Neutralized copolymer crumbs and process for their preparation

A technology of copolymerization and copolymerization, applied in the direction of one-component synthetic polymer rayon, textiles and papermaking, one-component polyamide rayon, etc., can solve the problems of low investment economy and expensive known methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

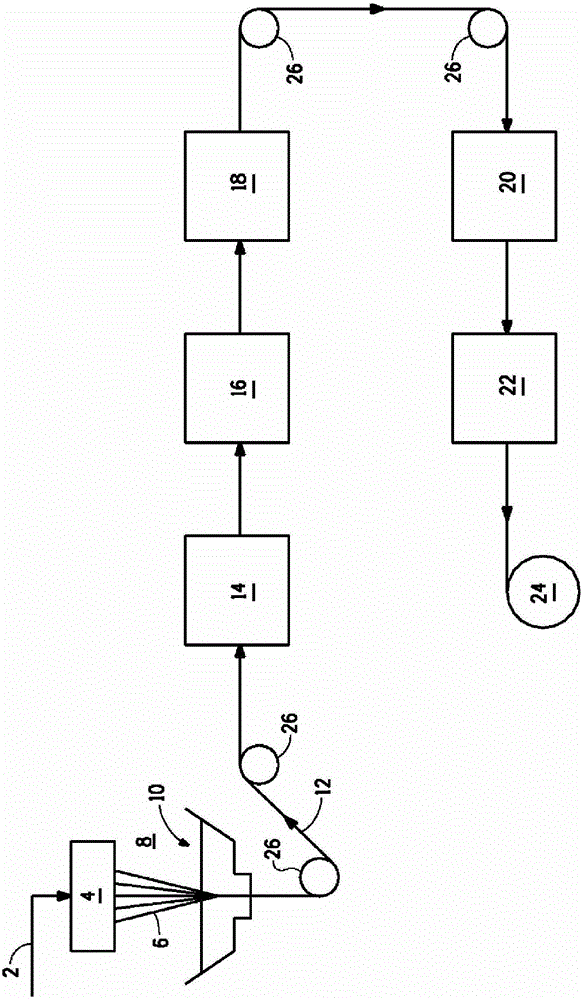

Method used

Image

Examples

example 1

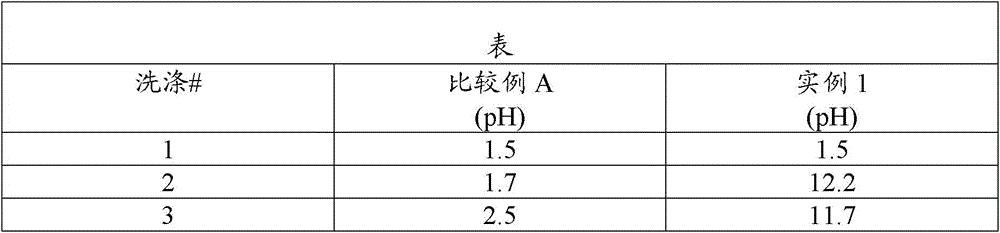

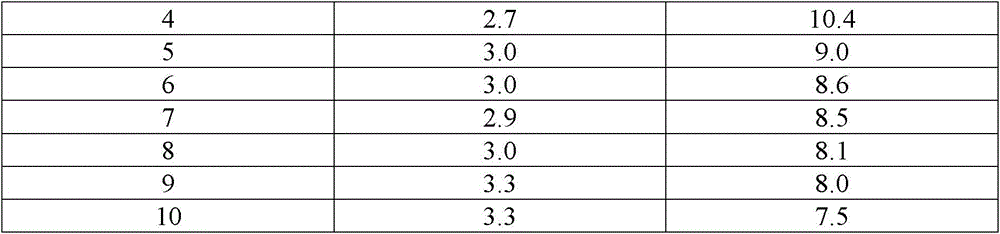

[0060] The second portion of the copolymer crumb has a different wash sequence. Wash 2 consisted of the following steps: The previously single washed copolymer crumb was washed with 4.2 g of 50% caustic and sufficient water for a total of 260 g. The pH was measured after the blender was running for three minutes and the material was filtered. The copolymer was then washed an additional eight times with distilled water only. Each wash consisted of adding distilled water to the previously washed filter cake until the total mass reached 260 g, further chopping in a Waring mixer for three minutes, measuring the pH of the slurry and filtering. The pH after each wash (2-10) is shown in the table. As can be seen from the wash data in the table, polymers in the pH range 5-9 were easily obtained with only a few washes.

[0061] After the final wash, the recovered copolymer was dried under vacuum at 120°C with a nitrogen purge. The measured intrinsic viscosity of this copolymer samp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com