A kind of antifreeze liquid with metal anticorrosion performance and preparation method thereof

A metal anti-corrosion and antifreeze technology, applied in the field of antifreeze, can solve the problems of low freezing point and high boiling point, and achieve the effect of low freezing point, high boiling point and small foam volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

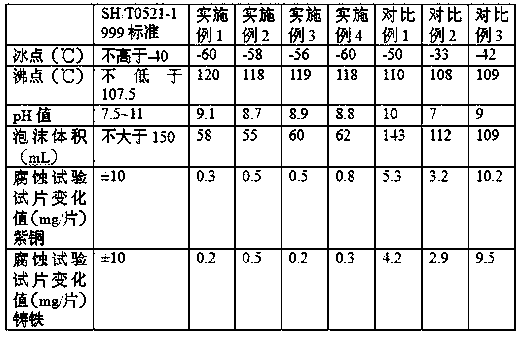

Examples

Embodiment 1

[0017] An antifreeze solution with metal anticorrosion properties, comprising the following raw materials in parts by weight: 30 parts of ethylene glycol, 8 parts of polyethylene glycol, 20 parts of sodium hydroxide, 20 parts of sodium phosphate, 15 parts of sodium nitrate, sodium silicate 45 parts, 15 parts of methacrylic acid, 25 parts of dodecyltrimethylammonium chloride, 20 parts of 2-methylthiobenzothiazole, 10 parts of pH regulator, 20 parts of dye, 25 parts of sodium stearyl fumarate parts, 55 parts of distilled water.

[0018] The dye is neutral red.

[0019] The pH regulator is orthophosphate and phosphoric acid in a mass ratio of 1:2.

[0020] The preparation method of above-mentioned antifreezing solution comprises the following steps: adjusting ethylene glycol, polyethylene glycol, sodium hydroxide, sodium phosphate, sodium nitrate, sodium silicate, methacrylic acid, 2-methylthiobenzothiazole, pH Mix the agent, dye, sodium stearyl fumarate, and distilled water in...

Embodiment 2

[0022] An antifreeze solution with metal anticorrosion properties, comprising the following raw materials in parts by weight: 20 parts of ethylene glycol, 4 parts of polyethylene glycol, 10 parts of sodium hydroxide, 15 parts of sodium phosphate, 10 parts of sodium nitrate, sodium silicate 40 parts, 10 parts of methacrylic acid, 20 parts of dodecyltrimethylammonium chloride, 10 parts of 2-methylthiobenzothiazole, 4 parts of pH regulator, 2 parts of dye, 20 parts of sodium stearyl fumarate parts, 50 parts of distilled water.

[0023] The dye is methylene blue.

[0024] The pH regulator is orthophosphate and phosphoric acid in a mass ratio of 1:2.

[0025] The preparation method of above-mentioned antifreezing solution comprises the following steps: adjusting ethylene glycol, polyethylene glycol, sodium hydroxide, sodium phosphate, sodium nitrate, sodium silicate, methacrylic acid, 2-methylthiobenzothiazole, pH After mixing agent, dye, sodium stearyl fumarate and distilled wat...

Embodiment 3

[0027] An antifreeze solution with metal anticorrosion properties, comprising the following raw materials in parts by weight: 50 parts of ethylene glycol, 10 parts of polyethylene glycol, 30 parts of sodium hydroxide, 25 parts of sodium phosphate, 20 parts of sodium nitrate, sodium silicate 50 parts, 20 parts of methacrylic acid, 30 parts of dodecyltrimethylammonium chloride, 30 parts of 2-methylthiobenzothiazole, 20 parts of pH regulator, 30 parts of dye, 30 parts of sodium stearyl fumarate parts, 60 parts of distilled water.

[0028] The dye is neutral red.

[0029] The pH regulator is orthophosphate and phosphoric acid in a mass ratio of 1:2.

[0030] The preparation method of above-mentioned antifreezing solution comprises the following steps: adjusting ethylene glycol, polyethylene glycol, sodium hydroxide, sodium phosphate, sodium nitrate, sodium silicate, methacrylic acid, 2-methylthiobenzothiazole, pH After mixing agent, dye, sodium stearyl fumarate and distilled wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com