Thermoplastic polyimide, and laminated polyimide film and metal foil-laminated polyimide film using the thermoplastic polyimide

A technology of polyimide film and polyimide layer, which is applied in the field of thermoplastic polyimide, can solve the problems of warping and other problems, and achieve the effects of low glass transition temperature, not easy to deteriorate, and high elongation at break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

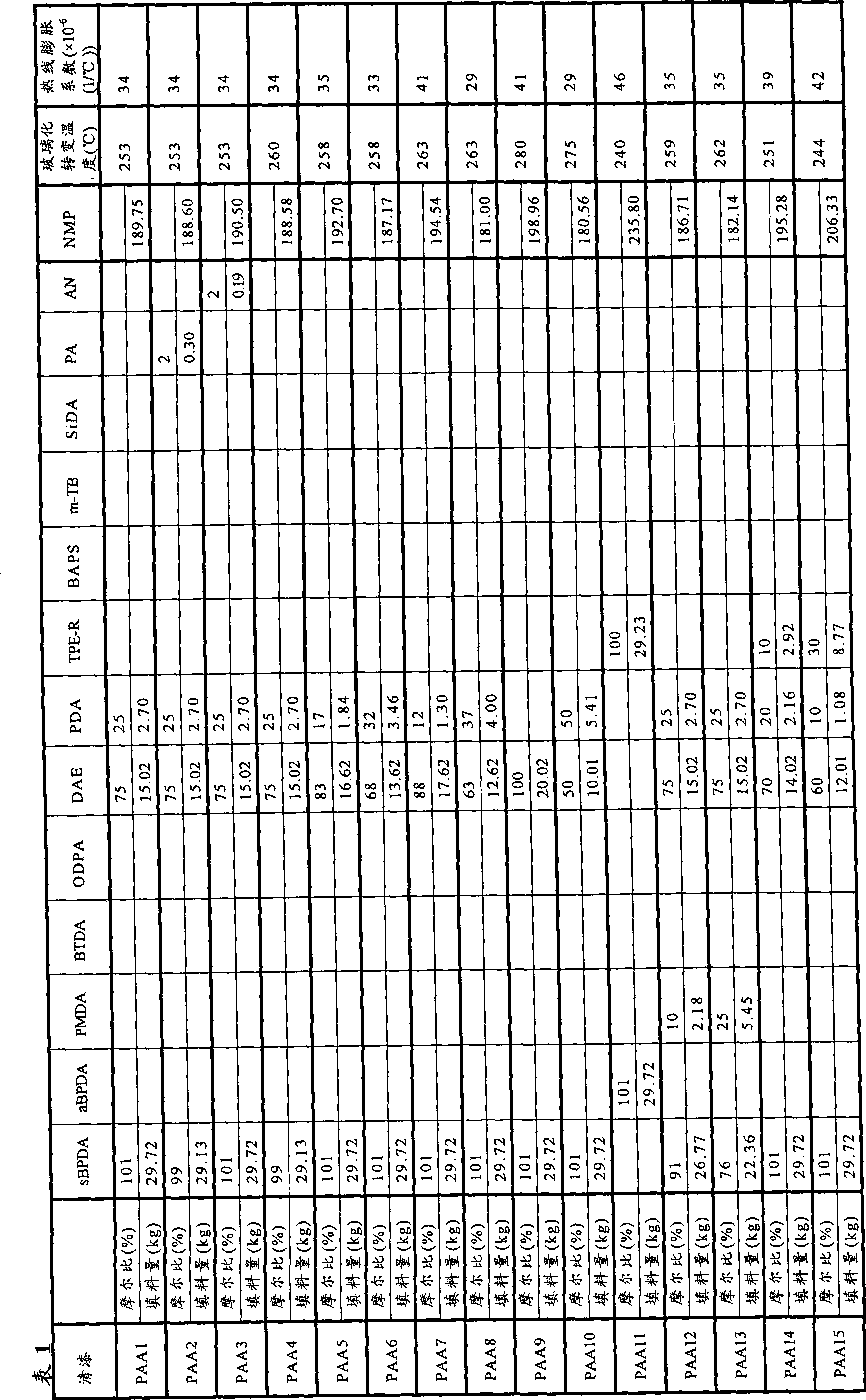

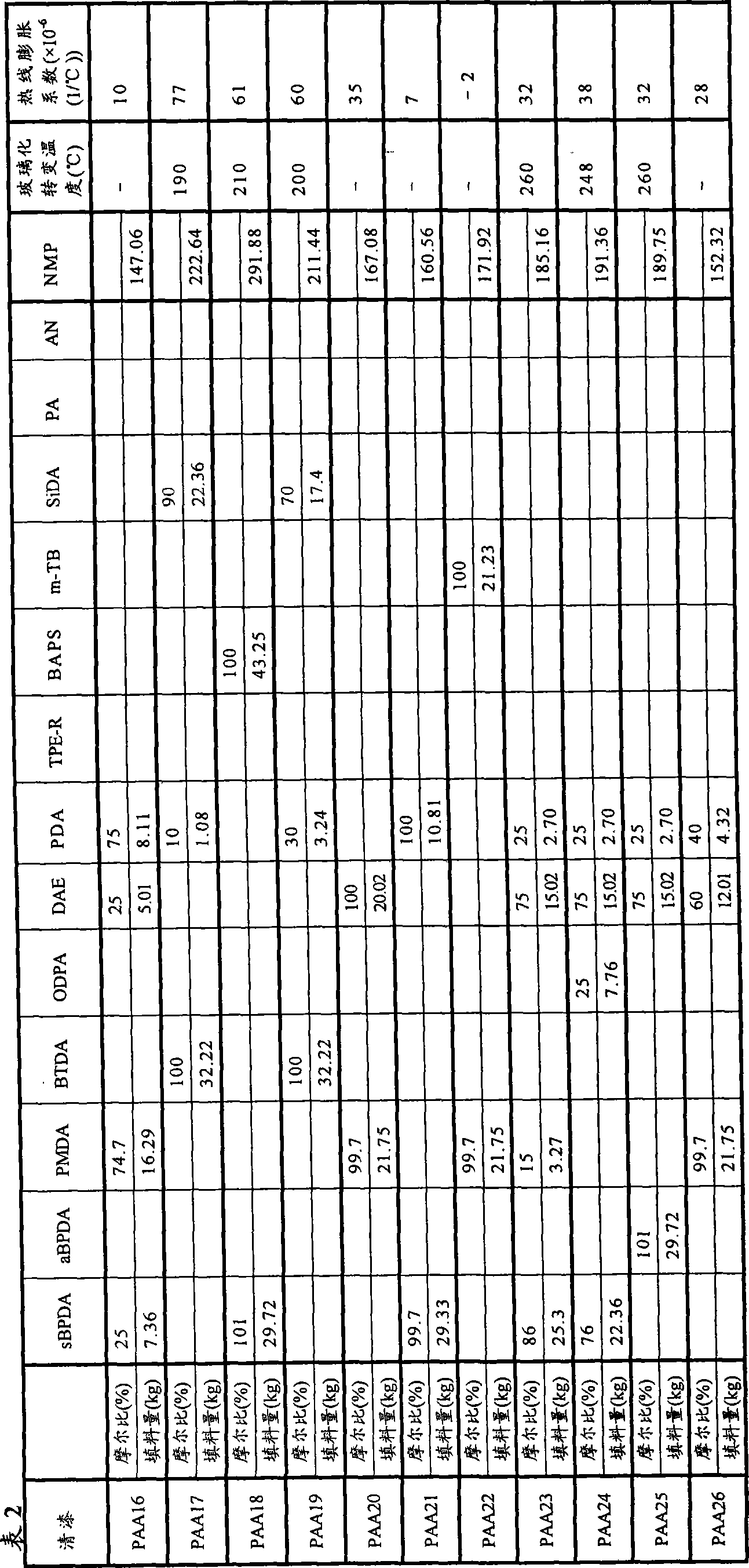

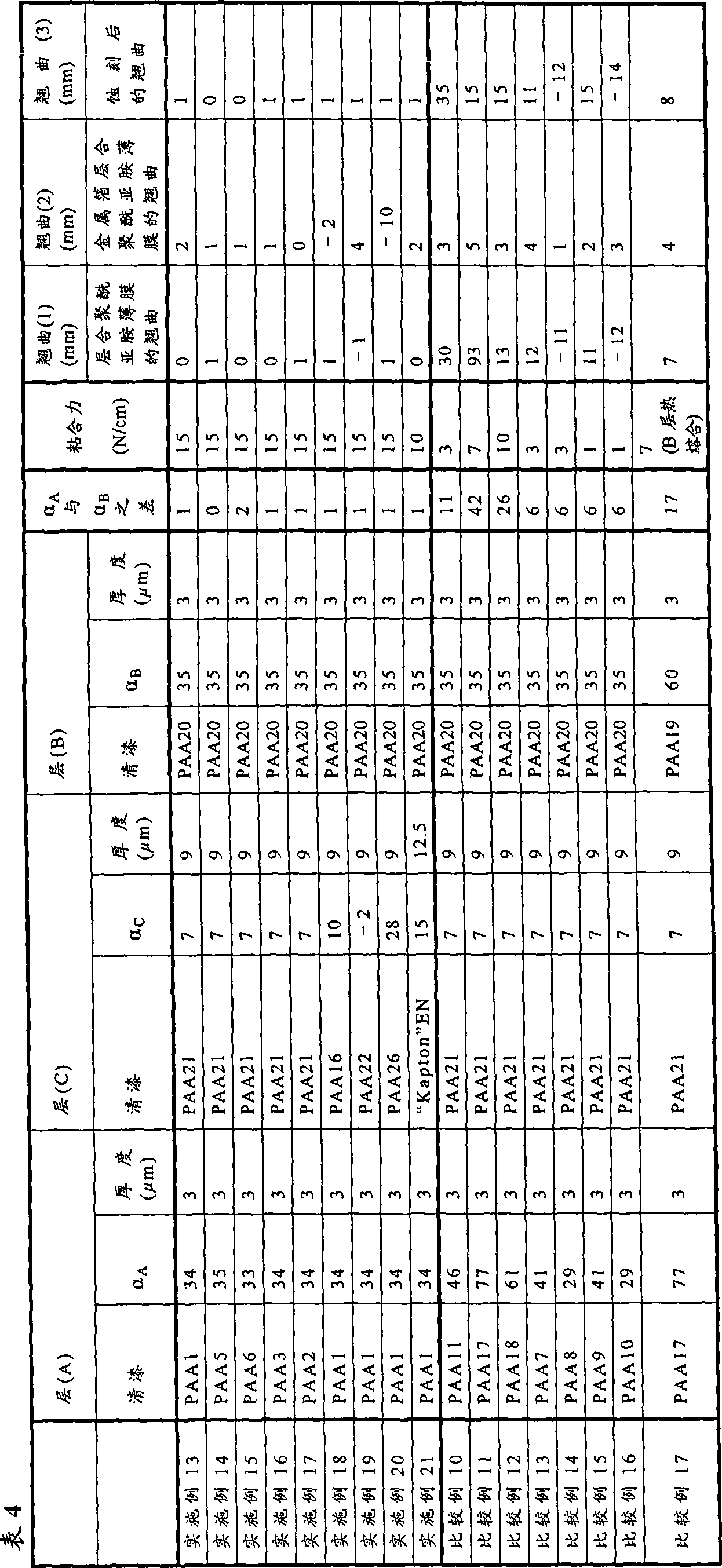

[0074] The following examples are given to illustrate the present invention, but the present invention is not limited by these examples. Evaluation methods for glass transition temperature, adhesive force, tensile modulus and elongation at break are as follows.

[0075] (1) Glass transition temperature

[0076] A polyimide film of about 5 mg was placed in an aluminum standard container, and the glass transition temperature was measured by the DSC method. The measuring device used a differential scanning calorimeter DSC-50 (manufactured by Shimadzu Corporation), heated to 350°C, cooled to 100°C, and then raised to 450°C at a rate of 20°C / min. The glass transition temperature was obtained from the inflection point of the curve.

[0077] (2) Adhesion

[0078] The metal foil of the metal foil laminated polyimide film was etched with a ferric chloride solution to form a 2 mm wide pattern. Using "Tensilon" UTM-4-100 (manufactured by TOYO BOLDWIN), the metal layer having a width ...

manufacture example 1

[0117] Add 2.70kg of PDA, 15.02kg of DAE, and 120kg of NMP into a reaction kettle equipped with a thermometer, a dry nitrogen inlet, a heating and cooling device using hot water and cold water, and a stirring device, and stir at 30°C to dissolve completely. Next, 29.72 kg sBPDA, 69.75 kg NMP were added at 30°C. Reaction was carried out at 60° C. for 4 hours to obtain 20% by weight of polyamic acid varnish 1 (PAA1). The glass transition temperature of the thermoplastic polyimide obtained by imidization is 253°C, and the thermal linear expansion coefficient at 30°C to 200°C is 34×10 -6 (1 / °C).

manufacture example 2

[0119] Add 2.70kg of PDA, 15.02kg of DAE, and 120kg of NMP into a reaction kettle equipped with a thermometer, a dry nitrogen inlet, a heating and cooling device using hot water and cold water, and a stirring device, and stir at 30°C to dissolve completely. Next, 29.13 kg sBPDA, 60 kg NMP were added at 30°C. After reacting at 60° C. for 4 hours, cool to 30° C., add 0.30 kg PA and 8.60 kg NMP, and react at 60° C. for another 2 hours to obtain 20% (by weight) polyamic acid varnish 2 (PAA2). The glass transition temperature of the thermoplastic polyimide obtained by imidization is 253°C, and the thermal linear expansion coefficient at 30°C to 200°C is 34×10 -6 (1 / °C).

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

| coefficient of linear thermal expansion | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com