High-viscosity fluid defoaming method and device thereof

A high-viscosity, fluid technology, applied in the direction of liquid degassing, separation methods, chemical instruments and methods, etc., can solve the problems of long degassing time, unable to meet the requirements of spinning process, unable to degassing and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

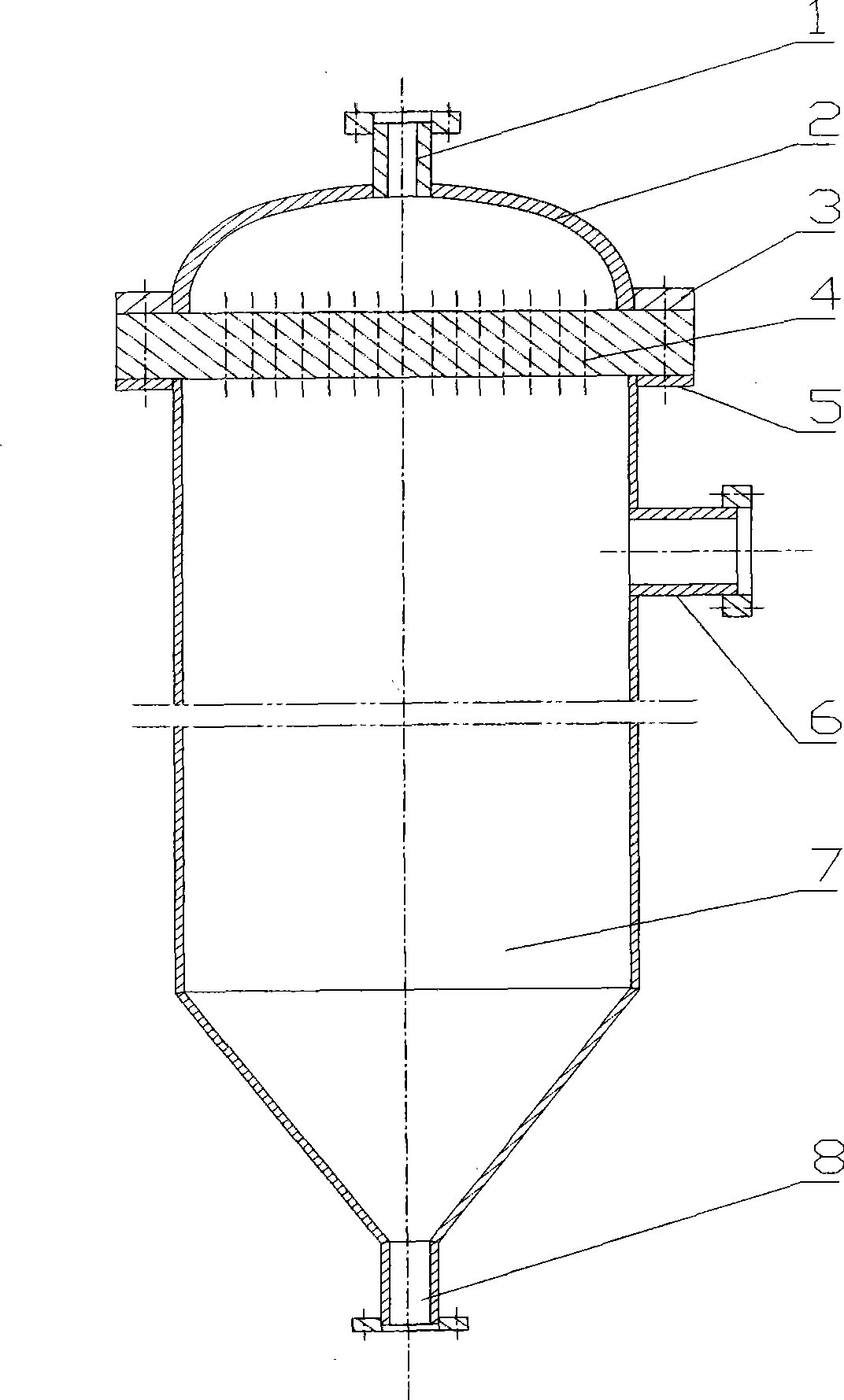

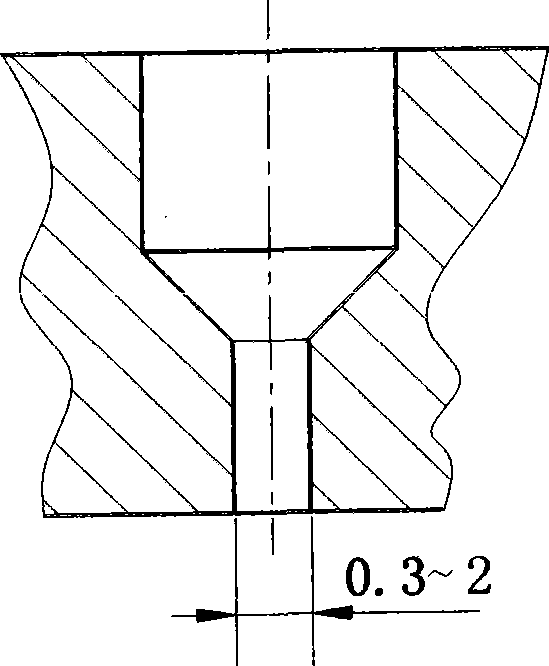

[0012] Such as figure 1 , 2 As shown, the embodiment of the present invention consists of feed inlet (1), end cap (2), upper flange (3), extruded film plate (4), lower flange (5), (6) vacuum suction port, vacuum It consists of a degassing tower (7) and a discharge port (8). The head (2) is located above the extruded plate (4), connected with the extruded plate (4) through the upper flange (3), and forms a fluid distribution chamber with the extruded plate (4). A feed port (1) is provided. The extruded film plate (4) is a circular disk, and it is provided with an oblong narrow hole penetrating up and down. The upper part of the narrow hole is wide, which is a fluid guide area, and the middle part has a slope, which is a tapered transition area. Film extrusion zone, the width of the film extrusion zone is 0.3-2 mm, and the aspect ratio of the film extrusion zone is about 5-15. The vacuum defoaming tower (7) is located directly below the extruded film plate (4), and is connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com