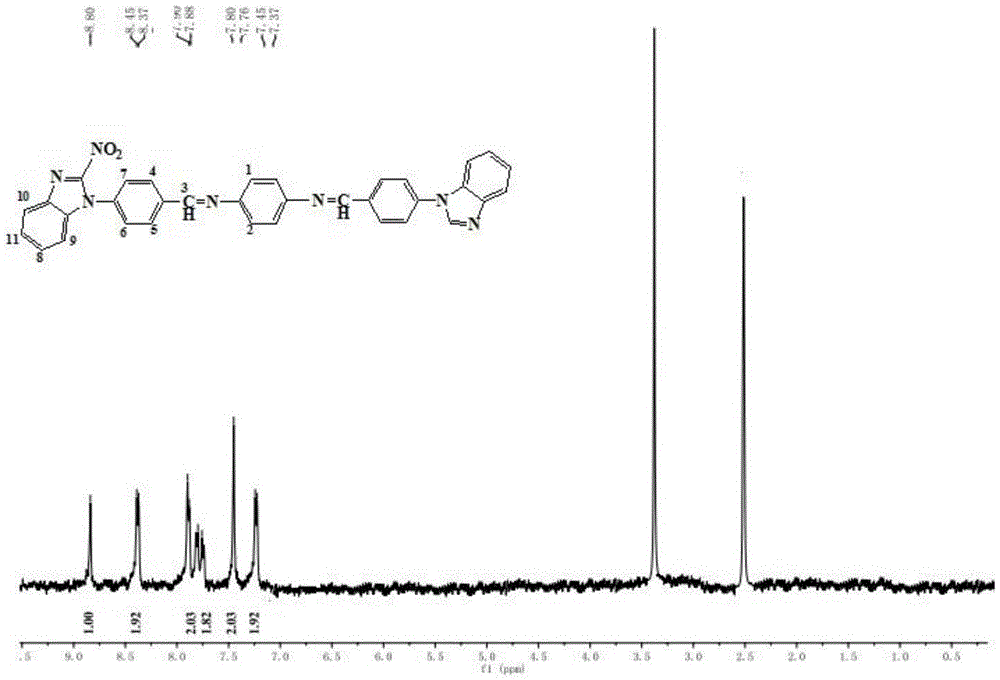

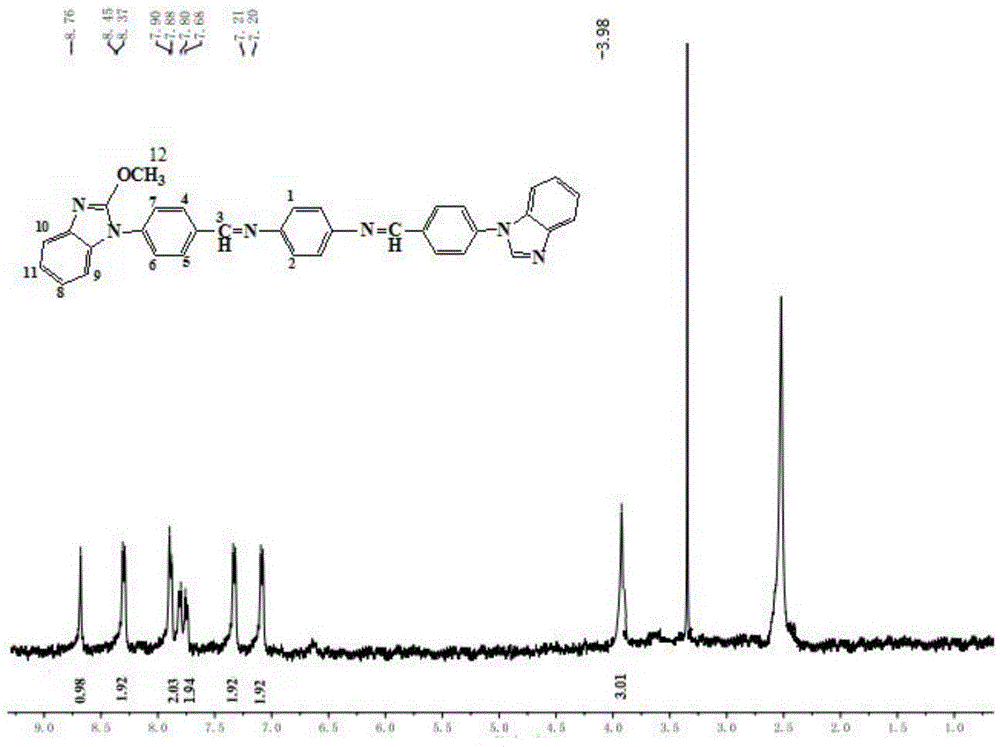

A kind of benzimidazole benzaldehyde acetal p-phenylenediamine bis-Schiff base and preparation method thereof

InactiveCN104119278BOrganic chemistryFluorescence/phosphorescenceBenzimidazole derivativeFluorescence

The invention relates to a benzimidazole benzaldehyde p-phenylenediamine bis-Schiff base and a preparation method thereof. First, benzimidazole and its derivatives and p-fluorobenzaldehyde are used as raw materials to prepare 4-benzimidazolyl benzaldehyde or benzimidazole derivative benzaldehyde, and then utilize it and p-phenylenediamine through the formation of aldehyde group and primary amine Condensation reactions yielded a series of bis-Schiff bases with larger conjugated structures. The process has low synthesis cost, high yield, easy control of reaction conditions and simple product purification. The novel compound of the invention has good fluorescence performance and is selective to metal ions, and can be applied in the field of materials or sensors.

Owner:QILU UNIV OF TECH

Preparation method for preparation of phenylenediamine through dinitrobenzene continuous catalytic hydrogenation

ActiveCN110437075AReduce lossEfficient collectionAmino compound purification/separationOrganic compound preparationHydrogenation reactionTower

The invention is applicable to the technical field of phenylenediamine preparation and provides a preparation method for preparation of phenylenediamine through dinitrobenzene continuous catalytic hydrogenation. Preparation of phenylenediamine is achieved by using a phenylenediamine preparation device, and the phenylenediamine preparation device comprises a preparation component, a recycling component and a purification component, wherein the preparation component comprises a hydrogenation reaction kettle, a maturing kettle, a multi-stage settling tank and a rectification tower; the recyclingcomponent comprises a recycling tank, a backflow tube, a feeding hopper, a first filter net, a second filter net, a gas sucking pump, a liquid leakage hopper, a liquid outlet valve, a backflow pump, acontroller, a timer, a gas inlet tube and a gas valve; and the purification component comprises a purification tank, a communicating tube, a diversion tube, an exhaust tube and a vent hole. Due to adoption of the recycling tank for recycling a catalyst, the gas sucking pump for drying the catalyst and the purification tank for purifying gases sucked out by using the gas sucking pump, the preparation method has the characteristics of being high in catalyst recycling efficiency and small in environment pollution.

Owner:上海鸿源鑫创材料科技有限公司

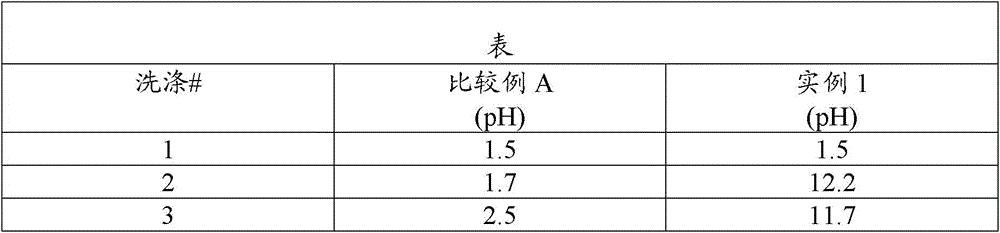

Neutralized copolymer crumbs and process for their preparation

ActiveCN103314035BHas intrinsic viscosityMonocomponent polyamides artificial filamentTitratable acidPara phenylenediamine

The present invention relates to a copolymer crumb derived from the copolymerization of p-phenylenediamine, 5(6)-amino-2-(p-aminophenyl)benzimidazole and terephthaloyl dichloride, said copolymer crumb The granules have an intrinsic viscosity of at least 3 dl / g with a titratable acid of less than 0.4 mol / Kg. Furthermore, the present invention also relates to filaments and yarns formed from such polymer crumbs and methods for forming said filaments and yarns.

Owner:DUPONT SAFETY & CONSTR INC

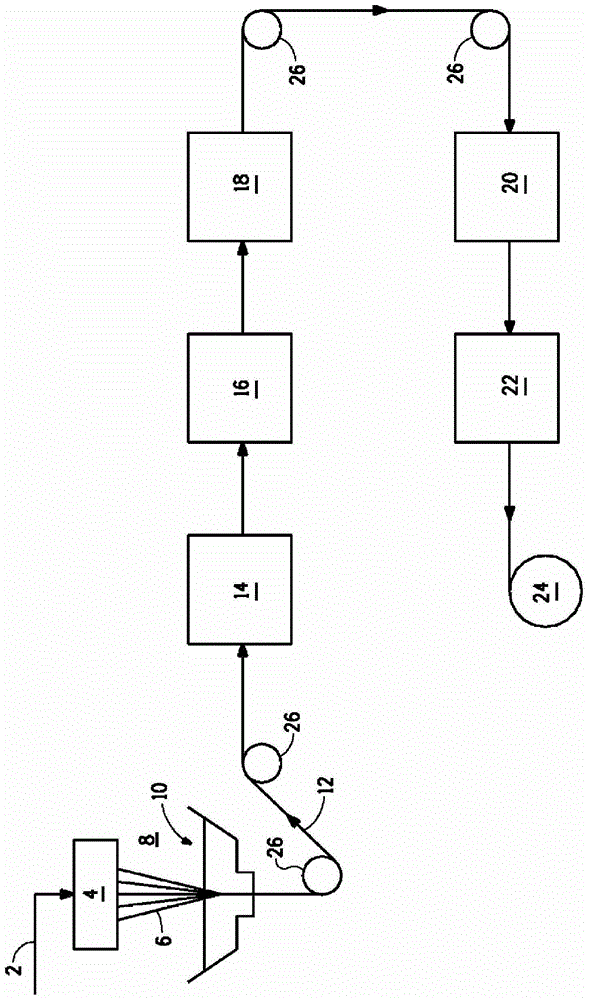

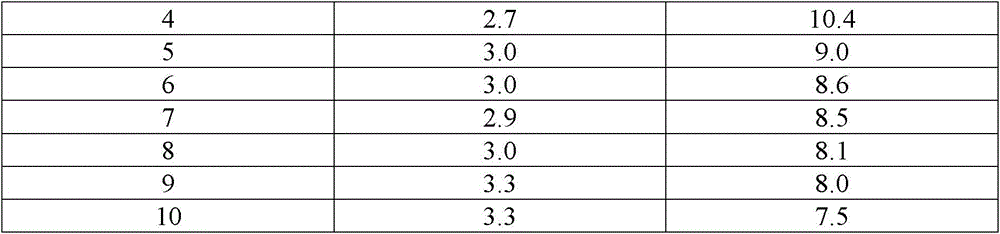

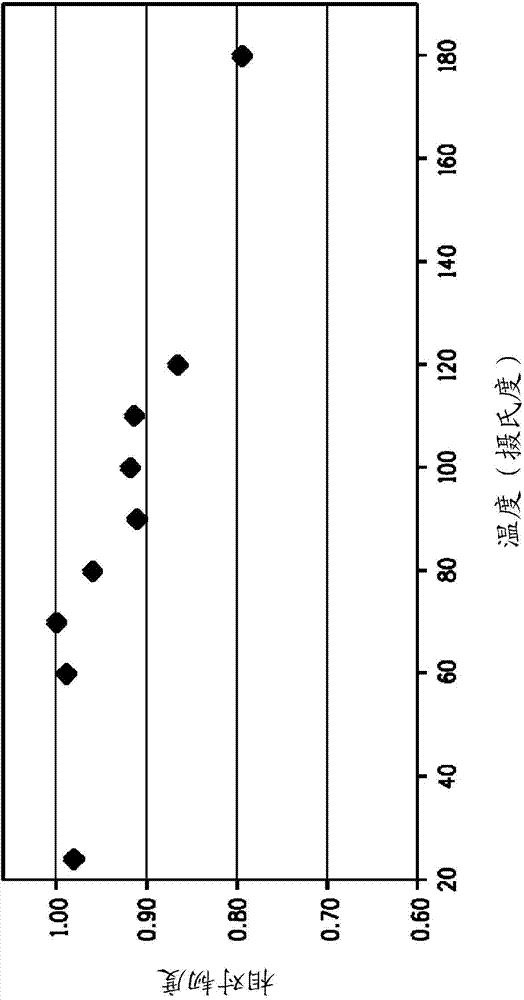

Preparation and drying of copolymer fibers

ActiveCN103314144BArtificial filament washing/dryingMonocomponent copolyamides artificial filamentFiberPolymer science

The present invention concerns processes for reducing water in never-dried fiber comprising copolymer derived from the copolymerization of para-phenylenediamine, 5(6)-amino-2-(p-aminophenyl)benzimidazole; and terephthaloyl dichloride, the process having the following steps in a continuous process, (a) a step of drying a never-dried fiber having at least 0.1% sulfur at less than 150° C. until the moisture content of the fiber is less than 60 weight percent; and (b) a step of further drying the fiber above 150° C. while the moisture content of the fiber is no more than 60 weight percent; and the fiber being further heated to at least 350° C. in either an additional continuous or separate step.

Owner:DUPONT SAFETY & CONSTR INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com