Industrial production method for para-aramid fiber filaments with high elongation

A para-aramid fiber, industrial production technology, applied in the field of aramid fiber and its preparation, can solve problems such as unsolved aramid filament

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

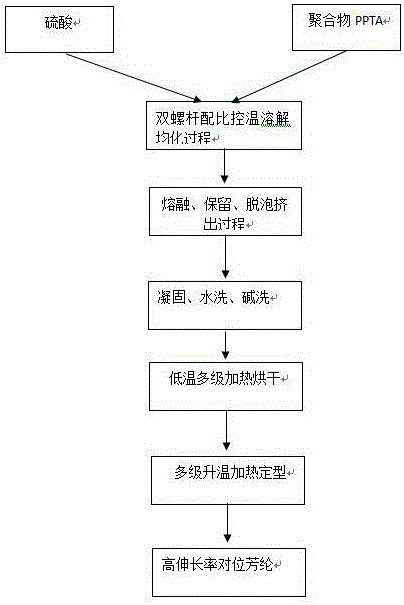

[0016] The spinning step of the present invention is as follows:

[0017] Add the poly(p-phenylene terephthalamide) polymer with an intrinsic viscosity of 7.5-8.5dL / g into sulfuric acid with a concentration of 98%-105% and mix evenly. After stirring, the temperature is controlled at 70-90°C to prepare The weight percentage of poly-p-phenylene terephthalamide is a mixed solution of 18.5%-21%; the prepared poly-p-phenylene terephthalamide mixed solution is extruded into a twin-screw extruder, The further dissolution of poly-p-phenylene terephthalamide in concentrated sulfuric acid is completed in the extruder, and the retention time is extended to 2-6 hours compared with the conventional variety process, and it is vacuum degassed for 2-4 hours; The screw extruder extrudes the spinning solution that is fully mixed, the temperature is well adjusted, and the air bubbles are completely removed. After being filtered by the metering pump, it is sent to the spinneret. The spinning solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com