Patents

Literature

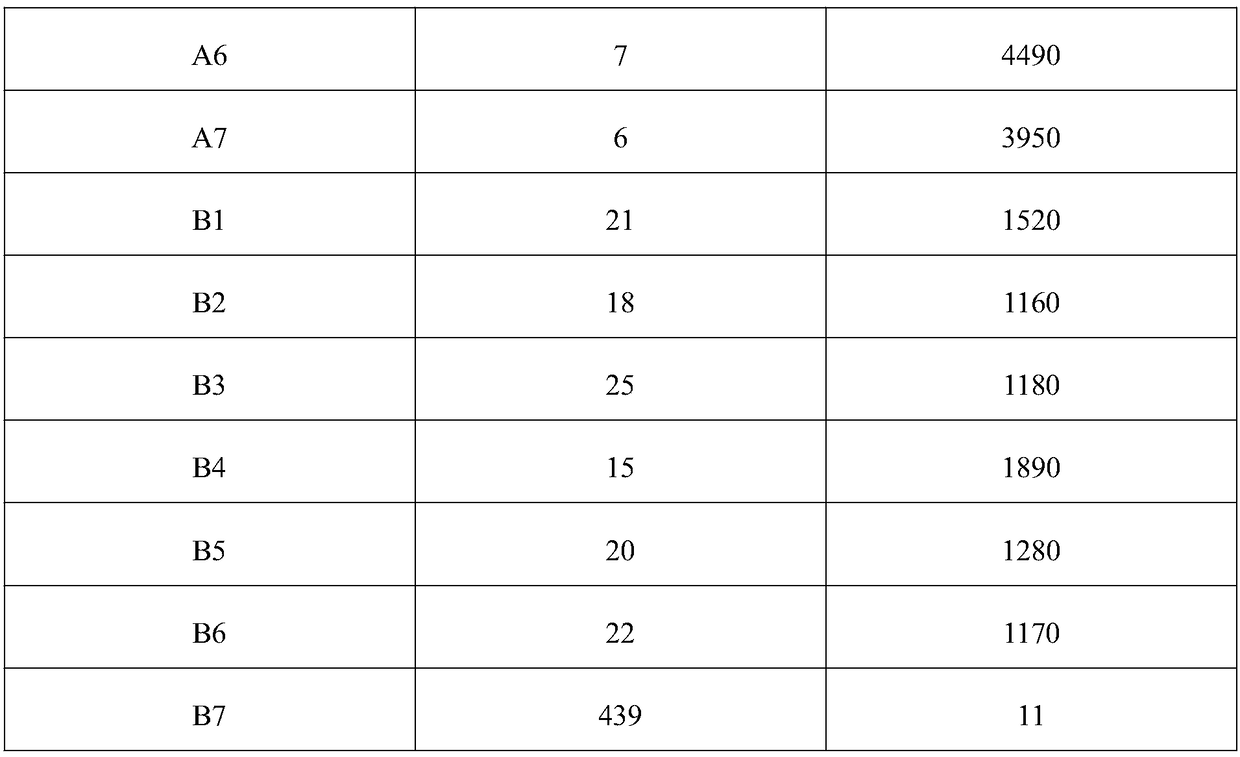

36results about How to "Short defoaming time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

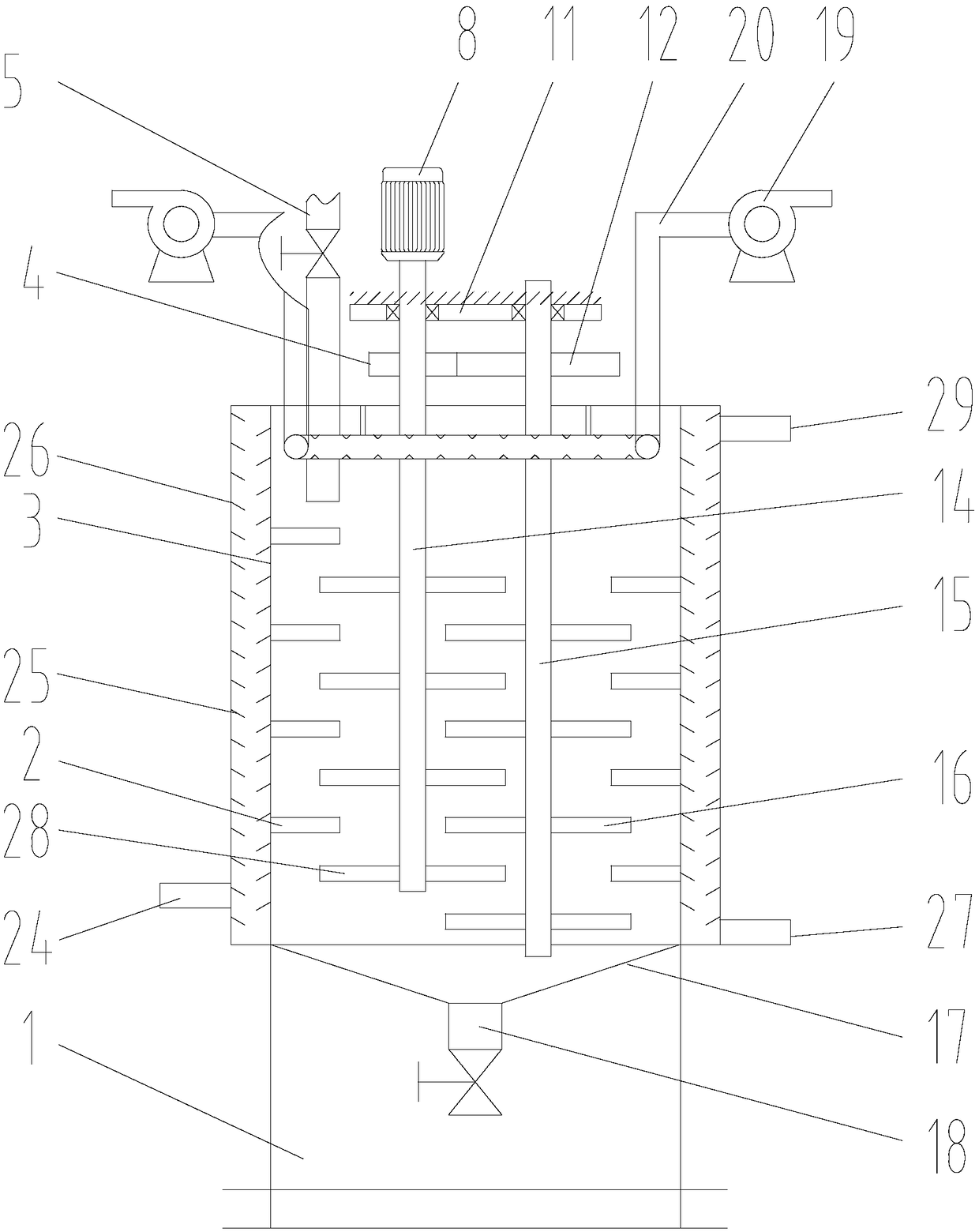

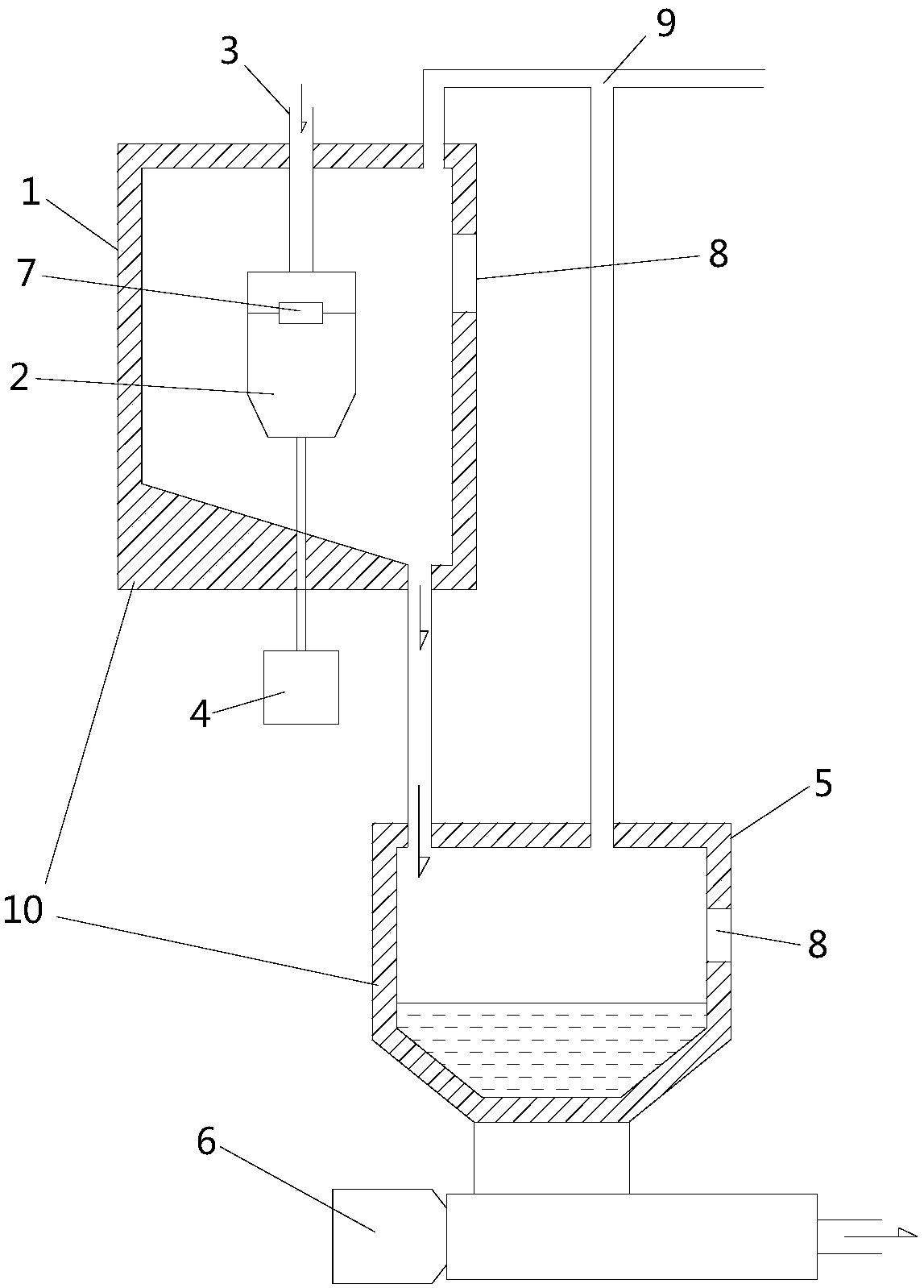

Defoaming kettle and defoaming method for preparing polyamide acid resin

ActiveCN104107565APrevent oxidationPrevent moisture absorptionFoam dispersion/preventionThin layerEngineering

The invention discloses a defoaming kettle and a defoaming method for preparing polyamide acid resin. A thin layer distributor with an arch rotary curve surface is fixedly installed in a defoaming kettle tank body; the distance from the curve surface arch top of the thin layer distributor to the lower end opening of a feeding pipe ranges from 0.01mm to 1 / 3 of the height of the tank body; the clearance between the lower edge of the curve surface of the thin layer distributor and the inner wall of the tank body is 0.01mm-10mm; the rotary curve surface of the thin layer distributor is a spherical surface; a resin conveying pipeline between a reaction kettle and the defoaming kettle is provided with a metering pump; the tank body is provided with a sandwiched sleeve, and an heat conduction medium inlet and outlet are formed at the top and bottom of the tank body. The defoaming method comprises the step that resin entering the defoaming kettle falls on the arch top of the curve surface of the thin layer distributor, and disperses and flows downward along the curve surface of the thin layer distributor to form a thin layer which results in bubble breakage. The metering pump is used for adjusting the flow rate of resin so as to keep that the thickness of the resin solution layer on the thin layer distributor is less than 5mm. Defoaming is completed immediately when resin is conveyed completely, and then pressurization is carried out for discharging. During defoaming, a heat conduction medium is introduced for warming, and negative pressure is kept in the tank body. According to the invention, defoaming is complete, and the defoaming time is shortened greatly so as to guarantee subsequent continuous film preparation. The defoaming kettle is simple in structure and convenient to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

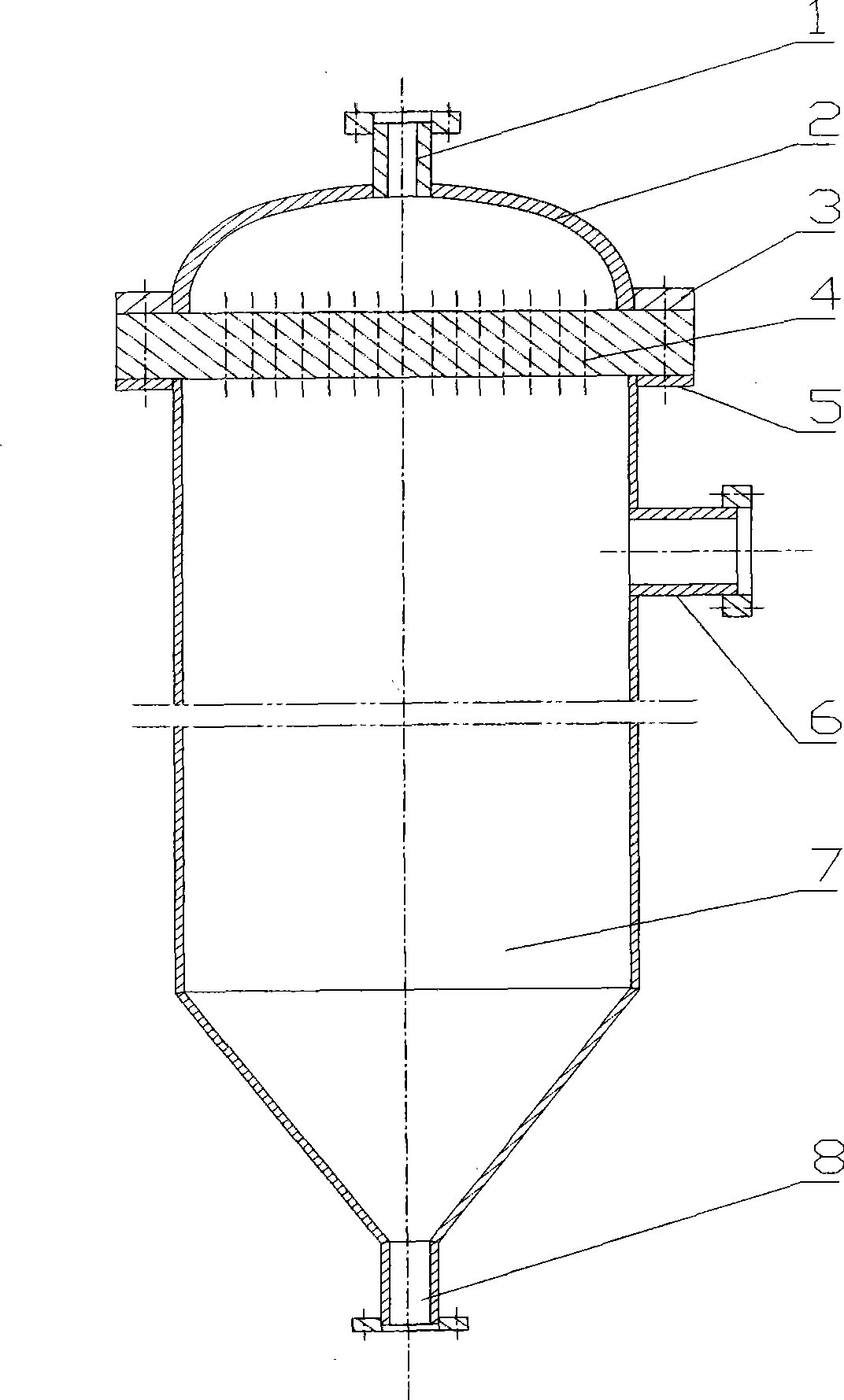

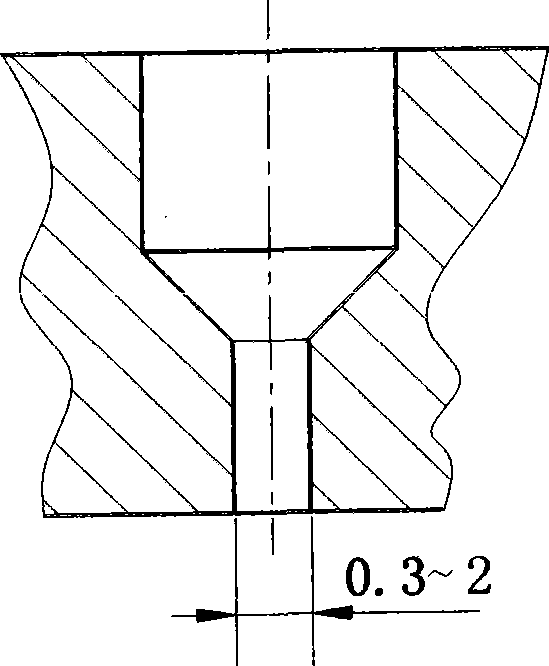

High-viscosity fluid defoaming method and device thereof

InactiveCN101519809AGood defoaming effectExtrusion speed is highLiquid degasificationFilament-forming treatmentThick plateBiochemical engineering

The invention relates to a high-viscosity fluid defoaming method and a device thereof. The upper part of the device is a round tank; the lower part is a cone; a feed inlet is arranged on the upper side of an end enclosure; the lower side of the end enclosure is connected with a film-extruding plate by a flange; and the end enclosure forms a containing cavity along with the film-extruding plate; normally, the film-extruding plate is a round or square thick plate, on which a large quantity of long-circular narrow holes are arranged; the upper part of each hole is wide and is a fluid-guiding area; the middle part of the hole is sloped and is a tapered transitional area; and the lower part of the hole is narrow and is a film-extruding area. A vacuum defoaming tower is located right below the film-extruding plate and connected with the film-extruding plate by a flange; a vacuumizing inlet is arranged on the side of the vacuum defoaming tower; and a discharge outlet is arranged on the lower side of the vacuum defoaming tower. The high-viscosity fluid rapid defoaming method and the device thereof have the advantages of good defoaming effect, short deforming time and high output.

Owner:SHAOYANG TEXTILE MACHINERY

Method of continuously preparing poly terephthaloyl-p-phenylene diamine fibre

InactiveCN1693543AShort defoaming timeImprove mixing uniformityFilament-forming treatmentMonocomponent polyolefin artificial filamentFiberViscosity

The invention discloses a method for continuously preparing p-phenylene terephthalamide (PPTA) fiber, including the steps of: (1) continuously adding 98-100% oil of vitriol and PPTA with specific logarithmic viscosity of 4.0-8.5 dl / g to an double spiral extruder, where the weight percent of PPTA is 14-24% and the mixing temperature is 50-100 deg.C; (2) fully mixing and entering in the other extruder, where the adjusting temperature is 50-100 deg.C and the staying time is 10-60 min, fully mixing, adjusting temperature and defoaming and then extruding them; (3) after measuring and filtering spinning solution, obtaining the invention by the routine steps, such as dry spraying-wet spinning. The advantages are short time for mixing materials, adjusting temperature and defoaming high mixing uniformity of materials able to implement continuous, stable filature in a short time, raising the production efficiency.

Owner:DONGHUA UNIV

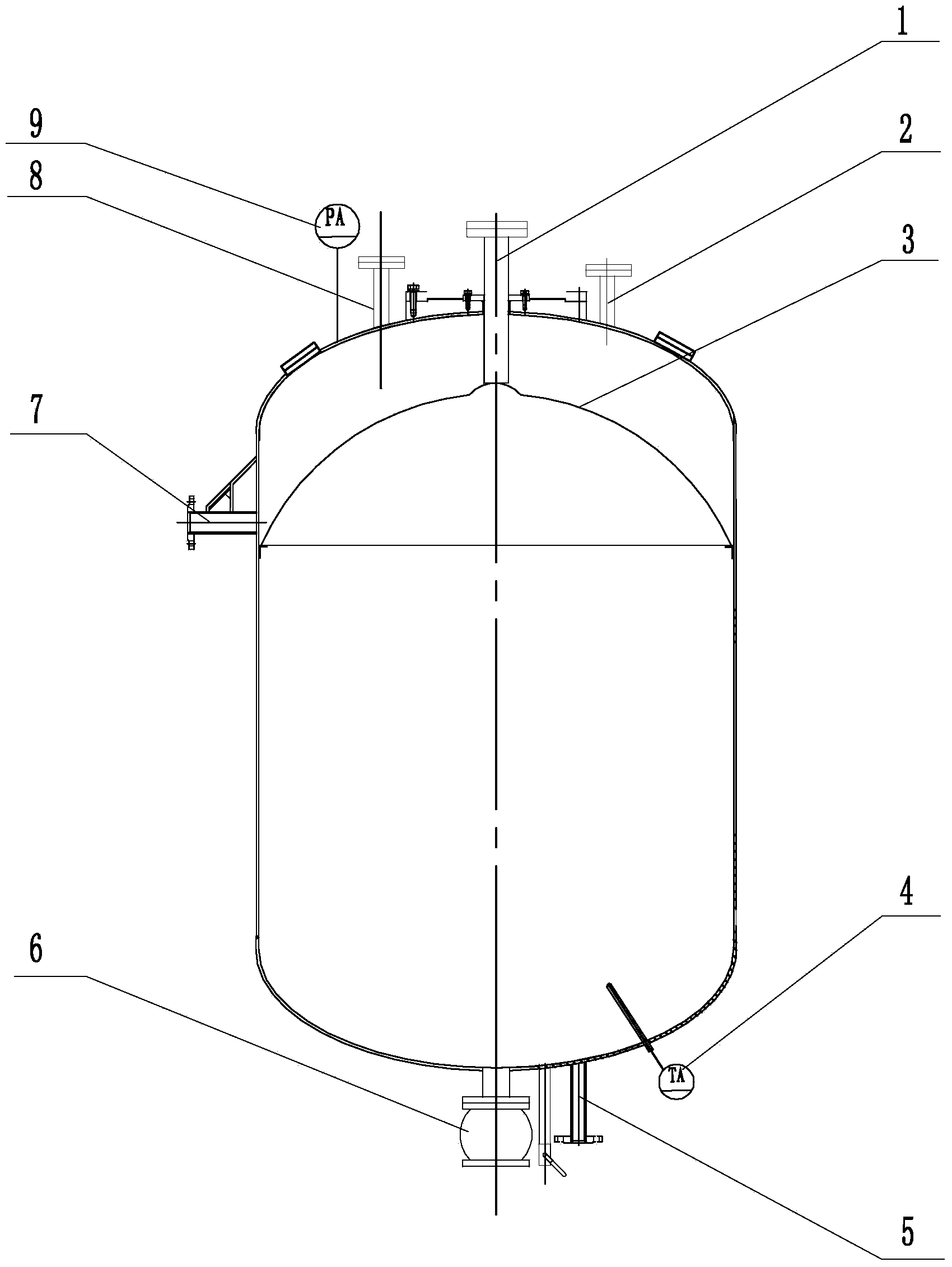

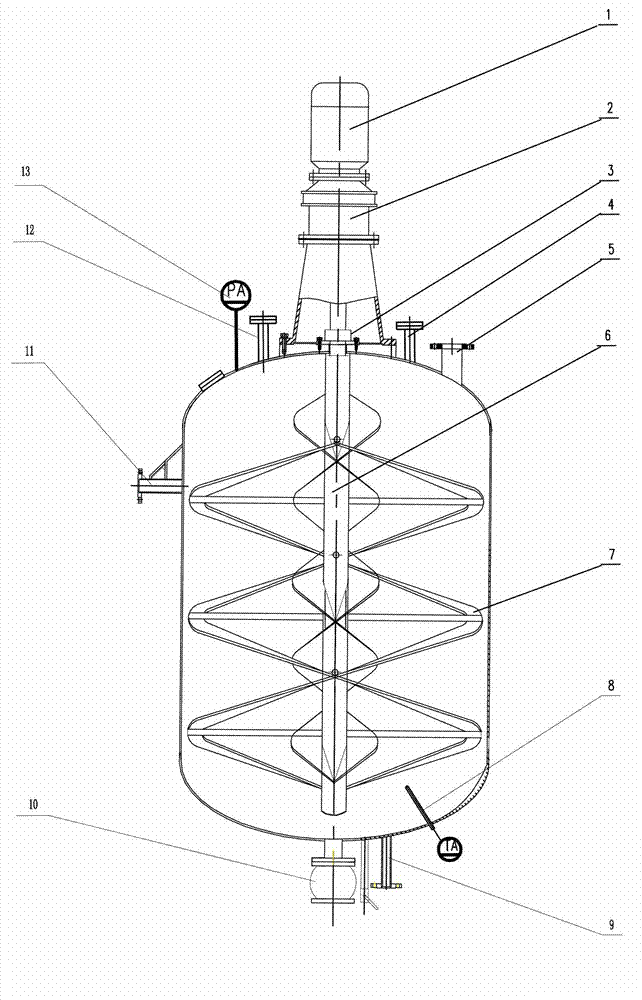

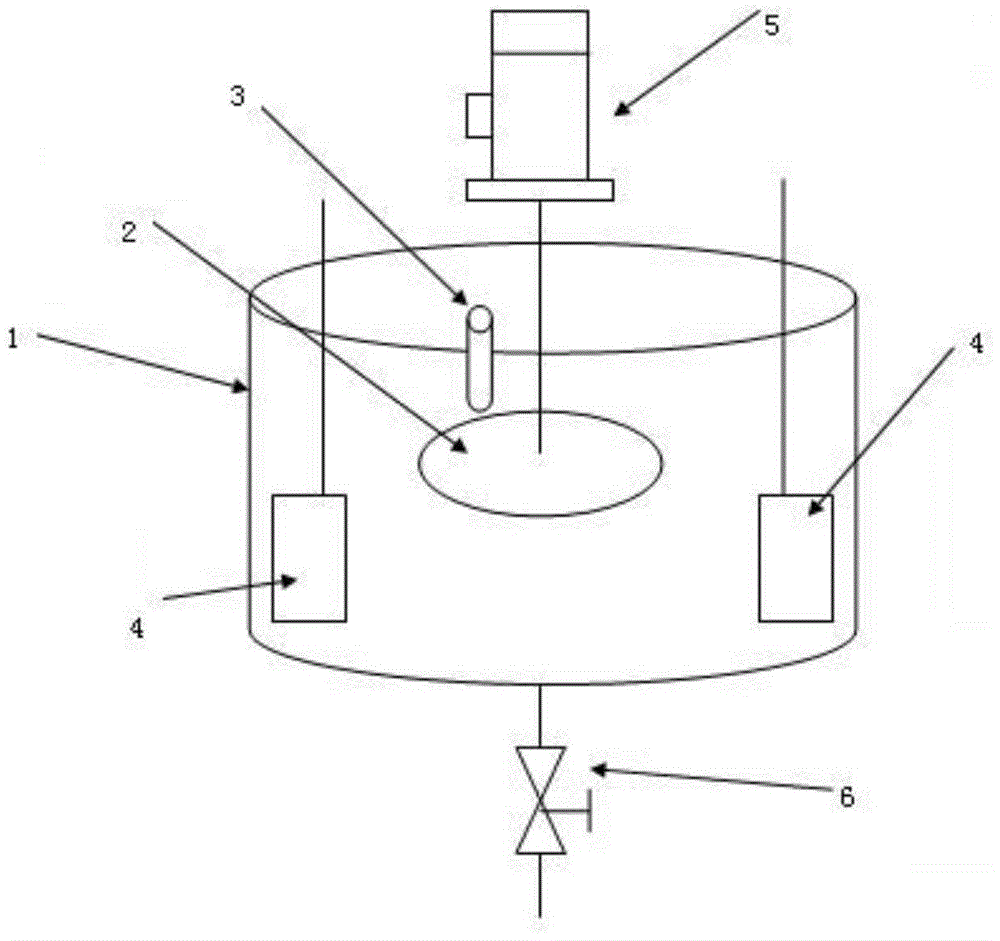

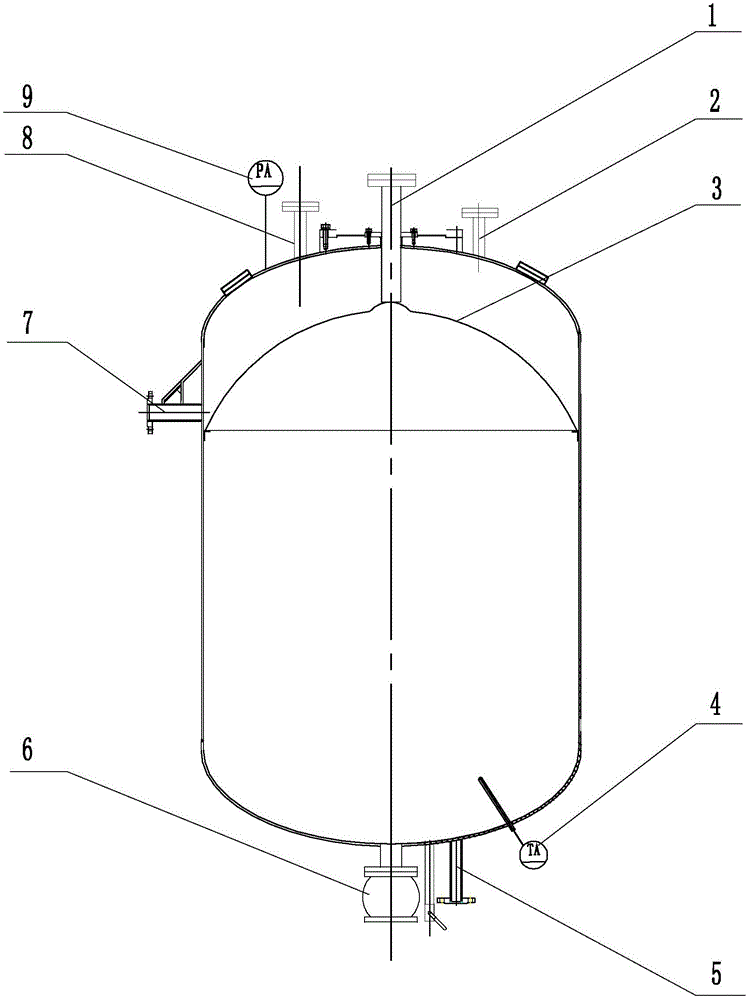

Defoaming kettle used in synthetic process of polyamic acid resin

InactiveCN103041620AUniform colorConvenient temperature and pressureFoam dispersion/preventionHeat conductingProduct gas

The invention discloses a defoaming kettle used in the synthetic process of polyamic acid resin. A pot body of the defoaming kettle is provided with a jacket; a stirring shaft of a multilayer spiral mixing blade is located in the defoaming kettle, and the top end of the stirring shaft is connected with a stirring electric motor and a reductor, which are located at the top of the pot body; the stirring shaft is a hollow shaft, and the mixing blade is a hollow blade, wherein a heat-conducting medium transmission pipeline is arranged in the mixing blade; a heat-conducting medium inlet on a rotary joint is connected with the upper end of the heat-conducting medium transmission pipeline of the mixing blade, and heat-conducting medium passes through the hollow shaft to a heat-conducting medium outlet at the upper end of the hollow shaft; a jacket medium inlet, a jacket medium outlet, the heat-conducting medium inlet and the heat-conducting medium outlet are connected with a heat-conducting medium heating device; and a gas inlet and a discharge pipe are arranged on the pot body in a sealed manner.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

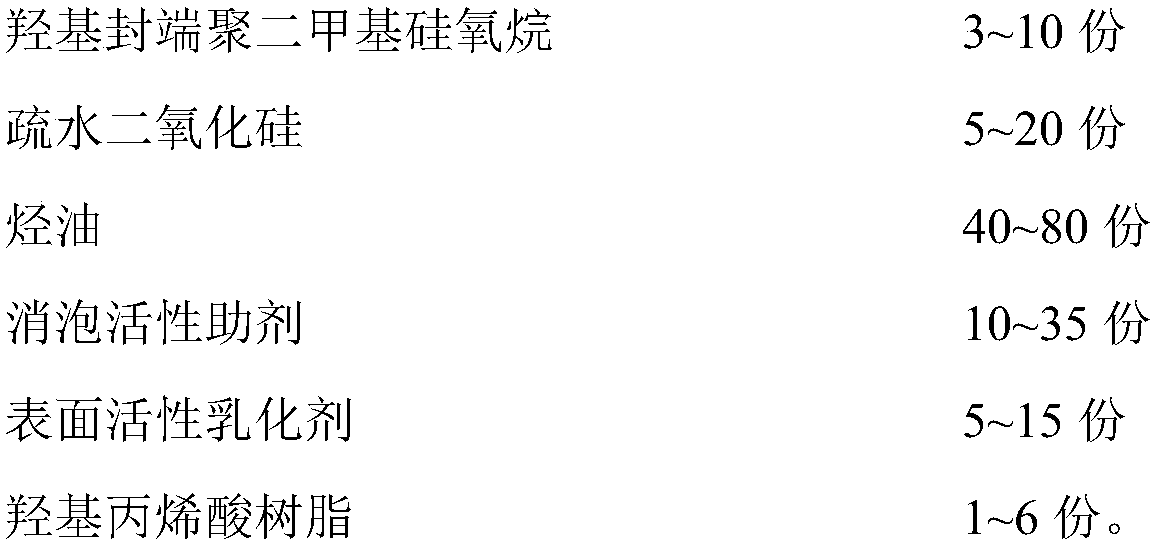

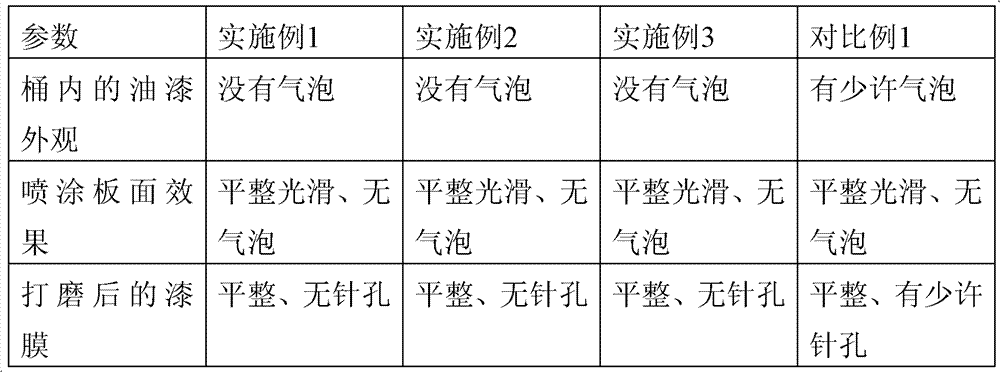

Mineral oil defoaming agent and preparation method thereof

The invention discloses a mineral oil defoaming agent and a preparation method thereof, and belongs to the technical field of fine chemical auxiliaries. The mineral oil defoaming agent provided by theinvention comprises the following components in parts by weight: 3-10 parts of hydroxyl-terminated polydimethylsiloxane; 5-20 parts of hydrophobic silicon dioxide; 40-80 parts of hydrocarbon oil; 10-35 parts of a defoaming coagent; 5-15 parts of a surface active emulsifier; and 1-6 parts of hydroxy acrylic resin. By adopting the mineral oil defoaming agent prepared by the invention, not only arethe polymerization, steam stripping and filling of harmful foam during a styrene-butadiene latex production process effectively inhibited, but also the effective control on oil shrinkage, pinhole, fisheye and foam inhibition of a subsequent coating is realized; at the same time, the mineral oil defoaming agent has the advantages of good stability, less addictive amount and the like.

Owner:安徽銮威化工科技开发有限公司

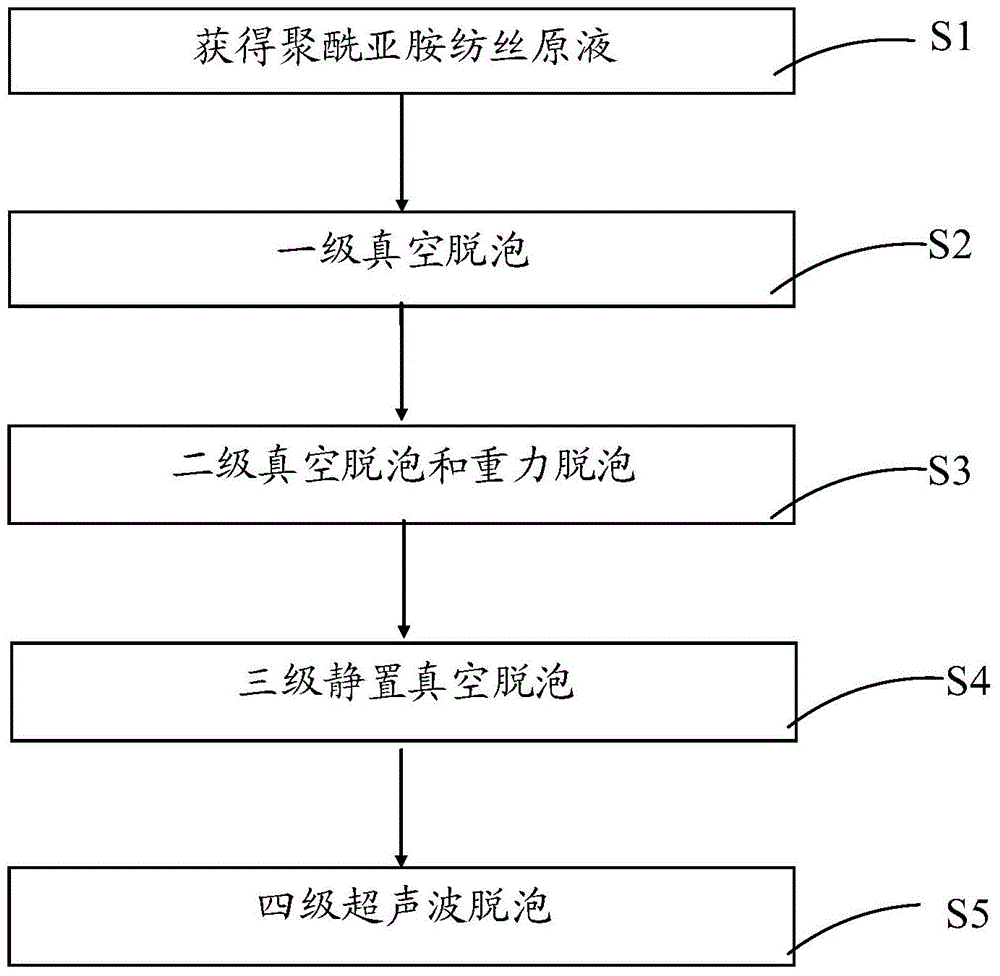

Deaeration method of polyimide spinning solution and device thereof

The invention provides a deaeration method of polyimide spinning solution. The method comprises the following steps that a polyimide spinning raw solution is obtained; a vacuum module, a cooling module and a centrifugal module are started; the polyimide spinning raw solution is injected into the centrifugal module to complete a first-level deaeration; the processed polyimide spinning raw solution is tossed into the inner wall of a deaeration device, the polyimide spinning solution flows down to the bottom of the deaeration device, and a second-level deaeration is completed; a standing treatment is carried out to complete a third-level deaeration; an ultrasonic module is started to complete a fourth-level deaeration, and the polyimide spinning solution is obtained. According to the method, continuous feeding of materials is carried out under a vacuum environment, the materials are subjected to centrifugal shaking under the vacuum environment to form a film so as to realize a dynamic deaeration and a vacuum deaeration, the process of a gravity deaeration and an ultrasonic terminal deaeration under the vacuum environment improves the effect of a deaeration and covers less area, and the cost is low.

Owner:徐东

Paint bubble removal device

InactiveCN109260769AEasy to overflowImprove stirring efficiencyLiquid degasificationEngineeringAir bubble

The invention relates to the technical field of paint production equipment, and discloses a paint bubble removal device. The paint bubble removal device is characterized in that a cover plate is arranged at the upper end of a barrel, and a discharge outlet is formed in the lower end of the barrel; a feed inlet and a vacuumizing opening are fixedly connected onto the cover plate; a stirring assembly is arranged in the barrel and comprises a driving rotary shaft, the top of the driving rotary shaft extends out of the barrel, and a motor is connected with the top of the driving rotary shaft; a driving gear is fixedly arranged on the driving rotary shaft and is positioned outside the barrel; a driven rotary shaft is further arranged in the barrel, the top of the driven rotary shaft extends outof the barrel, and a driven gear is fixedly arranged on the top of the driven rotary shaft and is connected with the driving gear in a meshing manner; stirring blades are arranged on the driving rotary shaft and the driven rotary shaft; support plates are fixedly connected onto the driving rotary shaft and the driven rotary shaft by bearings; a heating assembly is fixedly arranged outside the barrel. The paint bubble removal device which is a quick defoaming device has the advantages that the paint bubble removal device is high in paint oil stirring efficiency; paint can be dramatically turned over and mixed, accordingly, bubble in the paint can be easily and quickly spilled over, the paint bubble removal device is short in defoaming time, and good defoaming effects can be realized by thepaint bubble removal device.

Owner:攀枝花荣鑫油漆有限责任公司

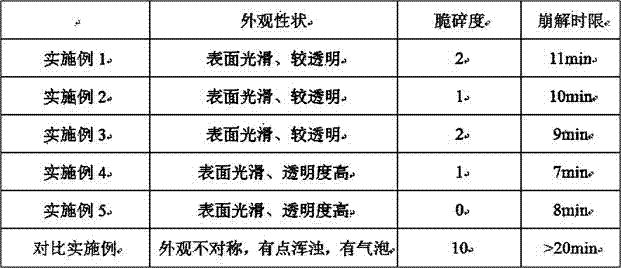

Defoaming method of unsaturated polyester transparent undercoat

InactiveCN103087616AElimination of defoaming effectFast foamingPolyester coatingsFoam dispersion/preventionPolyesterFiltration

The present invention provides a defoaming method of unsaturated polyester transparent undercoat, which is characterized by comprising the steps of: (1) preparing the unsaturated polyester transparent undercoat including: producing unsaturated polyester transparent undercoat; (2 ) leaching by a suction filtration machine including: leaching the unsaturated polyester transparent undercoat by using a suction filtration machine; wherein the leaching temperature is 0-50 DEG C, the leaching pressure is 0.1-0.25 Mpa, and the leaching speed is 1.2-1.8 t / h; and (3) packaging including: directly packaging the unsaturated polyester transparent undercoat after leaching. The defoaming time of the present invention is shortened from the original 48 hours to 1-4 hours. All air bubbles and small bubbles are removed. The product prepared by the present invention has no pinholes in the coating process.

Owner:上海展辰涂料有限公司 +2

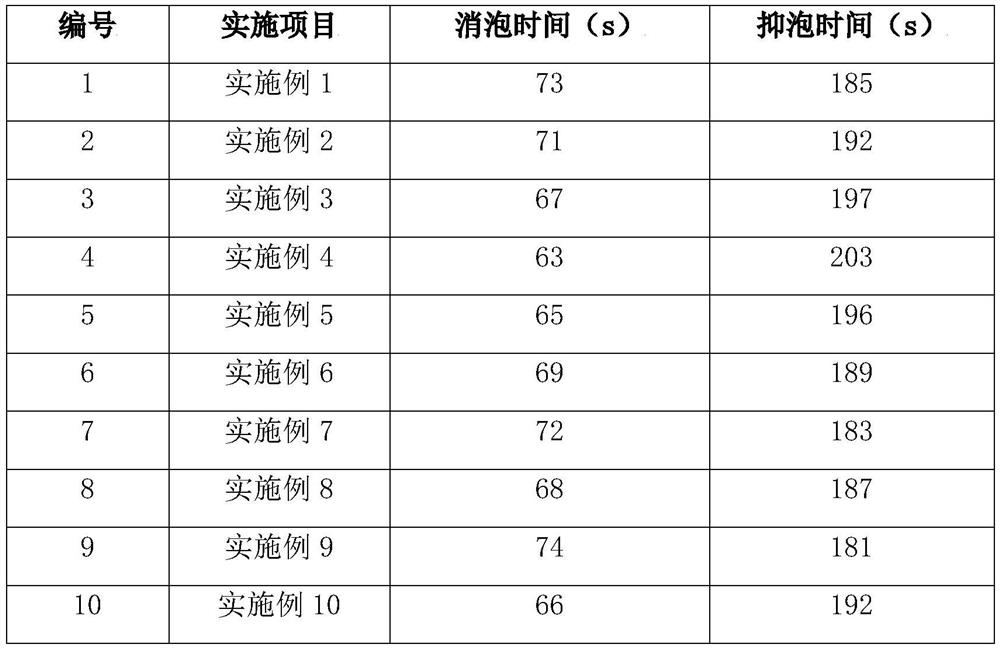

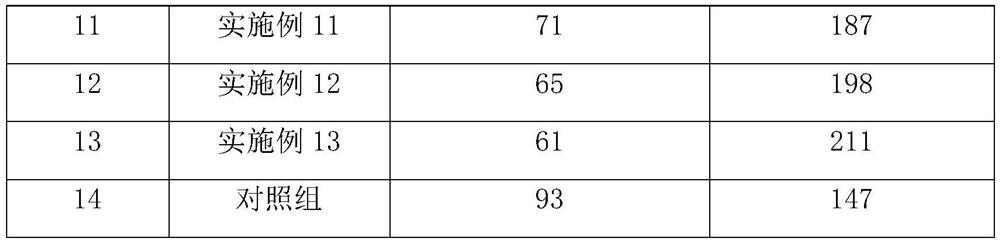

Composite defoaming agent and preparation method thereof

ActiveCN109432831AImprove defoaming and antifoaming performanceAvoid the problem of different qualityFoam dispersion/preventionEthylenediamineHydrogen

The invention provides a composite defoaming agent and a preparation method thereof. The method comprises the following steps: 1) mixing stearic acid and an antioxidant; heating until the temperatureis 80-100 DEG C and stearic acid is smelted to obtain a mixing solution X1; adding ethidene diamine and a first catalyst to the mixing solution X1; and stirring and mixing for 3-5h under the temperature of 140-150 DEG C to obtain a base material Y1; 2) mixing hydrogen containing silicone oil and allyl polyoxyethylene polyoxypropylene ether in presence of a second catalyst under the temperature of80-100 DEG C to obtain a base material Y2; 3) mixing and reacting silicon dioxide and dimethicone for 4-6h in presence of a third catalyst under the temperature of 150-180 DEG C to obtain a base material Y3; and 4) mixing and emulsifying the base material Y1, the base material Y2, the base material Y3 and water to obtain the composite defoaming agent. The composite defoaming agent is simple to prepare, mild in condition, high in foam removing and inhibiting performances and is applicable to various foam forms.

Owner:广州碧驰新材料股份有限公司

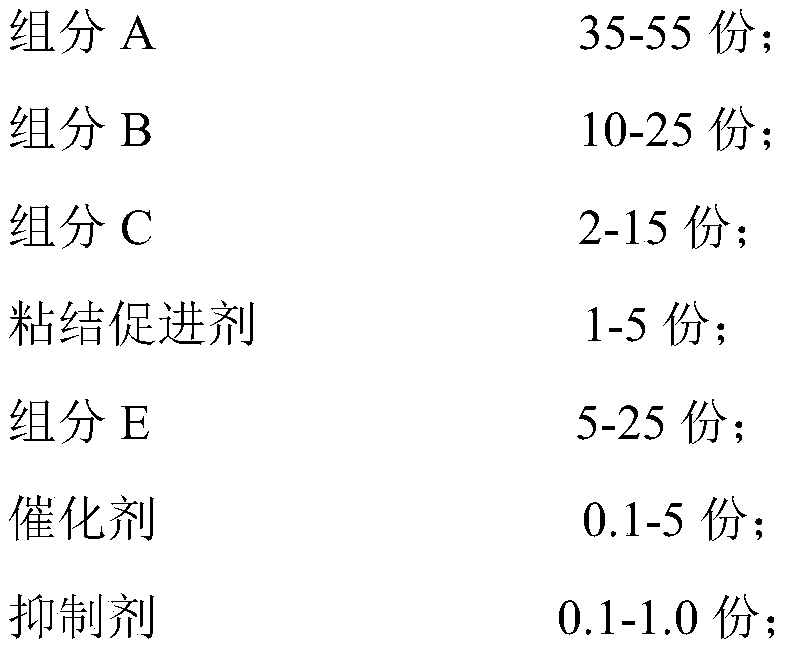

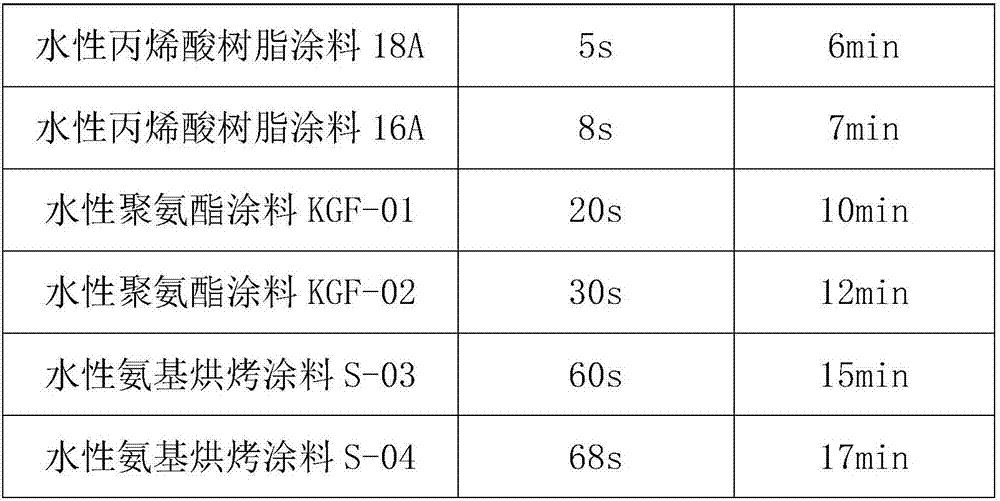

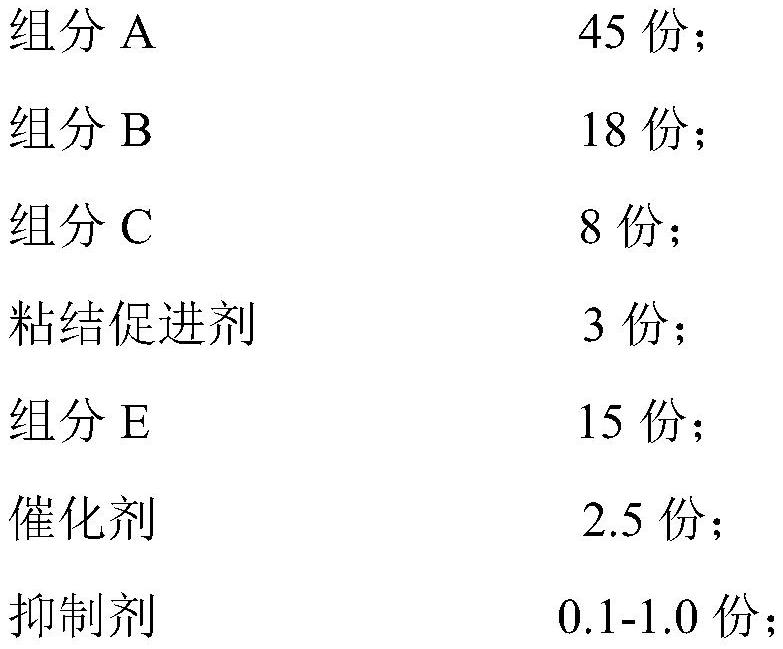

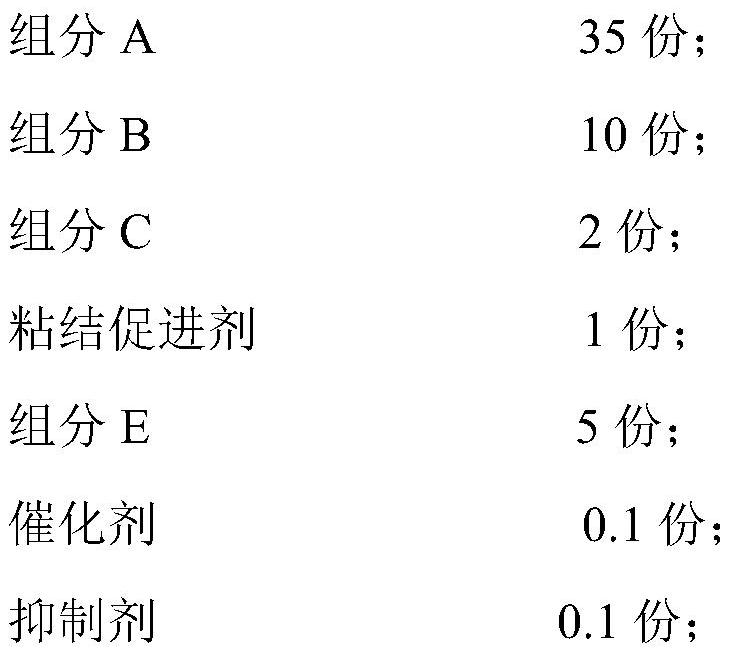

Transparent silica gel for liquid crystal display fitting

The invention relates to a transparent silica gel for liquid crystal display fitting. A raw material formula comprises 35-55 parts of component A, 10-25 parts of component B, 2-15 parts of component C, 5 parts of bonding accelerant, 5-25 parts of component E, 0.1-5 parts of catalyst and 0.1-1.0 part of inhibitor; the component A is vinyl-terminated polysiloxane conforming to general formula (1); the component B is allyloxy-terminated polypropylene oxide conforming to general formula (2); the component C is vinyl MQ silicon resin; ratio of M to Q is at 0.8-1.5; the component E is hydrogen-endedpolysiloxane conforming to general formula (3). The transparent silica gel for liquid crystal display fitting prepared according to the invention has the advantages of low viscosity, short defoamingtime, quick curing molding and moderate hardness.

Owner:铜陵桐力光电有限公司

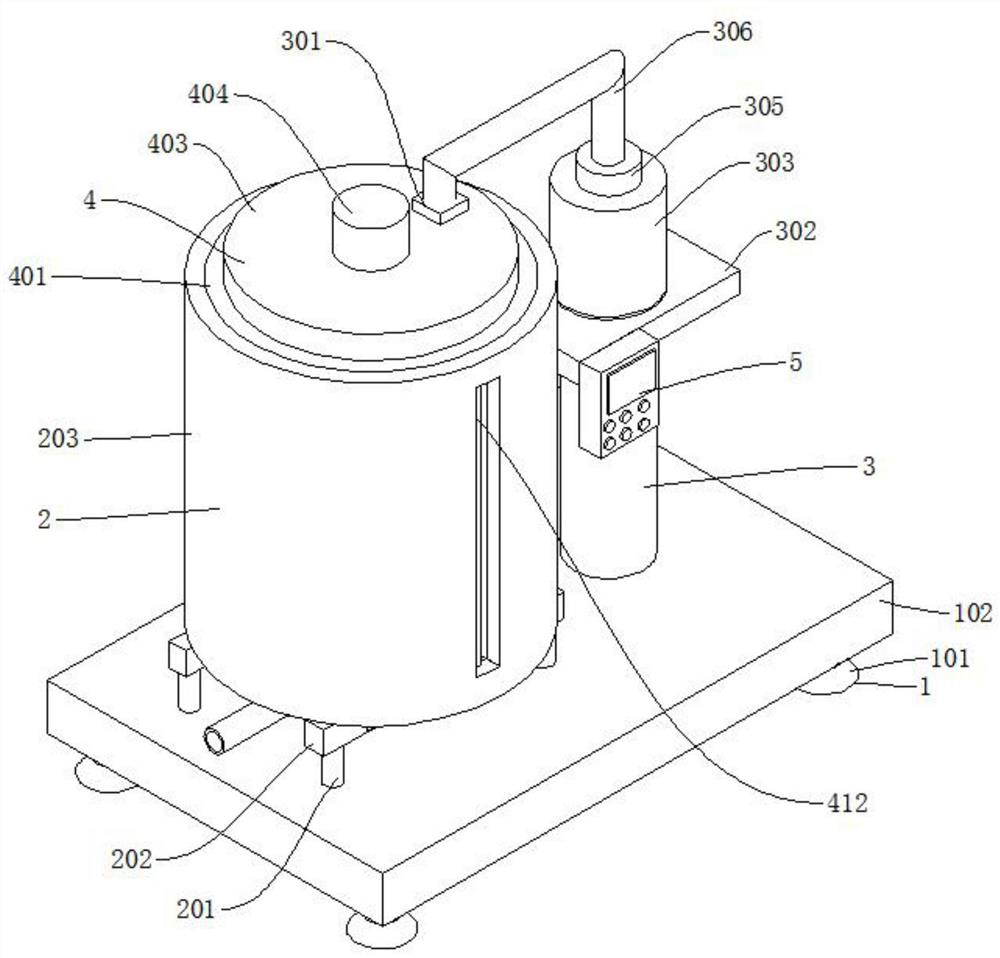

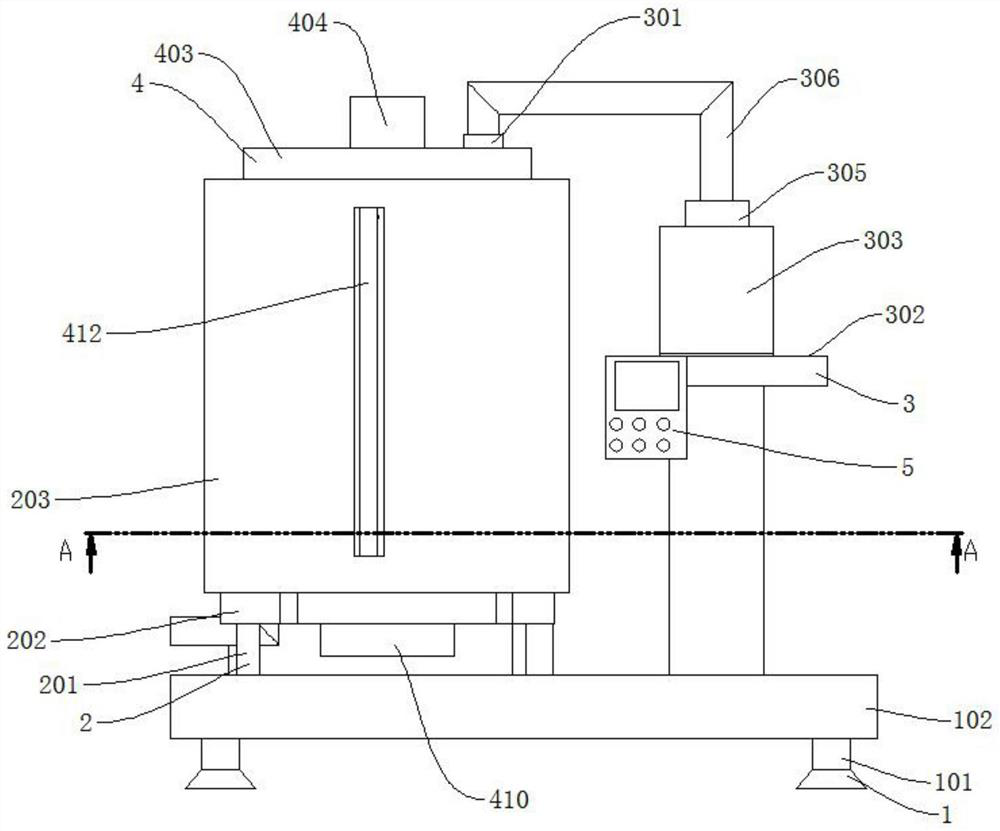

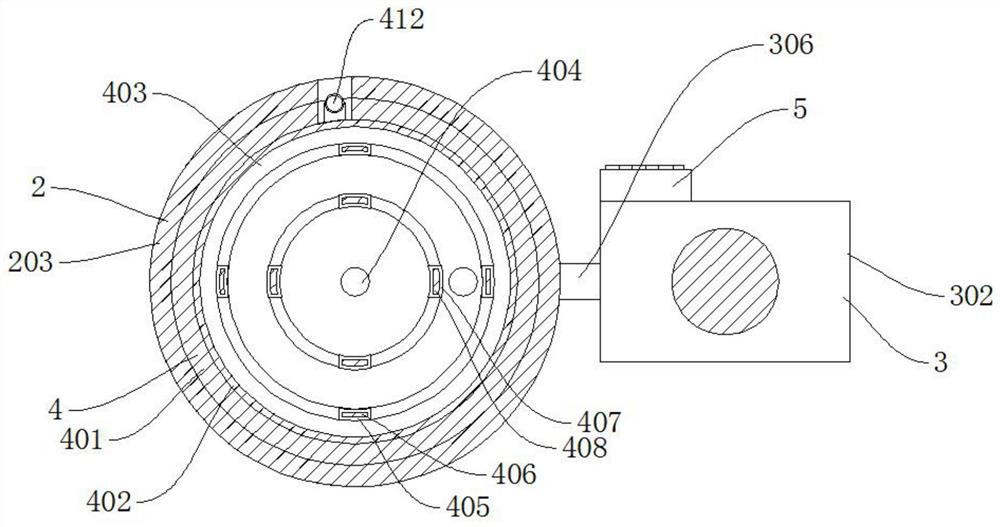

Defoaming device for water-based paint

InactiveCN112295268AShort defoaming timeLiquid degasification by vibrationElectric machineProcess engineering

The invention discloses a defoaming device for water-based paint, which comprises a first supporting mechanism, a second supporting mechanism, an auxiliary mechanism and a control box. The second supporting mechanism is mainly composed of supporting legs, a support and a fixing cylinder. The defoaming device further comprises a defoaming mechanism, and the defoaming mechanism comprises a filling block, a defoaming cylinder, an upper cover, a micro vacuum pump, a first sliding block, a first stirring frame, a second sliding block, a second stirring frame, a bottom plate, an oscillation motor, aconnecting rod, an observation pipe, a discharging pipe and an electric control valve. The first stirring frame and the second stirring frame are beneficial to accelerated and full mixing of a solvent in the water-based paint, the oscillation motor and the filling block are arranged to enable the defoaming cylinder to vibrate to accelerate defoaming and shorten the defoaming time, and the observation pipe is arranged to be beneficial to calculating the adding amount of the solvent to prevent the solvent from being added excessively or insufficiently.

Owner:浙江长兴万华包装有限公司

Cooling liquid used in cutting process, preparation method and application thereof

ActiveCN111254002AEasy to operateLow costEnergy based wastewater treatmentLubricant compositionProcess engineeringSilicone oil

The invention relates to a cooling liquid used in a cutting process, a preparation method and application thereof. The cooling liquid comprises the following components in percentage by mass: 70-80% of a dispersing agent, 0.1-3% of a stabilizing agent, 0.1-0.5% of an antioxidant acid agent and the balance of deionized water, wherein the dispersing agent comprises alkynol-terminated polyoxyethyleneether. According to the invention, the components are reasonably matched, so that the cooling liquid has advantages of excellent cooling, excellent lubricating, excellent rust resistance, excellent cleaning performance, long service life, easy recycling, no pollution or low pollution to the environment, and low foaming property without the addition of the defoaming agent while the dispersion effect is ensured, and eliminates adverse effects of the silicone oil component in the defoaming agent on the cooling liquid; and the preparation method of the cooling liquid is easy to operate, safe, reliable, low in comprehensive cost and suitable for large-scale production.

Owner:LUOYANG CSI PHOTOVOLTAIC TECH CO LTD

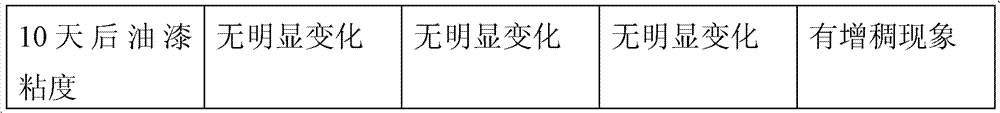

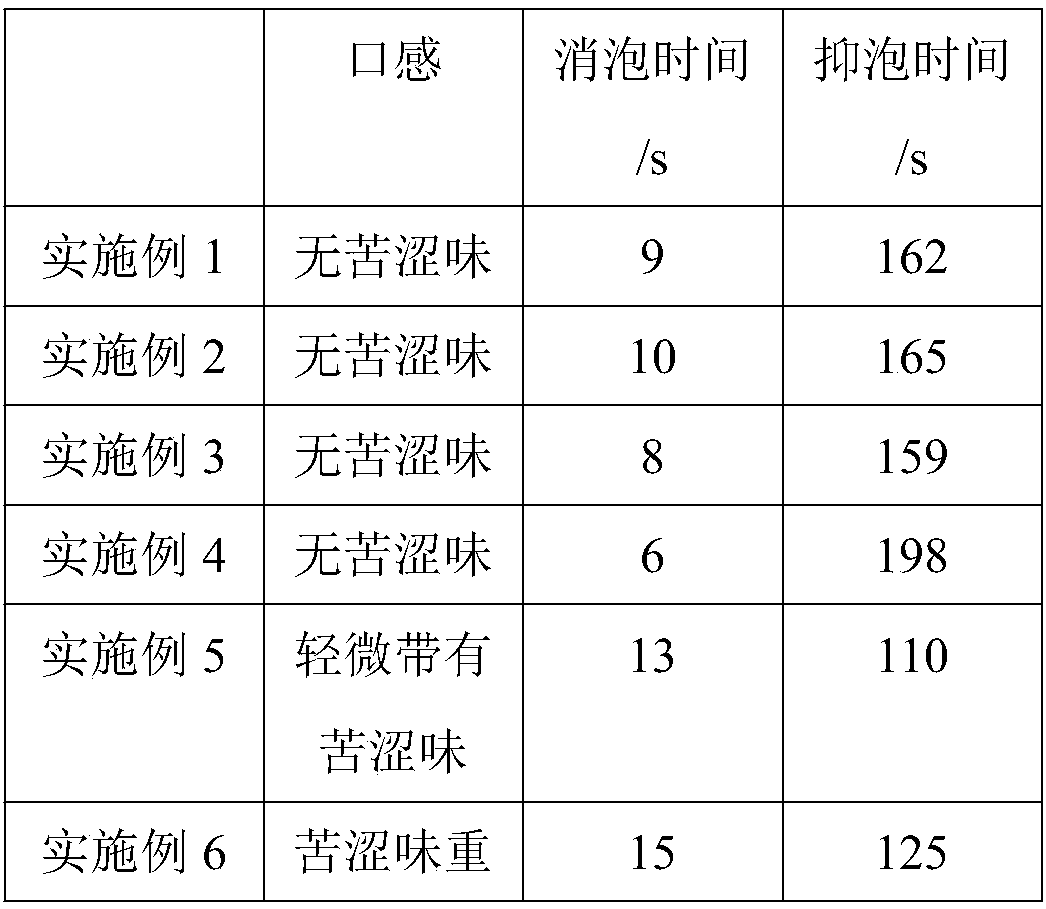

Food antifoaming agent and preparation method thereof

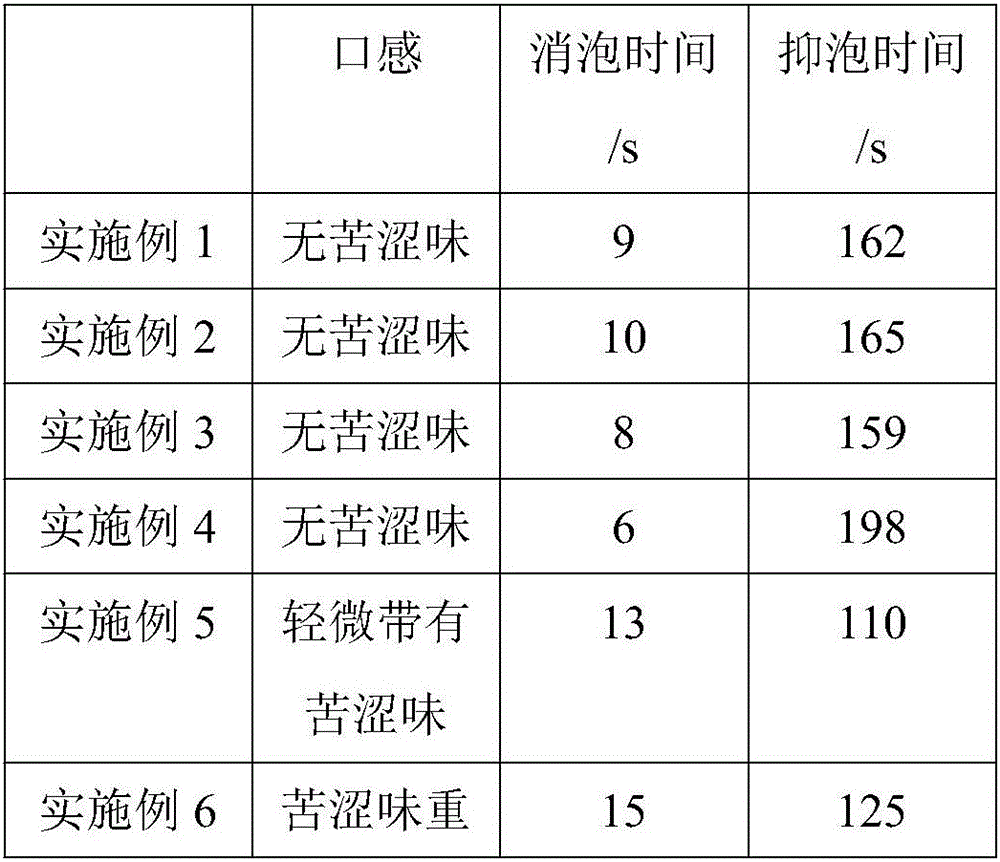

ActiveCN106621476ANo bitternessGreat tasteFoam dispersion/preventionReaction temperatureSilicon dioxide

The invention relates to a food antifoaming agent without bitterness and a preparation method thereof. The antifoaming agent is prepared from the raw materials of dimethicone, silicon dioxide, glyceryl polyether, span, tween and water. By means of regulating matching, reaction temperature and time, temperature rise speed, emulsification temperature and emulsification time of all components, the food antifoaming agent prepared through the method has no any bitterness. The preparation method avoids adding a thickening agent and is simple; a prepared product has the advantages of being stable and free of layering for a long time and having short defoaming time and long antifoaming time.

Owner:LINYI YUWANG VEGETABLE PROTEIN

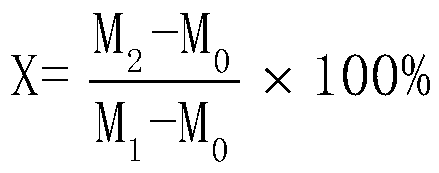

Method for efficient and quick determination of defoaming property of water-based paint

The invention discloses a method for efficient and quick determination of the defoaming property of a water-based paint. The method comprises the following steps: step A, selecting a wide-mouth bottle, weighing a set quantity of the water-based paint, and pouring the weighed water-based paint into the wide-mouth bottle; step B, injecting water into the wide-mouth bottle at a height, set distance away from the liquid level in the wide-mouth bottle, and stopping water injection when foam generated by the water-based paint in the water injection process reaches the bottleneck of the wide-mouth bottle; and step C, recording time from stop of water injection to complete foam disappearing to determine the defoaming time. Water injection foaming can quickly generate lots of foams, and the water-based paint is diluted by water injection, so that the generated foam is low in density and short in defoaming time, accordingly, the defoaming property of the water-based paint can be quickly determined, and the determination efficiency is improved.

Owner:FOSHAN COMWIN LIGHT & ELECTRICITY

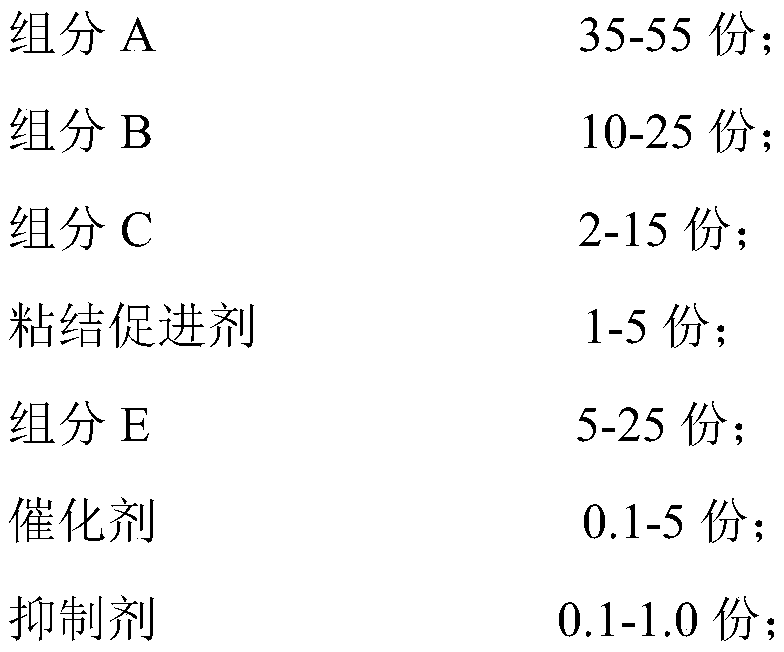

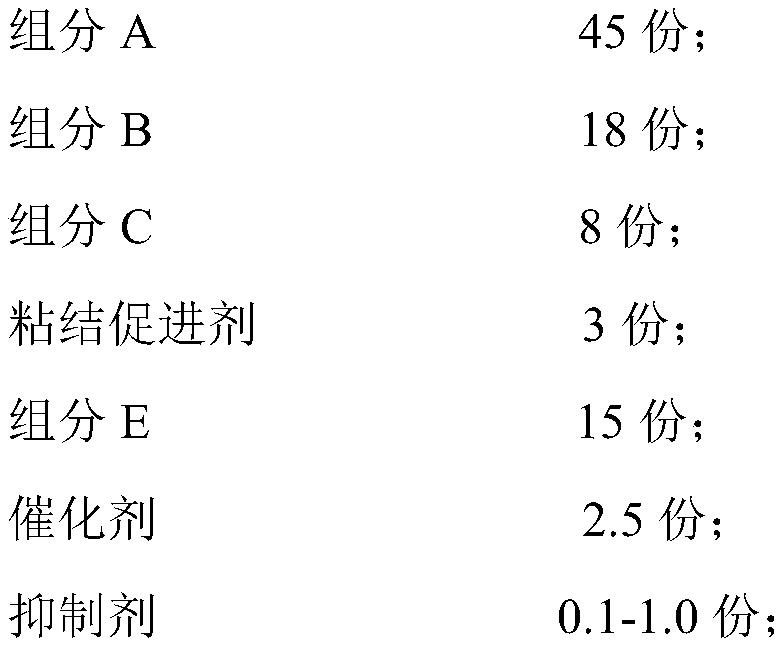

A kind of transparent silicone gel for laminating liquid crystal screen

A transparent silicone gel for bonding liquid crystal screens. The raw material formula includes 35-55 parts of component A; 10-25 parts of component B; 15 parts of component C2; 5 parts of adhesion promoter; 5-25 parts of component E; 0.1-5 parts of the catalyst; 0.1-1.0 parts of the inhibitor; the component A is a vinyl-terminated polysiloxane conforming to the general formula (1): the component B is a vinyl-terminated polysiloxane conforming to the general formula (2) Propoxy polypropylene oxide: the component C is a vinyl MQ silicone resin, and the M:Q ratio is 0.8-1.5; the component E is a terminal hydrogen polysiloxane conforming to the general formula (3). The transparent silicone gel for bonding liquid crystal screens prepared by the invention has the advantages of low viscosity, short defoaming time, fast curing and molding, and moderate hardness.

Owner:铜陵桐力光电有限公司

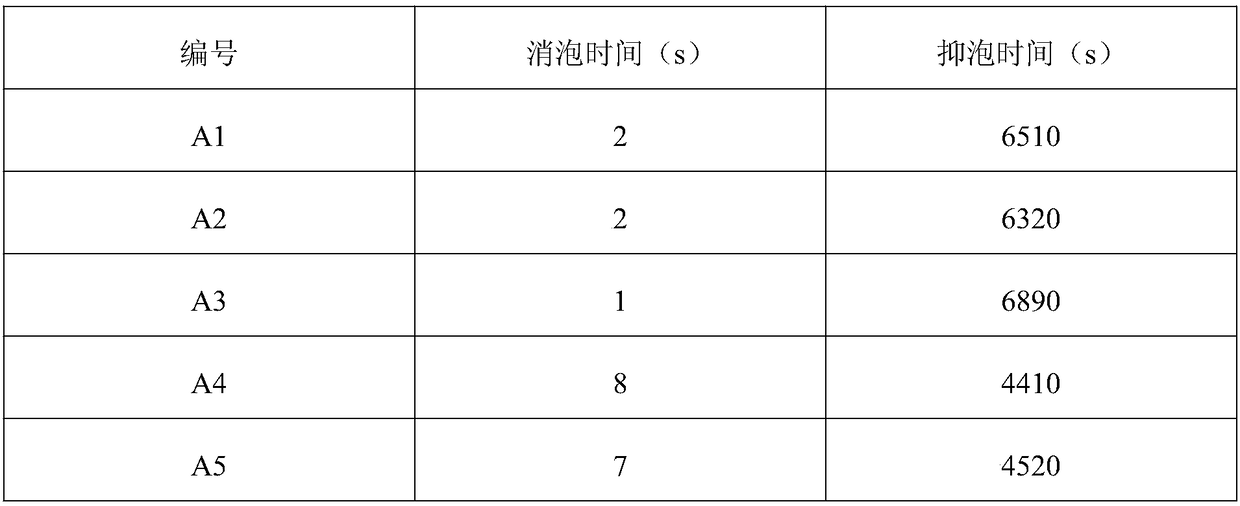

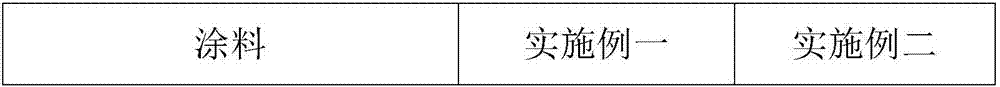

Defoaming agent for coating and ink emulsion and preparation method of defoaming agent

The invention belongs to the technical field of fine chemical assistants, and particularly relates to a defoaming agent for water-based paint and ink emulsion and a preparation method of the defoaming agent. The method comprises the following steps: firstly, carrying out hydrosilylation reaction on hydrogen-containing silicone oil, EO / PO block or random allyl polyether and long-chain alkyl olefin to prepare long-chain alkane and polyether composite modified silicone oil; after the addition reaction, adding modified fumed silica to obtain silicon paste. finally, mixing span 80, Tween 80, carboxymethyl cellulose sodium, a thickening agent and the silicon paste; and after adding water, emulsifying and dispersing at a high speed to prepare the defoaming agent. According to the method, an organic solvent does not need to be added, the preparation method is simple, and the obtained defoaming agent is short in defoaming time, long in foam inhibition time and free of floating oil by regulating and controlling the molar ratio and molecular weight of polyether EO / PO, and has a good application prospect in the field of defoaming agents of coatings and printing ink.

Owner:SOUTH CHINA UNIV OF TECH +1

Preparation method of high-efficiency water-based silicon polyether defoaming agent

PendingCN112843797AShort defoaming timeIncreased foam suppression timeFoam dispersion/preventionDefoamerSiloxane

The invention is suitable for the technical field of defoaming agents, and provides a preparation method of a high-efficiency water-based silicon polyether defoaming agent; the polydimethylsiloxane and polyether modified polysiloxane are blended into the same system, so that the defoaming capability of polydimethylsiloxane and the foam inhibition capability of polyether modified polysiloxane are fully exerted, and by utilizing the synergistic interaction of the two components, defoaming time of the prepared efficient water-based silicon polyether defoaming agent is greatly shortened, and the foam inhibition time is greatly improved, so that the efficient water-based silicon polyether defoaming agent has excellent defoaming and foam inhibition properties, and can meet the production requirements at lower concentration.

Owner:安徽博纳新材料科技有限公司

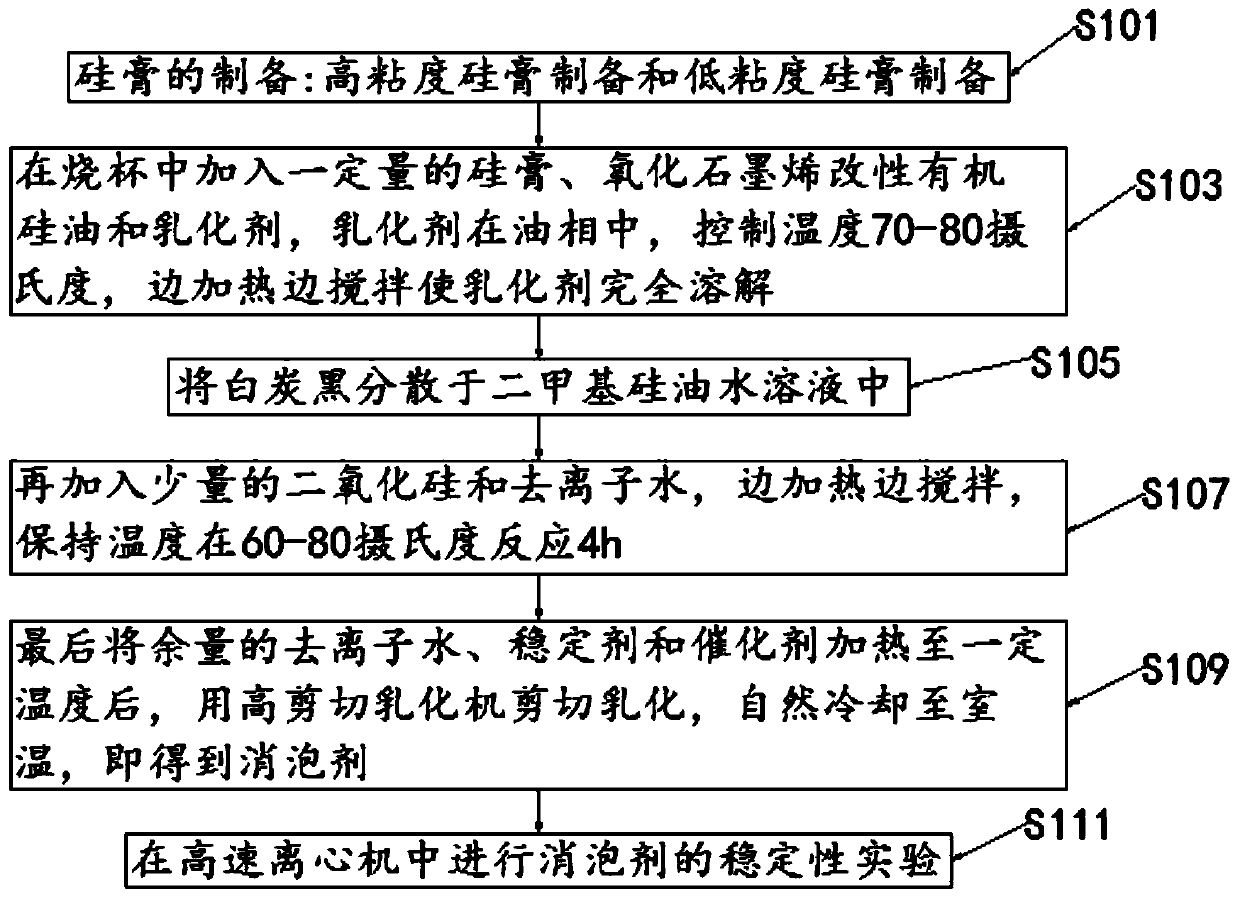

Graphene oxide modified organic silicon defoamer and preparation method thereof

InactiveCN110559695ASimple production processRaw materials are easy to getFoam dispersion/preventionPapermakingTemperature resistance

The invention discloses a graphene oxide modified organic silicon defoamer, which comprises the following raw materials in percentage: graphene oxide modified organic silicone oil 5-12%, dimethyl silicone oil 10-25%, silica 2-5%, polyether 7-10%, emulsifier 5-7%, catalyst 0.05-0.15%, stabilizer 1-4%, deionized water 50-60%, fixed high viscosity silica paste 3-5%, low viscosity silica paste 2-6% and white carbon black 3-10%. The invention has the advantages of simple production process, easily available raw materials, no pollution, easy industrial production, short defoaming time, high efficiency, high temperature resistance, acid and alkali resistance, hydrophilicity and the like, and moderate price, and can be widely applied to printing and dyeing, ink, coating, papermaking and other industries.

Owner:安徽銮威化工科技开发有限公司

A kind of food defoamer and preparation method thereof

ActiveCN106621476BNo bitternessGreat tasteFoam dispersion/preventionReaction temperatureSilicon dioxide

Owner:LINYI YUWANG VEGETABLE PROTEIN

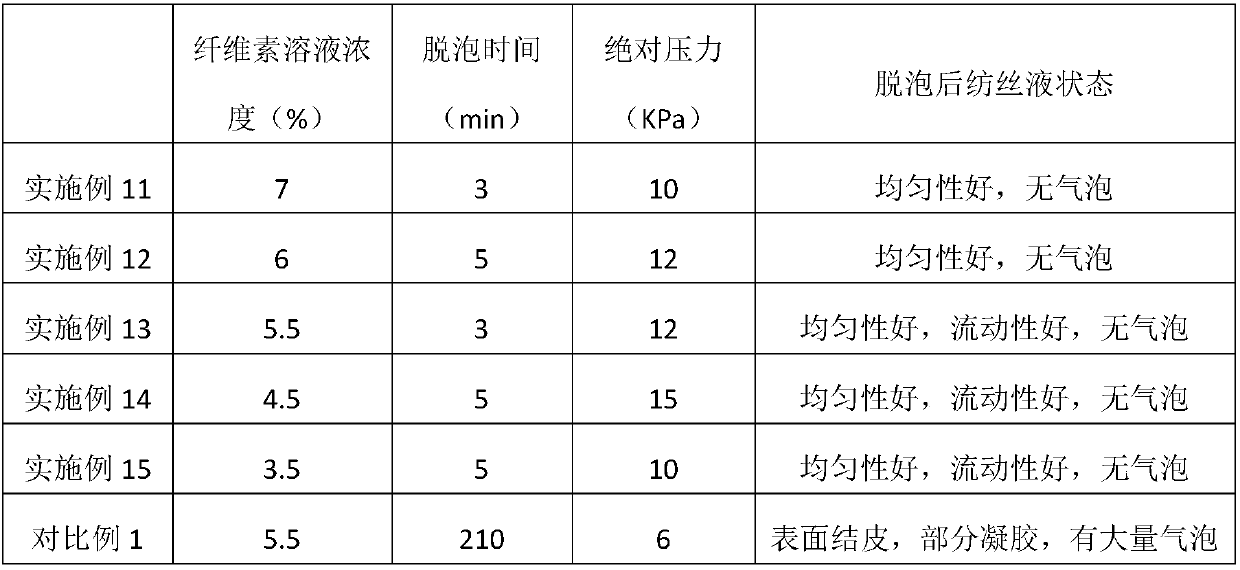

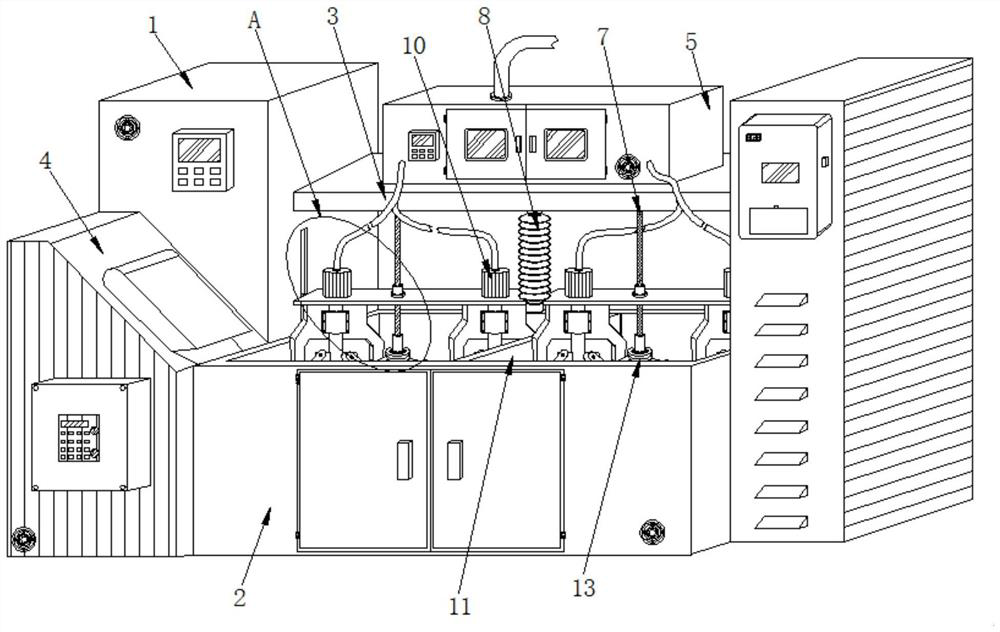

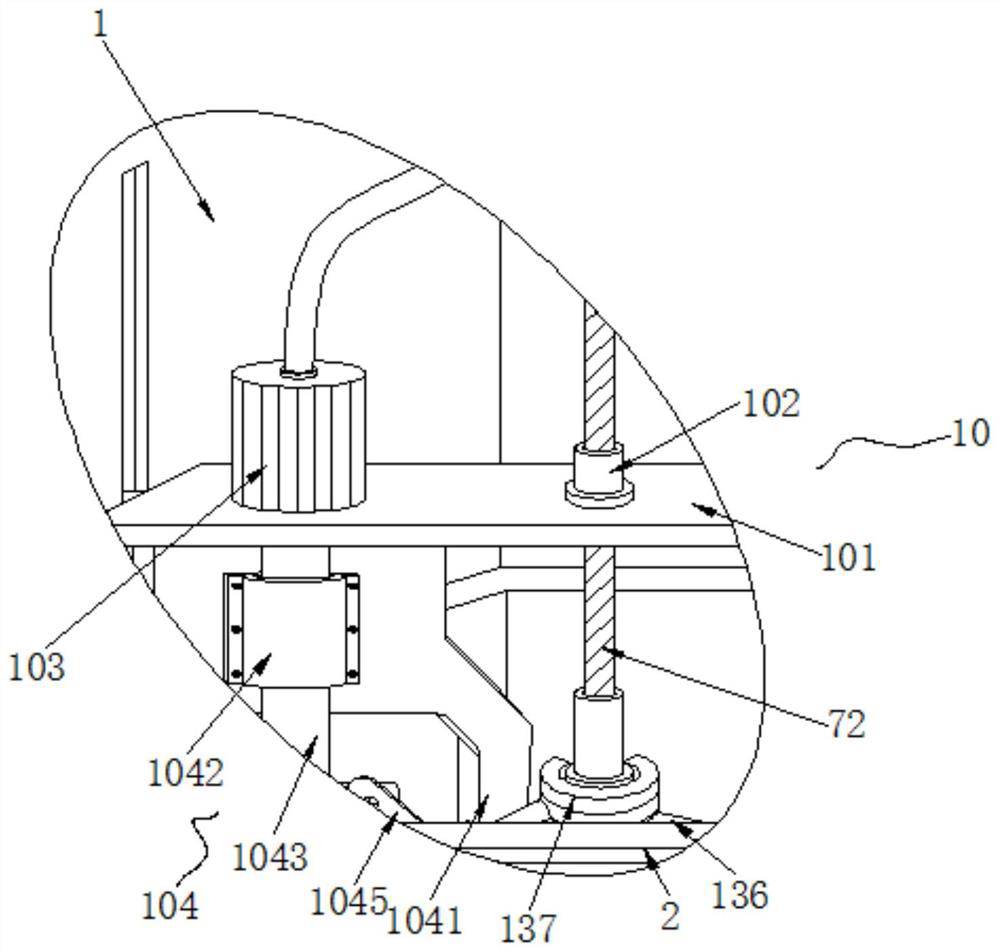

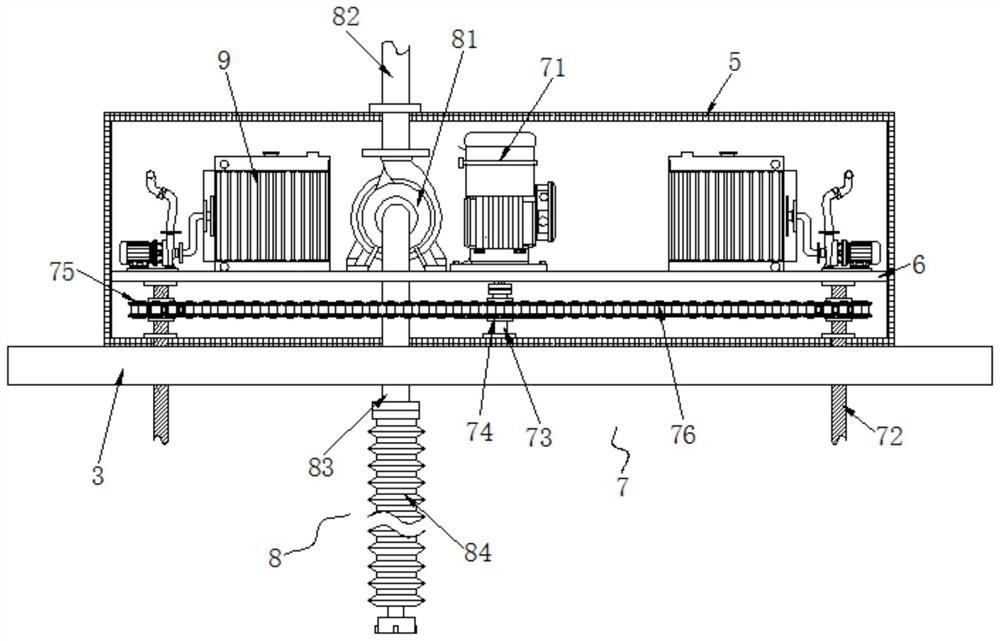

Defoaming device for cellulose solution, and defoaming method of defoaming device

PendingCN109957844AAvoid destructionImprove defoaming efficiencySpinning solution filteringCelluloseEngineering

The invention discloses a defoaming device for a cellulose solution, and a defoaming method of the defoaming device. The defoaming device comprises an outer barrel, a material barrel, a speed regulation device, a liquid inlet pipe and a material storage device, wherein the outer barrel is configured into a main body of the defoaming device; a liquid outlet is formed in the bottom of the outer barrel; the material barrel is arranged in the outer barrel and is provided with a through hole; the speed regulation device is used for driving the material barrel to make centrifugal movement; the liquid inlet pipe passes through the outer barrel and feeds a solution into the material barrel; the material storage device is communicated with the liquid outlet formed in the bottom of the outer barrel,and is arranged at the position lower than the outer barrel; a discharge device is arranged at the bottom of the material storage device. The defoaming device, which is simple in structure and easy to operate, for the cellulose solution has the characteristics of being high in defoaming efficiency, realizing continuous defoaming, and guaranteeing the continuous proceeding of the subsequent spinning; material conveying is not affected by a defoaming process, and efficient defoaming and continuous production are carried out at the same time; furthermore, the defoaming method is good in effect;the defoaming device for the cellulose solution can be used for producing a spinning solution with good stability and evenness, and does not produce gel.

Owner:CHINESE TEXTILE ACAD

Environment-friendly intelligent defoaming system based on chemical product production

ActiveCN113101701AEasy to produceWon't suckChemical/physical/physico-chemical stationary reactorsFoam dispersion/preventionProcess engineeringChemical products

The invention discloses an environment-friendly intelligent defoaming system based on chemical product production. The system comprises two cases, a reaction tank and a cross frame, the reaction tank and the cross frame are fixedly mounted between the two cases, the cross frame is arranged above the reaction tank, a control terminal is fixedly mounted on one side of each case, and a control box is fixedly mounted on the top of the cross frame. The invention relates to the technical field of chemical product production. According to the environment-friendly intelligent defoaming system based on chemical product production, more thorough defoaming treatment can be carried out by adopting a scraping type defoaming structure, and the purpose of improving the defoaming efficiency by carrying out comprehensive intelligent scraping on a reaction tank is well achieved; and defoaming is carried out by adopting a defoaming method combining suction and scraping, the defoaming effect is obviously improved, defoaming is thorough, defoaming time is short, reaction liquid cannot be sucked away, and foams attached to the wall of the reaction container can be completely removed, so production of chemicals is greatly facilitated.

Owner:长沙创新药物工业技术研究院有限公司

A kind of preparation method of medicinal hydroxypropyl starch capsule

ActiveCN104800188BSignificant progressAffect qualityPharmaceutical non-active ingredientsCapsule deliveryDigestionImpurity

Owner:HUNAN ER KANG PHARMA

Defoaming kettle and defoaming method for producing polyamic acid resin

ActiveCN104107565BAvoid it happening againPrevent oxidationFoam dispersion/preventionThin layerEngineering

The invention discloses a defoaming kettle and a defoaming method for preparing polyamide acid resin. A thin layer distributor with an arch rotary curve surface is fixedly installed in a defoaming kettle tank body; the distance from the curve surface arch top of the thin layer distributor to the lower end opening of a feeding pipe ranges from 0.01mm to 1 / 3 of the height of the tank body; the clearance between the lower edge of the curve surface of the thin layer distributor and the inner wall of the tank body is 0.01mm-10mm; the rotary curve surface of the thin layer distributor is a spherical surface; a resin conveying pipeline between a reaction kettle and the defoaming kettle is provided with a metering pump; the tank body is provided with a sandwiched sleeve, and an heat conduction medium inlet and outlet are formed at the top and bottom of the tank body. The defoaming method comprises the step that resin entering the defoaming kettle falls on the arch top of the curve surface of the thin layer distributor, and disperses and flows downward along the curve surface of the thin layer distributor to form a thin layer which results in bubble breakage. The metering pump is used for adjusting the flow rate of resin so as to keep that the thickness of the resin solution layer on the thin layer distributor is less than 5mm. Defoaming is completed immediately when resin is conveyed completely, and then pressurization is carried out for discharging. During defoaming, a heat conduction medium is introduced for warming, and negative pressure is kept in the tank body. According to the invention, defoaming is complete, and the defoaming time is shortened greatly so as to guarantee subsequent continuous film preparation. The defoaming kettle is simple in structure and convenient to operate.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

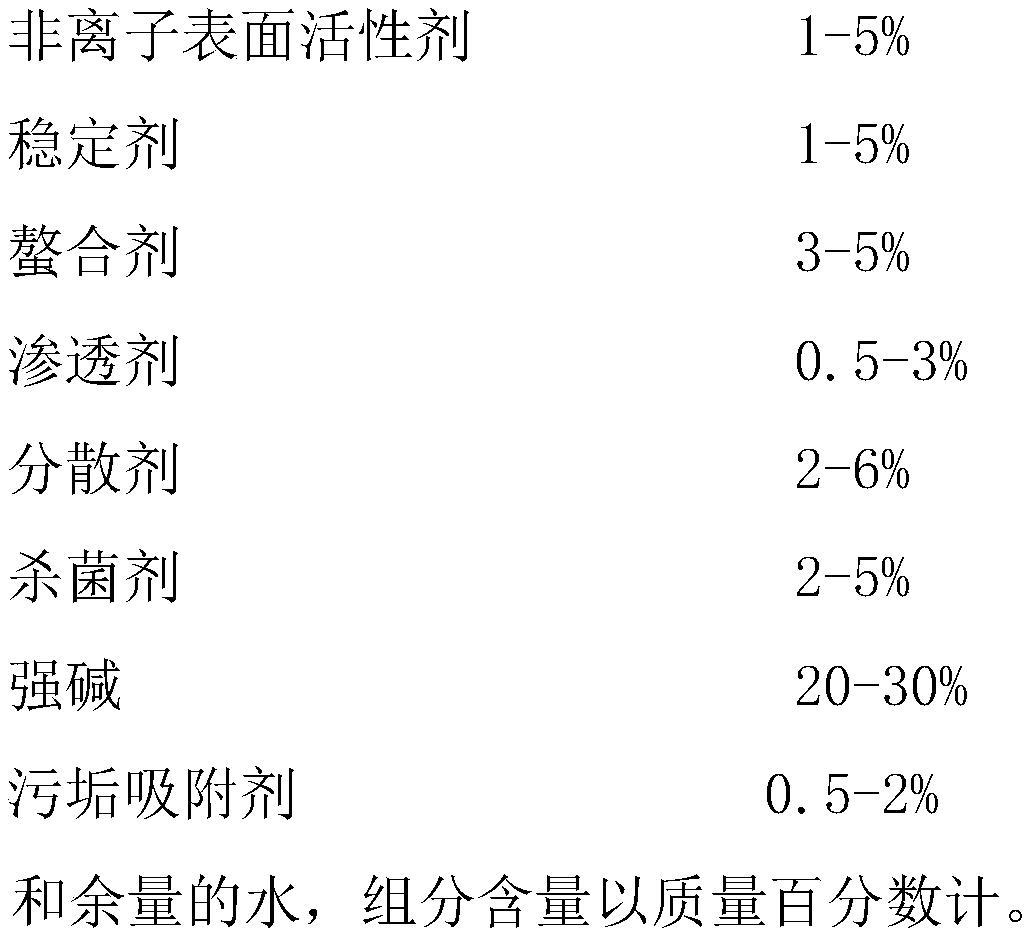

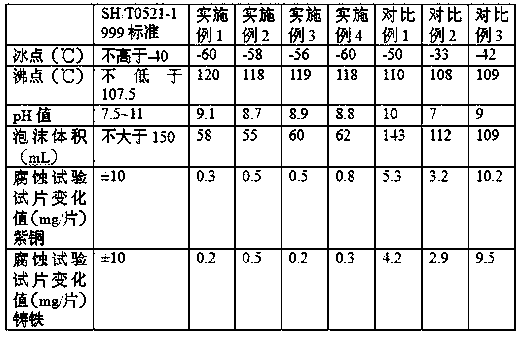

Alkaline cleaning composition for dairy processing equipment and preparation method thereof

ActiveCN107338121BLess corrosiveEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsBiotechnologyDairy foods

The alkaline cleaning composition for dairy product processing equipment disclosed by the invention includes: 1-5% nonionic surfactant, 1-5% stabilizer, 3-5% chelating agent, 0.5-3% penetrant, 2- 6% dispersant, 2-5% bactericide, 20-30% strong alkali, 0.5-2% dirt adsorbent and the balance water. After treating the surface with this alkaline cleaning composition, the foam is reduced to less than 5 mm. The time is no more than 10 seconds. The preparation method of the cleaning composition includes the following steps: mix deionized water and strong alkali and stir until dissolved; add chelating agent, dispersant, bactericide and stabilizer in sequence, stir until dissolved, and control the reaction temperature at 50-60°C during the stirring process ℃; add penetrant, nonionic surfactant, and dirt adsorbent in sequence, stir until complete dissolution and the solution appears clear and transparent, and cool to room temperature. The alkaline cleaning composition disclosed by the invention is less corrosive, has strong cleaning power, less foam, is easy to rinse, resists dirt redeposition, can sterilize and inhibit corrosion and scale, and is an efficient and environmentally friendly cleaning agent.

Owner:CHANGJIANGMAI MEDICINE SCI & TECH BEIJING

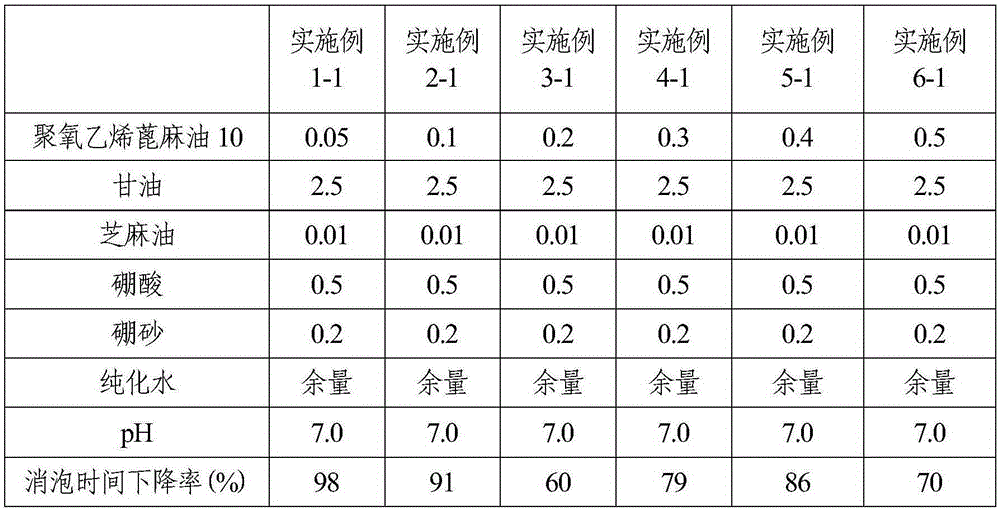

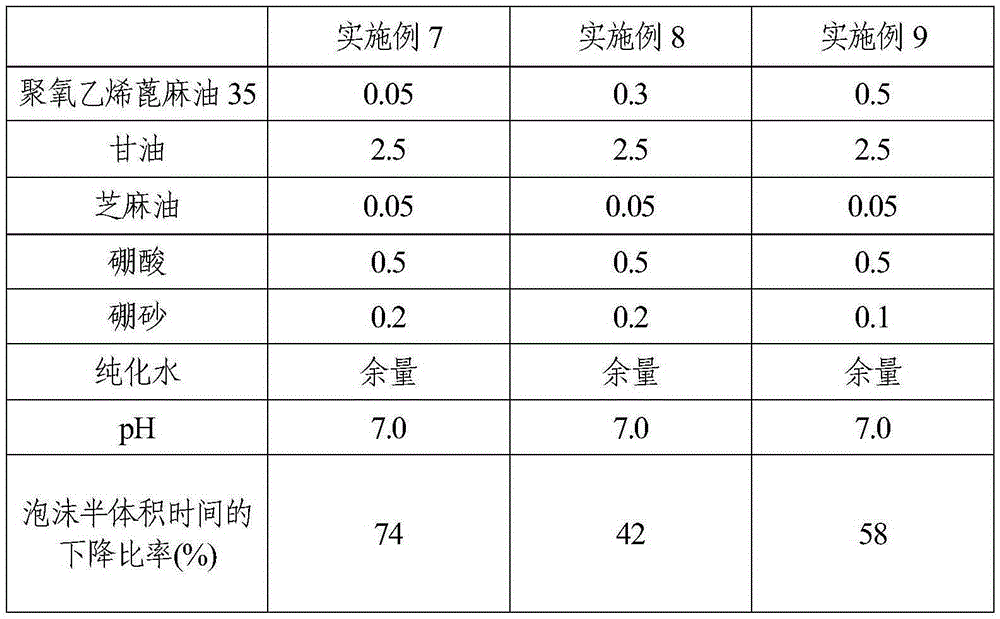

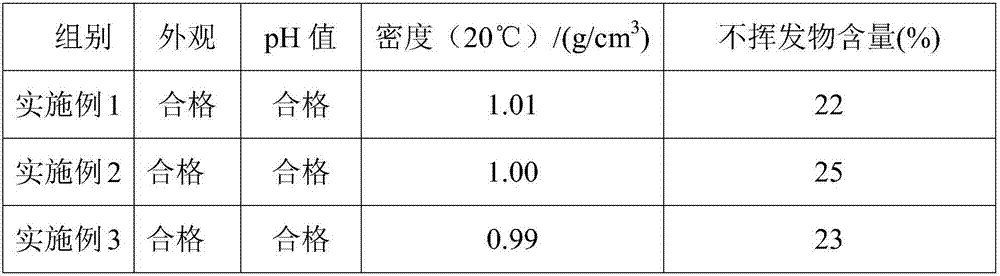

Aqueous ophthalmic composition

ActiveCN103764168BShort defoaming timeReduce the amount of dropsSenses disorderInorganic non-active ingredientsPolyoxyethylene castor oilMedicine

According to the aqueous ophthalmic composition comprising (A) polyoxyethylene castor oil and (B) sesame oil, defoaming time is reduced, preservative efficacy is enhanced, and photostability is improved.

Owner:ROHTO PHARM CO LTD

A food defoamer

ActiveCN105944406BShort defoaming timeExtended defoaming timeFoam dispersion/preventionFood additiveSilicone oil

Owner:GUANGZHOU CARDLO BIOCHEM TECH

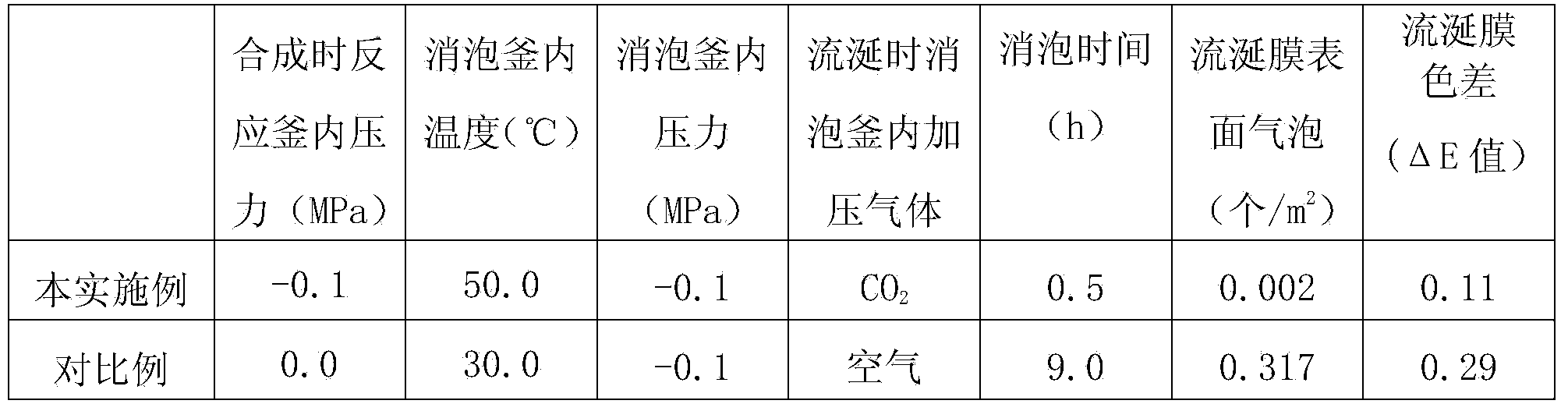

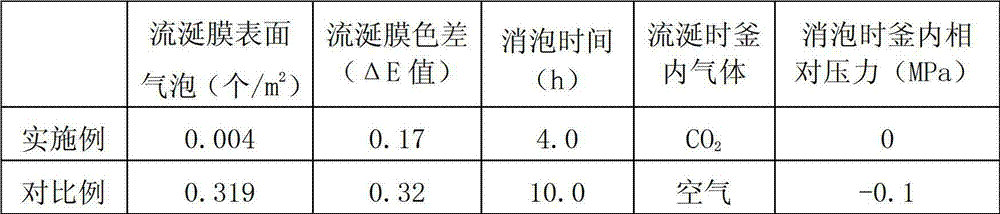

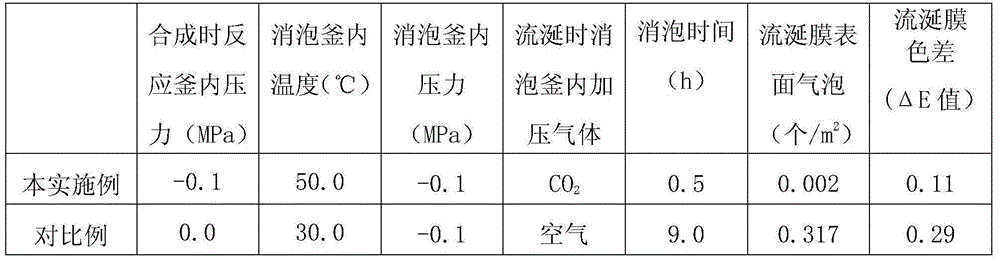

Defoaming method in synthesizing process of polyamide resin

ActiveCN103028274BSimple structureUniform colorFoam dispersion/preventionRelative pressurePolymer science

The invention discloses a defoaming method in the synthesizing process of polyamide resin. The method comprises the following steps: heating and slowly stirring polyamide resin solution in a kettle at first at the temperature of 35 to 100 DEG C at normal pressure for 0.5 to 1.5h, wherein the stirring speed is less than or equal to 50r / min; then, quickly stirring the polyamide resin solution at a stirring speed of 60 to 100r / min at the same temperature for 2 to 4h; and casting film when the defoaming is completed, wherein CO2, nitrogen or other inert gas can be fed during the casting of the film to prevent the resin from discoloring and deteriorating at a gas flow of 0.1 to 0.8 m<3> / min, and a relative pressure of 0.3 to 0.5MPa is kept in the kettle. According to the method, the foaming is thorough, the surface quality of the film obtained later is improved, the defoaming time is short and the defoaming process is convenient in operation.

Owner:GUILIN ELECTRICAL EQUIP SCI RES INST

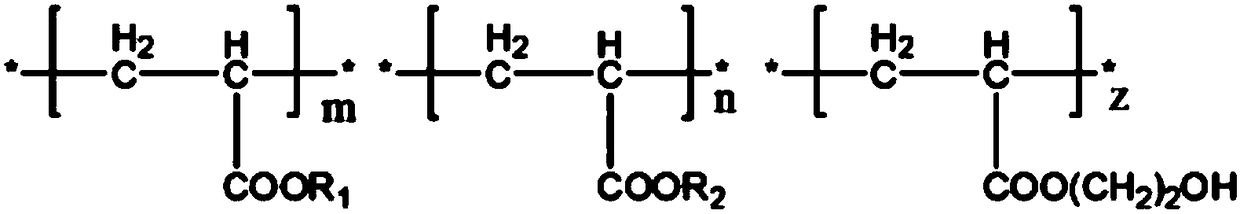

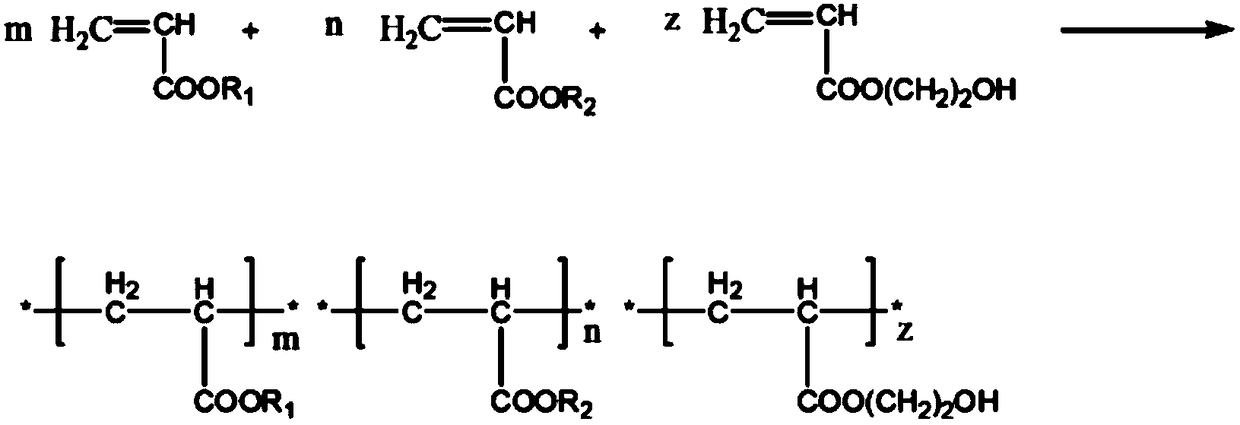

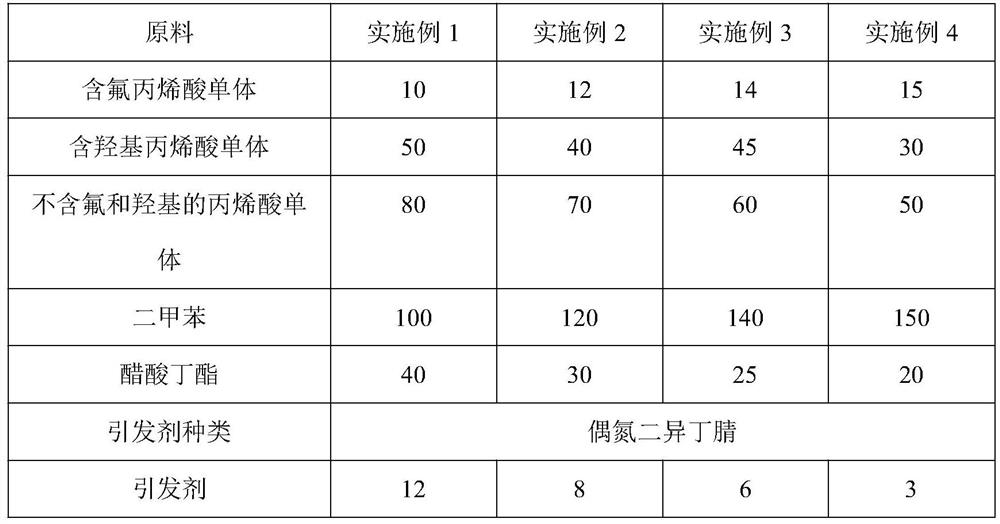

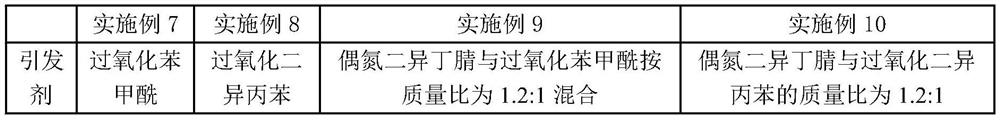

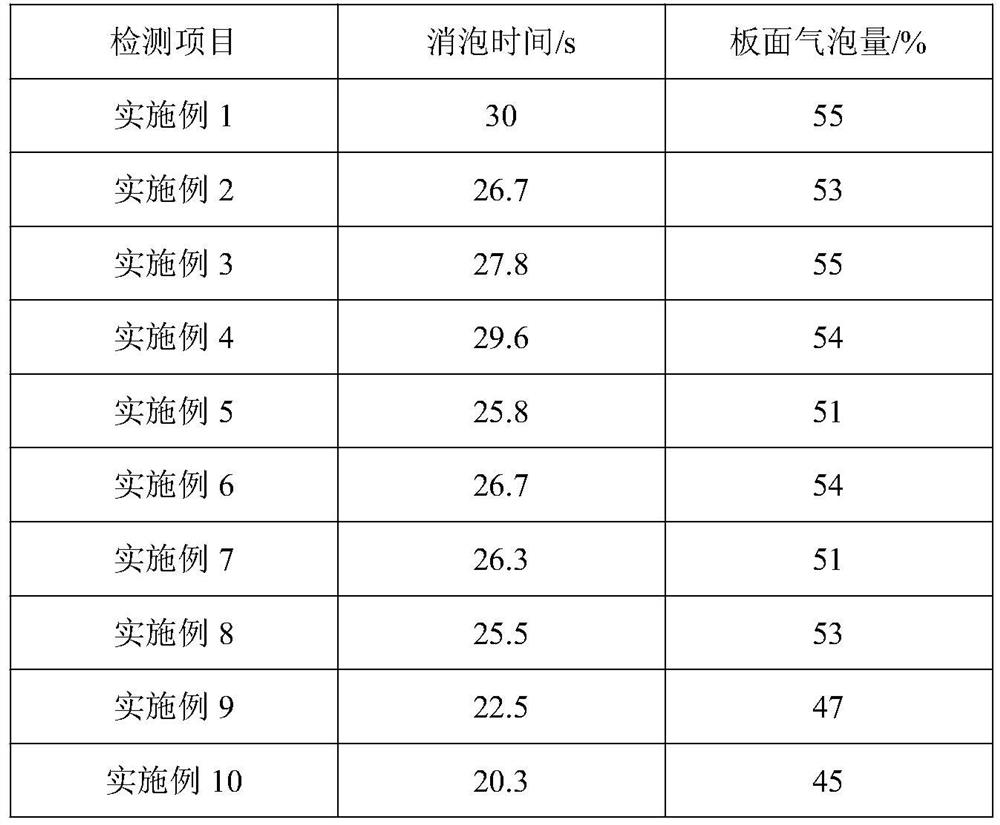

Defoaming agent suitable for curtain coating of mirror back coating, preparation method of defoaming agent and mirror back coating

ActiveCN114213578AGood anti-foam performanceShort defoaming timeCoatingsSolar thermal energy generationXylylenePolymer science

The invention relates to the technical field of defoaming agents, and particularly discloses a defoaming agent suitable for curtain coating of a mirror back coating, a preparation method of the defoaming agent and the mirror back coating. The defoaming agent suitable for curtain coating of the mirror back coating comprises the following raw materials: a fluorine-containing acrylic monomer, a hydroxyl-containing acrylic monomer, an acrylic monomer without fluorine and hydroxyl, xylene, butyl acetate, an initiator and a silane coupling agent, wherein the initiator is one or more of dicumyl peroxide, benzoyl peroxide and azodiisobutyronitrile; the defoaming agent prepared in the invention has high defoaming performance and foam inhibition performance, hydroxyl in the hydroxyl-containing acrylic monomer is crosslinked with amino in the coating, CASS of a mirror back coating product is also protected to a certain extent, and meanwhile, the initiator is compounded to ensure that the prepared polymer does not cause a broken screen phenomenon, so that the defoaming agent has high defoaming performance and foam inhibition performance. And the coating has good compatibility with a mirror back coating, and meets the market demand.

Owner:TIANJIN CITY XINLIHUA COLOR MATERIAL

A kind of antifreeze liquid with metal anticorrosion performance and preparation method thereof

ActiveCN105255456BHigh boiling pointLowering the freezing pointHeat-exchange elementsSodium phosphatesPolyethylene glycol

The invention discloses an antifreeze liquid with metal anticorrosion performance and a preparation method thereof. The antifreeze liquid comprises the following raw materials: ethylene glycol, polyethylene glycol, sodium hydroxide, sodium phosphate, sodium nitrate, sodium silicate, methacrylic acid , Lauryltrimethylammonium Chloride, 2-Methylthiobenzothiazole, pH Adjuster, Dyes, Sodium Stearyl Fumarate, Distilled Water. Its preparation method is: ethylene glycol, polyethylene glycol, sodium hydroxide, sodium phosphate, sodium nitrate, sodium silicate, methacrylic acid, 2-methylthiobenzothiazole, pH regulator, dyestuff, stearin Sodium fumarate and distilled water are mixed and placed in a flat-bottomed bottle, and the flat-bottomed bottle is placed on a magnetic stirrer. After stirring for 10-20 minutes, add dodecyltrimethylammonium chloride and continue stirring. The antifreeze liquid of the invention has high boiling point, low freezing point, small foam volume, short defoaming time and good corrosion resistance.

Owner:DONGYING HAOMING LUBRICATION TECH CO LTD

Method of continuously preparing poly terephthaloyl-p-phenylene diamine fibre

InactiveCN100395381CShort defoaming timeImprove mixing uniformityFilament/thread formingMonocomponent synthetic polymer artificial filamentFiberViscosity

The invention discloses a method for continuously preparing p-phenylene terephthalamide (PPTA) fiber, including the steps of: (1) continuously adding 98-100% oil of vitriol and PPTA with specific logarithmic viscosity of 4.0-8.5 dl / g to an double spiral extruder, where the weight percent of PPTA is 14-24% and the mixing temperature is 50-100 deg.C; (2) fully mixing and entering in the other extruder, where the adjusting temperature is 50-100 deg.C and the staying time is 10-60 min, fully mixing, adjusting temperature and defoaming and then extruding them; (3) after measuring and filtering spinning solution, obtaining the invention by the routine steps, such as dry spraying-wet spinning. The advantages are short time for mixing materials, adjusting temperature and defoaming high mixing uniformity of materials able to implement continuous, stable filature in a short time, raising the production efficiency.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com