Tire rubber composition comprising an acetylacetonate compound

A technology of rubber composition and chromium acetylacetonate, which is applied in the field of anti-degradation agent system and anti-degradation agent, semi-finished products or products such as rubber composition of tires, which can solve the problems of changing the internal structure of tires, high cost, complicated manufacturing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

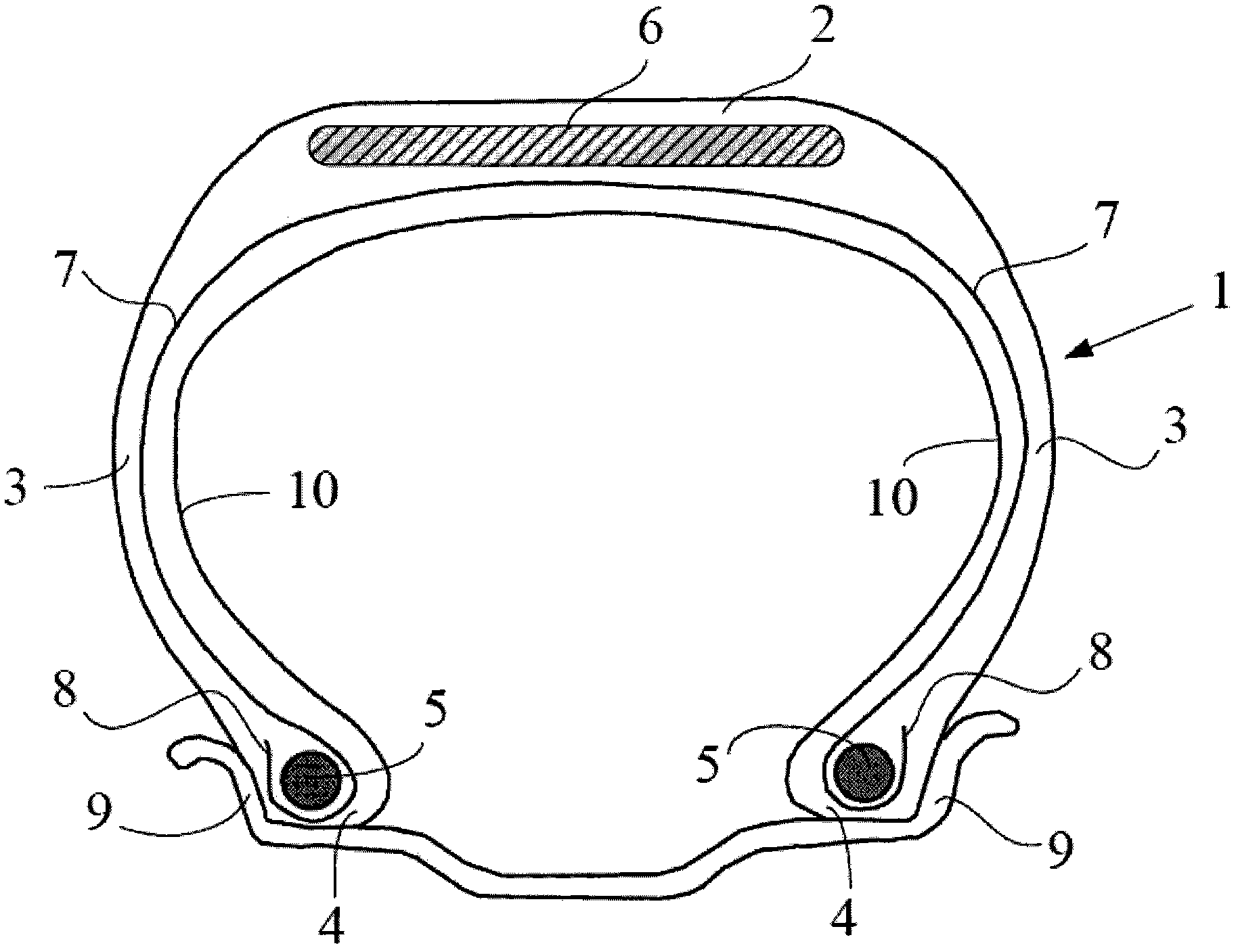

[0118] A) Use of the composition of the invention in tires

[0119] The rubber composition of the invention described above can be used for the manufacture of any semi-finished or finished product composed of rubber, in particular for automobile tires, whether the composition is external or internal to the tire structure.

[0120] The "outer" composition (or mixture) is here understood to mean any tire component made of rubber facing the outside of the tyre, that is to say in contact with air or inflation gas; particular mention is made of the tire's tread, tire side wall or airtight layer.

[0121] Conversely, "inner composition" (or mixture) is understood to mean any tire component made of rubber that is not facing the outside of the tyre, that is to say not in contact with air or inflation gas, and therefore is actually located inside the structure of the tire; And the calendered compound, carcass reinforcement or crown reinforcement present in the bead area of the tyr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com