Patents

Literature

203 results about "Paraphenylene diamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

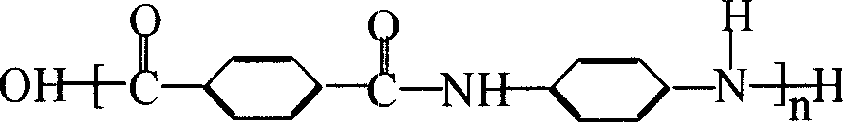

Para-Phenylenediamine (PPD), also known as paraphenylenediamine, p-phenylenediamine or 1, 4 diaminobenzene, is an aromatic amine with many industrial and cosmetic applications. The chemical is a common ingredient in permanent hair dye products, as well as dyes for fabrics, fur and dark makeup.

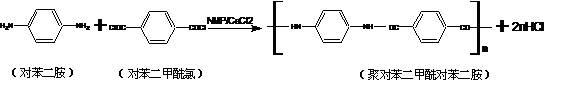

Large scale process for polymerization of dapbi-containing polyaramid

A method for obtaining an aromatic polyamide crumb from an aromatic diamine and an aromatic diacid chloride, which aromatic polyamide comprises 5(6)-amino-2-(p-aminophenyl)benzimidazole terephthalamide units and has a relative viscosity ηrel of at least 3, by: (1) adding at least monomers (i)-(iii) in N-methyl pyrrolidone as solvent wherein (i) is 0-30 mole % para-phenylenediamine (PPD), (ii) is 20-50 mole % 5(6)-amino-2-(p-aminophenyl)benzimidazole (DABPI), (iii) is 49.05-50.05 mole % terephthaloyl dichloride (TDC), and optionally calcium chloride to obtain a CaCl2 / aromatic diamine molar ratio less than 0.5, and an aromatic diamine / aromatic diacid chloride ratio between 0.99 and 1.01; (2) mixing the monomers and the optional calcium chloride to a homogenous mixture having a monomer concentration of 5 to 12 wt %; followed by (3) adding calcium chloride to the homogeneous mixture to obtain a CaCl2 / aromatic diamine molar ratio 0.6-1.0; and (4) polymerizing the mixture.

Owner:TEIJIN ARAMID BV

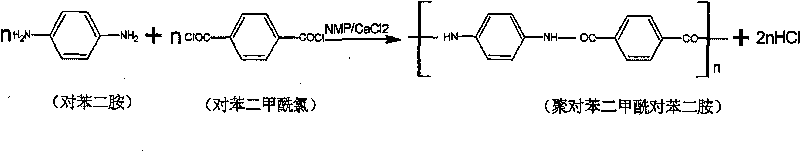

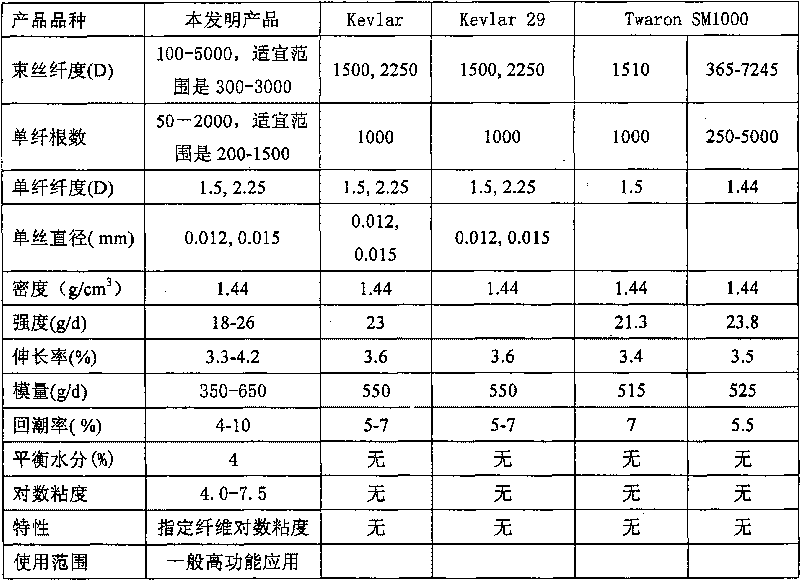

Polyphenylene terephthalamide fibre and preparation method thereof

ActiveCN101724935AHigh overall process efficiencyLow efficiencyWet spinning methodsMonocomponent polyamides artificial filamentPolymer scienceAramid

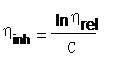

The invention discloses a polyphenylene terephthalamide fibre and a preparation method thereof. For the polyphenylene terephthalamide fibre (PPTA) which has with high performance and is prepared by the dry-jet wet spinning method, a polyphenylene terephthalamide fibre (PPTA) polymer which has the inherent viscosity of 4.5-8.0dL / g and is obtained by adopting the low-temperature solution polycondensation method is used as the start point, and the polyphenylene terephthalamide fibre is adaptive to the industrial large-scale production. The inherent viscosity of the fibre is reduced by 0.5dL / g than the inherent viscosity of the polymer. The polyphenylene terephthalamide fibre (PPTA) with high performance comprises the specific indexes as follows: a synnema titer is 300-3000 denier, an intensity is 18-26g / denier, an elongation rate is 3.2-3.8percent, a modulus is 350-650 g / denier, a water ratio is 3-10 percent and an inherent viscosity is 4-7.5dL / g. The physical property of the fibre is superior to the traditional aramid fibre II fibre. The invention discloses the inherent viscosity with the purpose of specifically showing the material of polyphenylene terephthalamide with higher molecular weight.

Owner:中蓝晨光化工有限公司

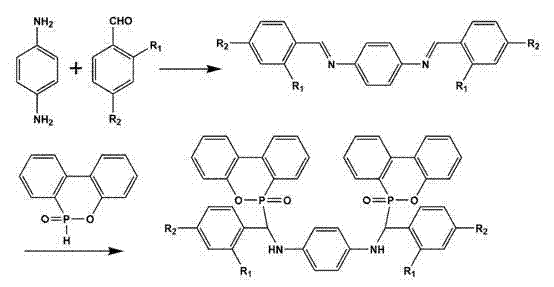

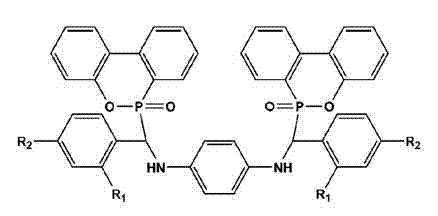

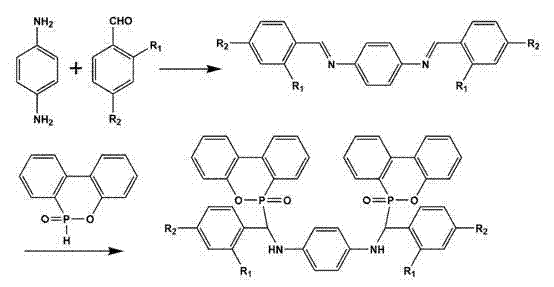

Nitrogen and phosphorus containing flame retardant agent and preparation method thereof as well as application thereof

ActiveCN102391545AHigh yieldSimple post-processingGroup 5/15 element organic compoundsEpoxyPolymer science

The invention relates to a preparation method of a nitrogen and phosphorus containing flame retardant agent, the nitrogen and phosphorus containing flame agent and application thereof. The preparation method comprises the following steps of: carrying out condensation reaction on phenylene diamine and aromatic aldehyde, then carrying out addition reaction with DOPO (9, 10-Dihydro-9-oxa-10-phosphaphenanthrene 10-oxide) to obtain solid nitrogen and phosphorus containing flame retardant agent molecules. The preparation method has the advantages of easiness in control, good repeatability, high yield and suitability for expanded production. The obtained flame retardant agent molecules have amino groups and phenolic hydroxyl active groups and can further react with matters containing expoxy group functional groups. The flame retardant agent molecules contain nitrogen and phosphorus elements and have good expansion char forming characteristic and very good flame retardant effect in the burning process; when the flame retardant agent molecules resist the flaming of the epoxy resin, the flame retardant agent molecules can further undergo cross-linking reaction with resin, thereby increasing the glass transition temperature, the bonding strength, the mechanical property and the like of the resin; meanwhile, the flame retardant agent molecules have good flame retardant property; the limiting oxygen index of the flame retardant agent molecules is substantially increased; and the vertical burning grade of the flame retardant agent molecules reaches a UL-94V-0 grade.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

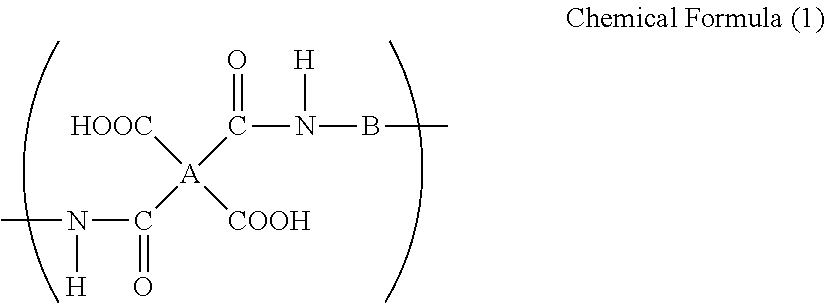

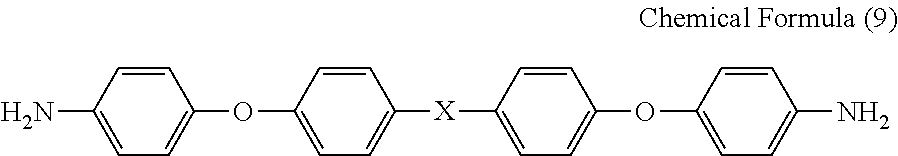

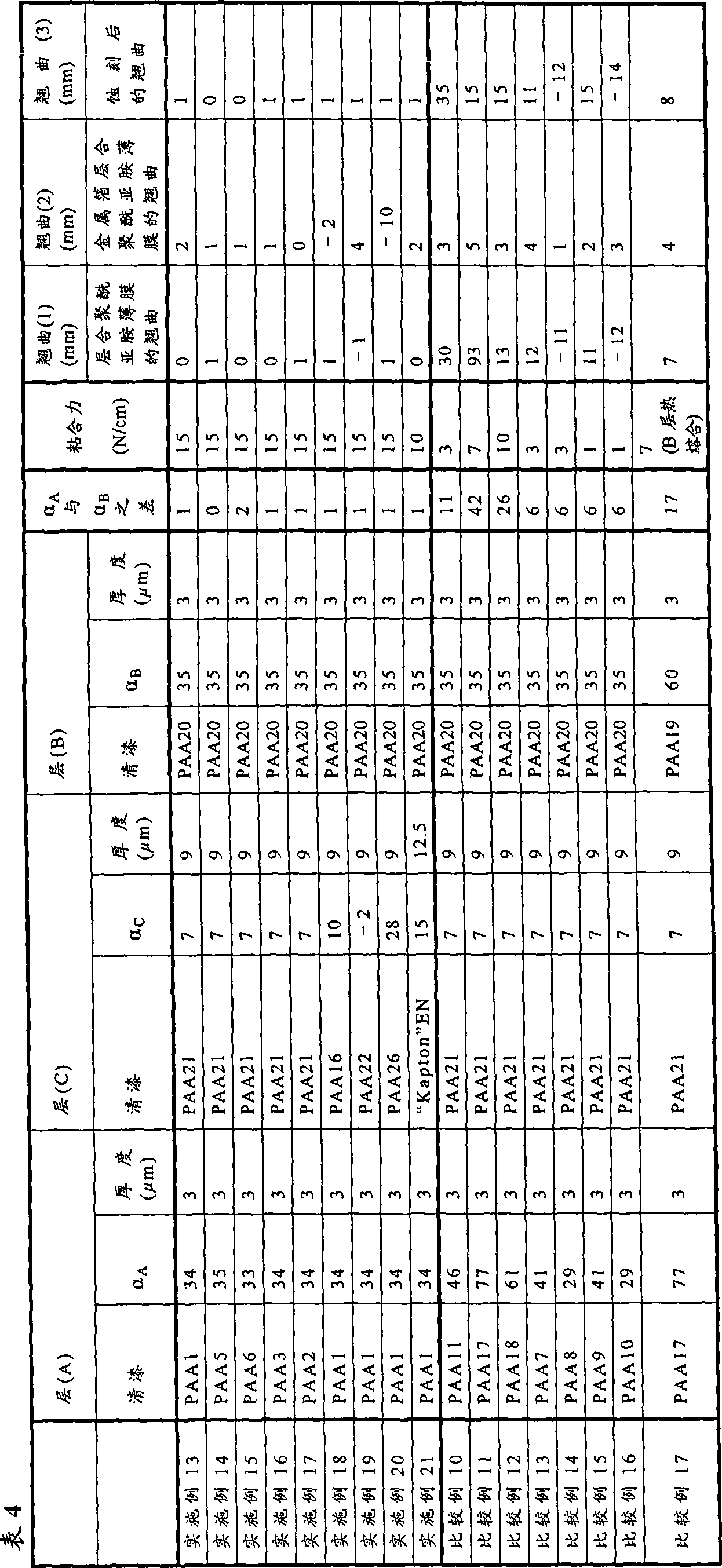

Binder resin composition for electrode, electrode mixture paste, and electrode

ActiveUS20120168688A1Small degree of swellingIncreased fracture energyHybrid capacitor electrodesElectrolytic capacitorsDiaminodiphenyl etherCarboxylic acid

The present invention relates to a binder resin composition for an electrode, including a polyamic acid and a solvent, wherein the polyamic acid is (i) a polyamic acid which includes a tetracarboxylic acid component including 10 to 100 mol % of 4,4′-oxydiphthalic acid and 90 to 0 mol % of 3,3′,4,4′-biphenyltetracarboxylic acid and / or pyromellitic acid and a diamine component including an aromatic diamine having 1 to 4 aromatic rings, (ii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 10 to 90 mol % of p-phenylene diamine and 90 to 10 mol % of 4,4′-diaminodiphenyl ether, or (iii) a polyamic acid which includes a tetracarboxylic acid component including 3,3′,4,4′-biphenyltetracarboxylic acid dianhydride and a diamine component including 40 mol % or more of a bis[4-(4-aminophenoxy)phenyl] compound.

Owner:UBE IND LTD

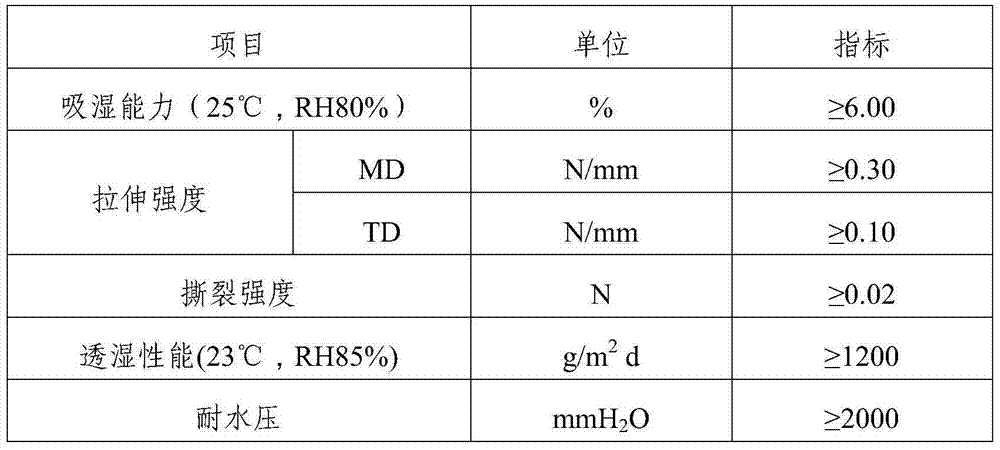

Water resistible and breathable plastic film with drying function as well as preparation method and application thereof

InactiveCN103571013AWith moisture absorption functionDoes not affect breathabilitySynthetic resin layered productsMetal layered productsSodium BentoniteMoisture absorption

The invention provides a water resistible and breathable plastic film with a drying function. The plastic film is prepared from the following raw materials in parts by weight: 40-80 parts of macromolecule plastic, 20-60 parts of an adsorbent and 1-5 parts of an auxiliary material, wherein the macromolecule plastic is at least one of polyethylene, polypropylene, thermoplastic elastomer and the like; the adsorbent is selected at least one of silica gel, montmorillonite, bentonite, molecular sieve, calcium carbonate, titanium dioxide and the like; the auxiliary material is selected from at least one of macromolecule wax, modified polyphthalamide, calcium stearate and the like. The plastic film adopts a plastic film (bidirectional or unidirectional) tension technique, and the adsorbent with the drying function is added into the raw material formula for manufacturing a water resistible and breathable film, so that a material has a certain moisture absorption function under the condition that the air permeability of the material is not affected.

Owner:昆山威胜干燥剂研发中心有限公司

Preparation method of polyether imide flexible printed circuit substrate material

A process for preparing the polyether imide material as the base material of flexible printed circuit includes such steps as polycondensation between triphenyldiether tetrabasic acid bianhydride, biphenyl tetrabasic acid bianhydride, p-phenyldiamine and 3,3'-dimethyl-4,4'-diaminobibenzene, synthesizing polyamide, varnish, coating it on copper foil and high-temp. imidating. Its advantages are low expansibility and no curling.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

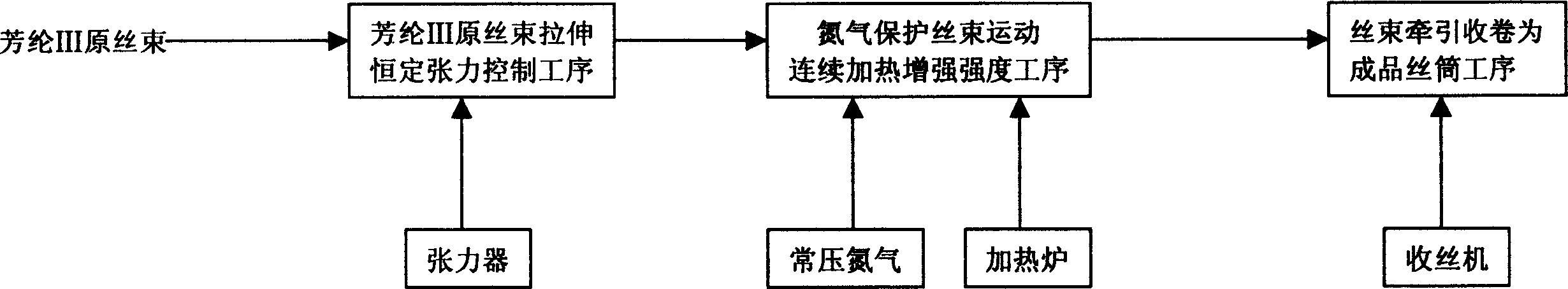

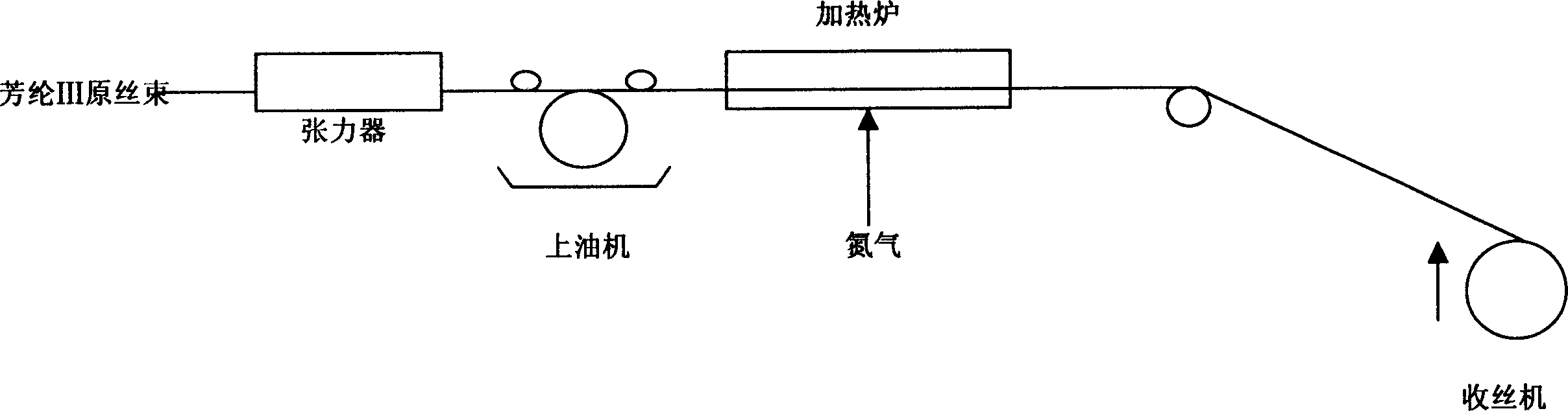

Post-treatment new process for aramid fibre III raw tow

InactiveCN1473969AGuaranteed uniformityImprove yieldArtificial filament heat treatmentMonocomponent polyamides artificial filamentNitrogen gasSolvent

The aramid III fiber as a new kind of high-strength material has wide application. Aramid III liquid is prepared with the materials including p-phenlenediamine, terephthalyl chloride and 5(6)-amino-2-(3-aminophenyl) benzimidazole and through low temperature copolymerization in dimethyl acetamide solvent; and is produced into aramid III fiber through serial spinning steps. The present invention provides the post-treatment technological process to raise the strength of aramid III fiber from 1.5 GPa to 4.5 GPa. The post-treatment process includes the treatment in the apparatus comprising tensioner, oiling machine, heating furnace and winding machine with the tension controlled in 0.2-1.0 CN / tex, temperature inside the nitrogen protected furnace 320-500 deg.c, and heating time 0.5-5 min. The raw tow is heated under motion inside the furnace homogeneously.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

Method for continuously preparing poly p phenylene diamine terephthalamide resin

The present invention discloses a method for continuously preparing poly(p-phenylene terephthalamide) resin, said method includes the following steps: (1). after the p-benzenediol powder is completely dissolved in the solvent containing cosolvent, adding P-benzenediol solid and terephthaloyl powder into extruder according to the ratio of 1:1-1.01; (2). feeding the solvent contaiing P-benzenediol and cosolvent into extruder adopting low-temperature medium cooling, its temperature is -20-5 deg.C, the residence time of reaction system in reactor is 2-25 min, polycondensation temp. is 30-90 deg.C, after the reaction is completed, extruding the above-mentioned material; and (3). making the extruded polymer body undergo the processes of standing still, washing, dewatering and drying so as to obtain light yellow polymer body powder.

Owner:DONGHUA UNIV

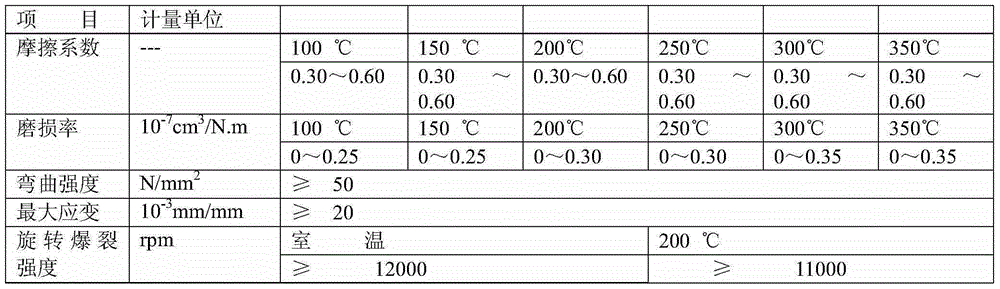

Poly-p-phenylene terephthamide composite fiber dry clutch facing and preparation method thereof

ActiveCN105114498AImprove mechanical propertiesLow production costOther chemical processesFriction liningBursting strengthFiber

The invention relates to the field of friction materials in automobile transmission structures, and discloses a poly-p-phenylene terephthamide composite fiber dry clutch facing which is prepared from the following substances: 30-70 parts of composite fibers, 15-40 parts of adhesive, 2-10 parts of rubber compound ingredients, 5-20 parts of a friction performance modifying agent, and 5-20 parts of fillers. The invention further discloses a preparation method of the poly-p-phenylene terephthamide composite fiber dry clutch facing. The preparation method comprises the following steps of (1) fiber compounding; (2) steeping and drying; (3) friction coil preparing; (4) hot press molding; (5) vulcanization heat treatment; (6) coarse grinding machining; (7) spot facing; (8) fine grinding machining; and (9) printing and marking, and packing. The poly-p-phenylene terephthamide composite fiber dry clutch facing prepared according to the preparation method has higher rotating burst strength, higher bending strength, a maximum strain value and excellent friction and wear performance and high temperature resistance. The preparation method of the poly-p-phenylene terephthamide composite fiber dry clutch facing is low in production cost, and can save 3-8 percent of raw materials effectively.

Owner:杭州科瑞特摩擦材料有限公司 +1

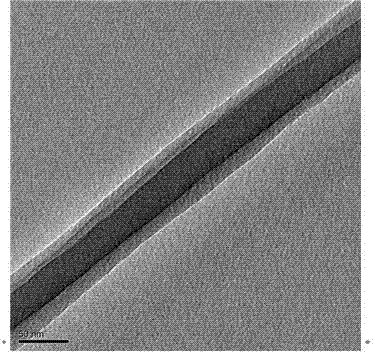

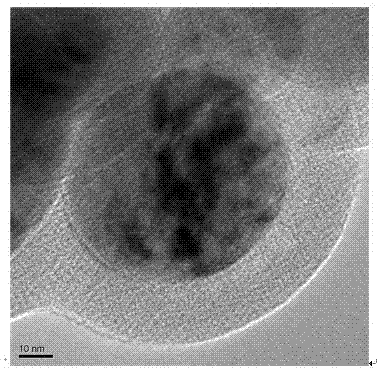

Surface modification method for lossless environment-friendly convenient aramid fiber material

The invention relates to a surface modification method for a lossless environment-friendly convenient aramid fiber material. The surface modification method comprises the following steps of: taking and placing a Tris-HCl buffer solution with the Ph of 0.7-10.8 in a flask, adding the aramid fiber material into the buffer solution for fully steeping, adding a dopamine hydrochloride modifying agent to the flask, reacting in an open environment under the magnetic stirring condition, and enabling the self-polymerization of the modifying agent to occur; washing and drying the reacted aramid fiber material to obtain the aramid fiber material with modified surface; and continuously steeping the modified aramid fiber material in the dopamine hydrochloride modifying agent solution to enable the self-polymerization of the aramid fiber material to occur, thereby obtaining the modified aramid fiber material with the activated surface and adjustable thickness. The aramid fiber material is a poly-p-phenylene terephthamide or polyisophthaloyl metaphenylene diamine long fiber, chopped fiber or powder. The concentration of the dopamine hydrochloride in the buffer solution is 0.05-2.0mg / ml. A poly-dopamine layer rich in catechol groups is formed on the surface of the modified aramid fiber material obtained by the method; and the modified aramid fiber material has excellent reaction activity and is adjustable in thickness.

Owner:WUHAN UNIV OF TECH

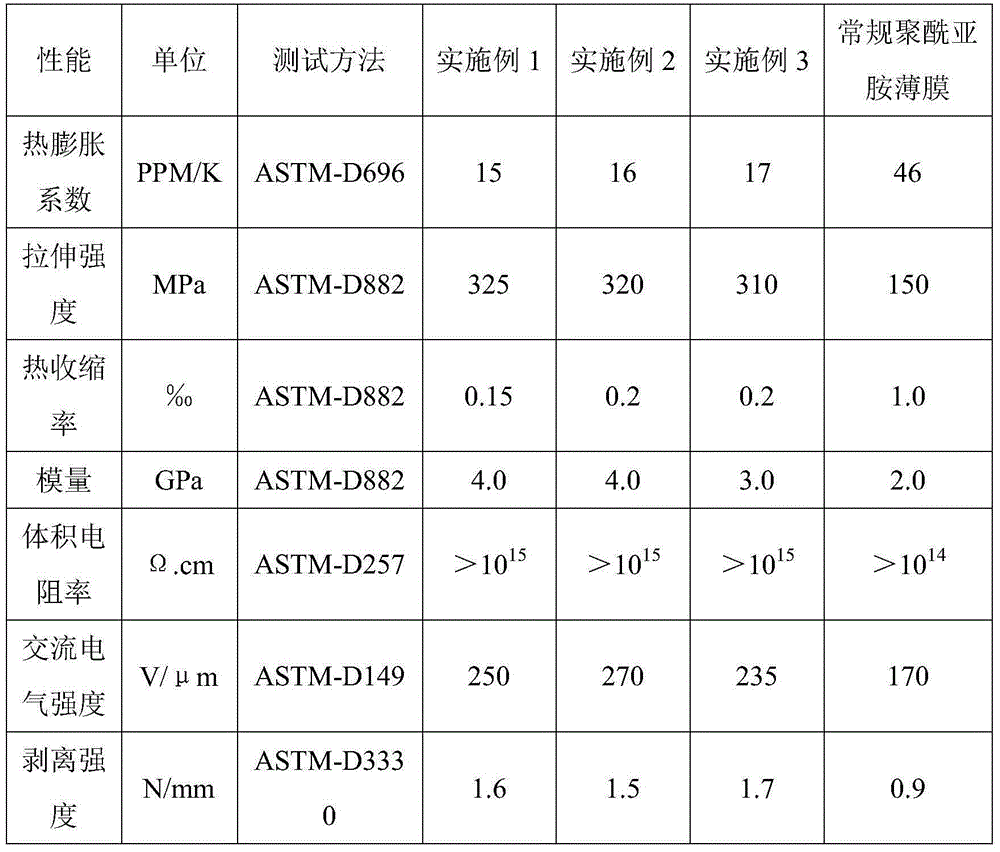

Preparation method for polymide film with low thermal expansion coefficient

The invention provides a preparation method for a polymide film with the low thermal expansion coefficient. The method comprises the following steps that 1, pyromellitic anhydride and ursol are placed into a dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution A; 2, 2, 3',3,4'- biphenyltetracarboxylic dianhydride and 4,4'-diaminodiphenyl ether are placed into the dimethylacetamide solvent for condensation polymerization to obtain a polyamide acid glue solution B; 3, the polyamide acid glue solution A and the polyamide acid glue solution B are mixed for a high-speed stirring reaction to obtain a polyamide acid glue solution C; 4, the tape casting technology is adopted on the polyamide acid glue solution C to obtain a film, and finally the film is fed into an imidization furnace to be processed to obtain the polymide film with the low thermal expansion coefficient. The CTE of the polymide film with the low thermal expansion coefficient is 15-17 ppm / K, and the polymide film further has the advantages of being high in strength, stability, electrical strength and the like.

Owner:安徽统唯新材料科技股份有限公司

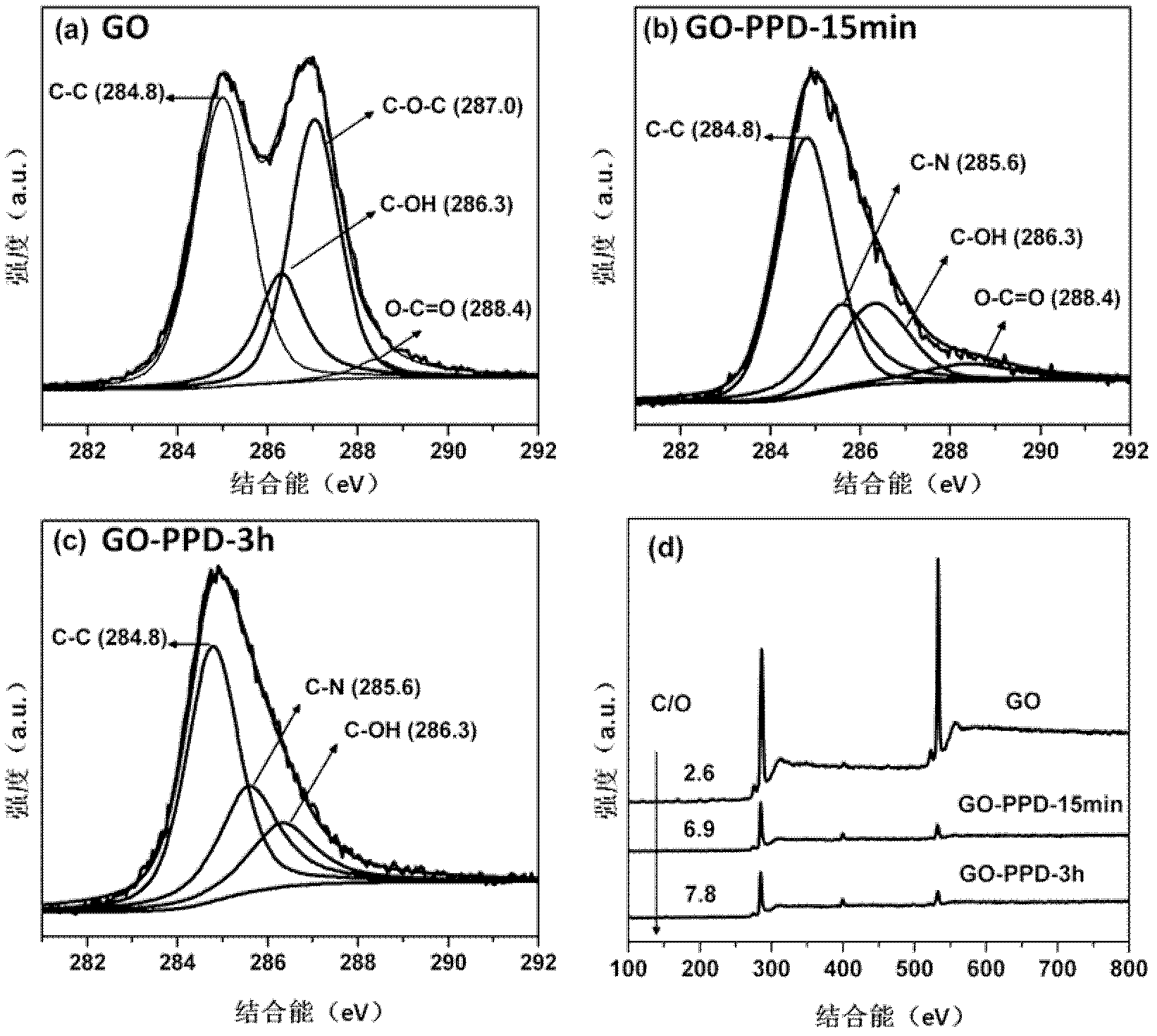

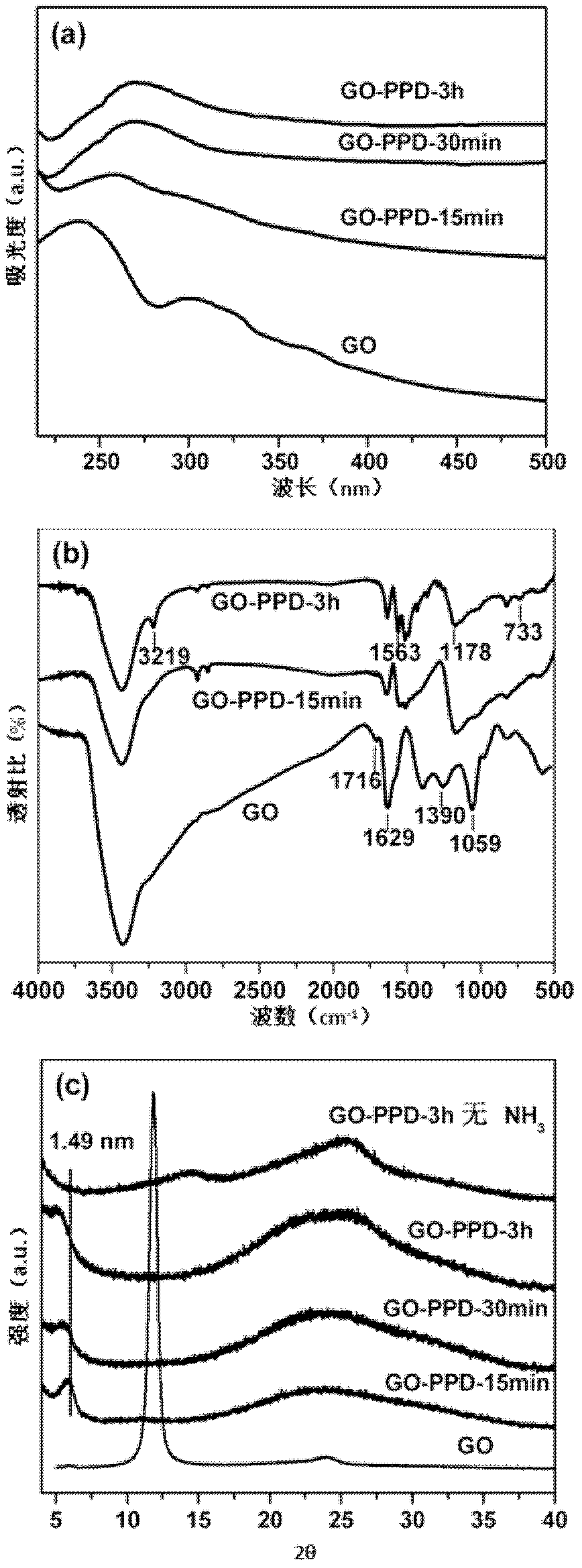

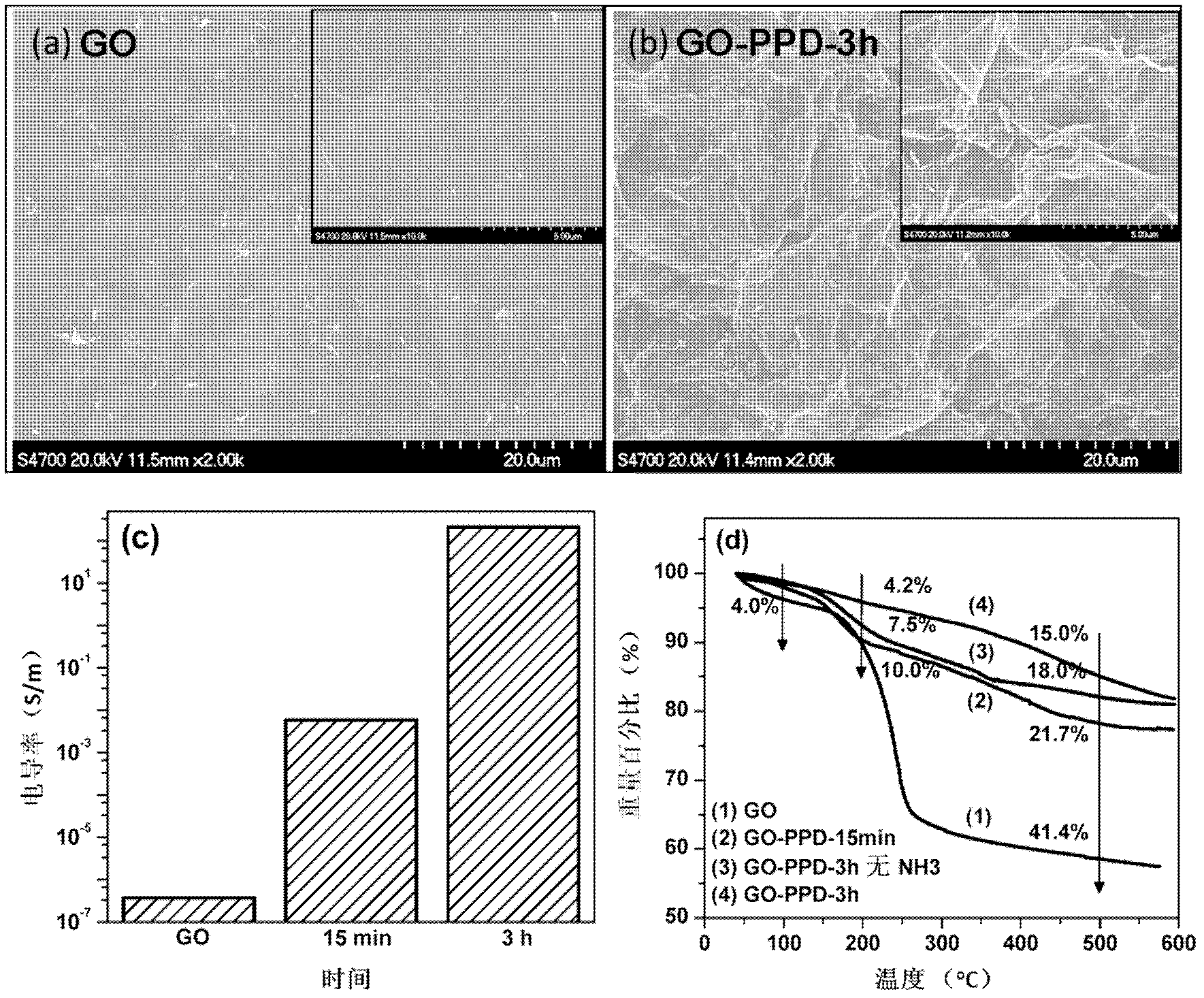

Method for reducing graphene oxide and preparing conductive nanometer composite material

InactiveCN102602915AAvoid harmImprove securityCarbon compoundsCable/conductor manufacturePolystyreneBis epoxide

The invention relates to a method for reducing graphene oxide and preparing a conductive nanometer composite material, and particularly relates to a simple and effective method for simultaneously functionalizing and reducing the graphene oxide. The functionalizing and reducing of the graphene oxide can be realized by simple reflux with para-phenylene diamine, and epoxy groups on the graphene oxide react with amidogroup of the para-phenylene diamine in ammonia solution. Electric conductivity of graphene oxide-para-phenylene diamine is increased to 2.1*10<2>S / m, which is increased about nine orders of magnitude compared with the electric conductivity of the graphene oxide. In addition, since the graphene oxide-para-phenylene diamine can be well dispersed in a polymer and be reduced, graphene oxide-para-phenylene diamine is added into the polystyrene, so that the electric conductivity of the polystyrene can be effectively improved; and a seepage threshold value of the composite material is low to 0.34vol%, so that a sharp change happens from insulation to conductivity. Compared with the polystyrene, the polystyrene / graphene oxide-para-phenylene diamine can be improved in the thermal stability by 8 DEG C.

Owner:BEIJING UNIV OF CHEM TECH

Method for synthesizing p-phenylene diisocyanate

InactiveCN1687022ANo pollution in the processNo toxicityIsocyanic acid derivatives preparationOrganic compound preparationRoom temperatureNitrogen gas

The present invention relates to a method for synthesizing p-phenylene diisocyanate. Said method includes the following steps: adding inert organic solution of di(trichloromethyl) carbonate into reaction flask, introducing nitrogen gas to make protection, under the condition of cooling slowly adding inert organic solution of p-phenylene diamine, making reaction for 2-4 hr, at 15-200 deg.C and 0-0.3 MPa, after the reaction is completed, removing solvent, filtering and washing so as to obtain solid product p-phenylene diisocyanate.

Owner:杭州崇舜化学有限公司

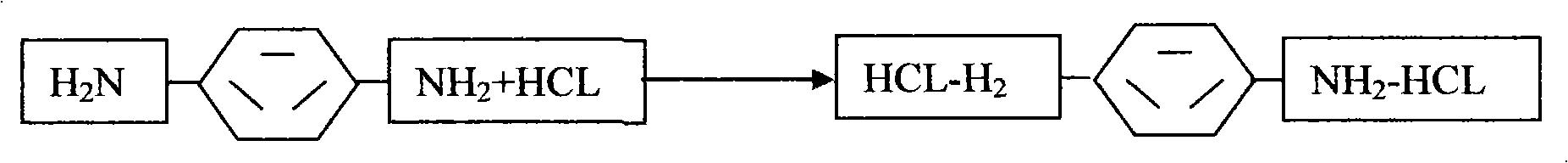

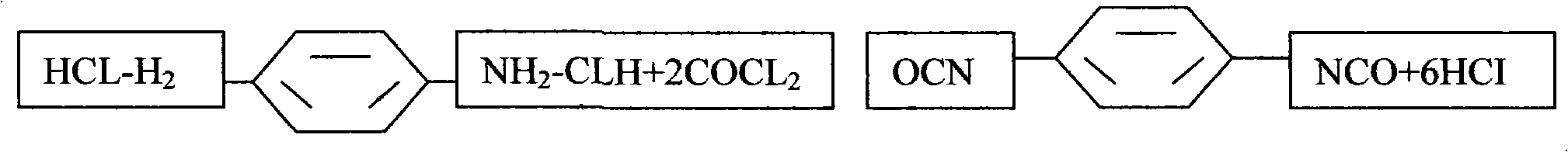

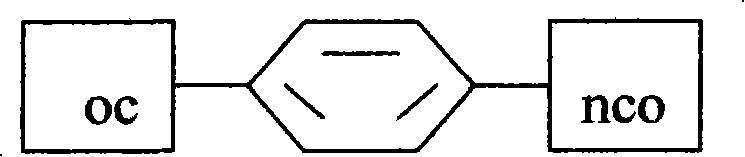

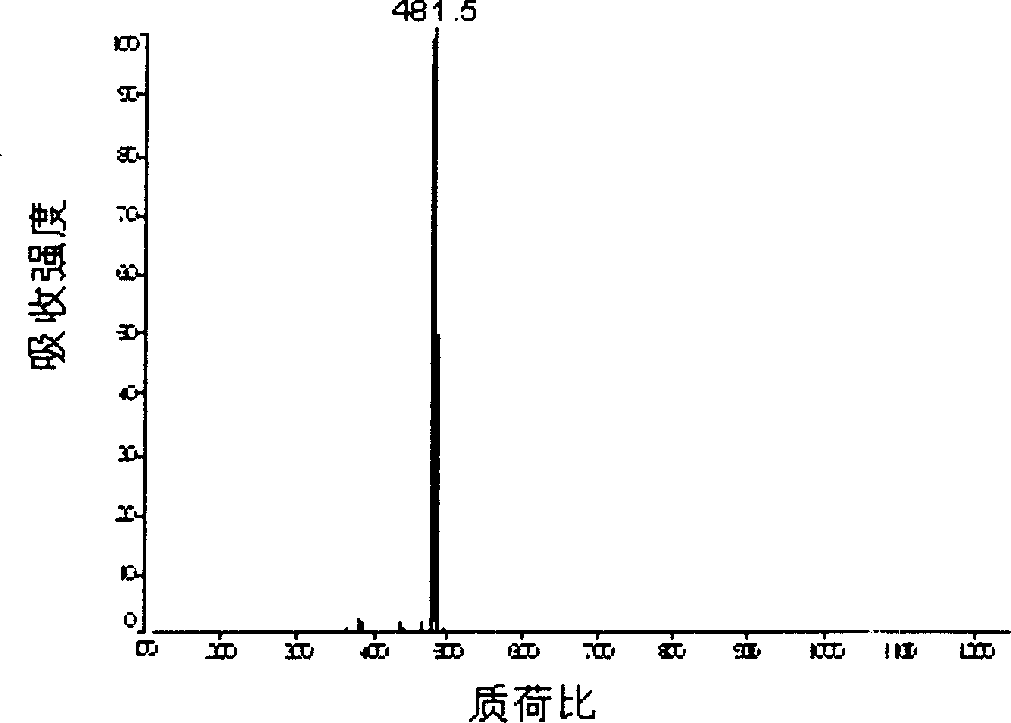

Novel process for preparing p-phenylene diisocyanate (PPDI) based on phosgene

InactiveCN101638372AEmission reductionIsocyanic acid derivatives preparationOrganic compound preparationPhosgeneRaw material

The invention provides a novel process for preparing p-phenylene diisocyanate (PPDI) based on phosgene, which relates to a process for preparing chemical raw materials, in particular to a novel process for preparing the p-phenylene diisocyanate (PPDI). The process comprises the following steps: 1, hydrochloric acid formation reaction; 2, salifying reaction; and 3, photochemical reaction which is to transfer a mixture solution of para-phenylene diamine dihydrochloride-o-dichlorohenzene to a photochemical kettle, control the temperature, introduce the phosgene in an infinite reflux state to react, determine that the reaction is terminated after reaction materials are settled, introduce quantitative nitrogen to remove acid, sample and analyze the reactant, and obtain the p-phenylene diisocyanate PPDI through rectifying, crystallizing, centrifugating, drying, packaging or refining, slicing and packaging when the acidity content is qualified. In the process, a reasonable salifying reactioncondition is customized to avoid slow reaction of a prepolymer, complicated reaction mechanism, and easy generation of side products and adverse factors influencing the reaction in the next step.

Owner:XINYI AGRI CHEM PLANT JIANGSU PROV

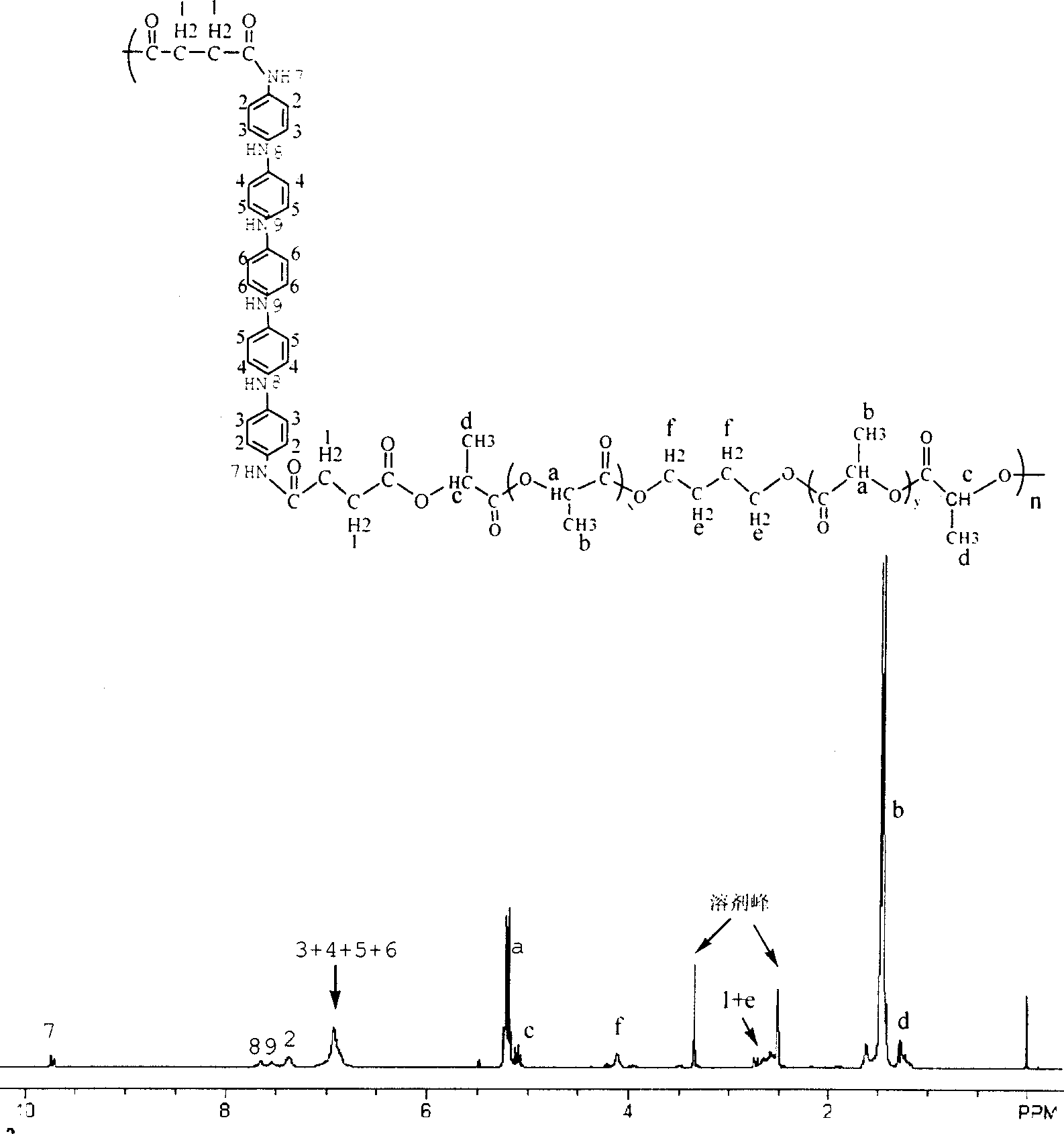

Aniline oligomer, its aliphatic polyester copolymer and their prepn

InactiveCN1887854AImprove electrical activityGood biocompatibilityAmino compound preparation by condensation/addition reactionsPolyesterPentamer

The present invention provides aniline oligomers, their aliphatic polyester copolymer and their preparation. Two kinds of aniline oligomers are first synthesized with N-phenyl-1, 4-p-phenylene diamine as material, and then copolymerized with aliphatic polyester to obtain electrically active biodegradable polymers. During the preparation, N-phenyl-1, 4-p-phenylene diamine has its end amido group protected with butanedioic anhydride and is then reacted with end amido aniline dimer and phenylene diamine to obtain aniline tetramer with one end carboxyl group and one end amino group and aniline pentamer with two end carboxyl groups; and the aniline oligomers are finally polycondensated with double hydroxyl group terminated aliphatic polyester to obtain the copolymers containing electrically active aniline oligomer block. The copolymers possess the advantages of both aniline oligomer and aliphatic polyester, and is used as biomedicine material mainly.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

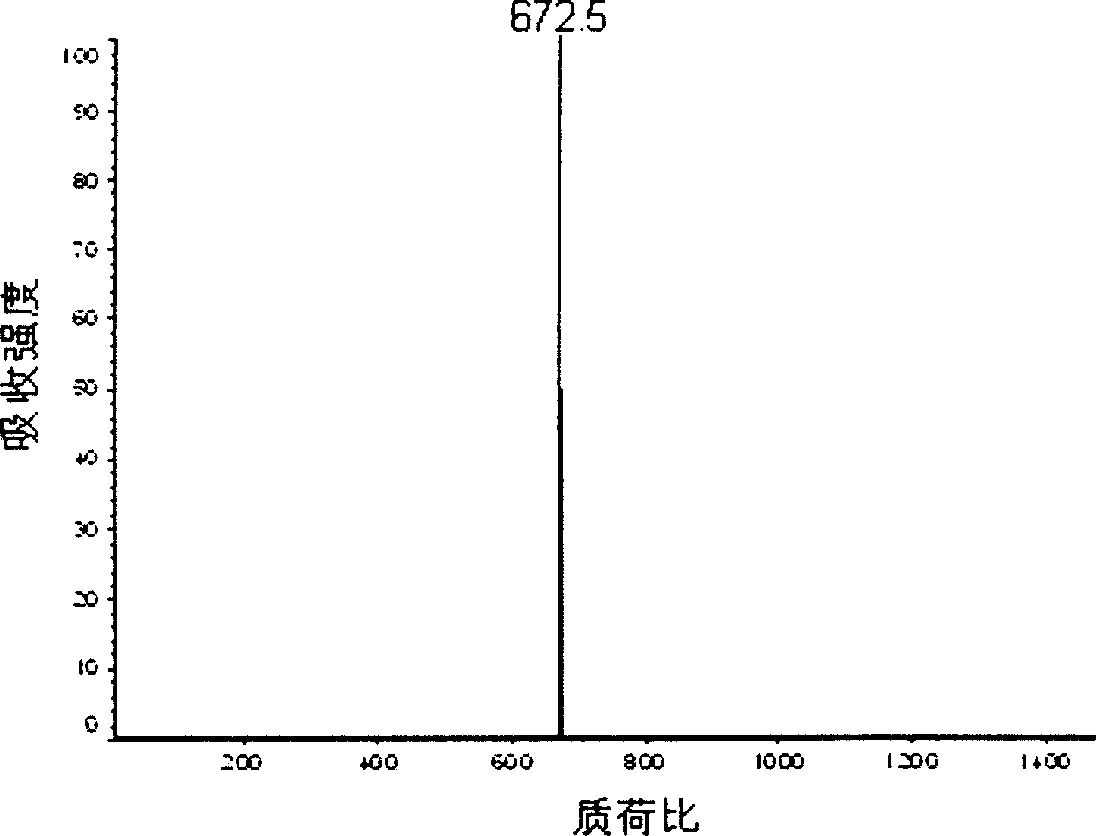

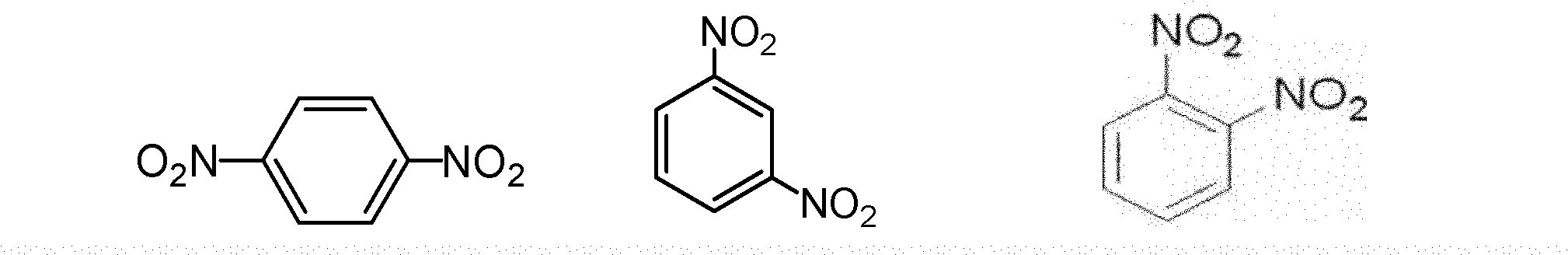

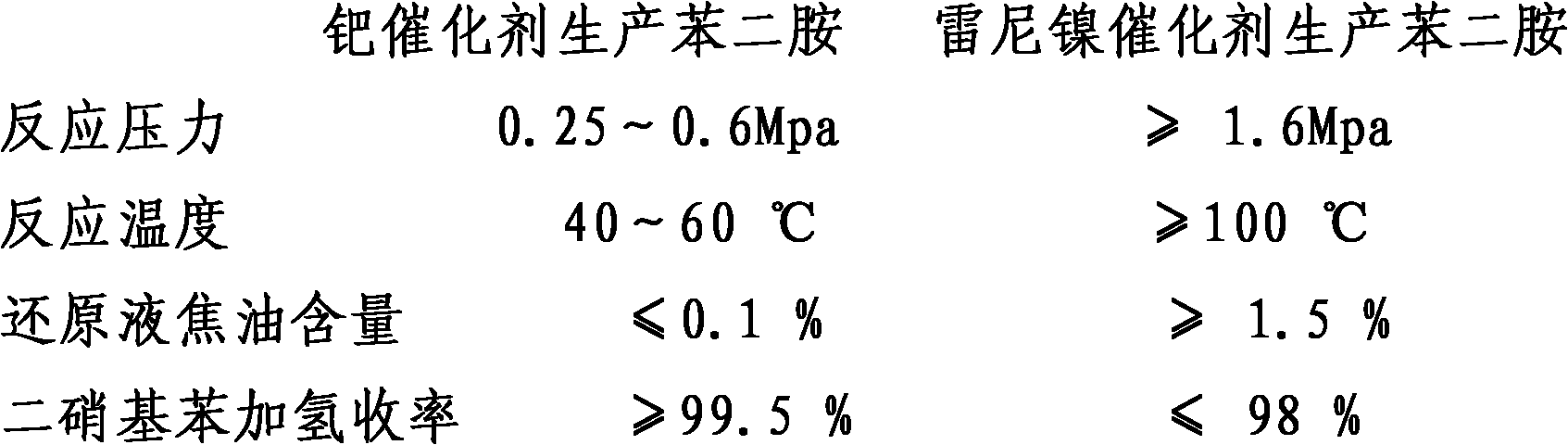

Method for producing phenylene diamine by performing hydrogenation reduction on mixed dinitrobenzene with palladium catalyst

ActiveCN102070464AReduce consumptionImprove product qualityOrganic compound preparationAmino compound preparationHigh energyPalladium catalyst

The invention belongs to a method for producing phenylene diamine, in particular to the method for producing the phenylene diamine by performing hydrogenation reduction on mixed dinitrobenzene with palladium catalyst. The prior art which produces the phenylene diamine by performing the hydrogenation reduction by adopting a Raney nickel or carrier nickel catalyst has the disadvantages of high energy consumption, low raw material conversion rate, and poor product quality. The method comprises the following steps of: adding 100 weight parts of dinitrobenzene, 100 to 200 weight parts of alcohols solvents and 0.5 to 1 weight part of the palladium catalyst into a reaction kettle, wherein the temperature in the reaction kettle is between 40 and 60 DEG C and the pressure is between 0.25 and 0.60 MPa; performing hydrogenation for 30 to 120 minutes; conveying a reaction product to a filter; dealcoholizing in a dealcoholization tower for recovering to obtain phenylene diamine solution; and obtaining m-phenylenediamine, o-phenylenediamine and p-phenylenediamine products by dewatering, rectifying and separating. The method has the advantages of improving product quality, reducing raw material consumption and reducing production cost.

Owner:上海鸿源鑫创材料科技有限公司 +1

Signal amplification type immunofluorescence probe as well as preparation method and application thereof

InactiveCN102565383AEasy to operateWith quantitative detection functionFluorescence/phosphorescenceBiotin-streptavidin complexImmunofluorescence

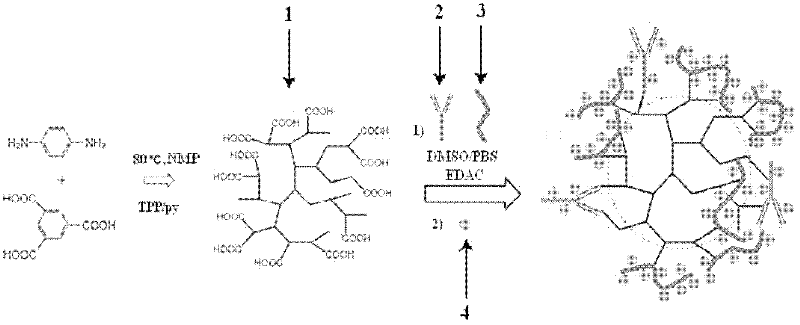

The invention discloses a signal amplification type immunofluorescence probe as well as a preparation method and application thereof. The preparation method of the probe includes the steps as follows: carrying out condensation reaction of phenylene diamine and trimesic acid to obtain poly-carboxylic macromolecules under the premise that condensing agent exists; and activating the poly-carboxylic macromolecules, and adding an antibody, polylysine sequentially for reaction; labeling the prepared probe through fluorescence label objects. Or the preparation method of the probe includes the steps as follows: adding the antibody and the polylysine in a biotin solution sequentially for reaction, so as to obtain the corresponding compound; labeling the compound through the fluorescence label objects; and mixing the antibody-biotin compound labeled by fluorescence and a streptavidin solution for reaction, so as to obtain the probe. The probe prepared through adopting the method is labeled by more fluorescence label objects, has a stable structure and is easy to store, can be used for fluorescence immune detection, and has the characteristics of high detection sensitivity, short detection time, low cost and the like.

Owner:吴坚

Method of continuously preparing poly terephthaloyl-p-phenylene diamine fibre

InactiveCN1693543AShort defoaming timeImprove mixing uniformityFilament-forming treatmentMonocomponent polyolefin artificial filamentFiberViscosity

The invention discloses a method for continuously preparing p-phenylene terephthalamide (PPTA) fiber, including the steps of: (1) continuously adding 98-100% oil of vitriol and PPTA with specific logarithmic viscosity of 4.0-8.5 dl / g to an double spiral extruder, where the weight percent of PPTA is 14-24% and the mixing temperature is 50-100 deg.C; (2) fully mixing and entering in the other extruder, where the adjusting temperature is 50-100 deg.C and the staying time is 10-60 min, fully mixing, adjusting temperature and defoaming and then extruding them; (3) after measuring and filtering spinning solution, obtaining the invention by the routine steps, such as dry spraying-wet spinning. The advantages are short time for mixing materials, adjusting temperature and defoaming high mixing uniformity of materials able to implement continuous, stable filature in a short time, raising the production efficiency.

Owner:DONGHUA UNIV

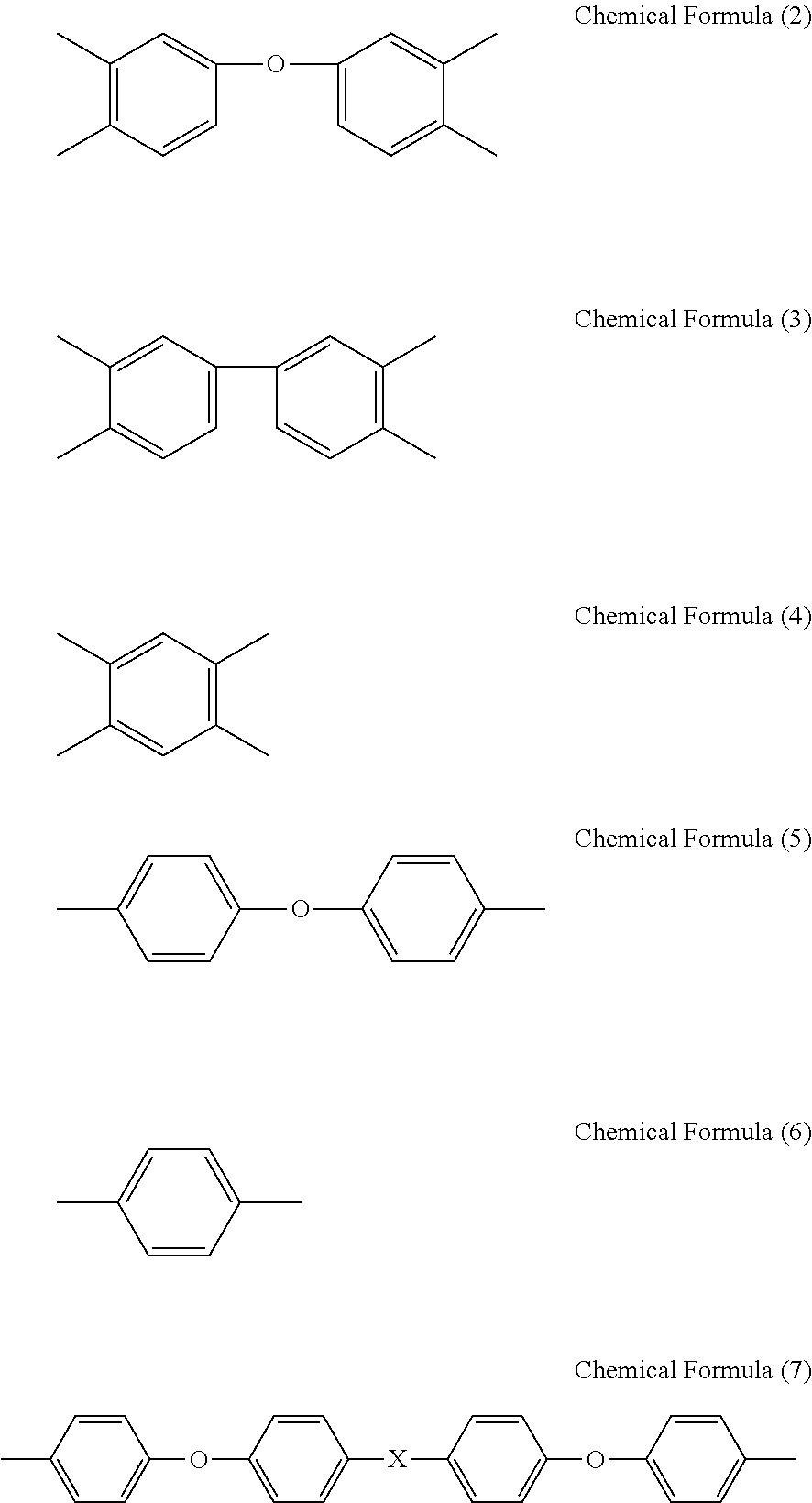

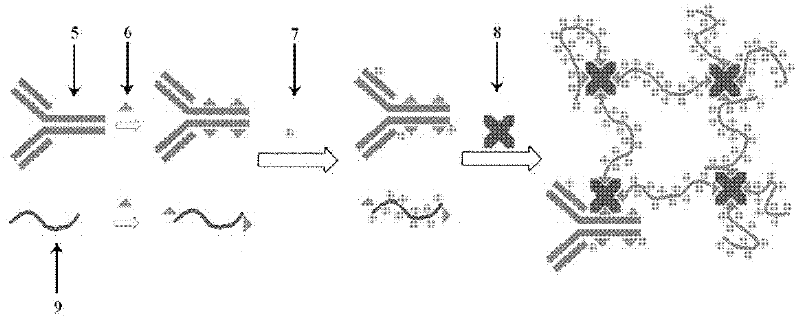

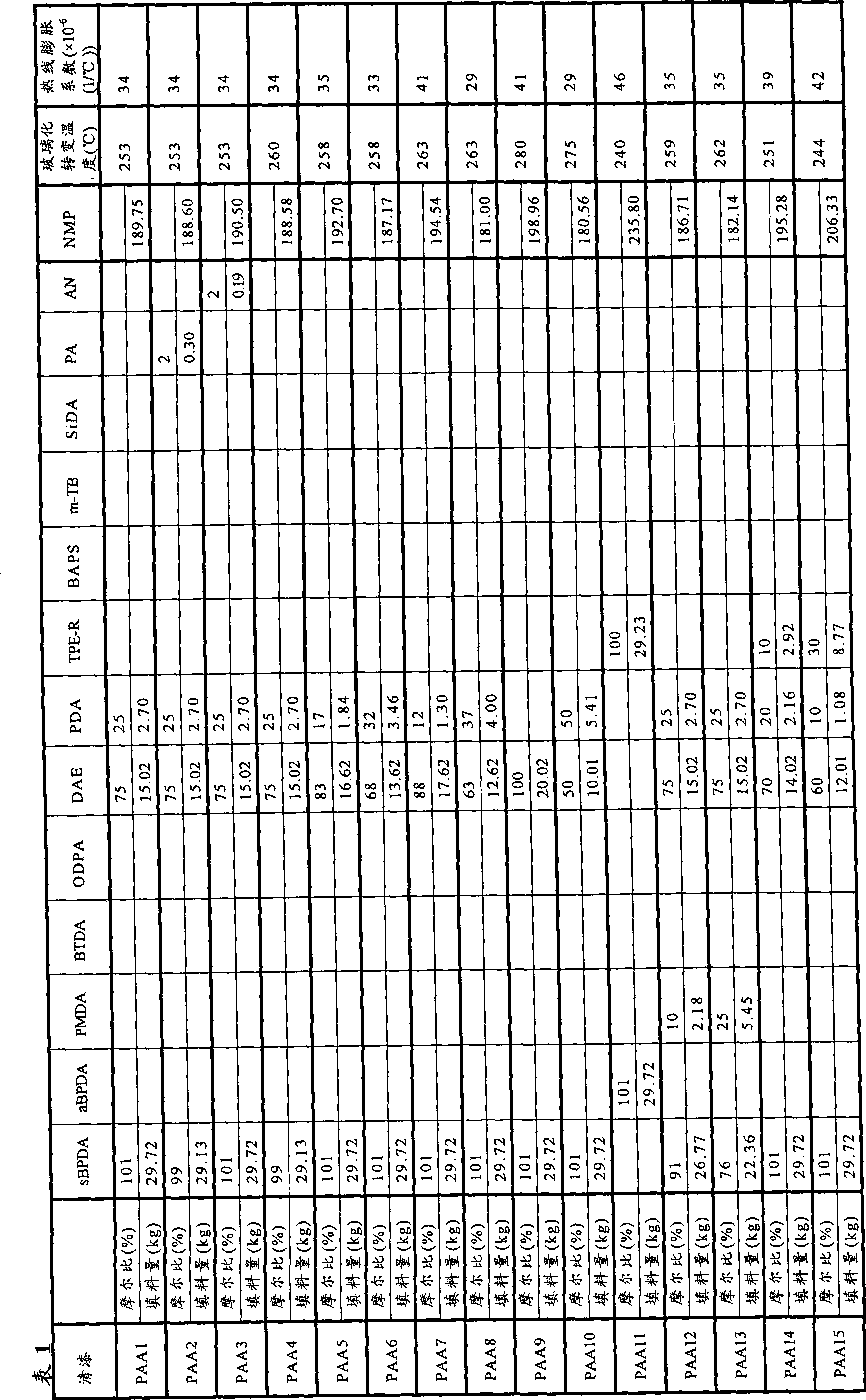

Thermoplastic polyimide, and laminated polyimide film and metal foil-laminated polyimide film using the thermoplastic polyimide

InactiveCN101484500AHigh elongation at breakSynthetic resin layered productsMetal layered productsDiaminodiphenyl etherMetal foil

Disclosed is a thermoplastic polyimide which has excellent heat resistance and can adhere to a metal foil by thermocompression bonding for a short-time. The thermoplastic polyimide comprising a tetracarboxylic dianhydride residue and a diamine residue wherein the biphenyl tetracarboxylic dianhydride residues account for 80 mol% or more of the total tetracarboxylic dianhydride residues, the 4,4'-diaminodiphenyl ether residues for 65 mol% or more and 85 mol% or less of the total diamine residues, and the paraphenylene diamine residues for 15 mol% or more and 35 mol% or less of the total diamine residues.

Owner:TORAY IND INC

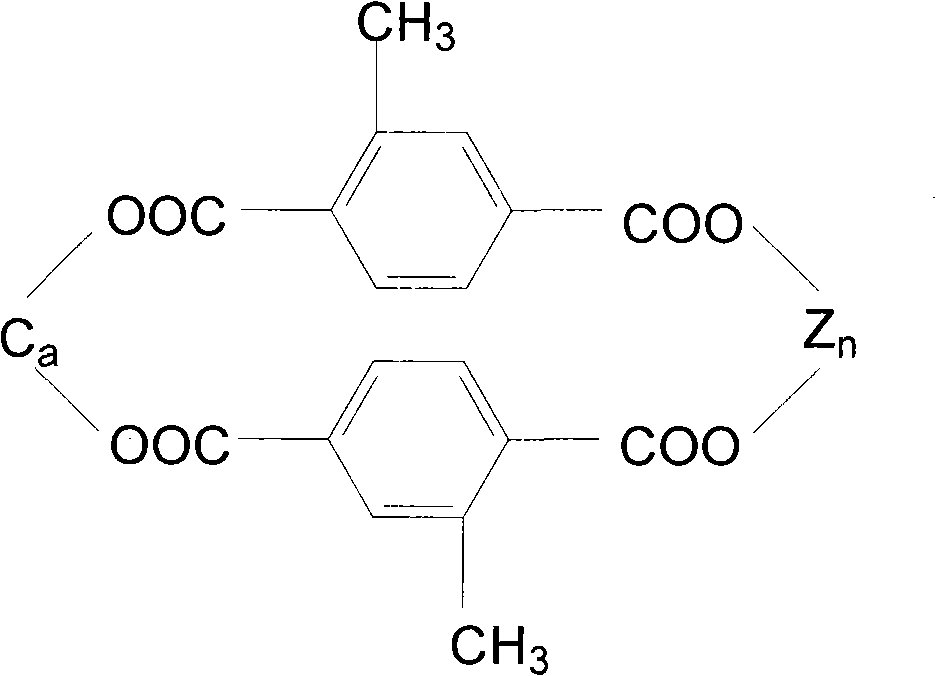

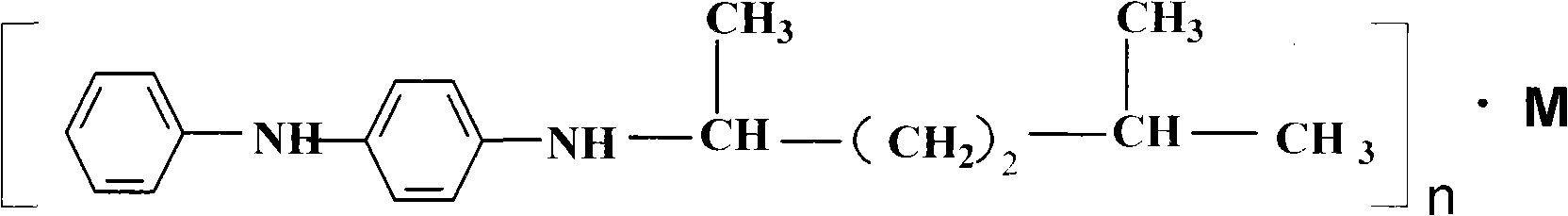

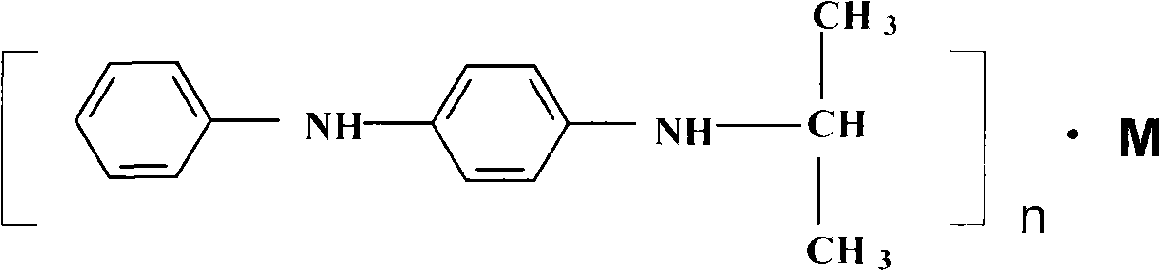

Rubber antiager and method for preparing same

ActiveCN101333304AImprove aging resistanceImproved discoloration migration propertiesZinc organic compoundsAntioxidantAging resistance

The invention discloses a rubber antioxidant and a preparation method thereof. The rubber antioxidant is prepared through the complex reaction of para-phenylene diamine antioxidant and autunite-zinc polymethyl terephthalate; wherein the weight ratio of para-phenylene diamine antioxidant to autunite-zinc polymethyl terephthalate is 2:1-3:1. The preparation method includes the following steps: 1)dissolving para-phenylene diamine antioxidant in acetone solution based on weight ratio of 1:1-1.5:1, producing a mixture solution; 2)adding autunite-zinc polymethyl terephthalate aqueous solution and hyamine catalyzer at the same time into a reactor and blending the two; 3)introducing high temperature steam to the jacket of the reactor and when the temperature reaches 110-120 DEG C, adding the mixture ssolution prepared in step 1); 4) conducting complex reaction for 1.5-3h when the material is at infinite reflux state and finally distilling and recovering the acetone. The rubber antioxidant is of excellent ageing resistance and is free from problems of serious color deterioration, fusion and agglomeration.

Owner:常州市五洲化工有限公司

Thermoplastic polyimide, and laminated polyimide film and metal foil-laminated polyimide film using the thermoplastic polyimide

InactiveUS20090252957A1High elongationLower glass transition temperatureSynthetic resin layered productsFlat articlesDiaminodiphenyl etherMetal foil

Disclosed is a thermoplastic polyimide which has excellent heat resistance and can adhere to a metal foil by thermocompression bonding for a short-time. The thermoplastic polyimide comprising a tetracarboxylic dianhydride residue and a diamine residue wherein the biphenyl tetracarboxylic dianhydride residues account for 80 mol % or more of the total tetracarboxylic dianhydride residues, the 4,4′-diaminodiphenyl ether residues for 65 mol % or more and 85 mol % or less of the total diamine residues, and the paraphenylene diamine residues for 15 mol % or more and 35 mol % or less of the total diamine residues.

Owner:TORAY IND INC

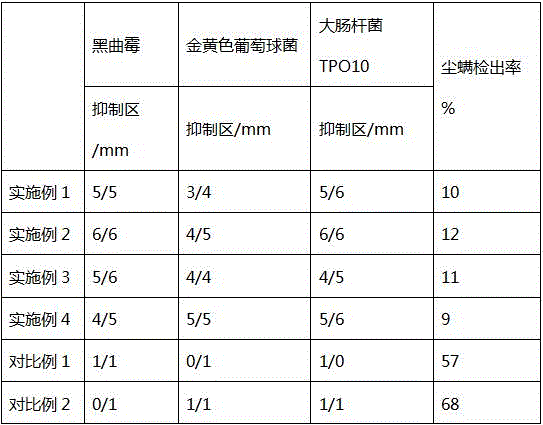

Antifungal anti-mite textile material and preparation method thereof

InactiveCN105696325ASave raw materialsSimple processBiochemical fibre treatmentVegetal fibresPolyesterPolymer science

The invention discloses an antifungal anti-mite textile material. The antifungal anti-mite textile material comprises, by weight, 20-40 parts of polyester fiber, 20-40 parts of polyester fiber, 15-35 parts of nylon fiber, 15-35 parts of natural bamboo fiber, 15-35 parts of polylactic acid fiber, 15-30 parts of cellulose acetate, 25-45 parts of kapok, 15-25 parts of cotton, 15-25 parts of sisal hemp, 15-25 parts of flax, 10-25 parts of chitin, 5-15 parts of azadirachtin, 5-10 parts of chloroacetic acid, 2-5 parts of p-phenylenediamine, 2-5 parts of bis-hydroxypropyl polydimethylsiloxane ester, 2-5 parts of phosphoric acid monoisotridecyl ester, 5-10 parts of dispersing agent, 5-10 parts of sizing agent and 5-10 parts of adhesive. The antifungal anti-mite textile material can have excellent antifungal and anti-mite effects. The invention further discloses a preparation method of the antifungal anti-mite textile material.

Owner:WUJIANG LINWANG WEAVING MILL

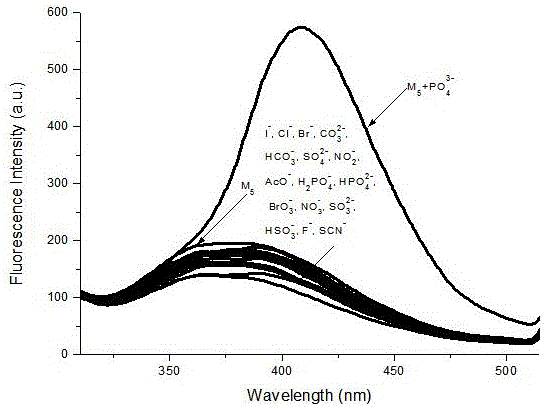

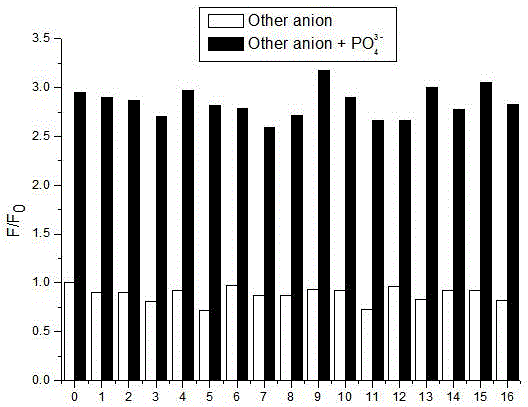

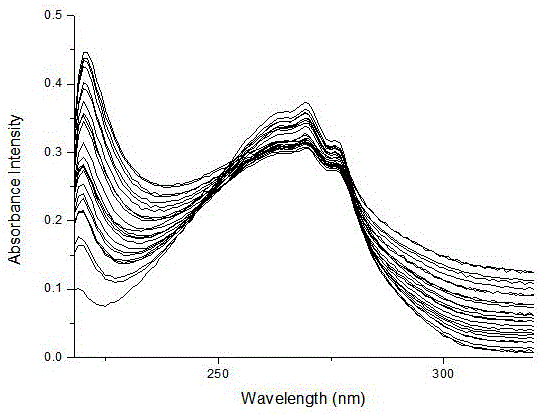

Benzimidazole derivative phosphate anion fluorescence probe synthesis and application method

ActiveCN106349167ASimple detection operationSimple and convenient detection operationOrganic chemistryFluorescence/phosphorescenceBenzimidazole derivativePhosphate ion

The invention discloses a method for synthesis of a benzimidazole derivative phosphate anion fluorescence probe and an application method thereof, and relates to the field of synthesis and application of the fluorescence probe. The synthesis of the benzimidazole derivative phosphate anion fluorescence probe can solve the problem that the florescence probes used for detecting PO43- are very scarce in kinds, that the identification of PO43- can be easily influenced by H2PO4- and HPO42-, and that the florescence probes can not directly carry out identification independently. The Benzimidazole derivative phosphate anion fluorescence probe is 1,4 phenyl double (carbamoyl methyl) N e alkylbenzimidazole ammonium chloride], which is obtained under quaterisation between Dichloro acetyl para-phenylene diamine and N-E alkyl benzene and imidazole. The fluorescence probe dissolves in HEPES buffered solution prepared by deionized water, and then test change in the absorbance value and fluorescence intensity to adjust the existence of PO43-. The Benzimidazole derivative phosphate anion fluorescence probe can be used to directly detect the po43- in water and blood.

Owner:QIQIHAR UNIVERSITY

Method of manufacturing thermoplastic olefine polymer modified asphalt having good stability

InactiveCN1429880AMeet layingFulfil requirementsVertical chamber coke ovensBuilding insulationsPolymer sciencePolymer modified

A process for preparing high-stability modified asphalt features that the asphalt is modified by thermoplastic olefine polymer (SBS) or unsulfurized rubber (SBR) while a composite stabilizer is added, which is prepared from arylhydrocarbon concentration regulator, zinc oxide, S,N-substituted 2-benzothiazole sulfenamide, zinc dithioaminoformate, and p-phenyldiamine.

Owner:重庆美仑道路沥青工程有限公司

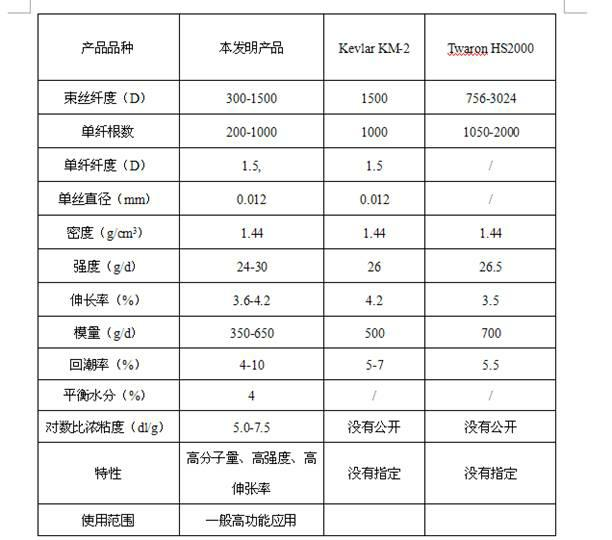

High-intensity poly(terephthaloyl-p-phenylene diamine) (PPTA) fiber and preparation method thereof

InactiveCN102154727ALow cost of industrializationImprove efficiencyFilament/thread formingMonocomponent polyamides artificial filamentFiberPolymer science

The invention discloses a high-intensity poly(terephthaloyl-p-phenylene diamine) (PPTA) fiber. The fiber is prepared by performing special treatment on a PPTA polymer, which has the logarithmic viscosity of 5.5-8.0 dL / g and serves as a raw material, in the dry-jet wet spinning process. The specific indexes of the PPTA fiber are that: the bundle fineness is 300-3,000 D, the intensity is 24-30 g / D, the elongation percentage is 3.6-4.2 percent, the modulus is 350-650 g / D, the water content is 4-10 percent, and the logarithmic viscosity is 5.0-7.5 dL / g. In the dry-jet wet spinning process, the spinning speed is controlled at 100-500 m / min, and the diameter of a spinning hole is less than or equal to 0.05 millimeter, so that a PPTA fiber product with ultrahigh intensity and elongation percentage is obtained. The product has high impact resistance and bullet resistance, and is relatively suitable for military bullet resistance; and the blank in corresponding aspect in China is filled up.

Owner:BLUESTAR CHENGDU NEW MATERIALS

Method for purifying N-methyl pyrrolidone

InactiveCN102993078AEfficient removalMeeting high-purity demandsOrganic chemistryInorganic saltsDistillation

The invention relates to a method for purifying N-methyl pyrrolidone. The method comprises the steps of (1) washing poly-p-phenylene terephthamide polymers obtained after the polycondensation through deionized water repeatedly to obtain washing liquor containing the N-methyl pyrrolidone (NMP), adding antalkali into the washing liquor to perform neutralizing treatment, and regulating PH of the solution to 6-7; (2) performing extraction separation on the washing liquor to obtain solution with an NMP-extraction agent system on the lower layer and a water-inorganic salt system on the upper layer, and performing secondary extraction on the water-inorganic salt system on the upper layer; and (3) adding an organic solution with an isocyanic acid functional group into a crude product of the NMP, and performing filtering and distillation to obtain the high-purity NMP. By means of the method, the purity of the finally-obtained NMP solvent is remarkably improved, processing procedures are simplified, accordingly, working efficiency is improved, and operability is strong. Furthermore, the purity of the NMP solvent obtained by means of purifying is higher than 99.8%, and the water content of the NMP solvent is smaller than 0.01%.

Owner:DONGHUA UNIV +1

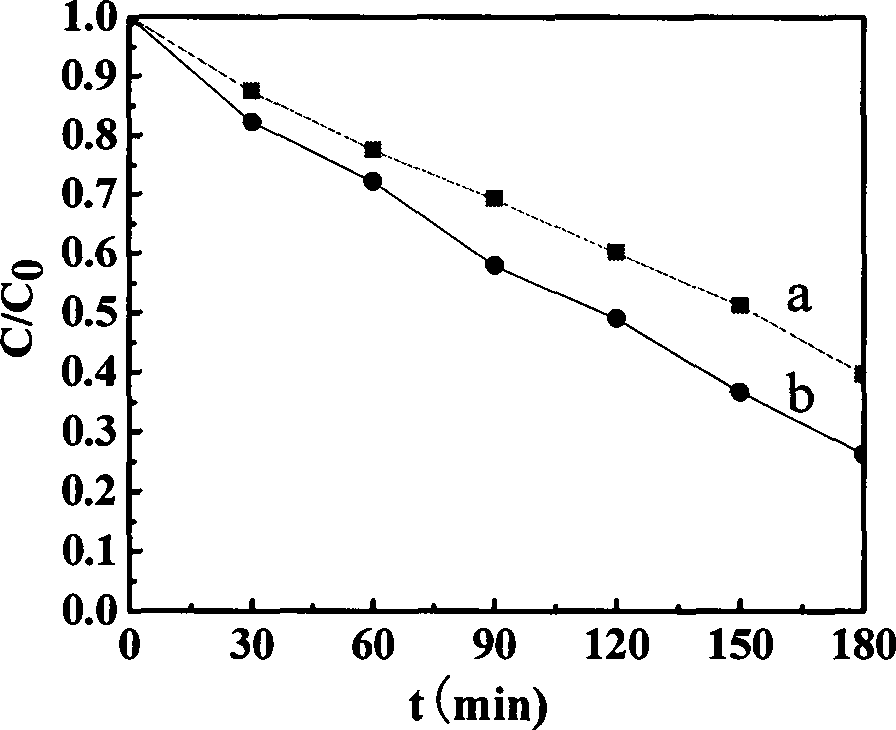

Method for preparing molecular imprinting-doped TiO2 with high catalytic degradation activity under visible light

InactiveCN103611520AIncrease profitImprove adsorption capacityPhysical/chemical process catalystsWater/sewage treatment by irradiationS dopingCompound (substance)

The invention relates to a method for preparing molecular imprinting-doped TiO2 with high catalytic degradation activity under visible light and belongs to the technical field of preparation of photocatalysts. The method comprises the following steps: synthesizing S-doped TiO2 by taking TiCl4 as a titanium source by a hydrothermal method; and performing chemical oxidative polymerization by taking phenylenediamine as a monomer and a crosslinking agent and organic pollutants as template molecules to synthesize the molecular imprinting-doped TiO2. Compared with the S-doped TiO2, the synthesized molecular imprinting-doped TiO2 has stronger adsorption capability on the organic pollutants and higher catalytic degradation activity on the organic pollutants under the visible light, improves the catalytic degradation capability by 30%, and has a high actual application value.

Owner:JIANGNAN UNIV

Lithium battery composite diaphragm coated with hybrid aramid fibers and preparation method of lithium battery composite diaphragm

InactiveCN109935760AReduce sensitivityEasy to storeLi-accumulatorsCell component detailsSlurryAramid

The invention discloses a lithium battery composite diaphragm coated with hybrid aramid fibers and a preparation method of the lithium battery composite diaphragm. One side or two sides of the batterydiaphragm are coated with the hybrid aramid fibers, and the hybrid aramid fiber coating is formed by the coating slurry containing hybrid aramid fibers. The hybrid aramid fibers are fibers made of one or two of poly (p-phenylene Isophthalamide) and poly-m-phenylene terephthalamide. The aramid fibers are employed for forming the hybrid aramid fiber coating, and the hybrid aramid fibers are low insensitivity to water, are not liable to separate out and are easy to store, so that the water tolerance of the aramid fiber slurry is greatly improved, the storage cost of the aramid fiber coating slurry and the requirements on coating equipment are reduced. The lithium battery diaphragm is suitable for industrial production.

Owner:CHONGQING YUNTIANHUA NEWMI-TECH CO LTD

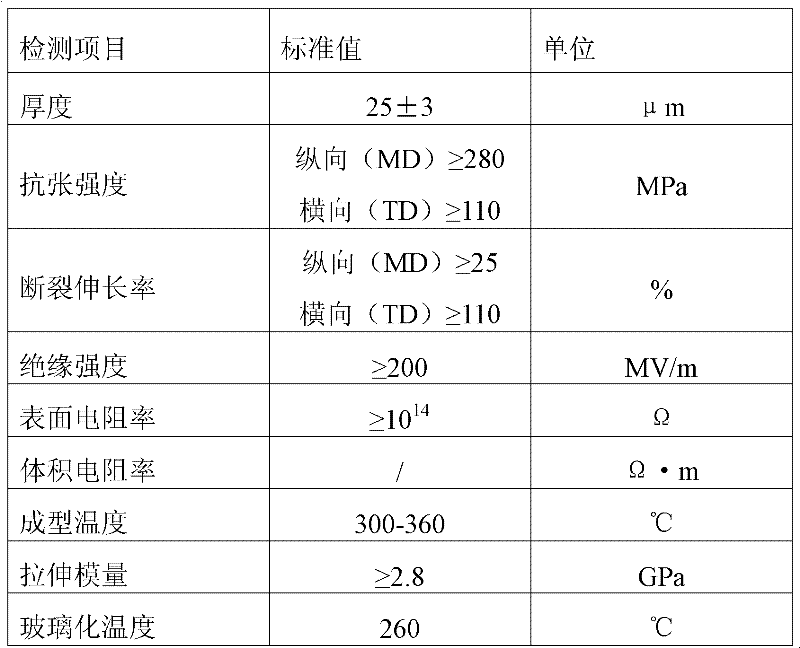

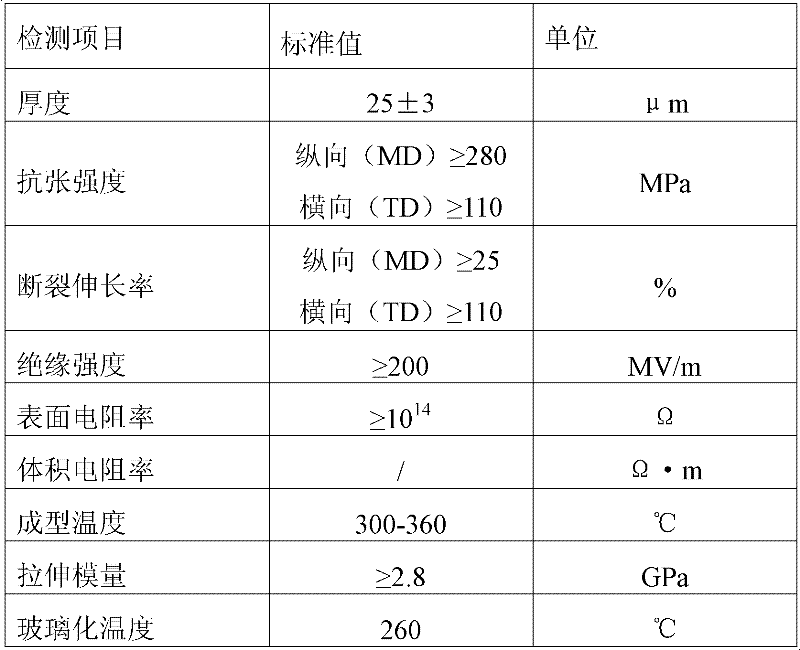

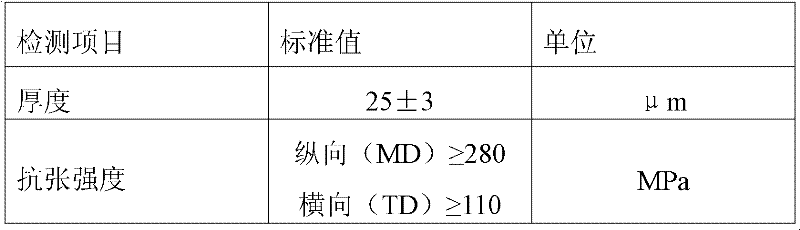

Production method for formable polyimide film

The present invention discloses a production method for a formable polyimide film. The method comprises resin synthesizing, defoaming, slobbering and film forming, and winding and splitting. The resin synthesizing treatment comprises: pressing 4,4'-dimethyl acetamide into an amine dissolving kettle; adding a calculated mixture comprising 4,4'-diaminodiphenyl ether, para-phenylenediamine and 4,4'-diamino-diphenyl-methane to the amine dissolving kettle, stirring for 1 hour until the mixture is completely dissolved in the 4,4'-dimethyl acetamide; pressing the resulting mixing solution into a reaction kettle; adding a calculated mixture comprising 4,4'-oxydiphthalic anhydride, 3,3',4,4'-biphenyl tetracarboxylic diandhydride and pyromellitic dianhydride to the reaction kettle, carrying out a reaction for 4 hours to form a sol type polyamide acid resin, wherein the viscosity of the resin is adjusted by adjusting the amount of the residual anhydride. The prepared formable polyimide film by the method of the present invention can not be deformed after forming, and good physical properties, good electrical properties and good mechanical properties of the film can be maintained.

Owner:宁波今山电子材料有限公司

2-methyl-5-chloro-1,4-diaminobenzene and its prepn and application

InactiveCN1349974AHigh outputWide range of usesOrganic compound preparationElectrography/magnetographyAcetic anhydrideIron powder

The present invention discloses a compound 2-methyl-5-chloro-1,4-p-phenylenediamine, its preparation method and use. It is characterized by that under the acidic condition 2-methyl-5-chloro-phenylamine and acetic anhydride are reacted to obtain N-acetyl-2-methyl-5-chloro-phenylamine, then it uses a mixed acid to make said obtained material undergo the process of nitrate to obtain N-acetyl-2-methyl-4-nitro-5-chloro-phenylamine, and then makes said material undergo the hydrolysis to remove acetyl, and finally utilizes hydrochloric acid and adds the iron powder to make reduction to obtain the invented product. Said compound can be used for synthesizing paint, and synthesizing dyestuff, also can be used for preparing colour developing reagent.

Owner:WUHAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com