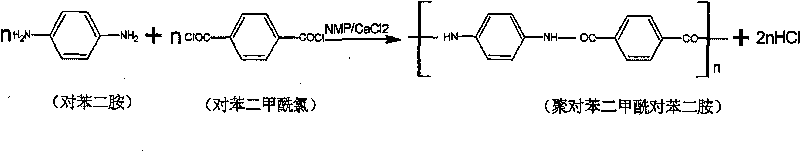

Polyphenylene terephthalamide fibre and preparation method thereof

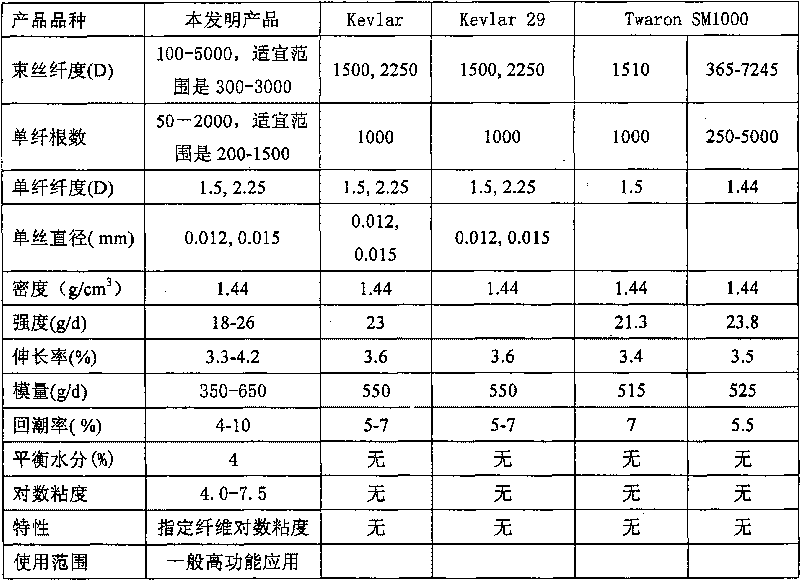

A technology of poly-p-phenylene terephthalamide and p-phenylene phthalamide, which is applied in the field of high-performance poly-p-phenylene terephthalamide fiber and its preparation technology, and can solve the difficulties in fiber technology , affecting industrial efficiency and other issues, to achieve the effect of wide application range, low industrial cost and good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] A kind of p-phenylene terephthalamide fiber (PPTA), prepared from poly-p-phenylene terephthalamide (PPTA) polymer with a logarithmic viscosity of 4.5dL / g, and its logarithmic viscosity Compared with the polymer's logarithmic viscosity, the decrease rate is less than 0.5dL / g. The specific indicators of the high-performance poly-p-phenylene terephthalamide fiber (PPTA) include: yarn density 300 denier, strength 18 g / den, The elongation is 3.2%, the modulus is 350 g / denier, the moisture content is 3%, and the logarithmic viscosity is 4.0 dL / g.

[0042] A method for preparing polyparaphenylene terephthalamide fiber (PPTA), including polymerization and spinning steps, wherein:

[0043] A, aggregation

[0044] (a) Polymerization raw materials include:

[0045] P-phenylene diamine [PPD],

[0046] Terephthaloyl chloride [TPC],

[0047] The solvent is (N-methyl pyrrolidone)[NMP],

[0048] The co-polysalt (ie co-solvent) is calcium chloride (CaCl 2 );

[0049] Among them: the molar ratio of...

Embodiment 2

[0057] A kind of poly(p-phenylene terephthalamide) fiber (PPTA), prepared from poly(p-phenylene terephthalamide) (PPTA) polymer with logarithmic viscosity 8.0dL / g as a starting point, its logarithm The viscosity is lower than the polymer logarithmic viscosity by less than 0.5dL / g. The specific indicators of the high-performance poly(p-phenylene terephthalamide) fiber (PPTA) include: bundle fineness 3000 denier, strength 26 g / denier , The elongation is 3.8%, the modulus is 650 g / den, the moisture content is 10%, and the logarithmic viscosity is 7.0dL / g.

[0058] A method for preparing polyparaphenylene terephthalamide fiber (PPTA), including polymerization and spinning steps, wherein:

[0059] A, aggregation

[0060] (a) Polymerization raw materials include:

[0061] P-phenylene diamine [PPD],

[0062] Terephthaloyl chloride [TPC],

[0063] The solvent is (N-methyl pyrrolidone)[NMP],

[0064] The co-polysalt (ie co-solvent) is calcium chloride (CaCl 2 );

[0065] Among them: the molar rat...

Embodiment 3

[0073] A poly(p-phenylene terephthalamide) fiber (PPTA), prepared from a poly(p-phenylene terephthalamide) (PPTA) polymer with a logarithmic viscosity of 6.0dL / g as a starting point. The viscosity is lower than the polymer logarithmic viscosity by less than 0.5dL / g. The specific indicators of the high-performance poly(p-phenylene terephthalamide) fiber (PPTA) include: yarn fineness 2000 denier, strength 20 g / den , Elongation rate 3.5%, modulus 500 g / denier, moisture content 6%, logarithmic viscosity 5.0dL / g.

[0074] A method for preparing polyparaphenylene terephthalamide fiber (PPTA), including polymerization and spinning steps, wherein:

[0075] A, aggregation

[0076] (a) Polymerization raw materials include:

[0077] P-phenylene diamine [PPD],

[0078] Terephthaloyl chloride [TPC],

[0079] The solvent is (N-methyl pyrrolidone)[NMP],

[0080] The co-polysalt (ie co-solvent) is calcium chloride (CaCl 2 );

[0081] Among them: the molar ratio of PPD / TPC is equal to 1.0-1.015, CaCl 2 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com