Fluorine-containing rubber valve composite material and preparation method thereof

A composite material and fluorine-containing rubber technology, which is applied in the field of rubber material processing, can solve problems such as the limitation of mechanical properties of materials, and achieve the effects of being beneficial to wear resistance and tensile strength, improving service life, and improving hardness and wear resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

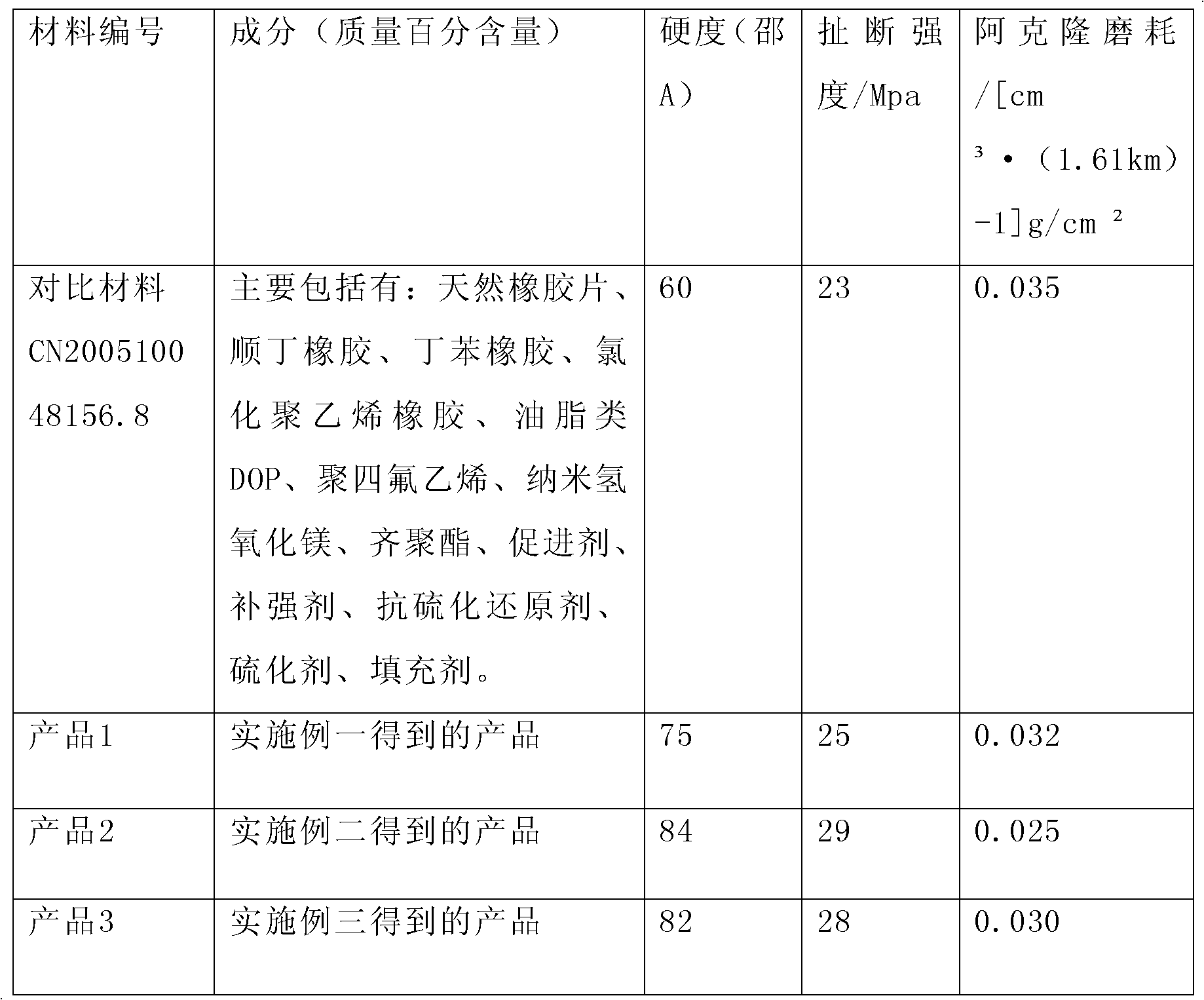

Examples

Embodiment 1

[0036] 1. Raw material preparation:

[0037] Weigh 60 parts of fluororubber, 10 parts of nitrile rubber, 3 parts of magnesium hydroxide, 1 part of calcium hydroxide, 1 part of microcrystalline wax, 2 parts of quinone, 1 part of sulfur, accelerator N-cyclohexyl-2- Benzothiazole sulfenamide C 13 h 16 N 2 S 2 1 part, 1 part of antioxidant N-phenyl-N'-yl p-phenylenediamine.

[0038] 2. The preparation process is as follows:

[0039] (1) Mixing: Start the open mill, put the fluororubber and nitrile rubber into the open mill, turn over until the two kinds of rubber are fused, then add calcium hydroxide, magnesium hydroxide and microcrystalline wax, quinone, Sulfur, anti-aging agent N-phenyl-N-yl-p-phenylenediamine, refining 6-8 times, and then adding accelerator N-cyclohexyl-2-benzothiazole sulfenamide C 13 h 16 N 2 S 2 Then fully smelt, the number of times of thinning is 11 times, and the temperature of the equipment should be controlled at 116-122°C during the mixing proc...

Embodiment 2

[0043] 1. Raw material preparation:

[0044] Weigh 70 parts of fluororubber, 15 parts of nitrile rubber, 5 parts of magnesium hydroxide, 2 parts of calcium hydroxide, 2 parts of microcrystalline wax, 3 parts of quinone, 2 parts of sulfur, accelerator N-cyclohexyl-2- Benzothiazole sulfenamide C 13 h 16 N 2 S 2 2 parts, 2 parts of antioxidant N-phenyl-N'-base p-phenylenediamine.

[0045] 2. The preparation process is as follows:

[0046] (1) Mixing: Start the open mill, put the fluororubber and nitrile rubber into the open mill, turn over until the two kinds of rubber are fused, then add calcium hydroxide, magnesium hydroxide and microcrystalline wax, quinone, Sulfur, anti-aging agent N-phenyl-N-yl-p-phenylenediamine, refining 6-8 times, and then adding accelerator N-cyclohexyl-2-benzothiazole sulfenamide C 13 h 16 N 2 S 2 Then fully smelt, the number of times of thinning is 15 times, and the temperature of the equipment should be controlled at 116-122°C during the mixi...

Embodiment 3

[0050] 1. Raw material preparation:

[0051] Weigh 65 parts of fluororubber, 12 parts of nitrile rubber, 4 parts of magnesium hydroxide, 1.5 parts of calcium hydroxide, 1.5 parts of microcrystalline wax, 1.5 parts of sulfur, 2.5 parts of diphenol, accelerator N-cyclohexyl-2-benzene Parathiazole sulfenamide C 13 h 16 N 2 S 2 1.5 parts, anti-aging agent N-phenyl-N'-base p-phenylenediamine 1.5 parts.

[0052] 2. The preparation process is as follows:

[0053] (1) Mixing: Start the open mill, put the fluororubber and nitrile rubber into the open mill, turn over until the two kinds of rubber are fused, then add calcium hydroxide, magnesium hydroxide and microcrystalline wax, quinone, Sulfur, anti-aging agent N-phenyl-N-yl-p-phenylenediamine, refining 6-8 times, and then adding accelerator N-cyclohexyl-2-benzothiazole sulfenamide C 13 h 16 N 2 S 2Then fully smelt, the number of times of thinning is 13 times, and the temperature of the equipment should be controlled at 116-1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shore hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com